|

Re: TTL modulation help needed September 01, 2016 05:33AM |

Admin Registered: 16 years ago Posts: 13,891 |

... I'm "identifying" unknown laserdiodes by the threshold current, which is needed to start the laser effect.

Below this current the diode only lights blue like a LED, but with reaching the threshold level you can see a much brighter line in the middle.

For this I'm using a controllable laboratory PS with adjustable voltage and current.

Set the voltage to 5V and the current to min (0.01A with my PS) ... then connect the diode to the output - it should light dim blue. like a LED ... then rise the current, until it starts with the bright lasering ...

*** EDIT *** - I've searched for the threshold currents of 1W- and 2W-diodes - they seem to have nearly the same between 100 - 300mA! - so won't be distinguishable by threshold current only

Either you get the exact infos from the seller, or clean the back and look, if there is a mark or bit-code, what could help to identify the diode ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Below this current the diode only lights blue like a LED, but with reaching the threshold level you can see a much brighter line in the middle.

For this I'm using a controllable laboratory PS with adjustable voltage and current.

Set the voltage to 5V and the current to min (0.01A with my PS) ... then connect the diode to the output - it should light dim blue. like a LED ... then rise the current, until it starts with the bright lasering ...

*** EDIT *** - I've searched for the threshold currents of 1W- and 2W-diodes - they seem to have nearly the same between 100 - 300mA! - so won't be distinguishable by threshold current only

Either you get the exact infos from the seller, or clean the back and look, if there is a mark or bit-code, what could help to identify the diode ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed September 01, 2016 08:24AM |

Registered: 9 years ago Posts: 346 |

Basically it can be the M140 or Nichia NDB7875 or the Osram PLTB450B .

It is pretty easy to identify which one if you can get to look at it physically, just google the names and you can find pictures of how the diode looks.

If you can't get to look at the actual diode then I don't know - But they all more or less run the same current (A) so just run it at 1.6 A and you will be OK.

See the below links and scroll down to the test pictures - It must be STRESSED that even same brand and type diode does not perform identically. Yours will do a little different from the below links. Especially the VOLTAGE will be different even with the same type of diode. Do NOT try to adjust power by measuring the VOLTAGE across the diode (!!!). You must get a way to measure current (A).

[sites.google.com] (NDB7875 - 1.6A = ~2.3W )

[sites.google.com] (M140 - 1.6A = ~ 2.2W )

[sites.google.com] (PLTB450B - 1.6A = ~2W )

So you see, it doesn't really matter which diode it is. Just adjust the driver to outputting 1.6A and you will be just fine.

It is pretty easy to identify which one if you can get to look at it physically, just google the names and you can find pictures of how the diode looks.

If you can't get to look at the actual diode then I don't know - But they all more or less run the same current (A) so just run it at 1.6 A and you will be OK.

See the below links and scroll down to the test pictures - It must be STRESSED that even same brand and type diode does not perform identically. Yours will do a little different from the below links. Especially the VOLTAGE will be different even with the same type of diode. Do NOT try to adjust power by measuring the VOLTAGE across the diode (!!!). You must get a way to measure current (A).

[sites.google.com] (NDB7875 - 1.6A = ~2.3W )

[sites.google.com] (M140 - 1.6A = ~ 2.2W )

[sites.google.com] (PLTB450B - 1.6A = ~2W )

So you see, it doesn't really matter which diode it is. Just adjust the driver to outputting 1.6A and you will be just fine.

|

Re: TTL modulation help needed September 01, 2016 08:36AM |

Registered: 9 years ago Posts: 346 |

|

Re: TTL modulation help needed September 02, 2016 05:47AM |

Registered: 9 years ago Posts: 93 |

Thanks every one for this help

I think i damaged ttl input on driver (12v my bad)

So i got new module ordered and new ttl chip (RSS100 N03) hope ill get it fixed if not new module on its way..

And as suggested got 0.1Ohm 5w resistor ordered to adjust current

So this time i want to approach this again freshly.

I had nice experience with this so far learned alot about it as well.

Thanks every one that helped me in hard times

Ill see u soon when receive all parts

Regards

I think i damaged ttl input on driver (12v my bad)

So i got new module ordered and new ttl chip (RSS100 N03) hope ill get it fixed if not new module on its way..

And as suggested got 0.1Ohm 5w resistor ordered to adjust current

So this time i want to approach this again freshly.

I had nice experience with this so far learned alot about it as well.

Thanks every one that helped me in hard times

Ill see u soon when receive all parts

Regards

|

Re: TTL modulation help needed September 05, 2016 06:03AM |

Registered: 9 years ago Posts: 93 |

Quote

LarsK

Basically it can be the M140 or Nichia NDB7875 or the Osram PLTB450B .

It is pretty easy to identify which one if you can get to look at it physically, just google the names and you can find pictures of how the diode looks.

If you can't get to look at the actual diode then I don't know - But they all more or less run the same current (A) so just run it at 1.6 A and you will be OK.

