bed level sensor trouble

Posted by bizit524

|

bed level sensor trouble February 29, 2016 02:21PM |

Registered: 8 years ago Posts: 49 |

Heythere guys I have a problem which I don't know how to fix

so recently a kind one of you gave me the firmware for my exact printer with bed leveling already setup. however now the problem is. I cant get it to trigger...

I have tested my regular endstops with my multi meter and when it is not being touched it is at about 4.82 -4.88 volts on x,y, and z. when I trigger the end stop it goes to 0 like it should

So I hook up my inductive sensor and when it is not triggered it reads 5.34 and when it triggers by touching metal (4mm above it) it goes UP to 5.81 instead of to zero

not sure what I did wrong but clearly something is wrong

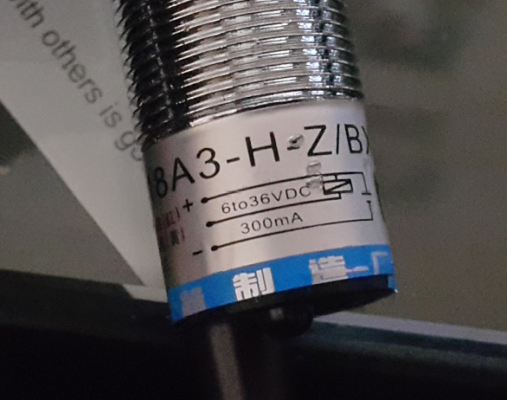

Here is the one I have purchased "LJ12A3-4-Z/BX " which is a PNP inductive 4 mm switch

I just ordered a NPN 8 mm switch because I am having trouble with it going though the 3 mm glass and it being detected. this will arrive in 3 weeks from china

I used this guide

[www.youtube.com]

and I used the same exact resistor values as Tom uses

any suggestions?

from looking at it I didn't buy a NPN so this could be the problem? if that is the problem is there anyway to rewire it to get it to work

so recently a kind one of you gave me the firmware for my exact printer with bed leveling already setup. however now the problem is. I cant get it to trigger...

I have tested my regular endstops with my multi meter and when it is not being touched it is at about 4.82 -4.88 volts on x,y, and z. when I trigger the end stop it goes to 0 like it should

So I hook up my inductive sensor and when it is not triggered it reads 5.34 and when it triggers by touching metal (4mm above it) it goes UP to 5.81 instead of to zero

not sure what I did wrong but clearly something is wrong

Here is the one I have purchased "LJ12A3-4-Z/BX " which is a PNP inductive 4 mm switch

I just ordered a NPN 8 mm switch because I am having trouble with it going though the 3 mm glass and it being detected. this will arrive in 3 weeks from china

I used this guide

[www.youtube.com]

and I used the same exact resistor values as Tom uses

any suggestions?

from looking at it I didn't buy a NPN so this could be the problem? if that is the problem is there anyway to rewire it to get it to work

|

Re: bed level sensor trouble March 02, 2016 06:58AM |

Registered: 8 years ago Posts: 49 |

|

Re: bed level sensor trouble March 14, 2016 07:07PM |

Registered: 8 years ago Posts: 49 |

Well there has been absolutely no help in this so I just bought another sensor this time an 8mm sensor distance which i need. however still not working. This time when I touch metal it goes from 5.85v to about 5v but does not go to zero. any help?

Also it doesn't sense actually at 8mm

Suggestions?

Also it doesn't sense actually at 8mm

Suggestions?

|

Re: bed level sensor trouble March 14, 2016 09:28PM |

Registered: 12 years ago Posts: 548 |

On one printer I'm using a 12v relay board, this one: [www.amazon.com]

I just use the switched side like a endstop. The jumper on the board lets it trigger on high or low. No resister network needed.

I bought these: [www.ebay.com] for the sensor and they work fine with that relay board. Doesn't get the 8mm on 1/4" MIC-6 aluminum, more like just less than 3mm.

You probably can find that relay board cheaper, but that one didn't have the long wait from China.

I just use the switched side like a endstop. The jumper on the board lets it trigger on high or low. No resister network needed.

I bought these: [www.ebay.com] for the sensor and they work fine with that relay board. Doesn't get the 8mm on 1/4" MIC-6 aluminum, more like just less than 3mm.

You probably can find that relay board cheaper, but that one didn't have the long wait from China.

|

Re: bed level sensor trouble March 15, 2016 08:20AM |

Registered: 8 years ago Posts: 413 |

I think the sensors are designed for 12v feed so you can't use the 5v feed on the end stop circuit. You just get 12v from the power feed. Theres some old stuff on the web that says you need to put some resistors in to drop the signal voltage to about 4v. That would then be on the return side of the end stop circuit.

Alternatively you could use the relay board as Stepenrc suggests so the signal trips the relay and switches the 5V end stop circuit.

Since the sensors are intended for 12v you wont get the detection range running on 5v

Not my field but this may help.

Alternatively you could use the relay board as Stepenrc suggests so the signal trips the relay and switches the 5V end stop circuit.

Since the sensors are intended for 12v you wont get the detection range running on 5v

Not my field but this may help.

|

Re: bed level sensor trouble March 16, 2016 07:31PM |

Registered: 8 years ago Posts: 49 |

you are correct. The link i put in the first post describes how to make a voltage divider in with resisters which I have done exactly how the video describes and it works it brings it down from 12 to 5.85 volts. I might have to go down stephenrc router but problem with relays is it will give a slight delay so i will have to figure out the compensation of how far it goes down to when it triggers. There is only some microseconds between that I know but that does affect then end product which I am trying to avoid.

