Bolt hobbing

Posted by xistix

|

Bolt hobbing January 22, 2016 11:08AM |

Registered: 8 years ago Posts: 15 |

I'm new to the forum. I'm building my first RepRap. I would like to make a hobbed bolt for my extruder. I found various instructions and videos how to make one. I tried to hob an M8 shoulder bolt with an M5 tap. I put two ball bearings on the bolt. I put the tap to a drill press. The problem is when I press the bolt against the spinning tap (holding the ball bearings), the bolt does not start to turn. I tried to apply light and strong pressure. I tried slow and fast drill speeds. The result is the same. Bolt does not turn or it stops turning after a couple of degrees. I also tried to cut a groove to the bolt with a file before tapping. It did not make a difference. Am I missing something?

|

Re: Bolt hobbing January 22, 2016 05:46PM |

Registered: 8 years ago Posts: 67 |

|

Re: Bolt hobbing January 23, 2016 02:36AM |

Registered: 8 years ago Posts: 15 |

|

Re: Bolt hobbing January 23, 2016 09:44PM |

Registered: 11 years ago Posts: 471 |

|

Re: Bolt hobbing January 24, 2016 02:45AM |

Registered: 8 years ago Posts: 15 |

I have bought the printed parts for my printer. The kit contains Wade's extruder. I only have limited access to 3d printers. Changing the extruder is not an option until I actually can print with my own printer. Typical chicken- egg problem. The gunstruder looks interesting. I will get back to it once my printer starts working.

|

Re: Bolt hobbing February 07, 2016 02:56AM |

Registered: 8 years ago Posts: 15 |

|

Re: Bolt hobbing February 07, 2016 05:33AM |

Registered: 12 years ago Posts: 2,470 |

The wade extruder is actually one of the most reliable extruders available. If it works for you, keep it.

For self hobbing i printed a small gadget that keeps two bolts in bearings parallel to each other, but pointing in opposite directions. If you calculate the distance correctly you can thread two bolts at the same time this way. For me only ever one of the bolts worked out, but it solved the problem of pressure and even breaking threading tools nicely.

Edited 1 time(s). Last edit at 02/07/2016 05:36AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

For self hobbing i printed a small gadget that keeps two bolts in bearings parallel to each other, but pointing in opposite directions. If you calculate the distance correctly you can thread two bolts at the same time this way. For me only ever one of the bolts worked out, but it solved the problem of pressure and even breaking threading tools nicely.

Edited 1 time(s). Last edit at 02/07/2016 05:36AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Bolt hobbing February 07, 2016 10:05AM |

Registered: 12 years ago Posts: 1,450 |

Back when I made my first Prusa Mendel printer with Wades extruder I made a jig from a block of nylon to hold two 608 bearings with a groove for the boltI held this in a vice and used an M2 tap to hob the bolt. I have now made a dozen or more hobbed drive gears both on bolts and on 8mm ground shaft and have not found any need to replace it. To make the jig I did need a lathe to cut the holes for the bearings but everything else was hacksaw and file.

Edit: I used a Dremel (actually a Proxxon) to hold the tap and merely held this firmly by hand. It takes about 10 seconds for the sound to change showing that it is cutting a clean path and another 20 seconds to finish the hobbing

Another edit: I use the slowest speed available on the Proxxon - andy faster and it skips about without starting correctly.

Jig.

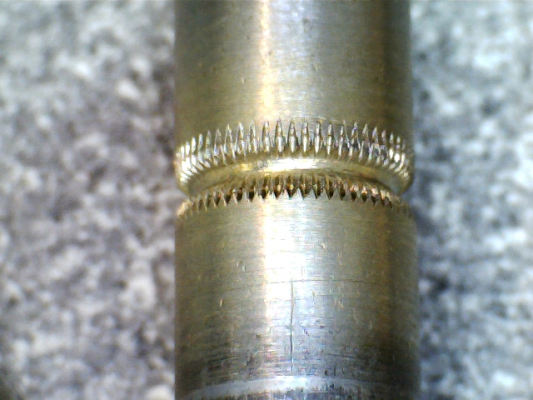

A couple of hobbed drive gears. To get the M2 tap to ride in the right place you will need to cut a shallow groove around the bolt/shaft. In the second picture the groove was deliberately cut too deep to see if this imprved the push (it didn't)

Mike

Edited 2 time(s). Last edit at 02/07/2016 01:51PM by leadinglights.

Edit: I used a Dremel (actually a Proxxon) to hold the tap and merely held this firmly by hand. It takes about 10 seconds for the sound to change showing that it is cutting a clean path and another 20 seconds to finish the hobbing

Another edit: I use the slowest speed available on the Proxxon - andy faster and it skips about without starting correctly.

Jig.

A couple of hobbed drive gears. To get the M2 tap to ride in the right place you will need to cut a shallow groove around the bolt/shaft. In the second picture the groove was deliberately cut too deep to see if this imprved the push (it didn't)

Mike

Edited 2 time(s). Last edit at 02/07/2016 01:51PM by leadinglights.

Sorry, only registered users may post in this forum.