Almost Done!!!

Posted by Demented Chihuahua

|

Almost Done!!! January 13, 2008 02:19AM |

Registered: 16 years ago Posts: 622 |

Hi all. Just wanted to post on my progress in building the McWire RepStrap as I've made some significant progress since I talked about it last time. I have a link to my public albums so check those out to see what I'm talking about.

[picasaweb.google.com]

Here is the frame I first started with

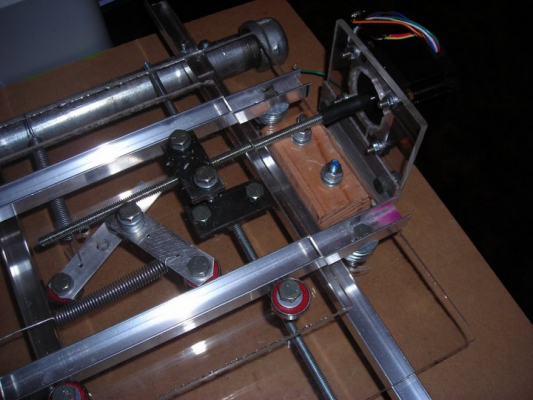

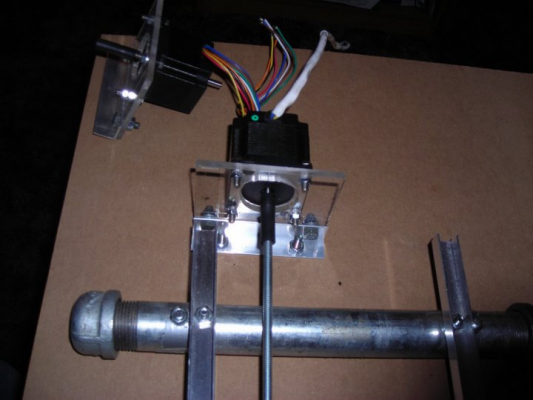

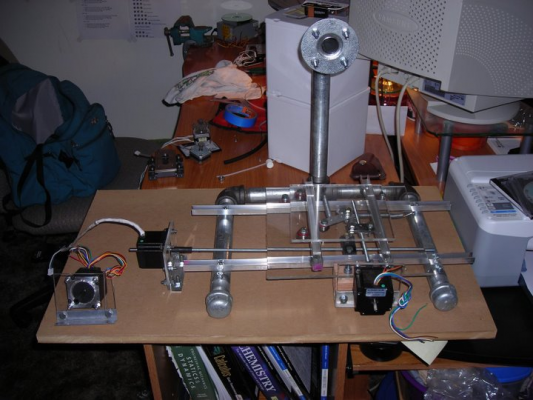

I then did some tinkering over a few months and then had this slide system worked out.

I think you can see a few of the "oh, shit!" holes that are proof of my youth, exuberance and allergies to planning! :-) Never the less, it came out right in the end and I was able to tweak and tune it so that things run fairly straight and true. I then attached everything to a piece of MDF and it started looking stable.

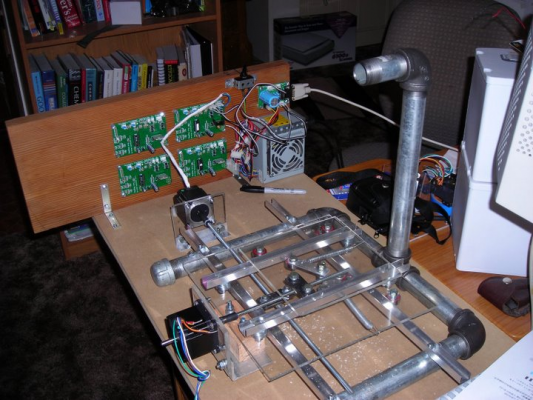

I next added a command center--spot for the electronics shit--and it started looking like something I could show people. Funny thing, that. I have to show it to the Mechanical Engineering department at the end of January and am hoping that it will be able to print by then.