And all over the internet I have seen people use these. This is why I have bought one.

And all over the internet I have seen people use these. This is why I have bought one.

|

Re: bed level sensor trouble March 16, 2016 10:03PM |

Registered: 12 years ago Posts: 548 |

|

Re: bed level sensor trouble March 17, 2016 02:03PM |

Registered: 8 years ago Posts: 49 |

|

Re: bed level sensor trouble March 17, 2016 07:41PM |

Registered: 8 years ago Posts: 3,525 |

Some sensors work on 5v I've got two that do with slightly reduced sensing distance. Some need 12v to work. The 12v only ones need a voltage divider to prevent them providing 12v to the ramps signal pin which would damage the board.

Pnp sensors work by grounding the signal pin, so a NC sensor outputs 12v (5v with divider) until triggered then it outputs 0v. This logic is set to false in marlin.

Npn sensors connect the signal pin to the +v when triggered so output 0v open and 12v triggered, so they use true logic in marlin.

You need the internal pull up resistor off for any sensor as they provide their own power. You need pullups for PNP, but not for NPN.

Edited 2 time(s). Last edit at 03/18/2016 04:46AM by DjDemonD.

Pnp sensors work by grounding the signal pin, so a NC sensor outputs 12v (5v with divider) until triggered then it outputs 0v. This logic is set to false in marlin.

Npn sensors connect the signal pin to the +v when triggered so output 0v open and 12v triggered, so they use true logic in marlin.

Edited 2 time(s). Last edit at 03/18/2016 04:46AM by DjDemonD.

|

Re: bed level sensor trouble March 17, 2016 10:26PM |

Registered: 8 years ago Posts: 916 |

Quote

DjDemonD

Pnp sensors work by grounding the signal pin, so a NC sensor outputs 12v (5v with divider) until triggered then it outputs 0v. This logic is set to false in marlin.

Npn sensors connect the signal pin to the +v when triggered so output 0v open and 12v triggered, so they use true logic in marlin.

I think you might have those two around the wrong way...

My understanding is that NPN is a common-emitter mode, so the collector of the transistor (attached to the signal wire inside the sensor) is grounded when triggered. This means that NPN sensors can be used on a 5V RAMPS board, even if the sensor requires 12V to run, with no extra wiring. Just enable your 5V pullup in your config, hook up 12V to the sensor, and off you go.

PNP is like that weird uncle: it looks like it should work, but is a pain to get anything useful out of. You need to faff around with voltage dividers and pulldown resistors, and you never quite end up with a perfect 5V step signal.

That's my understanding anyway.

|

Re: bed level sensor trouble March 18, 2016 05:20AM |

Registered: 8 years ago Posts: 3,525 |

I think I have got it the right way around. This diagram explains all

The PNP type ground the signal, the NPN type energise the signal. So the reality is PNP can be attached without voltage dividers, but you need internal pullups. What is more confusing is that some sensors do work on 5v therefore all the issues with dividers etc... can be ignored. Also confusing as you can get both NC and NO in both NPN and PNP.

There would be a large market opportunity for someone who could manufacture a sensor of this type specifically for 3d printing, it would work on 5v. It would have a reasonably long detection distance i.e. 8mm, it would be able to be triggered using induction or capacitance, to work with the widest range of bed surfaces. It would be PNP as grounding the signal pin which is internally pulled up to 5v is the safest way to do this, and it would be NC so that if the sensor fails the axis stops moving during homing. It would also be small and light.

I know there are alternative technologies like IR such as DC42's, and other means of detecting z height. These proximity sensors however are widely used and once you get one working they are quite good, but they are little understood and not particularly suited in terms of their wiring requirements, even though their detection performance is usually quite up to the job.

Edited 2 time(s). Last edit at 03/18/2016 05:48AM by DjDemonD.

The PNP type ground the signal, the NPN type energise the signal. So the reality is PNP can be attached without voltage dividers, but you need internal pullups. What is more confusing is that some sensors do work on 5v therefore all the issues with dividers etc... can be ignored. Also confusing as you can get both NC and NO in both NPN and PNP.

There would be a large market opportunity for someone who could manufacture a sensor of this type specifically for 3d printing, it would work on 5v. It would have a reasonably long detection distance i.e. 8mm, it would be able to be triggered using induction or capacitance, to work with the widest range of bed surfaces. It would be PNP as grounding the signal pin which is internally pulled up to 5v is the safest way to do this, and it would be NC so that if the sensor fails the axis stops moving during homing. It would also be small and light.

I know there are alternative technologies like IR such as DC42's, and other means of detecting z height. These proximity sensors however are widely used and once you get one working they are quite good, but they are little understood and not particularly suited in terms of their wiring requirements, even though their detection performance is usually quite up to the job.

Edited 2 time(s). Last edit at 03/18/2016 05:48AM by DjDemonD.

|

Re: bed level sensor trouble March 18, 2016 06:22AM |

Registered: 10 years ago Posts: 14,672 |

Quote

DjDemonD

The PNP type ground the signal, the NPN type energise the signal. So the reality is PNP can be attached without voltage dividers, but you need internal pullups.

