Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C)

Posted by Karma

|

Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) October 08, 2013 03:29PM |

Registered: 10 years ago Posts: 4 |

Moved here from GitHub as I thougt I had a firmware problem, while thanks to stela111 and whosawhatsis realized to have an hardware problem!

[github.com]

As I posted some pictures please have a look at that discussion and then please come back here if you have any suggestion about how to solve the matter.

Edited 3 time(s). Last edit at 10/10/2013 10:36AM by Karma.

[github.com]

As I posted some pictures please have a look at that discussion and then please come back here if you have any suggestion about how to solve the matter.

Edited 3 time(s). Last edit at 10/10/2013 10:36AM by Karma.

|

Re: Extruder's thermistor spikes/Drops on HeatedBed reaching setpoint October 08, 2013 07:05PM |

Registered: 14 years ago Posts: 1,092 |

Things to check/do:

1. Use shielded cable for the thermistor, and make sure the thermistor ground is the shield. This should stop/reduce induction of a signal in the cable.

2. Check for high-resistance or even capacitive paths between your thermistor and hot end. Almost all types of high temp adhesive are conductive in some manner (though usually not very conductive, from memory usually in the range of 100Mohm/mm2). Even if they aren't very conductive, they can provide a capacitive effect. I therefore try and avoid all electrical contact to high temp adhesives (hot end resistor leads, thermistor leads, etc). I'm using axial thermistors (one lead out each end) to avoid all the issues with the standard glass bead ones, as it's too easy to get adhesive on the leads, or to short them to your heater block.

Note: Things like MakerGear hot-end ceramic adhesive and various sodium silicate based adhesives definitely produce a capacitive effect. I've used some as an improv cap before.

1. Use shielded cable for the thermistor, and make sure the thermistor ground is the shield. This should stop/reduce induction of a signal in the cable.

2. Check for high-resistance or even capacitive paths between your thermistor and hot end. Almost all types of high temp adhesive are conductive in some manner (though usually not very conductive, from memory usually in the range of 100Mohm/mm2). Even if they aren't very conductive, they can provide a capacitive effect. I therefore try and avoid all electrical contact to high temp adhesives (hot end resistor leads, thermistor leads, etc). I'm using axial thermistors (one lead out each end) to avoid all the issues with the standard glass bead ones, as it's too easy to get adhesive on the leads, or to short them to your heater block.

Note: Things like MakerGear hot-end ceramic adhesive and various sodium silicate based adhesives definitely produce a capacitive effect. I've used some as an improv cap before.

|

Re: Extruder's thermistor spikes/Drops on HeatedBed reaching setpoint October 08, 2013 08:38PM |

Registered: 13 years ago Posts: 1,352 |

Besides the above, probably all that has been said also on the git link are still valid. At this point from your description, it could be any of those things. Ppls can point some fingers, but it is you the only one who can approach the problem and do a analytic and systematic way and chopping off all that is not valid, until the real issue stands out and reveals itself. You have done nothing of the sort, not even started, have not even defined the problem properly in the above post, and the git link is kinda mixed up.

One easy method of abstract debugging is, start replacing/changing stuff till you notice something different with the problem. For example to decide if its hardware or software, its quite easy: upload another different firmware - if it does the same problem with different software then yes is hardware.

Only after you established that is clearly because of hardware, then its worth proceeding further. So imo, at this point first try upload other firmware. Along the same line of isolating the problem, you can remove all motor wiring and also disable heated bed, disable the fan, etc, so we know its nothing with them. And first off, i assume the control method in config.h is bang-bang and not pid, for both extruder and heated bed. You should not try use pid for heated bed, if you did, i give it a chance that fet is in trouble.

And a semi-obvious question is if its related to printer movement, or heating up the extruder, or switching on the neon lights in the room or another motor in the house, or the refrigerator starting the motor, or any other device that functions around at the time, or well, related to anything else less obvious.

Here is some generic stuff:

- What i would do first, i would try check or replace the 10uF capacitor on the signal line - and see if anything different. Also the resistor that is part of the voltage divider with thermistor, i would measure and re-melt all solder joints in relation with those.

