new guy in the deep end

Posted by aparkin

|

Re: new guy in the deep end January 15, 2015 01:28PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

More great info! Many thanks.

Yes, I'm using Marlin firmware. I was looking it over and seems to be one of the standard firmwares for 3d printing. I was able to test out my Ramps 1.4 and stepper motors and have managed to get Pronterface working the motors without having anything else hooked up - still dabbling and piecing it all together.

Nice! That seems like a good idea. So what I mentioned about the thermistors is that certain thermistors have different heating curves- at a specific heat, thermistor A may give a different voltage than thermistor B. So what the people did who created Marlin was generate tables of these values from measuring these voltages along the range of temperatures. They included this information in the program so your printer can heat things accurately.

The thermistors are divided up into different names, from different manufacturers, and there is a list in Marlin's Configuration.h that has them laid out:

//// Temperature sensor settings: // -2 is thermocouple with MAX6675 (only for sensor 0) // -1 is thermocouple with AD595 // 0 is not used // 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup) // 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup) // 3 is Mendel-parts thermistor (4.7k pullup) // 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !! // 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (4.7k pullup) // 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup) // 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup) // 71 is 100k Honeywell thermistor 135-104LAF-J01 (4.7k pullup) // 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup) // 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup) // 10 is 100k RS thermistor 198-961 (4.7k pullup) // 11 is 100k beta 3950 1% thermistor (4.7k pullup) // 12 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup) (calibrated for Makibox hot bed) // 13 is 100k Hisens 3950 1% up to 300°C for hotend "Simple ONE " & "Hotend "All In ONE" // 20 is the PT100 circuit found in the Ultimainboard V2.x // 60 is 100k Maker's Tool Works Kapton Bed Thermistor beta=3950

So basically make sure that whatever thermistors you order are ones that are definitely on this list. 1, 5, and 8 are pretty common. Otherwise, you will have a hell of a time figuring out the actual temperature of your hotend.

Quote

psneddon

I also purchased a RepRap Full Graphic LCD 12864 display but it's not working properly. I found that a lot of people were having problems with this display on their I3's - unfortunately, I didn't know that until after I bought it.

I was finally able to get the display to come on properly and I was able to access the first submenu, but the scroll knob doesn't work. So, I've put that aside for now and am waiting on my rods to arrive so I can get down to business building my I3 Rework.

Hmm. Mine has been working just fine so far, so I'm not sure what's going on. In fact, I had no idea that there were issues with this display until now. Did you download the u8glib library and put it in the right location?

The E3D hotend that I am referring to is one of the official ones, which you can buy here. The nozzles are removable and switchable as well, which is cool (although the hotends are pricey).

Quote

psneddon

Unfortunately, the ones I find are all Bowden versions and I think I need to get a Wade style. I know it's probably one of the better hot ends out there right now, but were there any major problems using a standard J head with your printer?

Yes, you should get a Wade hotend. I haven't had any major problems with the J-Head. Although based on the amount you will spend (probably $20-$30 on a cheap J-head), I would get a nicer hotend for more. You can sometimes run into issues with the ebay ones or other clones, as you can see in the post by RPW (the inventor of the J-head) here. Just be careful.

Quote

psneddon

I expect a huge learning curve getting the printer to print properly and I also want to start with 1.75mm and work up to 3mm maybe later.

It doesn't really work like that- they are both just as easy to work with. I would strongly recommend to use 3mm because the Wade's extruder in meant for it, and so is the hobbed bolt. You are going to have to modify the extruder to start out if you want to use 1.75mm filament.

And yes, there will be a learning curve. But you will make lots of discoveries on your own that help you to figure out the quirks of your own printer. I keep a logbook for notes like this, which comes in handy a lot.

Quote

psneddon

So, a .4mm hole for the extruder head would be a good selection then?

Thanks again for the feedback and information!

Sure! 0.4mm sounds great.

Edited 1 time(s). Last edit at 01/15/2015 01:31PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 16, 2015 08:19AM |

Registered: 9 years ago Posts: 124 |

Yes, I was looking for a hot end that had one of the listed thermistors - still researching.

I put the u8glib library in two places and compiled it with no problems - the configuration.h tab and the first tab that opens up (can't remember the name right now).