It's the other way round. The NPN type grounds the output when triggered, so can be used directly, with the pullup resistor in the endstop input enabled. However, if the sensor ground connection fails, it will probably feed some fraction of the supply voltage (typically 12V) into its output, which is likely to damage the printer electronics.

The PNP type connects 12V (or whatever the supply voltage is) to the output when triggered. So it needs a voltage divider on the output to interface it to 3.3V or 5V electronics. This is complicated by the fact that the endstop input on the electronics board may have a pullup resistor or even an LED connected to it.

One other thing to watch for is that the trigger height may vary with supply voltage. The 12V supply on a 3D printer doesn't normally need to be well regulated. You may find there is a small variation in the sensor trigger height depending on whether the bed heater is on or off.

Quote

DjDemonD

There would be a large market opportunity for someone who could manufacture a sensor of this type specifically for 3d printing, it would work on 5v. It would have a reasonably long detection distance i.e. 8mm, it would be able to be triggered using induction or capacitance, to work with the widest range of bed surfaces.

I tried ultrasonic, capacitive and inductive sensing before I settled on differential IR. Capacitive is too sensitive to temperature and humidity to be reliable on non-conductive surfaces. Inductive has too short a range to work with glass beds, unless you use a large sensing coil that makes the sensor bulky and heavy. I came to the conclusion that the most promising technologies were differential IR, and solenoid activated probe. Differential IR is smaller than lighter than a solenoid activated probe and its power requirements are easier to satisfy, which is why I went with the IR approach when I got it working well.

There are of course other techniques that use the nozzle itself as the probe, with a force sensor or sensors built into either the nozzle mount or the bed supports.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: bed level sensor trouble March 18, 2016 06:32AM |

Registered: 8 years ago Posts: 3,525 |

Hi David. This would make the diagram I have linked to wrong? There are other diagrams suggesting this is the other way around. I am not attempting to start an argument I just think that these things cause so much confusion it might be worth someone (I volunteer if I can get a little advice and information from others such as yourself) writing a decent guide in the wiki relating to these types of sensors, NPN/PNP/NC/NO etc... and trying to pull it all together, with information on what settings to use, which ones need voltage dividers, how to wire them etc...

|

Re: bed level sensor trouble March 18, 2016 04:42PM |

Registered: 8 years ago Posts: 3,525 |

HI guys, this has got me thinking hard about these sensors. So I dug some out.

Here are the diagrams from the sides of two sensors I have in front of me:

The first is an NPN, the wiring diagram clearly shows the signal connected to positive.

The second is a PNP, the diagram clearly shows the signal connected to ground.).

So this is exactly as in the diagram I linked in my previous message.

So either these are labelled wrong or we need to settle on exactly how each sensor type works.

I've started to put together a wiki page about these sensors as I think we need to remove the ambiguity from them as soon as possible.

Here are the diagrams from the sides of two sensors I have in front of me:

The first is an NPN, the wiring diagram clearly shows the signal connected to positive.

The second is a PNP, the diagram clearly shows the signal connected to ground.).

So this is exactly as in the diagram I linked in my previous message.

So either these are labelled wrong or we need to settle on exactly how each sensor type works.

I've started to put together a wiki page about these sensors as I think we need to remove the ambiguity from them as soon as possible.

|

Re: bed level sensor trouble March 18, 2016 05:28PM |

Registered: 8 years ago Posts: 49 |

I have figured out my error!!! huzzah. no where I could see in any documentation or videos how to wire it up truely. What I mean by this is. obviously positive and negative you hook up and create the voltage divider which i did. What I was doing wrong I hooked up the main ground to the ground on the RAMPs board. What I needed to do is hook up the main ground just to general power. Now I have it working with both NPN and PNP

Now the PNP drops to 0 like it should and my z axis stops yaaaaaaaaaaaaaaaaaaaaaaaaay

yaaaaaaaaaaaaaaaaaaaaaaaaay

nebbian - you are correct i found that out after i bought it... haha wasn't really paying attention to NPN or PNP

Dj- your diagrams are correct and I was following the one on mine

HOWEVER the new problem i have. it detects great except... I bought an 8 mm detecting distance PNP annnnnnnnnnnnd it definitely doesn't do 8 MM I detects maybe .5 mm above the glass which would be about 3.5 mm in total with 3 mm being glass then going to the aluminum bed. While I am still happy with this and this will work for my bed I was hoping for the full 8mm because I would just adjust the offset to the appropriate level

Does anybody have any suggestions on this? for my NPN i tried this as well and it is only a 4mm one which doesn't work through the 3mm glass hence why i bought the 8mm PNP

The sensor is currently running on 12v does it need higher voltage to run higher range to 8mm? I personally would expect no since its rated at 8mm between the voltage 6-36 from what I understand.

