backlash trouble

Posted by icefire

|

Re: backlash trouble April 10, 2016 10:06PM |

Registered: 8 years ago Posts: 155 |

I wanted to update this post because: your circles, lookes exactly as mines. And I finally found the source; Seeing a video, not related to this issue, I saw the way that person adjusted the belts and I noticed something: he unscrew the screws of the pulleys before adjusting the belts... And I re adjusted my belts again unscrewing those screws, adjust the belt and srewing the screws of the pulley againg. And that solved the issue!!!!!

What was ging on? If you jsut adjust the belt, what happend? you adjust only 1 side of the belt, the one you are putting tension. The other side is "hold" by the pulley teeths, so it does not get adjusted. So 1 side of the belt is tight and the other not so tight. If you unscrew the the pulley, when you adjust the belt, the pulley accomodates itsels, all the belt receives the same tension and get equally tightened.

Hope it helps

What was ging on? If you jsut adjust the belt, what happend? you adjust only 1 side of the belt, the one you are putting tension. The other side is "hold" by the pulley teeths, so it does not get adjusted. So 1 side of the belt is tight and the other not so tight. If you unscrew the the pulley, when you adjust the belt, the pulley accomodates itsels, all the belt receives the same tension and get equally tightened.

Hope it helps

|

Re: backlash trouble April 11, 2016 06:30AM |

Registered: 9 years ago Posts: 1,873 |

Quote

Tinchus

I wanted to update this post because: your circles, lookes exactly as mines. And I finally found the source; Seeing a video, not related to this issue, I saw the way that person adjusted the belts and I noticed something: he unscrew the screws of the pulleys before adjusting the belts... And I re adjusted my belts again unscrewing those screws, adjust the belt and srewing the screws of the pulley againg. And that solved the issue!!!!!

What was ging on? If you jsut adjust the belt, what happend? you adjust only 1 side of the belt, the one you are putting tension. The other side is "hold" by the pulley teeths, so it does not get adjusted. So 1 side of the belt is tight and the other not so tight. If you unscrew the the pulley, when you adjust the belt, the pulley accomodates itsels, all the belt receives the same tension and get equally tightened.

Hope it helps

I don't understand. The belts typically run around an idler that's free to move - tension is equally distributed along the length of the belt. Maybe I misunderstood what you are saying, or maybe there was some other effect involved that made a difference. Which pulley did you unscrew - the one on the stepper?

|

Re: backlash trouble April 11, 2016 06:44AM |

Registered: 8 years ago Posts: 155 |

Yes, and in my case that is another yes. I dont know how to explain it.... somehow the idler does not distribute the tension evenly. May be it does and the part of the belt around the pulley doesnt received tension... I dont know. What I can tell for sure, and I measured it, is that if you just tighten the belt without unscrewing the pulley's screws, one part of the belt is a little more tight than the other and this is fixed unscrewing those screws, and THEN tightening the belt. I have been for months fighting against this circles problem, I tried everything. And 1 dy ago, I tried this and it fixed the problem.

|

Re: backlash trouble April 11, 2016 07:22AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: backlash trouble April 11, 2016 07:54AM |

Registered: 11 years ago Posts: 5,780 |

None of this makes any sense. If the pulley is free to turn, as it should be, loosening the screw that holds it in place should have no effect. If it isn't free to turn, that is your problem.

Please post a picture of the machine showing the belt path and point out the pulley whose screw you are loosening. Also post a link to the youtube video you mentioned.

Edited 1 time(s). Last edit at 04/11/2016 07:56AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Please post a picture of the machine showing the belt path and point out the pulley whose screw you are loosening. Also post a link to the youtube video you mentioned.

Edited 1 time(s). Last edit at 04/11/2016 07:56AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble April 11, 2016 08:16AM |

Registered: 8 years ago Posts: 155 |

Ok... but, at this point may be my explanation is wrong, whatever... but tightening the belt in this way solved my problem, and my problem was exactly the same as the one posted here. I had adjusted, re adjusted DOZENS of times in the past. I have assembled and re assembled Y and X axis like 10 times. I have changed the belt 3 times. I have changed pullyes, I have used oild, grease, nothing for lubricateing the axis. I have been insane in the way I aligned the X and Y axis. I have tried EVRYTHING. And the only thing that gave a perfect circle has been adjusting the belt in this way. I dont know what else to say.