See the below links and scroll down to the test pictures - It must be STRESSED that even same brand and type diode does not perform identically. Yours will do a little different from the below links. Especially the VOLTAGE will be different even with the same type of diode. Do NOT try to adjust power by measuring the VOLTAGE across the diode (!!!). You must get a way to measure current (A).

[sites.google.com] (NDB7875 - 1.6A = ~2.3W )

[sites.google.com] (M140 - 1.6A = ~ 2.2W )

[sites.google.com] (PLTB450B - 1.6A = ~2W )

Thanks for reply

So you see, it doesn't really matter which diode it is. Just adjust the driver to outputting 1.6A and you will be just fine.

|

Re: TTL modulation help needed September 05, 2016 06:22AM |

Registered: 9 years ago Posts: 93 |

|

Re: TTL modulation help needed September 05, 2016 06:44AM |

Admin Registered: 16 years ago Posts: 13,891 |

... carefully! - your link to a newer NDB7875 states 3W @2.4A - the older type will blow pretty fast at more than 1.8A !!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed [SOLVED] October 03, 2016 03:49AM |

Registered: 9 years ago Posts: 93 |

|

Re: TTL modulation help needed October 03, 2016 12:47PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: TTL modulation help needed October 03, 2016 02:07PM |

Registered: 9 years ago Posts: 93 |

|

Re: TTL modulation help needed October 03, 2016 03:56PM |

Admin Registered: 16 years ago Posts: 13,891 |

... I'm receiving best results with focal distances of 20mm to 40mm - the shorter, the smaller and 'rounder' is the spot ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed October 04, 2016 05:35AM |

Registered: 9 years ago Posts: 93 |

|

Re: TTL modulation help needed October 10, 2016 03:42PM |

Registered: 9 years ago Posts: 93 |

Hi all again just passing by

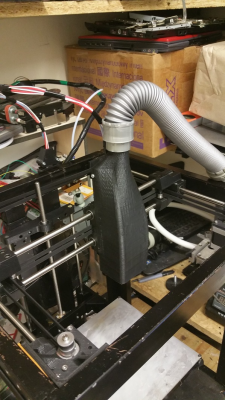

After load of hours designing extraction system got somewhere

I used PS3 Fan with 3d printed prop works extremely well no smoke just bit of smell (And i got it PWM controlled with arduino)

Here result below

Thanks again everyone for your time and effort to help me!!!

After load of hours designing extraction system got somewhere

I used PS3 Fan with 3d printed prop works extremely well no smoke just bit of smell (And i got it PWM controlled with arduino)

Here result below

Thanks again everyone for your time and effort to help me!!!

|

Re: TTL modulation help needed October 11, 2016 04:23PM |

Registered: 9 years ago Posts: 93 |

|

Re: TTL modulation help needed October 12, 2016 01:08PM |

Admin Registered: 16 years ago Posts: 13,891 |

... most driver/laserdiode-combinations don't give linear power output, so you'll have to calibrate the output for your setup to get some precision.

Another issue is the moving speed while lasering - when engraving with accelerated moves, then the line-ends tend to get more burnt than faster moves in the middle - so you have to move really slow, so your driver won't accelerate/deccelerate the head.

I'm setting my drivers mostly to max. laser power and define the "effective burning power" through the length of a single pulse typically from 0,5 to 400 microseconds.

But this is only usefull for "velocity-independent" pulsing strategies - either with my own drivers -- or with 3D-printing-softwares, which calculate the pulses for the extruder-stepper in relation to travelled way ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Another issue is the moving speed while lasering - when engraving with accelerated moves, then the line-ends tend to get more burnt than faster moves in the middle - so you have to move really slow, so your driver won't accelerate/deccelerate the head.

I'm setting my drivers mostly to max. laser power and define the "effective burning power" through the length of a single pulse typically from 0,5 to 400 microseconds.

But this is only usefull for "velocity-independent" pulsing strategies - either with my own drivers -- or with 3D-printing-softwares, which calculate the pulses for the extruder-stepper in relation to travelled way ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed October 12, 2016 02:51PM |

Registered: 9 years ago Posts: 93 |

Quote

VDX

... most driver/laserdiode-combinations don't give linear power output, so you'll have to calibrate the output for your setup to get some precision.

Another issue is the moving speed while lasering - when engraving with accelerated moves, then the line-ends tend to get more burnt than faster moves in the middle - so you have to move really slow, so your driver won't accelerate/deccelerate the head.

I'm setting my drivers mostly to max. laser power and define the "effective burning power" through the length of a single pulse typically from 0,5 to 400 microseconds.

But this is only usefull for "velocity-independent" pulsing strategies - either with my own drivers -- or with 3D-printing-softwares, which calculate the pulses for the extruder-stepper in relation to travelled way ...

Thanks for reply is there any books or source where to learn all this??

I still lost in this world

Regards

|

Re: TTL modulation help needed October 12, 2016 04:15PM |

Admin Registered: 16 years ago Posts: 13,891 |

... this sort of infos is scatteread around various sources - blogs, user-forums (like this one), random finds ...