Now the PNP drops to 0 like it should and my z axis stops

yaaaaaaaaaaaaaaaaaaaaaaaaay

yaaaaaaaaaaaaaaaaaaaaaaaaaynebbian - you are correct i found that out after i bought it... haha wasn't really paying attention to NPN or PNP

Dj- your diagrams are correct and I was following the one on mine

HOWEVER the new problem i have. it detects great except... I bought an 8 mm detecting distance PNP annnnnnnnnnnnd it definitely doesn't do 8 MM I detects maybe .5 mm above the glass which would be about 3.5 mm in total with 3 mm being glass then going to the aluminum bed. While I am still happy with this and this will work for my bed I was hoping for the full 8mm because I would just adjust the offset to the appropriate level

Does anybody have any suggestions on this? for my NPN i tried this as well and it is only a 4mm one which doesn't work through the 3mm glass hence why i bought the 8mm PNP

The sensor is currently running on 12v does it need higher voltage to run higher range to 8mm? I personally would expect no since its rated at 8mm between the voltage 6-36 from what I understand.

|

Re: bed level sensor trouble March 18, 2016 05:39PM |

Registered: 8 years ago Posts: 3,525 |

My understanding is that with higher voltage you get a little greater detection range. Also inductive sensors are calibrated by detecting steel not aluminium so the detection distance will be shorter using aluminium. Many people move over to capacitative sensors as they detect any surface but they are more susceptible to temperature/moisture and both are sensitive to changes in supply voltage.

A lot of it is luck, I have a NPN NO sensor on one printer which works on 5v (so I just connected it to ramps z min +,-,sig directly and it detects a double thickness sheet of aluminium kitchen foil under a 3mm glass sheet at about 2mm above the glass. But I suspect I could buy another and get different performance from it.

A lot of it is luck, I have a NPN NO sensor on one printer which works on 5v (so I just connected it to ramps z min +,-,sig directly and it detects a double thickness sheet of aluminium kitchen foil under a 3mm glass sheet at about 2mm above the glass. But I suspect I could buy another and get different performance from it.

|

Re: bed level sensor trouble March 19, 2016 05:32PM |

Registered: 8 years ago Posts: 3,525 |

I think I might have stumbled across the reason why there seems to be a discrepancy in the NPN vs. PNP wiring and operation. It seems that some mainly Western world technical information has the PNP sensor connecting the signal to the input voltage whereas almost all of the Chinese sensors I have come across have this the other way around.

So in writing this wiki entry I will have to point this out and ask readers to be especially careful to look at the wiring diagram on the sensor they are holding.

So in writing this wiki entry I will have to point this out and ask readers to be especially careful to look at the wiring diagram on the sensor they are holding.

|

Re: bed level sensor trouble March 20, 2016 05:40PM |

Registered: 8 years ago Posts: 49 |

I will try the aluminium foil. I tried with my sensor with different things. aluminium, steel and it didn't seem to affect the detecting distance. i was thinking of getting a step up transformer to 24 volts, but then I would have to change the resistors again

That is interesting, nice catch about the differences

That is interesting, nice catch about the differences

|

Re: bed level sensor trouble March 20, 2016 08:32PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: bed level sensor trouble March 20, 2016 10:33PM |

Registered: 8 years ago Posts: 916 |

DjDemonD,

I think the wiring diagram is correct, you might have just been reading it wrong. The rectangle with a slash through it is normally considered your 'load', ie the light bulb or whatever you want the sensor to activate.

So for an NPN sensor, you connect the 'load' between the +V and signal, as the sensor will switch signal to ground.

For those experienced with old school electronics, it makes sense for NPN sensors to switch the signal to ground. This mode is called 'open collector' or 'common emitter', and is very common in signal amplification.

I think the wiring diagram is correct, you might have just been reading it wrong. The rectangle with a slash through it is normally considered your 'load', ie the light bulb or whatever you want the sensor to activate.

So for an NPN sensor, you connect the 'load' between the +V and signal, as the sensor will switch signal to ground.

For those experienced with old school electronics, it makes sense for NPN sensors to switch the signal to ground. This mode is called 'open collector' or 'common emitter', and is very common in signal amplification.

|

Re: bed level sensor trouble March 21, 2016 04:12AM |

Registered: 8 years ago Posts: 3,525 |

Quote

nebbian

DjDemonD,

So for an NPN sensor, you connect the 'load' between the +V and signal, as the sensor will switch signal to ground.

I take the point they that it makes more sense to consider the rectangle the load, than to consider it a sensor/switch.

However people considerably experienced in electronics naturally assume these sensors work the other way around to the way they actually work and this causes a lot of confusion.

Yes if you consider the signal wire to be the ground to the load, the npn sensor connects supply voltage to it then yes you could say it works the same as any other npn transistor, but in reality this is semantics, as it's is a sensor and we're using it as a sensor.

What's important is that everyone gets it the right way around so that people asking for help on the forum with sensors get accurate information on how to connect them and setup their printers.

|

Re: bed level sensor trouble March 21, 2016 05:01AM |

Registered: 8 years ago Posts: 916 |

Quote

DjDemonD

What's important is that everyone gets it the right way around so that people asking for help on the forum with sensors get accurate information on how to connect them and setup their printers.

Indeed.

For those reading this, the symbol in the diagram is a coil, normally used in a relay. Below are two equivalent ways of displaying this information.

So the circuit diagram below is suggesting that for an NPN sensor, you connect a relay between +12V and the signal pin. This means that an NPN sensor switches 0V to the signal pin. The left hand side of the diagram goes into the sensor itself, and the right hand side is what you need to add to the sensor to get it to operate.

Obviously, we're trying to build 3D printers, which have logic boards instead of relays. So the take home message is this:

For normal usage, buy an NPN sensor. Feed it whatever voltage it needs, connect the signal pin directly to your Z min pin, and enable the pull up in firmware. This will work.