- Another idea is that a mosfet could create a short through resistor via heated block. Measure resistance between heater block and resistor leads, it should be no contact (heat up first coz it may only happen at high temp, then disconnect and measure when it does happen).

- If there is a tantalum capacitor, try replace it. Also if there is any small LC filter inductor on board, check out how its position is in schematic, and if it can be shunted then short its terminals. But can not short inductors blindly unless understand its place and role there: can short some filter inductors, obviously should not try short switch mode ones.

Also, put some pictures with the board and etc, put a link to the exact source files (as this is open source community), so readers can have things laid out for them so they dont have to guess around. The information you give kinda influences the feedback you get.

One easy method of abstract debugging is, start replacing/changing stuff till you notice something different with the problem. For example to decide if its hardware or software, its quite easy: upload another different firmware - if it does the same problem with different software then yes is hardware.

Only after you established that is clearly because of hardware, then its worth proceeding further. So imo, at this point first try upload other firmware. Along the same line of isolating the problem, you can remove all motor wiring and also disable heated bed, disable the fan, etc, so we know its nothing with them. And first off, i assume the control method in config.h is bang-bang and not pid, for both extruder and heated bed. You should not try use pid for heated bed, if you did, i give it a chance that fet is in trouble.

And a semi-obvious question is if its related to printer movement, or heating up the extruder, or switching on the neon lights in the room or another motor in the house, or the refrigerator starting the motor, or any other device that functions around at the time, or well, related to anything else less obvious.

Here is some generic stuff:

- What i would do first, i would try check or replace the 10uF capacitor on the signal line - and see if anything different. Also the resistor that is part of the voltage divider with thermistor, i would measure and re-melt all solder joints in relation with those.

- Another idea is that a mosfet could create a short through resistor via heated block. Measure resistance between heater block and resistor leads, it should be no contact (heat up first coz it may only happen at high temp, then disconnect and measure when it does happen).

- If there is a tantalum capacitor, try replace it. Also if there is any small LC filter inductor on board, check out how its position is in schematic, and if it can be shunted then short its terminals. But can not short inductors blindly unless understand its place and role there: can short some filter inductors, obviously should not try short switch mode ones.

Also, put some pictures with the board and etc, put a link to the exact source files (as this is open source community), so readers can have things laid out for them so they dont have to guess around. The information you give kinda influences the feedback you get.

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reachi setpoint (95°C) October 10, 2013 10:36AM |

Registered: 10 years ago Posts: 4 |

Hi again, had been far from the printer for a couple of days...

@Cefiar

It's a very good point, as it involves some major revision on my printer which is now encased in a plexiglass fume extractor this will be my next step checking right after I'll have excluded a board's hardware fault (3Drag producer swears this should not be happening on a functioning printer).

@NoobMan

I'm sorry you found my information lacking. Maybe this discussion suffered from the relocation from the other forum.

I just wanted to keep the connection to it alive as I think some good points had been set.

Your starting point, while valid in general, maybe in this case was due to bad digestion or similar...

For your ease as it seems you prefer writing than reading I'll sum up here the points we get to from the linked forum:

This indeed is a good thing to make this discussion more readable as I can comprehend that the link to the forum is due also partially to my lazyness.

-I used Autotune to set the Pid value which actually are

P 18.13

I 0.95

D 86.42

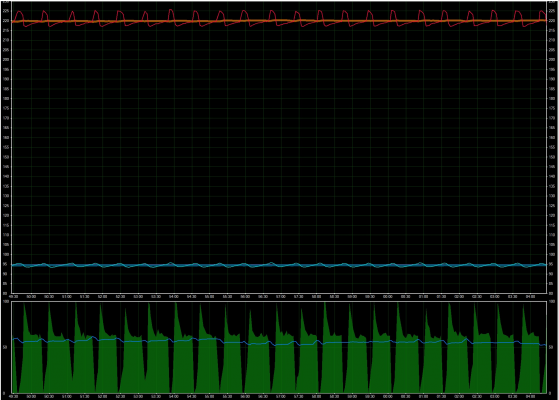

- The temperature/power graphs are really full of info if you can read them (attached see 2 pdf. with some annotation, first read 1 1_StartingSpikes.pdf)

- The problem happens both in manual heating and printing the same way (this can give you additional info, at least it's not due to mechanical/vibration interference).