My personal know-how about lasers and related applications is mostly DIY and collected over more than 30 years occasionally tinkering and working with all then available types of lasers and around all sorts of applications with them

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My personal know-how about lasers and related applications is mostly DIY and collected over more than 30 years occasionally tinkering and working with all then available types of lasers and around all sorts of applications with them

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed October 13, 2016 01:15PM |

Registered: 9 years ago Posts: 93 |

Quote

VDX

... this sort of infos is scatteread around various sources - blogs, user-forums (like this one), random finds ...

My personal know-how about lasers and related applications is mostly DIY and collected over more than 30 years occasionally tinkering and working with all then available types of lasers and around all sorts of applications with them

Thanks for reply

All i see here is big learning curve coming up!!!

Can you point me to good analog PWM laser controller please? or anything you think is better for precision (engraving only)

Regards

Edited 1 time(s). Last edit at 10/13/2016 02:00PM by rastaman46.

|

Re: TTL modulation help needed October 13, 2016 05:06PM |

Admin Registered: 16 years ago Posts: 13,891 |

... where are you located?

Lasertack in Germany has some laserdiode-drivers with "real" analog modulation - [www.lasertack.com]

This sort of optimized PWM can only be done with software - the driver can then be a simple constant current driver (e.g. a LM317 or LM338 in "constant-current configuration") with "Pulse-modulating" the current through the driver with a MOSFET ... I'm doing this regularly

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Lasertack in Germany has some laserdiode-drivers with "real" analog modulation - [www.lasertack.com]

This sort of optimized PWM can only be done with software - the driver can then be a simple constant current driver (e.g. a LM317 or LM338 in "constant-current configuration") with "Pulse-modulating" the current through the driver with a MOSFET ... I'm doing this regularly

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed October 14, 2016 03:32AM |

Registered: 9 years ago Posts: 93 |

Quote

VDX

... where are you located?

Lasertack in Germany has some laserdiode-drivers with "real" analog modulation - [www.lasertack.com]

This sort of optimized PWM can only be done with software - the driver can then be a simple constant current driver (e.g. a LM317 or LM338 in "constant-current configuration") with "Pulse-modulating" the current through the driver with a MOSFET ... I'm doing this regularly

Thanks for reply im Located in UK

Is there is any DIY Projects on this?

What about this one ?

[www.picengrave.com]

Or would be cheaper to buy your recommended module ?

Regards

|

Re: TTL modulation help needed October 14, 2016 04:39AM |

Admin Registered: 16 years ago Posts: 13,891 |

... this depends on your DIY experience - the laserdiode driver is only one component -- you'll need a complete controller setup with optimized firmware to set/calibrate the analog voltage or PWM ... then the diode-driver is only a "dumb driver", and any cheap chinese adjustable constant current driver will work too with the PWM modulation ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: TTL modulation help needed November 11, 2016 02:47PM |

Registered: 9 years ago Posts: 93 |

So can you clarify me if i heading right direction please?

So constant current parts is to create constant current for laser diode (No more no less always same)

TTL parts turns circuit on and off right? (Turns voltage on & off Keeps current on??)

So like u say using E-step pin to generate pulses according to speed. The way i understand this is that E steps generate pulses say E20 is this is equal to M106 Sxxx?

So using E- steps do i need some sort circuit to capture it all ??

And what software generate gcode for this ???

Regards

Edited 1 time(s). Last edit at 11/11/2016 02:48PM by rastaman46.

So constant current parts is to create constant current for laser diode (No more no less always same)

TTL parts turns circuit on and off right? (Turns voltage on & off Keeps current on??)

So like u say using E-step pin to generate pulses according to speed. The way i understand this is that E steps generate pulses say E20 is this is equal to M106 Sxxx?

So using E- steps do i need some sort circuit to capture it all ??

And what software generate gcode for this ???

Regards

Edited 1 time(s). Last edit at 11/11/2016 02:48PM by rastaman46.

|

Re: TTL modulation help needed November 11, 2016 05:40PM |

Admin Registered: 16 years ago Posts: 13,891 |

... I'm using a modified Pronterface with Marlin4Due firmware, but "normal" 3D-printing G-code will do it too.

My files looks like this:

The E-numbers gives the count of pulses, which will be executed while moving from the last to the actual XY-position with "even pulse distribution" along the line.

This is done in the firmware and the only needed modification for the laser-driver is to wire the pin for the E-step (as defined in the file "pins_RADDS.h" or "pins.h" with normal Marlin firmware) to the driver input ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My files looks like this:

Quote

...

G92 E0

G0 E0

G0 X59.4 Y23.3 F6000

G1 X56.725 Y23.35 E82 F2000

G1 X56.975 Y24.15 E105 F2000

G1 X57.25 Y24.475 E125 F2000

G1 X57.65 Y24.825 E138 F2000

...

The E-numbers gives the count of pulses, which will be executed while moving from the last to the actual XY-position with "even pulse distribution" along the line.

This is done in the firmware and the only needed modification for the laser-driver is to wire the pin for the E-step (as defined in the file "pins_RADDS.h" or "pins.h" with normal Marlin firmware) to the driver input ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.