I just finished getting my extruder working again. Jammed it up and tore off my piece of cable due to a poor soldering job and not enough room for the HDPE to go through. Worked out a straight shot mount too and will be trying that later. I've tested the x-y stages and they both drive so I'll be working almost exclusively on the z-axis from now on. Great to almost be completely done!

Demented

[picasaweb.google.com]

Here is the frame I first started with

I then did some tinkering over a few months and then had this slide system worked out.

I think you can see a few of the "oh, shit!" holes that are proof of my youth, exuberance and allergies to planning! :-) Never the less, it came out right in the end and I was able to tweak and tune it so that things run fairly straight and true. I then attached everything to a piece of MDF and it started looking stable.

I next added a command center--spot for the electronics shit--and it started looking like something I could show people. Funny thing, that. I have to show it to the Mechanical Engineering department at the end of January and am hoping that it will be able to print by then.

I just finished getting my extruder working again. Jammed it up and tore off my piece of cable due to a poor soldering job and not enough room for the HDPE to go through. Worked out a straight shot mount too and will be trying that later. I've tested the x-y stages and they both drive so I'll be working almost exclusively on the z-axis from now on. Great to almost be completely done!

Demented

|

Re: Almost Done!!! January 13, 2008 03:10PM |

Admin Registered: 16 years ago Posts: 13,905 |

|

Anonymous User

Re: Almost Done!!! January 15, 2008 10:51PM |

Demented,

That is great!

I just did a test fit with the pipes tonight. Something doesn't look right however. What are your pipe sizes? I followed the BOM, so I have, 2-12", 3-9", 1-6", plus elbows, tee, caps, and flange. Your assembly looks narrower than ~22" and your pipe connected to your flange looks like a 3" and not 6". Is the BOM incorrect?

Thanks,

David

That is great!

I just did a test fit with the pipes tonight. Something doesn't look right however. What are your pipe sizes? I followed the BOM, so I have, 2-12", 3-9", 1-6", plus elbows, tee, caps, and flange. Your assembly looks narrower than ~22" and your pipe connected to your flange looks like a 3" and not 6". Is the BOM incorrect?

Thanks,

David

|

Re: Almost Done!!! January 16, 2008 11:44PM |

Registered: 16 years ago Posts: 622 |

David,

Yeah, mine is drastically different than the plans Zach made up. Mine is approximately 16" wide. I have 3-12", 2-6", 1-3" and a 3" flange plus 3 elbows, 1 tee, and 2 caps. I wanted a smaller size at first due to my living space. I would go with larger sizes now. I would replace the two 6" with two 12". Also, I would get a larger vertical member than the 12" I have now.

My normal computer is down now and I'm forced to run off of the RepRap LIveCD. I think something ate my boot sector. Not nice. Anyway, when I get things back up and running I'll have the final mechanical build pics of my RepStrap to post here. Now all that is left is to completely wire up the electronics, make nice wire runs for the wires and turn the beast on!

I'm so close I can smell melted plastic and failed parts!

Demented

Yeah, mine is drastically different than the plans Zach made up. Mine is approximately 16" wide. I have 3-12", 2-6", 1-3" and a 3" flange plus 3 elbows, 1 tee, and 2 caps. I wanted a smaller size at first due to my living space. I would go with larger sizes now. I would replace the two 6" with two 12". Also, I would get a larger vertical member than the 12" I have now.

My normal computer is down now and I'm forced to run off of the RepRap LIveCD. I think something ate my boot sector. Not nice. Anyway, when I get things back up and running I'll have the final mechanical build pics of my RepStrap to post here. Now all that is left is to completely wire up the electronics, make nice wire runs for the wires and turn the beast on!

I'm so close I can smell melted plastic and failed parts!

Demented

|

Re: Almost Done!!! January 29, 2008 05:12AM |

Registered: 16 years ago Posts: 900 |

|

Re: Almost Done!!! January 29, 2008 07:34AM |

Registered: 16 years ago Posts: 622 |

Andy,

Not going to be milling or drilling on my machine. However, the idea has occured to me in a slight variation for the school build I am doing of a RepStrap. We will be enclosing the electronics in a similar way but with a full computer enclosed with it. We plan to put a control panel on the thing and mount all the electronics--RepRap and Host Computer--in there. Makes for a cleaner design.