- Then the problem doesn't arise if fan is on (which actually could lead the heat bed temperature never goes past the set-point and hence release the heater).

- Additionally if I ground the extruder thermistor the spike reverse (see 2_GroundedThermistor.pdf).

- I think I already isolated in some way the problem, if I remove something from this set-up the conditions for the problem to happen go away.

- As suggested the problem seem to be related with grounding level of the thermistore reading which shift when the Heat Bed reach set-point and switches off.

Of course all of the above statement can be discussed and are subject to error.

The suggestion you give (Noobman) then are really precious, I really thank you and I'll check for them.

Just leave me some time as I have to do a big mess to remove the board from my setup.

Here in the meantime the board's schematics

[www.open-electronics.org]

[reprap.org]

I'm trying also to get answers from the producer.

Actually the only one I've got are theese:

"we sold 3000 pieces of this unit and we never had a problem like this"

"we checked to print with ABS and we had not your problem".

I just asked for a printscreen of a graph with heatbed @95° and Heater @230 just to be sure they are not using the 'standard answer' for matters they don't whant to get into.

Actually navigating into both 3Drag (Futura group) and K8200 (Vellleman), which are exactly the same product, it seems no one ever printed ABS in theese conditions (they just arrived up to 60-65°C).

Actually I had to add a silicon + air insulating chamber to grant 95°C with their standard bed @12V.

To this you can add that, while higly requested, they have not given, up to now, an 'official' profile to print with ABS.

This is enough for me to ask for a simple proof for their simplistic statement!

My problem is that while with lower temperature the spikes where not perceivable, they definetively are at higher temp.

In my experience a plain degreased boron glass bed @95°C gives perfect adesion to ABS without all the assles of other more complex ABS sticking techniques.

I'd really like being able to keep the heater's temperature stable in theese conditions.

Will keep you updated and thanks for the contribution!

@Cefiar

It's a very good point, as it involves some major revision on my printer which is now encased in a plexiglass fume extractor this will be my next step checking right after I'll have excluded a board's hardware fault (3Drag producer swears this should not be happening on a functioning printer).

@NoobMan

I'm sorry you found my information lacking. Maybe this discussion suffered from the relocation from the other forum.

I just wanted to keep the connection to it alive as I think some good points had been set.

Your starting point, while valid in general, maybe in this case was due to bad digestion or similar...

For your ease as it seems you prefer writing than reading I'll sum up here the points we get to from the linked forum:

This indeed is a good thing to make this discussion more readable as I can comprehend that the link to the forum is due also partially to my lazyness.

-I used Autotune to set the Pid value which actually are

P 18.13

I 0.95

D 86.42

- The temperature/power graphs are really full of info if you can read them (attached see 2 pdf. with some annotation, first read 1 1_StartingSpikes.pdf)

- The problem happens both in manual heating and printing the same way (this can give you additional info, at least it's not due to mechanical/vibration interference).

- Then the problem doesn't arise if fan is on (which actually could lead the heat bed temperature never goes past the set-point and hence release the heater).

- Additionally if I ground the extruder thermistor the spike reverse (see 2_GroundedThermistor.pdf).

- I think I already isolated in some way the problem, if I remove something from this set-up the conditions for the problem to happen go away.

- As suggested the problem seem to be related with grounding level of the thermistore reading which shift when the Heat Bed reach set-point and switches off.

Of course all of the above statement can be discussed and are subject to error.

The suggestion you give (Noobman) then are really precious, I really thank you and I'll check for them.

Just leave me some time as I have to do a big mess to remove the board from my setup.

Here in the meantime the board's schematics

[www.open-electronics.org]

[reprap.org]

I'm trying also to get answers from the producer.

Actually the only one I've got are theese:

"we sold 3000 pieces of this unit and we never had a problem like this"

"we checked to print with ABS and we had not your problem".