Edited 3 time(s). Last edit at 03/21/2016 05:05AM by nebbian.

|

Re: bed level sensor trouble March 21, 2016 06:51PM |

Registered: 8 years ago Posts: 49 |

Well I guess I am back to square one and back to no clue. I appreciate all the detailed schematics and suggestions with relays and what not. I thought I had it working but I dont. I have it wired up and it currently sits at 4.9 volts when connected to the Z end stop when I put some metal in front of it it goes down to 3.3 volts. This is NOT enough to trigger it to stop.

however when I unplug it from the Z end stop but still leave it plugged in with 12 volts feeding it. Then measure the wire that goes to the end stop dangling it is at 4.9 put metal in front of it, it goes all the way down to 0 like it is suppose to.

however when I unplug it from the Z end stop but still leave it plugged in with 12 volts feeding it. Then measure the wire that goes to the end stop dangling it is at 4.9 put metal in front of it, it goes all the way down to 0 like it is suppose to.

WHAT THE HECK AM I DOING WRONG. ?!??!?!?!?!?

I am out of ideas. Yes I could buy another longer detecting NPN or a capacitive sensor but I am tired of buying them. I dont want to by more because these are working and I cant exactly sell these or even give these to people 90% of people dont know what they are

4mm is not enough, my 8mm is barely enough. The both sensors work I can test it with my multi meter. NPN goes up, PNP goes down like they should. I have both working on the 5v with voltage divider. They both trigger with metal. I have got the 8mm PNP to trigger longer distances with a thick steel than aluminum. The PNP currently hooked up is like it is not being grounded on the board properly. Even though I have tried grounding it through main PSU or I tried grounding it just on the RAMPS board and I have tried hooking it up to both. I can put back my original end stop and it works fine/drops to 0 when hit and everything works so it says that the circuit on the RAMPS is working.

any more suggestions?

Dumb request to the both of you. Can I just see a picture of your ends of how its connected to your boards? I am more of a visual learner I could read books all day and not really gain much but give me a wrench and let me wack at an engine or something for a few hours I'll learn stuff quick

Edited 1 time(s). Last edit at 03/21/2016 06:54PM by bizit524.

however when I unplug it from the Z end stop but still leave it plugged in with 12 volts feeding it. Then measure the wire that goes to the end stop dangling it is at 4.9 put metal in front of it, it goes all the way down to 0 like it is suppose to.

however when I unplug it from the Z end stop but still leave it plugged in with 12 volts feeding it. Then measure the wire that goes to the end stop dangling it is at 4.9 put metal in front of it, it goes all the way down to 0 like it is suppose to. WHAT THE HECK AM I DOING WRONG. ?!??!?!?!?!?

I am out of ideas. Yes I could buy another longer detecting NPN or a capacitive sensor but I am tired of buying them. I dont want to by more because these are working and I cant exactly sell these or even give these to people 90% of people dont know what they are

4mm is not enough, my 8mm is barely enough. The both sensors work I can test it with my multi meter. NPN goes up, PNP goes down like they should. I have both working on the 5v with voltage divider. They both trigger with metal. I have got the 8mm PNP to trigger longer distances with a thick steel than aluminum. The PNP currently hooked up is like it is not being grounded on the board properly. Even though I have tried grounding it through main PSU or I tried grounding it just on the RAMPS board and I have tried hooking it up to both. I can put back my original end stop and it works fine/drops to 0 when hit and everything works so it says that the circuit on the RAMPS is working.

any more suggestions?

Dumb request to the both of you. Can I just see a picture of your ends of how its connected to your boards? I am more of a visual learner I could read books all day and not really gain much but give me a wrench and let me wack at an engine or something for a few hours I'll learn stuff quick

Edited 1 time(s). Last edit at 03/21/2016 06:54PM by bizit524.

|

Re: bed level sensor trouble March 21, 2016 07:11PM |

Registered: 8 years ago Posts: 3,525 |

In your situation above I think you need to disable z_min_endstop pullup in marlin. Then try it again.

I think as you have pullup enabled, your signal pin is being supplied via the internal pullup resistor with 5v from the 5v power on the arduino/ramps, when your sensor attempts to ground the signal (when it is attached to your controller board) it is only managing to pull the voltage down to 3.3v which as you said is not enough. Turn the pullup off in marlin and the sensor supplies the 5v, until it triggers then the voltage is 0v and you should be able to get back z min endstop:triggered when you send m119.

If you want a more detailed explanation read on.

To give a quick overview of what pullups are: If you want to use sensor which grounds the signal when switched i.e. (I think a PNP type or might be NPN few if anyone can really pin this down definitively) your z min endstop signal pin needs to be sitting at 5v with nothing attached. A pullup resistor can be either external i.e. an actual full size resistor (quite a high resistance one) connected from the 5v to the pin, or it can be internal on the board/in a chip somewhere, which ramps/arduino boards have on the endstop signal pins. In Marlin you can select to turn on the endstop pullups which means the endstop pins now have 5v on them when nothing is connected. Check this by carefully putting your multimeter from 0v on the power supply to the z min endstop signal pin, if it reads 5v, then pullup is enabled. When your sensor triggers it grounds the signal pin through the sensor, the voltage drains away to ground and goes low i.e. towards 0v, the small high resistance pullup resistor can't bring this back to 5v as not enough current can flow through it (that's why you use one with a high resistance). The board sees the signal go low and triggers this is false endstop logic.

