truss structure in between X smooth rods good idea?

Posted by realthor

|

truss structure in between X smooth rods good idea? February 11, 2016 08:12AM |

Registered: 9 years ago Posts: 1,035 |

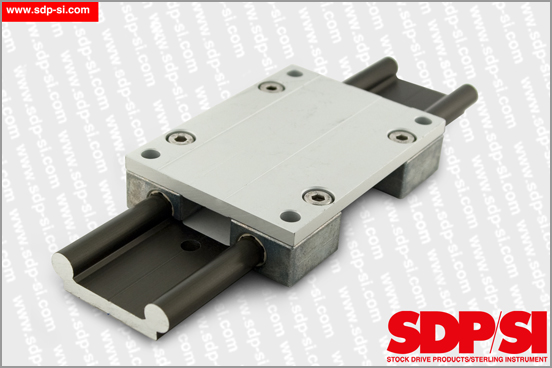

Hey, I am thinking that my 8mm smooth rods on X could be too thin on a ~320-330mm unsupported length, especially if heavier tools will be mounted there (i am planning light milling with Dremel). So, instead of replacing the X carriage CNC-style, I am thinking of completely bridging the two rods with a truss structure that can be 100% 3d printed. It will still be light enough to jerk around on the Y axis but I think it will be quite a bit stronger than the rods alone.

Basically I am thinking to replicate the following:

Of course in this solution there will not be a structural grip on the length of the rod unless we can somehow strongly bond the plastic with the metal of the rods, maybe using Loctite Plastics Bonding System. I would then use open bearings clamped top-down.

Would this do any good to an already existing 8mm X carriage? -- assuming that this is something doable because the open bearings shouldn't hit or rubb into this structure --

Edited 2 time(s). Last edit at 02/11/2016 08:15AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Basically I am thinking to replicate the following:

Of course in this solution there will not be a structural grip on the length of the rod unless we can somehow strongly bond the plastic with the metal of the rods, maybe using Loctite Plastics Bonding System. I would then use open bearings clamped top-down.

Would this do any good to an already existing 8mm X carriage? -- assuming that this is something doable because the open bearings shouldn't hit or rubb into this structure --

Edited 2 time(s). Last edit at 02/11/2016 08:15AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 09:21AM |

Registered: 9 years ago Posts: 1,873 |

It depends what force you are trying to mitigate. A printed truss between the rods similar to that photo would primarily oppose forces acting to move the rods closer together or further apart, which I wouldn't expect to be a particularly troublesome direction. It's not going to do much for vertical displacement or twisting around the long axis which are the cases I think are most likely to cause problems. It's difficult to deal with the forces for milling without going to heavier components. A box section gantry with the linear rails mounted to it would be a conservative choice. Using linear rails for structure is asking for trouble in anything but the lightest of applications.

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 10:31AM |

Registered: 11 years ago Posts: 5,780 |

You can get a quality, used industrial surplus linear guide on ebay for $35. I know, most are higher than that, but keep digging- I recently bought 3 of them for an average price of $34, shipped, including one that is unused. They are so close to perfect, at that kind of price it's crazy to use anything else.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 03:21PM |

Registered: 9 years ago Posts: 1,035 |

Yes you are absolutely right...it doesn't make sense at that price.

But if I find that kind of a deal I'll start building a new machine. I want to engineer out the shit out of this one. And I know when things can be done but don't have the skills to use CAM/CAE to test it.

Intuitively I know that clamping a bridge of sorts between the rods would make it some sort of I-beam, the rods clamped themselves by the X carriage , would make a stronger structure than the rods alone but I might be wrong about it. If I am wrong I want to understand why, but I can search the answer by myself if this is too much to ask.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

But if I find that kind of a deal I'll start building a new machine. I want to engineer out the shit out of this one. And I know when things can be done but don't have the skills to use CAM/CAE to test it.

Intuitively I know that clamping a bridge of sorts between the rods would make it some sort of I-beam, the rods clamped themselves by the X carriage , would make a stronger structure than the rods alone but I might be wrong about it. If I am wrong I want to understand why, but I can search the answer by myself if this is too much to ask.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 04:52PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 06:09PM |

Registered: 9 years ago Posts: 1,035 |

Quote

MechaBits

4 rail supports on a plate will support both ends, changing to 12mm rod is easy enough.

Can you explain that a bit more? I don't want to change, i want to use what I have and anything new will go to a new machine. Anf that most likely will be with linear guides.

But for the existing smooth rod X axes, a way to avoid flex due to the weight of the carriage is to make everything more rigid. If there was an easy way -and Loctite says there is- to glue the rods to the bridging material (be it plastic, wood or aluminum) I believe several benefits will have been reached without much gain in weight (going up from plastic to wood/metal).

Having "half bearings" is a bit exagerated, they would be open bearings that will have the opening oriented outwards from the in-between rods structure. Their job would be balanced from equally distributed weight over the "I-beam" structure.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 06:42PM |

Registered: 8 years ago Posts: 1,671 |

Rail supports added to a plate to support rods, one above the other,

Flex should be less than, unsupported(I was thinking end of X unsupported)

Sure it wont be as stiff as the rails in your picture, but 2x8mm above each other should(?) be stiffer(less sag) than side by side? but I have extra cross/tie bar to help out, but obviously cant help with sagging rails, though as I dont intend to hang 1Kg off my rails I am yet to see any effects of sagging...if its a problem I'll swap the rails for 12mm, and I should be less concerned about gravity waves buggering my prints.

Flex should be less than, unsupported(I was thinking end of X unsupported)

Sure it wont be as stiff as the rails in your picture, but 2x8mm above each other should(?) be stiffer(less sag) than side by side? but I have extra cross/tie bar to help out, but obviously cant help with sagging rails, though as I dont intend to hang 1Kg off my rails I am yet to see any effects of sagging...if its a problem I'll swap the rails for 12mm, and I should be less concerned about gravity waves buggering my prints.

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 07:06PM |

Registered: 9 years ago Posts: 1,035 |

Ok, I get it now. Yes, that's the kind of solution I am thinking of too, but instead of the metal plate I'm thinking 10mm honey-comb core or other sparse infill that would make the part very light but strong at the same time. My inspiration comes from the OSB I-beam used lately in the architecture and construction fields.

As I see it, the main forces that act upon the smooth rods of an X carriage are the dynamic forces that compound the static weight of the carriage with the momentum generated by movement (acceleration, jerk, inertia, etc). I don't know of any other forces that might have an influence.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: truss structure in between X smooth rods good idea? February 11, 2016 07:33PM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.