I just asked for a printscreen of a graph with heatbed @95° and Heater @230 just to be sure they are not using the 'standard answer' for matters they don't whant to get into.

Actually navigating into both 3Drag (Futura group) and K8200 (Vellleman), which are exactly the same product, it seems no one ever printed ABS in theese conditions (they just arrived up to 60-65°C).

Actually I had to add a silicon + air insulating chamber to grant 95°C with their standard bed @12V.

To this you can add that, while higly requested, they have not given, up to now, an 'official' profile to print with ABS.

This is enough for me to ask for a simple proof for their simplistic statement!

My problem is that while with lower temperature the spikes where not perceivable, they definetively are at higher temp.

In my experience a plain degreased boron glass bed @95°C gives perfect adesion to ABS without all the assles of other more complex ABS sticking techniques.

I'd really like being able to keep the heater's temperature stable in theese conditions.

Will keep you updated and thanks for the contribution!

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reachi setpoint (95°C) October 10, 2013 12:14PM |

Registered: 12 years ago Posts: 1,236 |

I've also seen weird thermistor fluctuations, and other people have reported this type of problem, on a variety of different hardware and software. So I think there is some generic issues, and we probably never got to the bottom of it. Often people say they swapped a few things and it started working.

Although the occurrence and offset seems to occur at random intervals, it persists for several seconds before going back to normal or another value. That suggests it is not random noise, but something like mechanical stress affecting the thermistor.

I would expect if it was a problem with heatbed switching affecting voltage levels, or the way the firmware samples the voltage, then a lot more people would see it, and it wouldn't be so random.

It could just be down to the glass bead thermistors being mechanically fragile.

Although the occurrence and offset seems to occur at random intervals, it persists for several seconds before going back to normal or another value. That suggests it is not random noise, but something like mechanical stress affecting the thermistor.

I would expect if it was a problem with heatbed switching affecting voltage levels, or the way the firmware samples the voltage, then a lot more people would see it, and it wouldn't be so random.

It could just be down to the glass bead thermistors being mechanically fragile.

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reachi setpoint (95°C) October 10, 2013 01:49PM |

Registered: 10 years ago Posts: 4 |

I can add also this picture

where actually the relation to the

heatbed turning off is more evident.

As the heatbed heating process is cyclyc/periodic also the spikes get periodic.

My call ideally would be for guys printing with a 3Drag or K8200 with bed at high temperature to inspect their Extruder's temperature curves. I suspect that due to the 'youth' of the product few people pushed this board so high, hence this could be also an explanation to the 'absence' of people seeing it.

The Spike need around 10 seconds to level back to normal. I guess it could be due to signal averaging made by the firmware. Could it be? Unfortunately I'm not able to look into the Marlin firmware to see if it gets raw datas or averages them in some way.

If Marlin firmware just reads raw value then the 'persistency' of the spike could be a good point further dissect the problem.

... it could deal also with repetier way of displaying the T values...

heatbed turning off is more evident.

As the heatbed heating process is cyclyc/periodic also the spikes get periodic.

My call ideally would be for guys printing with a 3Drag or K8200 with bed at high temperature to inspect their Extruder's temperature curves. I suspect that due to the 'youth' of the product few people pushed this board so high, hence this could be also an explanation to the 'absence' of people seeing it.

The Spike need around 10 seconds to level back to normal. I guess it could be due to signal averaging made by the firmware. Could it be? Unfortunately I'm not able to look into the Marlin firmware to see if it gets raw datas or averages them in some way.

If Marlin firmware just reads raw value then the 'persistency' of the spike could be a good point further dissect the problem.

... it could deal also with repetier way of displaying the T values...

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) October 10, 2013 02:05PM |

Registered: 13 years ago Posts: 1,352 |

This is open source community and as usual, i cant find the sources. Pictures arent soruces. Can you find them somewhere? If not, then the producer is full of it. And there is the first mistake, havent looked if sources are available when the purchase was made. My opinion, i wouldnt think to buy something open source if sources are not available. If he hasnt provided the source files, imo probably is not going to provide much else. At least i wouldnt expect much from there.

