RepRap Extrusion

Posted by RepRapRaj83

|

RepRap Extrusion June 23, 2011 02:44PM |

Registered: 12 years ago Posts: 85 |

Hi

I hope all on the forum are well.

First of all, thanks to all who have responded to my previous queries on my RepRap build concerning software freezes and SF/Firmware settings. Without help from the forum members, i would not have been able to get to this stage of my build.

I am close to printing objects but need some final help with calibration (i think). I have attached the test.gcode file generated by SF41 along with pictures of what is printed.

A quick overview of the situation.

The extrusion of plastic on my prints does not remain consistent, resulting in incomplete printouts.

I’m slicing using SF41 and i am trying to upload these through the RepRap Host/RepSnapper.

The extruder is an Adrians geared extruder connected directly to the Extruder Board.

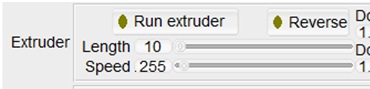

Manual tests which were made in RepSnapper to make sure the extruder works when commands are sent. I tested extrusions of 10mm at a speed of 255 (assuming this relates to ‘top speed’ from a PWM POV) which resulted in a consistent extrusion without any loss of torque. Test extrusions at a lower speed seem to make the stepper motor twitch/skip and the extrusion is not as smooth as at 255.

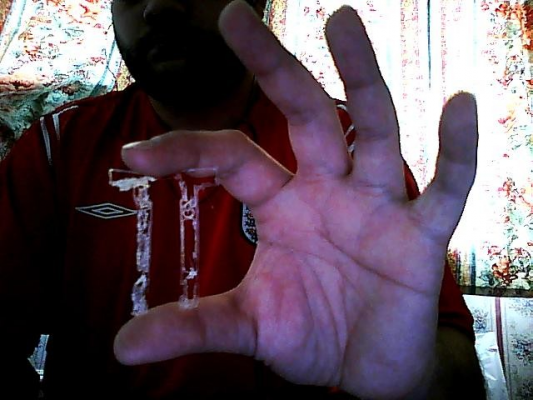

When sending gcode through the RepRap Host, the extruder motor tends to struggle to move when prints are carried out which result in printouts as attached. Ignore the big paw holding up the printout if you can. Even though it's a terrible print, it's good to see something being printed on the machine.

I am looking to troubleshoot the problem by looking at firmware, RepRap host preferences and possibly the replace.csv file in SF.

Before doing so thought it best to ask if anyone has had similar problems. As always, any input into which area to amend is very much appreciated.

I plan to look at updating the firmware on the extruder board, specifically the ‘#define STEP_PWM’ in the extruder boards configuration h file which is currently 140. By updating this to 255, i am hoping this will result in more consistent level of torque throughout the print.

RepRap Host Global and Extruder Variable update: - There are a lot of variables which may need updating on the Globals an Extruder tabs on the RepRap Preferences.

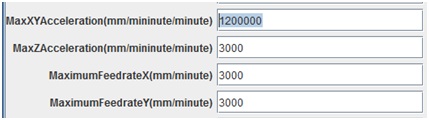

Globals which i think need amending are outlined below. These are the default settings in RepRap Host.

These seem very high. I have turned off acceleration in the firmware but i was thinking of updating the X and Y federates to roughly 1200mm/minute.

I’m not sure of these have any impact on the performance of the extruder, however they are slightly different to the settings i have in SF41.

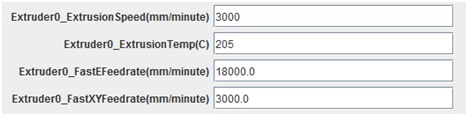

On the Extruder tabs, I thought the following areas may need amending.

Apart from the Temperature which i updated, the extrusions and feedrates again seem high. I looked to reduce these to 600, 1200 and 1200 respectively.

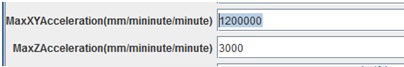

The variable above also seems high although it relates to acceleration.

Another possible cause of the drop in extrusion could be the Replace.csv parameters. I have outlined these below and they can also be seen on the attached gcode file. The Mcodes below have been commented out as they are deprecated codes.

M108 ;M108

M101 ;M101

M103 ;M103

M105 ;M105

If any more details are needed, please let me know.

Thanks in advance to all forum users.

Raj

I hope all on the forum are well.

First of all, thanks to all who have responded to my previous queries on my RepRap build concerning software freezes and SF/Firmware settings. Without help from the forum members, i would not have been able to get to this stage of my build.

I am close to printing objects but need some final help with calibration (i think). I have attached the test.gcode file generated by SF41 along with pictures of what is printed.

A quick overview of the situation.

The extrusion of plastic on my prints does not remain consistent, resulting in incomplete printouts.

I’m slicing using SF41 and i am trying to upload these through the RepRap Host/RepSnapper.

The extruder is an Adrians geared extruder connected directly to the Extruder Board.

Manual tests which were made in RepSnapper to make sure the extruder works when commands are sent. I tested extrusions of 10mm at a speed of 255 (assuming this relates to ‘top speed’ from a PWM POV) which resulted in a consistent extrusion without any loss of torque. Test extrusions at a lower speed seem to make the stepper motor twitch/skip and the extrusion is not as smooth as at 255.