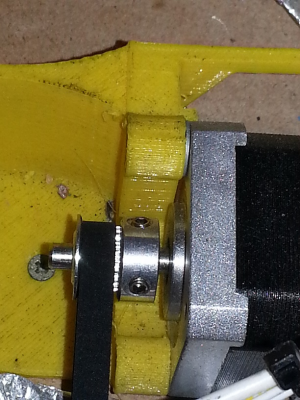

I post the photo of the 2 screws I loosen before adjusting the belt. Once the belt has the proper tension I screw them again, tight enough for the pulley not to move around the motor axis.

I post the photo of the 2 screws I loosen before adjusting the belt. Once the belt has the proper tension I screw them again, tight enough for the pulley not to move around the motor axis.

|

Re: backlash trouble April 11, 2016 08:26AM |

Registered: 9 years ago Posts: 517 |

Quote

the_digital_dentist

None of this makes any sense. If the pulley is free to turn, as it should be, loosening the screw that holds it in place should have no effect. If it isn't free to turn, that is your problem.

Please post a picture of the machine showing the belt path and point out the pulley whose screw you are loosening. Also post a link to the youtube video you mentioned.

This could be a problem if the motors were engaged and unable to turn freely. I know on my CoreXY machine when I tighten the belts, I can see the pulley on the motors turn when I tighten them. I always have the machine off though when I do it.

|

Re: backlash trouble April 11, 2016 08:28AM |

Registered: 8 years ago Posts: 155 |

|

Re: backlash trouble April 11, 2016 12:08PM |

Registered: 11 years ago Posts: 5,780 |

Is the pulley made for a 1/4" shaft? NEMA-17 motors have 5 mm shaft. If you try to use a 1/4" (6.35 mm) pulley on a 5mm shaft it will cause all sorts of problems. The pulley and shaft axes won't match and the belt tension will vary as the motor rotates. That would cause weird print problems for sure.

If it's a 5 mm shaft pulley, I can't see how doing anything with the screws could possibly affect the belt tension. If the screws were loose while the machine was operating it would definitely cause problems.

Edited 2 time(s). Last edit at 04/11/2016 02:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If it's a 5 mm shaft pulley, I can't see how doing anything with the screws could possibly affect the belt tension. If the screws were loose while the machine was operating it would definitely cause problems.

Edited 2 time(s). Last edit at 04/11/2016 02:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble April 11, 2016 02:09PM |

Registered: 9 years ago Posts: 141 |

I'm with DD here - this doesn't make sense to me either. That belt must go around an idler pulley at the other end, right? Is that free to turn? If so, the tension on the two sides of the belt MUST be essentially the same at all times as the idler will rotate to balance the tensions out - if it doesn't rotate freely then that is where the problem lies, not the motor end.

Also, does the motor shaft in that photo have a flat on it? If so, is one of the screws on the flat? I can't see from the photo but if you are tightening the screws down onto a round shaft then the pulley may be rotating on the shaft.

Richard

Also, does the motor shaft in that photo have a flat on it? If so, is one of the screws on the flat? I can't see from the photo but if you are tightening the screws down onto a round shaft then the pulley may be rotating on the shaft.

Richard

|

Re: backlash trouble April 11, 2016 02:42PM |

Registered: 13 years ago Posts: 268 |

Not every nema17 is a 5mm shaft. I have at least one 6.35mm/.25" in my collection. Not as common, but they are a thing.Quote

the_digital_dentist

Is the pulley made for a 1/4" shaft? NEMA-17 motors have 5 mm shaft. If you try to use a 1/4" (6.35 mm) pulley on a 5mm shaft it will cause all sorts of problems. The pulley and shaft axes won't match and the belt tension will vary as the motor rotates. That would cause weird print problems for sure.

If it's a 5 mm shaft pulley, I can't see how doing anything with the screws could possibly affect the belt tension. If the screws were loose while the machine was operating it would definitely cause problems.

Sorry, only registered users may post in this forum.