Also from what i understand from the pdf and your comments, this fluctuation seems to happen when the heated bed turns off, the extruder temperature rises. This would indicate a temporary (12 sec thats a lot??) voltage change in +5v to gnd which makes the voltage divider ends where thermistor is part of. It may mean that your psu is not reactly fast enough to turning on and off of a big consumer like the bed is. You should measure the voltage between psu +V and gnd, and 5V and gnd, when this fluctuation happens, and see if you can catch a similar voltage evolution, perhaps the voltage lowers accordingly. And see if you do have an 5V resistor/bleeder/consumer on the atx psu +5v line and gnd, as recommended on atx page. However the atx is a switch mode converter and as such it should have a feedback loop monitoring its levels so its hard to believe it gets overpowered by the bed unless its something wrong somewhere.

So, on short:

- confirm it still happens with PID disabled and only bang-bang method of control (changed in config.h) instead of pid

- confirm the problem disappears when the heated bed is disconnected

- confirm you have the consumer (bleeder) resistor on the atx psu 5v to gnd

- fast check of the thermistor table interval in question: how big temp interval vs how big adc interval is - or attach thermistor table and config.h and config_adv.h if there are more config files.

- measure votage between +5v to gnd and +12v to gnd when extruder temperature fluctuation appear

If i understand correctly, the problem disappears if the fan is running. That is a very good find. Should be a good indication, but dunno what it indicates. Nothing comes to mind, my head needs more scratching. So lets follow up on that. Take the fan away from its connector, but still "enable" it from firmware, and confirm it still makes same difference and problem disappears regardless of the fan not being actually present at those terminals. Touch diode D3 with the hand after some time and see if it gets noticeably hotter because of fluctuations.

Also from what i understand from the pdf and your comments, this fluctuation seems to happen when the heated bed turns off, the extruder temperature rises. This would indicate a temporary (12 sec thats a lot??) voltage change in +5v to gnd which makes the voltage divider ends where thermistor is part of. It may mean that your psu is not reactly fast enough to turning on and off of a big consumer like the bed is. You should measure the voltage between psu +V and gnd, and 5V and gnd, when this fluctuation happens, and see if you can catch a similar voltage evolution, perhaps the voltage lowers accordingly. And see if you do have an 5V resistor/bleeder/consumer on the atx psu +5v line and gnd, as recommended on atx page. However the atx is a switch mode converter and as such it should have a feedback loop monitoring its levels so its hard to believe it gets overpowered by the bed unless its something wrong somewhere.

So, on short:

- confirm it still happens with PID disabled and only bang-bang method of control (changed in config.h) instead of pid

- confirm the problem disappears when the heated bed is disconnected

- confirm you have the consumer (bleeder) resistor on the atx psu 5v to gnd

- fast check of the thermistor table interval in question: how big temp interval vs how big adc interval is - or attach thermistor table and config.h and config_adv.h if there are more config files.

- measure votage between +5v to gnd and +12v to gnd when extruder temperature fluctuation appear

If i understand correctly, the problem disappears if the fan is running. That is a very good find. Should be a good indication, but dunno what it indicates. Nothing comes to mind, my head needs more scratching. So lets follow up on that. Take the fan away from its connector, but still "enable" it from firmware, and confirm it still makes same difference and problem disappears regardless of the fan not being actually present at those terminals. Touch diode D3 with the hand after some time and see if it gets noticeably hotter because of fluctuations.

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) October 10, 2013 02:49PM |

Registered: 13 years ago Posts: 1,352 |

Also you could try making the derivative part to zero (e.g. set D to 0.01 instead of 86.42), see what happens. Making D go away means the system will be very slow to react. Usually if there is a noise, that makes some very aggressive derivatives, and your D part is already high, so it can be a culprit, and would be good to know if that is root of all problems. However if this would be the case then disabling PID and only using bang-bang control might also look different but we dont know that yet. Still try all these, the D part to zero and also that thingy with the fan, these two should corroborate to each other somehow.