When sending gcode through the RepRap Host, the extruder motor tends to struggle to move when prints are carried out which result in printouts as attached. Ignore the big paw holding up the printout if you can. Even though it's a terrible print, it's good to see something being printed on the machine.

I am looking to troubleshoot the problem by looking at firmware, RepRap host preferences and possibly the replace.csv file in SF.

Before doing so thought it best to ask if anyone has had similar problems. As always, any input into which area to amend is very much appreciated.

I plan to look at updating the firmware on the extruder board, specifically the ‘#define STEP_PWM’ in the extruder boards configuration h file which is currently 140. By updating this to 255, i am hoping this will result in more consistent level of torque throughout the print.

RepRap Host Global and Extruder Variable update: - There are a lot of variables which may need updating on the Globals an Extruder tabs on the RepRap Preferences.

Globals which i think need amending are outlined below. These are the default settings in RepRap Host.

These seem very high. I have turned off acceleration in the firmware but i was thinking of updating the X and Y federates to roughly 1200mm/minute.

I’m not sure of these have any impact on the performance of the extruder, however they are slightly different to the settings i have in SF41.

On the Extruder tabs, I thought the following areas may need amending.

Apart from the Temperature which i updated, the extrusions and feedrates again seem high. I looked to reduce these to 600, 1200 and 1200 respectively.

The variable above also seems high although it relates to acceleration.

Another possible cause of the drop in extrusion could be the Replace.csv parameters. I have outlined these below and they can also be seen on the attached gcode file. The Mcodes below have been commented out as they are deprecated codes.

M108 ;M108

M101 ;M101

M103 ;M103

M105 ;M105

If any more details are needed, please let me know.

Thanks in advance to all forum users.

Raj

|

Re: RepRap Extrusion June 23, 2011 02:59PM |

Registered: 13 years ago Posts: 113 |

Have you updated the E_STEPS_PER_MM value in your firmware? In SF40+ this value needs to detail how many steps it takes to feed in 1mm of filament to the extruder. Prior to SF40+ it detailed how many steps it took to extrude 1mm of filament from the extruder. That might explain why your object is rather sparse.

There are several good posts of the forum for configuring SF40+.

JB

--

Check out my blog: AdventuresIn3-DPrinting

There are several good posts of the forum for configuring SF40+.

JB

--

Check out my blog: AdventuresIn3-DPrinting

|

Re: RepRap Extrusion June 23, 2011 03:33PM |

Registered: 13 years ago Posts: 1,780 |

You can adjust the torque of the extruder stepper motor the M113 command. It takes an S parameter (for example M113 S0.8) and it ranges from 0 to 1. An M113 without a parameter selects the trim pot on the extruder controller board which you can manually adjust.

If you're using Skeinforge to generate g-codes and then sending them with the Reprap host, then you don't need to mess with the global variables in the Reprap host. Except for the ones dealing with the USB and baud rate settings, the other parameters are not important to you.

If you're using Skeinforge to generate g-codes and then sending them with the Reprap host, then you don't need to mess with the global variables in the Reprap host. Except for the ones dealing with the USB and baud rate settings, the other parameters are not important to you.

|

Re: RepRap Extrusion June 23, 2011 04:16PM |

Registered: 12 years ago Posts: 85 |

Hi JB,

Thanks for taking the time to read my query.

I have updated the E_STEPS_PER_MM parameter in the firmware. This now extrudes accurately. For anyone out there with an Adrians Geared Extruder connected directly to the extruder board pushing a 3mm filament via a 7.96mm Spline, this came out at roughly 85.8 using (400*(57/11)*(7.96*pi)).

Hi Brnrd,

As above, thanks for taking the time to read my query.

I have the M113 S1.0 set in my Gcode. I have pasted the first few lines of Gcode below. The codes which i believe have been deprecated have been commented out.

M104 S205 T0

G21

G90

G92 X0 Y0 Z20

;M108 S250

M6 T0

G0 Z0

G28

G90

G21

M113 S1.0

;M108 S16.0

;M108 S6.4

G1 X0.69 Y10.36 Z0.28 F4500.0

G1 F600.0

G1 E0.0

G1 F4500.0

G92 E0

Thanks again.

Raj

Thanks for taking the time to read my query.

I have updated the E_STEPS_PER_MM parameter in the firmware. This now extrudes accurately. For anyone out there with an Adrians Geared Extruder connected directly to the extruder board pushing a 3mm filament via a 7.96mm Spline, this came out at roughly 85.8 using (400*(57/11)*(7.96*pi)).

Hi Brnrd,

As above, thanks for taking the time to read my query.

I have the M113 S1.0 set in my Gcode. I have pasted the first few lines of Gcode below. The codes which i believe have been deprecated have been commented out.

M104 S205 T0

G21

G90

G92 X0 Y0 Z20

;M108 S250

M6 T0

G0 Z0

G28

G90

G21

M113 S1.0

;M108 S16.0

;M108 S6.4

G1 X0.69 Y10.36 Z0.28 F4500.0

G1 F600.0

G1 E0.0

G1 F4500.0

G92 E0

Thanks again.

Raj

Sorry, only registered users may post in this forum.