A bunch more on pullups [learn.sparkfun.com]

You need to use try both endstop logic settings with pullups off. Unless I've got this all wrong still, I've been testing loads of sensors and I've got two NPN NO sensors which behave differently, so there is the added dimension that maybe these things are mis-labelled or very inconsistent, just to make our lives even easier. I am thinking of rewriting my guide with a testing procedure to verify the sensor you have works the way it should then moving on to wiring it up.

Edited 4 time(s). Last edit at 03/21/2016 08:11PM by DjDemonD.

I think as you have pullup enabled, your signal pin is being supplied via the internal pullup resistor with 5v from the 5v power on the arduino/ramps, when your sensor attempts to ground the signal (when it is attached to your controller board) it is only managing to pull the voltage down to 3.3v which as you said is not enough. Turn the pullup off in marlin and the sensor supplies the 5v, until it triggers then the voltage is 0v and you should be able to get back z min endstop:triggered when you send m119.

If you want a more detailed explanation read on.

To give a quick overview of what pullups are: If you want to use sensor which grounds the signal when switched i.e. (I think a PNP type or might be NPN few if anyone can really pin this down definitively) your z min endstop signal pin needs to be sitting at 5v with nothing attached. A pullup resistor can be either external i.e. an actual full size resistor (quite a high resistance one) connected from the 5v to the pin, or it can be internal on the board/in a chip somewhere, which ramps/arduino boards have on the endstop signal pins. In Marlin you can select to turn on the endstop pullups which means the endstop pins now have 5v on them when nothing is connected. Check this by carefully putting your multimeter from 0v on the power supply to the z min endstop signal pin, if it reads 5v, then pullup is enabled. When your sensor triggers it grounds the signal pin through the sensor, the voltage drains away to ground and goes low i.e. towards 0v, the small high resistance pullup resistor can't bring this back to 5v as not enough current can flow through it (that's why you use one with a high resistance). The board sees the signal go low and triggers this is false endstop logic.

A bunch more on pullups [learn.sparkfun.com]

You need to use try both endstop logic settings with pullups off. Unless I've got this all wrong still, I've been testing loads of sensors and I've got two NPN NO sensors which behave differently, so there is the added dimension that maybe these things are mis-labelled or very inconsistent, just to make our lives even easier. I am thinking of rewriting my guide with a testing procedure to verify the sensor you have works the way it should then moving on to wiring it up.

Edited 4 time(s). Last edit at 03/21/2016 08:11PM by DjDemonD.

|

Re: bed level sensor trouble March 21, 2016 07:25PM |

Registered: 8 years ago Posts: 3,525 |

As for my wiring I am using a NPN NO sensor at the moment and its wired direct to the endstop so

sensor brown to endstop +

sensor blue to endstop -

sensor black to endstop signal

And to be clear the endstop + is towards the middle of the baord, - is in the middle of the 3 pins and signal is towards the outside of the board.

My sensor which is a LJ18A3-8-Z/BX works on 5v so no voltage dividers required.

Oddly my endstop logic is true but my pullup is on. Which makes no sense but it works perfectly.

EDIT - so I turned pullup off and it still works, in fact I wasn't sure my endstop pullup was working anyway.

Edited 2 time(s). Last edit at 03/21/2016 08:03PM by DjDemonD.

sensor brown to endstop +

sensor blue to endstop -

sensor black to endstop signal

And to be clear the endstop + is towards the middle of the baord, - is in the middle of the 3 pins and signal is towards the outside of the board.

My sensor which is a LJ18A3-8-Z/BX works on 5v so no voltage dividers required.

Oddly my endstop logic is true but my pullup is on. Which makes no sense but it works perfectly.

EDIT - so I turned pullup off and it still works, in fact I wasn't sure my endstop pullup was working anyway.

Edited 2 time(s). Last edit at 03/21/2016 08:03PM by DjDemonD.

|

Re: bed level sensor trouble March 21, 2016 07:43PM |

Registered: 8 years ago Posts: 3,525 |

In fact the more I think about this the more I think there is a really good market for finding both an inductive and capacitative sensor which is NC for safety, works on 5v reliably, has a long sensing distance and can be supplied to the 3d printing community with a 3 pin endstop plug fixed to it and a really simple guide which says - plug it in, set logic to false and pullup on, then print stuff. Yes it won't be $5 as I'll have to buy loads, test them, throw out the duff ones, crimp proper endstop plugs onto them and provide the foolproof guide to go with them. But the confusion that could be saved is massive.

EDIT - so it seems that the sensor I have meets all these requirements, it works on 5v, it sends 5v when open and 0v when triggered, so it fails safe (if I unplug it the endstop shows triggered, which means if it fails when homing the axis stops and doesnt crash), it detects through 3mm glass to aluminium foil (would work even better with aluminium plate i.e. a mk3 heatbed) with about a 1.2mm nozzle gap which is enough. I might order a few more and make sure they are all consistent and then stick some on ebay as "foolproof 3d printer proximity sensor".

As for selling the sensors you have stick em on ebay someone will take them, since they can get them fast not wait 3 weeks to get one from China.

Edited 1 time(s). Last edit at 03/21/2016 08:08PM by DjDemonD.

EDIT - so it seems that the sensor I have meets all these requirements, it works on 5v, it sends 5v when open and 0v when triggered, so it fails safe (if I unplug it the endstop shows triggered, which means if it fails when homing the axis stops and doesnt crash), it detects through 3mm glass to aluminium foil (would work even better with aluminium plate i.e. a mk3 heatbed) with about a 1.2mm nozzle gap which is enough. I might order a few more and make sure they are all consistent and then stick some on ebay as "foolproof 3d printer proximity sensor".

