Help with a 270W laser module

Posted by ciclonite

|

Help with a 270W laser module April 16, 2023 07:53AM |

Registered: 1 year ago Posts: 11 |

Hi,

I've a laser module dilas with this specs:

Center Wavelength nm 976

Wavelength Tolerance nm ±3

Output Power 270W

Spectral Width (FWHM) nm <5

Slope Efficiency W/A >7.5

Fiber Connector Fixed Pigtail Fiber

Fiber Core Diameter µm 225/240

Numerical Aperture NA 0.22

Power Conversion Efficiency % >51

Threshold Current (ITH) A <3

Operating Current (IOP) A <40

Operating Voltage (UOP) V <15

The connection is "Fixed Pigtails fiber".

How can I attach a new fiber with this connector?

[workdrive.zohopublic.eu]

[workdrive.zohopublic.eu]

[workdrive.zohopublic.eu]

Thank a lot

I've a laser module dilas with this specs:

Center Wavelength nm 976

Wavelength Tolerance nm ±3

Output Power 270W

Spectral Width (FWHM) nm <5

Slope Efficiency W/A >7.5

Fiber Connector Fixed Pigtail Fiber

Fiber Core Diameter µm 225/240

Numerical Aperture NA 0.22

Power Conversion Efficiency % >51

Threshold Current (ITH) A <3

Operating Current (IOP) A <40

Operating Voltage (UOP) V <15

The connection is "Fixed Pigtails fiber".

How can I attach a new fiber with this connector?

[workdrive.zohopublic.eu]

[workdrive.zohopublic.eu]

[workdrive.zohopublic.eu]

Thank a lot

|

Re: Help with a 270W laser module April 16, 2023 10:23AM |

Admin Registered: 16 years ago Posts: 13,895 |

... you can remove the fiber and drill a 15mm-bore instead - then open the housing and remove the internal focussing lens, so the collimated beam (around 4x4mm square) can escape ... then simply attach an extrnal focussing lens and you can get an even smaller focus diameter, than with a fiber

Edited 1 time(s). Last edit at 04/16/2023 10:24AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Edited 1 time(s). Last edit at 04/16/2023 10:24AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Help with a 270W laser module April 16, 2023 02:14PM |

Registered: 1 year ago Posts: 11 |

|

Re: Help with a 270W laser module April 16, 2023 03:12PM |

Admin Registered: 16 years ago Posts: 13,895 |

... with a 0,2mm fiber I've got only below 100 Watts through, then the fiber tip burnt up and emitted fumes - here you'll need perfect polishing and embedding in a cooled tube to get this working .. normally not available with DIY-measures.

Why not fixing to the CNC?

I've set this modules on a water-cooler, ready to fix on the Z-axis of the CNC-mill ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Why not fixing to the CNC?

I've set this modules on a water-cooler, ready to fix on the Z-axis of the CNC-mill ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Help with a 270W laser module April 16, 2023 03:14PM |

Admin Registered: 16 years ago Posts: 13,895 |

... if you want some insights of my "tinkering", then you can find older images and hints here (was then with a similar 200W-diode) - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Help with a 270W laser module April 16, 2023 05:06PM |

Registered: 1 year ago Posts: 11 |

My compliment VDX for your knowledge! I have 10 of these 270w modules and I got a Lumina LDD 40A power supply to test them because the modules were sold to me "as is". As for the cooling part, did you 3D print a specific flange to let the liquid flow? My modules had the fiber fixedly connected, but why did you say the fiber was smoking? These modules should in theory be part of a larger system and the power delivery for the single module through fiber should not be cooled with liquid. I would like to put together 3x270W to create a serious laser cut, even though I know it will be hard.

