Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions.

Posted by CptanPanic

|

Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 07, 2016 07:58AM |

Registered: 10 years ago Posts: 55 |

I saw this kickstarter, and thought that would be a nice type of printer to build. I would like to make it big enough to use standard reprap heated plate (200x200). Any builds or plans for this type?

[www.kickstarter.com]

[www.kickstarter.com]

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 07, 2016 08:05AM |

Registered: 11 years ago Posts: 5,780 |

It shouldn't be too hard to copy the design based on what I can see in the video.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 07, 2016 11:19AM |

Registered: 8 years ago Posts: 1,671 |

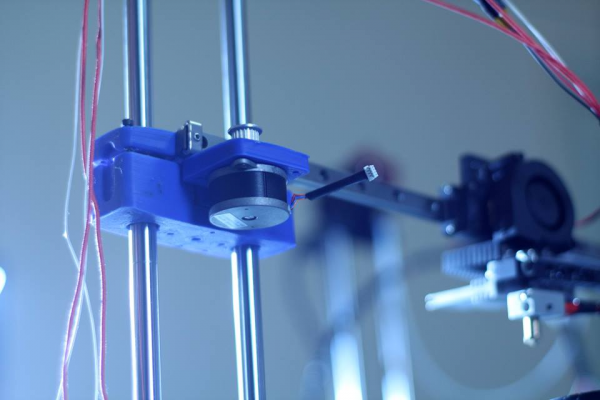

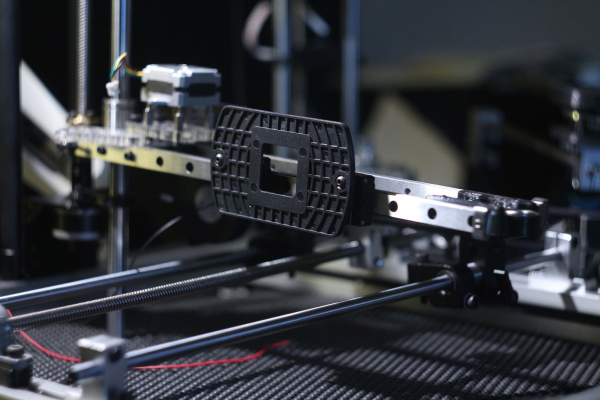

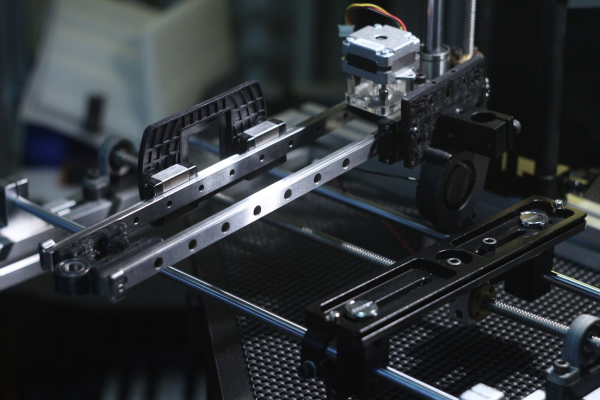

I've been building a larger one, 330mm rail, no screws in the build area....

but trying to keep things modular so i can use bed or other stuff from other machine, or clamp it to my cube(it can be the XY),

Not the ideal placement of the rail, still trying to incorporate some kind of belt tensioner.

Z is at least 300mm, build so far is around £100,(but thats without bed or controller) might have to swap out the X stepper.

I had it also with 2 rails on X for added stiffness(not that it needs it the rails a thicker one) but I wanted to use the rail for other place.

I'm wondering where Cetus is getting the ready supply of rails at a decent price to make it viable(ah its the green n red ones)

though short ones should be quite cheap, .

Edited 17 time(s). Last edit at 09/07/2016 11:25PM by MechaBits.

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 07, 2016 11:28AM |

Registered: 10 years ago Posts: 55 |

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 07, 2016 12:19PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 07, 2016 01:41PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 08, 2016 02:07AM |

Registered: 8 years ago Posts: 1,671 |

Lots of Mecha Bits on the kickstarter page

oops cant do that.

Edited 3 time(s). Last edit at 09/08/2016 02:12AM by MechaBits.

oops cant do that.

Edited 3 time(s). Last edit at 09/08/2016 02:12AM by MechaBits.

|

Re: Any builds/plans for a printer like this? Printrbot type arm made with linear rails, extrusions. September 08, 2016 05:52AM |

Registered: 8 years ago Posts: 3,525 |

I think making a cantilevered design printer using linear rails offers much more rigidity than using rods, but significantly increasing the size might be problematic. There are surely limits to the loading a linear rail can take when cantilevering an axis from it. Even if there is no play the lifespan of the bearings is going to be much shorter. The forces on the z-carriage on that rail will be quite high when the print head is at x-max, especially if the print head is the usual heavy (i3 type) design. Maybe with a super light print head (bowden/flex3drive), no giant inductive sensors, minimal fans etc it might work.

Whilst the cantilevered design is nice for a small printer and easier to build/cheaper, a full metal frame, offering dual sided support of all axes, of suitable size offers very high rigidity and will produce better prints.

I've gone from having a 180x180mm i3, to a 270x180mm corexy and am building a 330mm (circular) kossel XL and the difficulty of getting everything to work properly definitely increases with the square of the increase in size.

Edited 1 time(s). Last edit at 09/08/2016 05:53AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Whilst the cantilevered design is nice for a small printer and easier to build/cheaper, a full metal frame, offering dual sided support of all axes, of suitable size offers very high rigidity and will produce better prints.

I've gone from having a 180x180mm i3, to a 270x180mm corexy and am building a 330mm (circular) kossel XL and the difficulty of getting everything to work properly definitely increases with the square of the increase in size.

Edited 1 time(s). Last edit at 09/08/2016 05:53AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.