The E3D hot end you refer to - isn't that a Bowden hot-end? Can I put a Bowden on a Wade extruder?

I didn't know that 3mm was recommended for this 3d printer - I thought it could use 1.75mm and 3mm?

I plan on doing most of the mechanical build prior to the hot end portions. That way I can be building and reading/learning as I go.

I put the u8glib library in two places and compiled it with no problems - the configuration.h tab and the first tab that opens up (can't remember the name right now).

The E3D hot end you refer to - isn't that a Bowden hot-end? Can I put a Bowden on a Wade extruder?

I didn't know that 3mm was recommended for this 3d printer - I thought it could use 1.75mm and 3mm?

I plan on doing most of the mechanical build prior to the hot end portions. That way I can be building and reading/learning as I go.

|

Re: new guy in the deep end January 16, 2015 06:49PM |

Registered: 9 years ago Posts: 124 |

I read the article on J-head clones and I think it really helped knowing the differences. It looked like most of the clones use an aluminum block head while the original ones use a brass head. Also, the information on the venting was very informative. So, I waded (no pun intended) through the ones on eBay and found this one:

[www.ebay.com]

It has a .35mm head for 3mm filament.

Also, there's this one:

[www.ebay.com]

Also has a .35mm head only for 1.75mm filament.

Both are listed as MK V-BV and use a "standard" Marlin compatible thermistor - 104GT-2 (option #5 in the configuration file). I don't know if it comes with the liner or not - I'd have to ask.

I don't know if it comes with the liner or not - I'd have to ask.

They both have the same specs, look identical and seem to use the same parts, yet one is for 3mm filament while the other is for 1.75mm filament. ???? What am I missing here???

It looks like you'd have to put them together yourself and there's no wiring included with either of them. That's probably why most people are going with the cheap ones - less work and less money.

Edited 1 time(s). Last edit at 01/16/2015 07:15PM by psneddon.

[www.ebay.com]

It has a .35mm head for 3mm filament.

Also, there's this one:

[www.ebay.com]

Also has a .35mm head only for 1.75mm filament.

Both are listed as MK V-BV and use a "standard" Marlin compatible thermistor - 104GT-2 (option #5 in the configuration file).

I don't know if it comes with the liner or not - I'd have to ask.

I don't know if it comes with the liner or not - I'd have to ask.They both have the same specs, look identical and seem to use the same parts, yet one is for 3mm filament while the other is for 1.75mm filament. ???? What am I missing here???

It looks like you'd have to put them together yourself and there's no wiring included with either of them. That's probably why most people are going with the cheap ones - less work and less money.

Edited 1 time(s). Last edit at 01/16/2015 07:15PM by psneddon.

|

Re: new guy in the deep end January 18, 2015 01:58PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

Yes, I was looking for a hot end that had one of the listed thermistors - still researching.

I put the u8glib library in two places and compiled it with no problems - the configuration.h tab and the first tab that opens up (can't remember the name right now).

The E3D hot end you refer to - isn't that a Bowden hot-end? Can I put a Bowden on a Wade extruder?

Nope, the one that I posted is direct drive. You can't put a Bowden hotend on a Wade extruder- the extruder for a bowden setup is not on the carriage.

Quote

psneddon

I didn't know that 3mm was recommended for this 3d printer - I thought it could use 1.75mm and 3mm?

You can. However, the Wade extruder (cold-end) is designed for only 3mm filament. If you want to use 1.75mm filament, you will need to look at other extruders.

Quote

psneddon

I plan on doing most of the mechanical build prior to the hot end portions. That way I can be building and reading/learning as I go.

Sounds good!

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 18, 2015 05:46PM |

Registered: 9 years ago Posts: 43 |

|

Re: new guy in the deep end January 18, 2015 07:59PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

I read the article on J-head clones and I think it really helped knowing the differences. It looked like most of the clones use an aluminum block head while the original ones use a brass head. Also, the information on the venting was very informative. So, I waded (no pun intended) through the ones on eBay and found this one:

[www.ebay.com]

It has a .35mm head for 3mm filament.

Also, there's this one:

[www.ebay.com]

Also has a .35mm head only for 1.75mm filament.