As for selling the sensors you have stick em on ebay someone will take them, since they can get them fast not wait 3 weeks to get one from China.

Edited 1 time(s). Last edit at 03/21/2016 08:08PM by DjDemonD.

|

Re: bed level sensor trouble March 21, 2016 09:21PM |

Registered: 13 years ago Posts: 268 |

Inductive sensors derate when used with aluminum as opposed to steel. Every one is different, but it can typically be 40-50% of the distance that steel (in this case it's actually rated with a particular iron material) will be. It gets worse too, as you use longer range sensors, your accuracy goes down. Generally with these sensors it's around 10% of the full detection distance, therefore with a longer sensor distance the repeatability will be lower.

"Working" at 5v is a relative term, you aren't doing yourself favors running the internal circuit at a lower voltage either.

Poke around some of the documentation of sensors on automationdirect.com (no affiliation, just a happy customer) it will explain a LOT about these sensors.

"Working" at 5v is a relative term, you aren't doing yourself favors running the internal circuit at a lower voltage either.

Poke around some of the documentation of sensors on automationdirect.com (no affiliation, just a happy customer) it will explain a LOT about these sensors.

|

Re: bed level sensor trouble March 22, 2016 06:50AM |

Registered: 8 years ago Posts: 3,525 |

Hi, in this situation I'd say that using offset sensors like this isn't really ideal at all. Probing with the nozzle is better but thats beside the point as these sensors are cheap, readily available and they work, of a fashion. But the process of getting a sensor like this to work, for those who are not electronics experts is frustrating and confusing, even the people on here who are electronics experts disagree about how each sensor type works and how it should be used, and what settings to apply in firmware etc....I think this is because once you get one working you basically forget about how it works and how much hassle it was getting it going. The next time you wire one up you fall back on a sound knowledge of electronics and figure it out again, something the beginner may not be able to do.

I have two sensors both NPN NO sensors and I get these differing results when bench testing them: Yes one is inductive and one capacitative but why should that affect the switching (PNP/NPN NO/NC) behaviour? One sensor does not energise the signal at all, the other behaves in a very strange way if measuring the voltage from ground to signal it energises the signal wire. If measured from +12v to signal it grounds the signal.

Npn NO LJ12A3-4-Z/bx inductive

Nothing measured from 0v to signal wire

open or closed

Measured from +12v to signal wire

Supply 12.4v

Open voltage 0.12v

Closed voltage 12.41v

Npn NO ljc18a3-h-z/bx capacitative

Supply 12.4v

Measured from 0v to signal wire

Open voltage 10.13v

Closed voltage 0v

Measured from +12v to sign wire

Open 0v

Closed 12.40v

I also have an LJ18A3-8-Z/BX in my SmartrapCore Alu at the moment which should be an NPN NO sensor but which gives 12v open and 0v triggered (which means it is actually a NC sensor, despite it saying NPN NO on the side (in Chinese but which I had Google translate)!

I ran some tests on it and this is the m48 result:

SENDING:M48

M48 Z-Probe Repeatability test

Mean: 0.001875

Standard Deviation: 0.006875

Not bad for a sensor running 1v below its requirements. In fact this sensor and the printer in which it installed has been the least problematic printer I've used/built for bed level issues so far.

So we can't rely on the sensors themselves to actually work the way they are meant to. Or to be sold on ebay correctly described, one listing was for an NPN NC sensor which said NO in the detailed description below.

I want to see if I can help make this process less confusing for beginners. I was one not long ago and these things are frustrating, I got my sensors working by trial and error. There are two ways to help people with these problems. Firstly education as to the vagaries of all the sensor-types and their performance, modes of operation, wiring schemes, limitations etc... I have begun this process and have written an 8 page 3500 word guide, however it seems since there is both a lack of agreement amongst those who claim to understand these things about how they actually operate, AND a huge level of inconsistency in the actual sensors themselves. I do not think this is going to work.

My thought is that the vast majority of reprappers just want their printer to work, are on a budget and are not going to undertake a degree in electronic engineering. What would make the situation easier would be if someone sold a sensor such as this but it was adapted for (designed for would be even better) 3d printing. Call it the "No Hassle, Foolproof Proximity Sensor for 3D printers". It works on 5v, it has a decent sensing distance i.e. 6-8mm so it can detect aluminium through 3-4mm glass, it should be NC for failsafe operation, it should just plug into the endstop pins, the settings required in firmware (endstop logic and pullups) should be clear when the sensor is supplied and it should just work.

Now I understand DC42 supplies an IR sensor which meets most if not all of these requirements, but I am certain it is not $10! People are going to order a sensor for $5 from China and then spend hours struggling to make it do anything useful, then come on the forum where we will all spend hours trying to help them get it to work, or maybe I can supply them with one for $10 which just works, straight out of the box. I have ordered a number of sensors to begin to test them to find out if I can get a supply of sensors which meet these conditions and are reliable and consistent.

As for whether I'm doing myself a favour running the sensor on 5v, yes I am - if it works reliably and is simple and easy then I am doing myself/everyone else a favour.

I have two sensors both NPN NO sensors and I get these differing results when bench testing them: Yes one is inductive and one capacitative but why should that affect the switching (PNP/NPN NO/NC) behaviour? One sensor does not energise the signal at all, the other behaves in a very strange way if measuring the voltage from ground to signal it energises the signal wire. If measured from +12v to signal it grounds the signal.