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) January 10, 2014 02:42PM |

Registered: 11 years ago Posts: 9 |

So, just wanted to share my conclusions on similar issue with my Melzi. I eventually reinforced the ground plane by soldering an additional cable directly to the ground pin of the heatbed FET and connecting it to the ground terminal on the Melzi power input. This patch eliminated my temperature oscillations. I imagine the root cause for this problem is that my pcb is manufactured with too thin copper layer, as other Melzi users do not seem to have these problems. However, I still have problems with unreliable usb connection, not sure if this is related.

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) January 10, 2014 05:32PM |

Registered: 14 years ago Posts: 1,092 |

The usual issue here, apart from insufficient grounding, is that you're most likely getting a ground loop across the USB cable. You can usually tell if you measure current between the USB ground on your electronics to the USB ground on your PC.

This most likely means that the DC -VE on your PSU is wired directly to the AC Earth pin (in your electronics, and in your PC), which is probably not the best idea. It seems like a great idea from a protection point of view (so you don't get a shock) but it leads to an additional current path for your circuits, especially if the ground voltages differ by a small amount. This will cause current to flow across the USB cable ground.

Instead of wiring the DC -VE and AC Earth together, connect them via a reasonable valued resistor. This provides reasonable ground for AC, but blocks enough so that only a very small amount of DC will form a ground loop, if at all.

This most likely means that the DC -VE on your PSU is wired directly to the AC Earth pin (in your electronics, and in your PC), which is probably not the best idea. It seems like a great idea from a protection point of view (so you don't get a shock) but it leads to an additional current path for your circuits, especially if the ground voltages differ by a small amount. This will cause current to flow across the USB cable ground.

Instead of wiring the DC -VE and AC Earth together, connect them via a reasonable valued resistor. This provides reasonable ground for AC, but blocks enough so that only a very small amount of DC will form a ground loop, if at all.

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) January 10, 2014 06:41PM |

Registered: 11 years ago Posts: 9 |

|

Re: Extruder's thermistor spikes/Drops when HeatedBed reaching setpoint (95°C) January 11, 2014 11:28PM |

Registered: 14 years ago Posts: 1,092 |

When someone got the same problem with the RAMPS-FD board (meaning, the Due which has the ground reference has the issue), they suggested 1kohm.

I think you don't need to go that high. Even as low as 100 ohms may be enough to stop the problem.

Really though, the issue is the ground on the Melzi (and any board that has its own USB connector) is that the USB shield tends to be wired directly to the DC ground on the board. Using a resistor (even a small one like 100 Ohms) between the shield of the USB and the ground might solve this problem. That would of course require a redesign of the board to do it properly. Also while this "should" be fine, it needs to be tested, as we need to be sure the issue is with the USB shield, or the USB ground pin (which may be different again).

FYI: The main problem here is that most Arduino's, their clones, and the reference design, all expect that you'll be running them in the following scenarios:

1. Drawing all your power from the USB

2. Drawing all your power from a DC plugpack, which has no AC earth grounding.

3. Running the device completely stand-alone when in operation, and completely disconnected when programming.

As such, they haven't bothered to really worry about USB ground loop issues caused by wiring DC ground to AC ground at both ends. And therein lies the issue.

I think you don't need to go that high. Even as low as 100 ohms may be enough to stop the problem.

Really though, the issue is the ground on the Melzi (and any board that has its own USB connector) is that the USB shield tends to be wired directly to the DC ground on the board. Using a resistor (even a small one like 100 Ohms) between the shield of the USB and the ground might solve this problem. That would of course require a redesign of the board to do it properly. Also while this "should" be fine, it needs to be tested, as we need to be sure the issue is with the USB shield, or the USB ground pin (which may be different again).

FYI: The main problem here is that most Arduino's, their clones, and the reference design, all expect that you'll be running them in the following scenarios:

1. Drawing all your power from the USB

2. Drawing all your power from a DC plugpack, which has no AC earth grounding.

3. Running the device completely stand-alone when in operation, and completely disconnected when programming.

As such, they haven't bothered to really worry about USB ground loop issues caused by wiring DC ground to AC ground at both ends. And therein lies the issue.

Sorry, only registered users may post in this forum.