Both are listed as MK V-BV and use a "standard" Marlin compatible thermistor - 104GT-2 (option #5 in the configuration file).I don't know if it comes with the liner or not - I'd have to ask.

They both have the same specs, look identical and seem to use the same parts, yet one is for 3mm filament while the other is for 1.75mm filament. ???? What am I missing here???

It looks like you'd have to put them together yourself and there's no wiring included with either of them. That's probably why most people are going with the cheap ones - less work and less money.

Well, at those prices I would just get the J-Head from the inventor himself here: he is supposed to have great customer service as well.

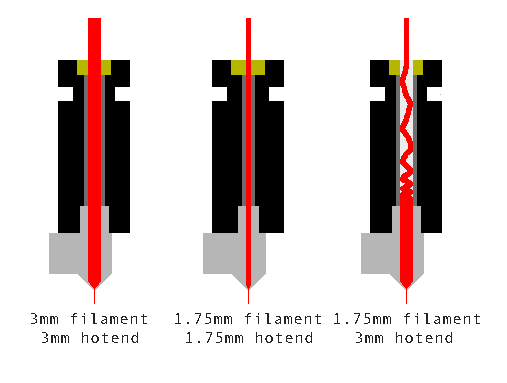

What is different between 3mm and 1.75mm hotends is the diameter of the inner tube of the hotend- as you can see in this diagram (I just whipped it up):

If you try to put 1.75mm filament in the 3mm hotend, it will fold because the inner tube has the wrong diameter. Hopefully that clears it up.

Edited 4 time(s). Last edit at 01/18/2015 08:07PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 18, 2015 08:33PM |

Registered: 9 years ago Posts: 120 |

Quote

aparkin

power supply

what's the recommended power supply for repraps i don't want something to cheep that i have to stand over it with a fire extinguisher and yet again i don't want a all singing and dancing power supply when all i need is for it to do its job reliably

Probably just buy this one. Or something similar. My PSU looks like this and the price here is pretty good.

I've also purchased filament from diyinks and it has worked just fine.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 18, 2015 09:12PM |

Registered: 10 years ago Posts: 167 |

the Jhead from www.hotends.com is the only "True" Jhead, the others are clones/knockoffs of copies, if your after a Jhead just get the offical one from the inventor, he is a great guy with great custoemr service, I don't know much about the E3D as I ahve not used one myself, but from the sounds of the forums, these are the main 2 that get used, there are others out there but most get relativly trouble free printing with these two, if you want to save some cash and only print in ABS or PLA temps then get the Jhead, else look at the E3D

|

Re: new guy in the deep end January 19, 2015 08:04AM |

Registered: 9 years ago Posts: 124 |

|

Re: new guy in the deep end January 19, 2015 09:15AM |

Registered: 9 years ago Posts: 43 |

hello all and thanks for some great information ive really learned a lot in the past couple of weeks so far i have bought all electrical parts( 28 days china postage ) except for the e3d hot end ill do this at the weekend and thermistors as the 1 listed are hard to make sure that they are the 1s listed but ill find a company with a good rep and shoot them a email asking i guess..

anyway ive bought and cut the mdf for the frame (ill upgrade this later ) i need to buy thesmooth rods , will iron smooth rods do are should i be looking for steel i found iron smooth rods from my local D.I.Y shop

and i have to buy the plastic printed parts and i also have a question with the extruder now i was going to use wades extruder as most printed parts are sold with this included but is the bowdens feeder better i read its a good upgrade as it save movment and little tugging and pulling buy print head moving (cart find any to buy) so is it a worth while upgrade when im up and running are best off hunting it down and use from the get go

Edited 1 time(s). Last edit at 01/19/2015 11:59AM by aparkin.

anyway ive bought and cut the mdf for the frame (ill upgrade this later ) i need to buy thesmooth rods , will iron smooth rods do are should i be looking for steel i found iron smooth rods from my local D.I.Y shop

and i have to buy the plastic printed parts and i also have a question with the extruder now i was going to use wades extruder as most printed parts are sold with this included but is the bowdens feeder better i read its a good upgrade as it save movment and little tugging and pulling buy print head moving (cart find any to buy) so is it a worth while upgrade when im up and running are best off hunting it down and use from the get go