Npn NO LJ12A3-4-Z/bx inductive

Nothing measured from 0v to signal wire

open or closed

Measured from +12v to signal wire

Supply 12.4v

Open voltage 0.12v

Closed voltage 12.41v

Npn NO ljc18a3-h-z/bx capacitative

Supply 12.4v

Measured from 0v to signal wire

Open voltage 10.13v

Closed voltage 0v

Measured from +12v to sign wire

Open 0v

Closed 12.40v

I also have an LJ18A3-8-Z/BX in my SmartrapCore Alu at the moment which should be an NPN NO sensor but which gives 12v open and 0v triggered (which means it is actually a NC sensor, despite it saying NPN NO on the side (in Chinese but which I had Google translate)!

I ran some tests on it and this is the m48 result:

SENDING:M48

M48 Z-Probe Repeatability test

Mean: 0.001875

Standard Deviation: 0.006875

Not bad for a sensor running 1v below its requirements. In fact this sensor and the printer in which it installed has been the least problematic printer I've used/built for bed level issues so far.

So we can't rely on the sensors themselves to actually work the way they are meant to. Or to be sold on ebay correctly described, one listing was for an NPN NC sensor which said NO in the detailed description below.

I want to see if I can help make this process less confusing for beginners. I was one not long ago and these things are frustrating, I got my sensors working by trial and error. There are two ways to help people with these problems. Firstly education as to the vagaries of all the sensor-types and their performance, modes of operation, wiring schemes, limitations etc... I have begun this process and have written an 8 page 3500 word guide, however it seems since there is both a lack of agreement amongst those who claim to understand these things about how they actually operate, AND a huge level of inconsistency in the actual sensors themselves. I do not think this is going to work.

My thought is that the vast majority of reprappers just want their printer to work, are on a budget and are not going to undertake a degree in electronic engineering. What would make the situation easier would be if someone sold a sensor such as this but it was adapted for (designed for would be even better) 3d printing. Call it the "No Hassle, Foolproof Proximity Sensor for 3D printers". It works on 5v, it has a decent sensing distance i.e. 6-8mm so it can detect aluminium through 3-4mm glass, it should be NC for failsafe operation, it should just plug into the endstop pins, the settings required in firmware (endstop logic and pullups) should be clear when the sensor is supplied and it should just work.

Now I understand DC42 supplies an IR sensor which meets most if not all of these requirements, but I am certain it is not $10! People are going to order a sensor for $5 from China and then spend hours struggling to make it do anything useful, then come on the forum where we will all spend hours trying to help them get it to work, or maybe I can supply them with one for $10 which just works, straight out of the box. I have ordered a number of sensors to begin to test them to find out if I can get a supply of sensors which meet these conditions and are reliable and consistent.

As for whether I'm doing myself a favour running the sensor on 5v, yes I am - if it works reliably and is simple and easy then I am doing myself/everyone else a favour.

|

Re: bed level sensor trouble March 22, 2016 07:56AM |

Registered: 13 years ago Posts: 268 |

What I meant was that you decrease accuracy and sensing distance by lowering the voltage. Something that can be determined by reading relevant material instead of trying by trial and error. If the parts don't match the data sheet perhaps you might question your source and why you can get something so cheap when most places don't have it that cheap. I deal with prox sensors in large machine tools, they need replacement or I need to wire in more to meet particular applications. In many years of doing so I have never had anything close to the issues with any of the various sizes or brands like you describe. These aren't rocket science.

|

Re: bed level sensor trouble March 22, 2016 08:48AM |

Registered: 8 years ago Posts: 3,525 |

I accept that, but I think my experience has shown me that for the sensors that are tolerant to this approach the accuracy and sensing distance reduction still puts the sensor well within the usable range for 3d printing. But it eliminates all the issues with voltage dividers and potential controller board damage from over-voltage etc... So the net gain is still a considerably positive one.

So perhaps the issues I've encountered relate to quality of sensors coming from the Far East? I know there is a massive price differential between a US/European made sensor and a Chinese made one. But is the quality differential the same also? I suspect the Chinese sensors are 80% as good but for 20% of the price so...

I still intend to purchase and test a batch of this type of sensor LJ18A3-8-Z/BX, which seems to be the most suitable for this application for all the reason given above. I'll throw out the bad ones and, then supply the good ones with clear simple instructions to those who want them. This is not intended to be a profit making exercise but they will not be as cheap coming this way as they are from China direct. But what price to save all that time and frustration?

Edited 1 time(s). Last edit at 03/22/2016 08:49AM by DjDemonD.

So perhaps the issues I've encountered relate to quality of sensors coming from the Far East? I know there is a massive price differential between a US/European made sensor and a Chinese made one. But is the quality differential the same also? I suspect the Chinese sensors are 80% as good but for 20% of the price so...

I still intend to purchase and test a batch of this type of sensor LJ18A3-8-Z/BX, which seems to be the most suitable for this application for all the reason given above. I'll throw out the bad ones and, then supply the good ones with clear simple instructions to those who want them. This is not intended to be a profit making exercise but they will not be as cheap coming this way as they are from China direct. But what price to save all that time and frustration?

Edited 1 time(s). Last edit at 03/22/2016 08:49AM by DjDemonD.

Sorry, only registered users may post in this forum.