|

Re: Help with a 270W laser module April 16, 2023 05:52PM |

Admin Registered: 16 years ago Posts: 13,895 |

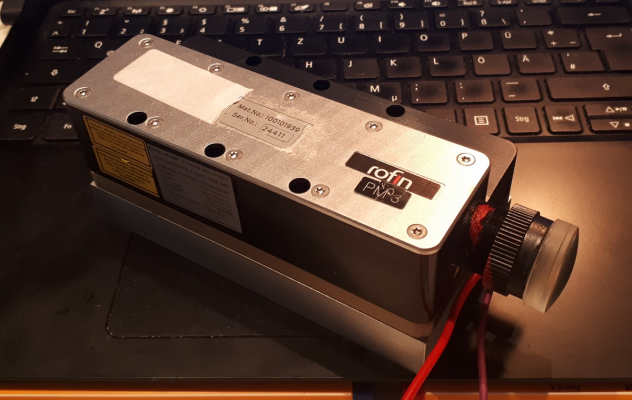

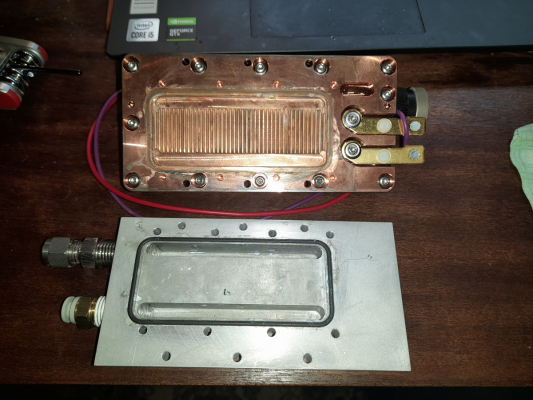

... I have CNC-milled watercooler-bricks under the housing and directly attached focussing lens with 50mm focal distance:

For the fiber-ends -- simply by emitting more than 100Watts out of the fiber-end it started to burning if not perfect polished and/or a tiny bit of dust on the surface.

But have hope, as I've ordered some better equipment and polishing mterials, so could maybe get the fiber more reliable in future ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

For the fiber-ends -- simply by emitting more than 100Watts out of the fiber-end it started to burning if not perfect polished and/or a tiny bit of dust on the surface.

But have hope, as I've ordered some better equipment and polishing mterials, so could maybe get the fiber more reliable in future ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Help with a 270W laser module April 17, 2023 02:58AM |

Registered: 1 year ago Posts: 11 |

|

Re: Help with a 270W laser module April 17, 2023 06:33AM |

Admin Registered: 16 years ago Posts: 13,895 |

... yes, a friend milled it from solid aluminium:

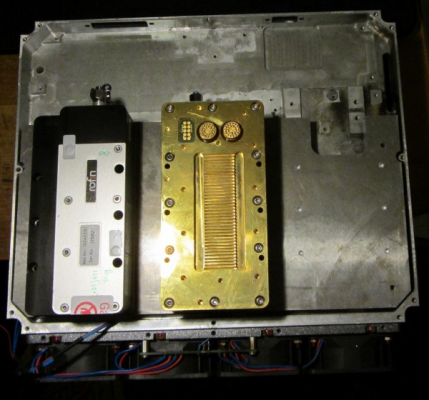

I have another bigger air cooler with 6x30W peltier-heat-exchangers to a housing of a broken and salvaged "small" fiberlaser (got only 9W and 25W laserdiodes from):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I have another bigger air cooler with 6x30W peltier-heat-exchangers to a housing of a broken and salvaged "small" fiberlaser (got only 9W and 25W laserdiodes from):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Help with a 270W laser module December 20, 2023 01:35AM |

Registered: 4 months ago Posts: 1 |

To attach a new fiber to your dials laser module:

Prepare Fiber:

Use a new fiber matching the specs (core diameter, NA).

Strip the protective coating, and expose the core.

Clean Connectors:

Clean laser module and new fiber connectors with isopropyl alcohol.

Alignment:

Align the stripped end of the new fiber precisely with the laser module's pigtail fiber.

Connection Method:

Fusion splice for low-loss, if possible. Follow equipment guidelines.

Use high-quality epoxy if fusion splicing isn't an option.

Testing:

Test power and efficiency with an optical power meter and light source.

Secure Connection:

Ensure strain relief to prevent stress on the connection.

Documentation:

Update documentation with changes made.

Follow safety guidelines and equipment instructions for a successful fiber connection. Good luck!

Prepare Fiber:

Use a new fiber matching the specs (core diameter, NA).

Strip the protective coating, and expose the core.

Clean Connectors:

Clean laser module and new fiber connectors with isopropyl alcohol.

Alignment:

Align the stripped end of the new fiber precisely with the laser module's pigtail fiber.

Connection Method:

Fusion splice for low-loss, if possible. Follow equipment guidelines.

Use high-quality epoxy if fusion splicing isn't an option.

Testing:

Test power and efficiency with an optical power meter and light source.

Secure Connection:

Ensure strain relief to prevent stress on the connection.

Documentation:

Update documentation with changes made.

Follow safety guidelines and equipment instructions for a successful fiber connection. Good luck!

Sorry, only registered users may post in this forum.