Edited 1 time(s). Last edit at 01/19/2015 11:59AM by aparkin.

|

Re: new guy in the deep end January 27, 2015 05:13PM |

Registered: 9 years ago Posts: 43 |

ok every thing is in the post now excpet thermistor for hot bed can any1 link me a 100k thermistor - best choice for EPCOS 100k (4.7k pullup) (ebay if possible i I'm ever over thinking it are just trying to do it way to tired

the other thing is on the ramps 1.4 i read people use only 2 wires from the end stop to the ramps board but what 2 wires i think its negative and signal and positive is left off is this correct

many thanks for putting up with my stupid questions

the other thing is on the ramps 1.4 i read people use only 2 wires from the end stop to the ramps board but what 2 wires i think its negative and signal and positive is left off is this correct

many thanks for putting up with my stupid questions

|

Re: new guy in the deep end February 04, 2015 10:47AM |

Registered: 9 years ago Posts: 120 |

Quote

aparkin

ok every thing is in the post now excpet thermistor for hot bed can any1 link me a 100k thermistor - best choice for EPCOS 100k (4.7k pullup) (ebay if possible i I'm ever over thinking it are just trying to do it way to tired

the other thing is on the ramps 1.4 i read people use only 2 wires from the end stop to the ramps board but what 2 wires i think its negative and signal and positive is left off is this correct

many thanks for putting up with my stupid questions

Just try this one: http://www.ebay.com/itm/High-Stability-NTC-Thermistor-100K-with-wire-RepRap-Prusa-Mendel-Bed-or-Hot-End-/331179095442?pt=LH_DefaultDomain_0&hash=item4d1bcff592

I use three wires on my endstops- I believe that one is signal and one of the other two is ground when the switch is open. Then the last wire is ground when the switch is closed. This is so RAMPS knows that the endstop is plugged in all the time- by the return current when the switch is open.

EDIT: corrected

Edited 1 time(s). Last edit at 02/05/2015 01:07AM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end February 04, 2015 11:33AM |

Registered: 10 years ago Posts: 14,672 |

Quote

aparkin

the other thing is on the ramps 1.4 i read people use only 2 wires from the end stop to the ramps board but what 2 wires i think its negative and signal and positive is left off is this correct

Yes, an endstop microswitch should be connected between signal and ground. Don't make the mistake some people do of wiring it to positive and ground, that tends to blow the regulator on the Arduino.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: new guy in the deep end February 05, 2015 10:23AM |

Registered: 9 years ago Posts: 43 |

|

Re: new guy in the deep end February 06, 2015 02:09PM |

Registered: 9 years ago Posts: 43 |

OK so apart from do I need direct support under the heat bed ??

I got anther problem I'm using a wades extruder and the E3d hot end was very lose I've used a rubber O ring to stop it wiggerling around but is there a better way as I don't think this will work for long if at all

Edited 2 time(s). Last edit at 02/06/2015 04:20PM by aparkin.

I got anther problem I'm using a wades extruder and the E3d hot end was very lose I've used a rubber O ring to stop it wiggerling around but is there a better way as I don't think this will work for long if at all

Edited 2 time(s). Last edit at 02/06/2015 04:20PM by aparkin.

|

Re: new guy in the deep end February 07, 2015 09:51AM |

Registered: 9 years ago Posts: 43 |

ok im using this thermistor

[www.ebay.co.uk]

and i keep getting error

: Extruder switched off. MAXTEMP triggered !

Error rinter stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)

rinter stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)

when i set maarlin thermistor to 0 i can get all motors working

i just cart get it to work when i change thermistoer setting to anything other than 0 any help wood be good thank

[www.ebay.co.uk]

and i keep getting error

: Extruder switched off. MAXTEMP triggered !

Error

rinter stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)

rinter stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)when i set maarlin thermistor to 0 i can get all motors working

i just cart get it to work when i change thermistoer setting to anything other than 0 any help wood be good thank

|

Re: new guy in the deep end February 07, 2015 12:54PM |

Registered: 9 years ago Posts: 43 |

|

Re: new guy in the deep end February 07, 2015 01:08PM |

Registered: 10 years ago Posts: 344 |

Sorry, only registered users may post in this forum.