I want to do a milling machine but I'm trying to get an "Actual" mini-mill. Lot's nicer...if you can get one!

Demented

Not going to be milling or drilling on my machine. However, the idea has occured to me in a slight variation for the school build I am doing of a RepStrap. We will be enclosing the electronics in a similar way but with a full computer enclosed with it. We plan to put a control panel on the thing and mount all the electronics--RepRap and Host Computer--in there. Makes for a cleaner design.

I want to do a milling machine but I'm trying to get an "Actual" mini-mill. Lot's nicer...if you can get one!

Demented

|

Re: Almost Done!!! February 17, 2008 10:50PM |

Registered: 16 years ago Posts: 622 |

Just got all of my (many) issues with the extruder ironed out and am now calibrating the machine in earnest. I'll have to get pics posted pretty soon. Right now I'm extruding blobs and lines of plastic in more or less the right places.

I'm having problems calibrating the height of each extruded layer and getting the first layer to adhere to the stage. Tried many different materials--mdf, hdpe, cutting board, tin-foil, plastic bags, etc--and finally setteld on duct-tape turned sticky side up. Works fairly well but still having the other problems.

Have a weird problem with the temp reading. Not at all accurate and can't get it to go any higher which is what I think needs to happen to get some better results.

Also, I'm currently using the largest nozzle available on RRRF store--1 mm. Pretty huge and could be part of my problem but I wanted to get away from clogged tips for my presentation--went well if not totally successful! I'll be putting on a .35 mm tip to see how a smaller filament size works. Finding that the filament is too large for it to break when the extruder turns off and moves away. A problem that the extruder wiper will solve no doubt. I'll post pictures a bit later of my crazy creations!!!

Demented

I'm having problems calibrating the height of each extruded layer and getting the first layer to adhere to the stage. Tried many different materials--mdf, hdpe, cutting board, tin-foil, plastic bags, etc--and finally setteld on duct-tape turned sticky side up. Works fairly well but still having the other problems.

Have a weird problem with the temp reading. Not at all accurate and can't get it to go any higher which is what I think needs to happen to get some better results.

Also, I'm currently using the largest nozzle available on RRRF store--1 mm. Pretty huge and could be part of my problem but I wanted to get away from clogged tips for my presentation--went well if not totally successful! I'll be putting on a .35 mm tip to see how a smaller filament size works. Finding that the filament is too large for it to break when the extruder turns off and moves away. A problem that the extruder wiper will solve no doubt. I'll post pictures a bit later of my crazy creations!!!

Demented

|

Re: Almost Done!!! February 18, 2008 01:26AM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Almost Done!!! February 18, 2008 02:56AM |

Registered: 16 years ago Posts: 900 |

Most excellent dude.

Given that it takes a certain amount of heat energy to convert the solid polymer to fluid, and a higher extrusion rate (1mm) takes more heat energy for the same head speed. Could your temperature thing be that the rate you are using up the heat your heater is generating is greater than your heater can generate it ????

(I actualy don't know here, just freewheeling ??)

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Given that it takes a certain amount of heat energy to convert the solid polymer to fluid, and a higher extrusion rate (1mm) takes more heat energy for the same head speed. Could your temperature thing be that the rate you are using up the heat your heater is generating is greater than your heater can generate it ????

(I actualy don't know here, just freewheeling ??)

Cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Almost Done!!! February 18, 2008 04:26AM |

Admin Registered: 17 years ago Posts: 7,879 |

Hi Demented,

You don't say which plastic. If it HDPE and it does not stick to HDPE board then it is not hot enough or the nozzle is too high. Measure the diameter of the extruded filament and set the nozzle to 0.8 times that above the bed. Extrude at a temperature of twice the melting point - ambient. I.e. about 240C for HDPE in a room at 20C.

Which electronics and which thermistor are you using? You will have problems at high temps with the 10K termistor on the orginal electronics. Switching to 100K should fix that.

The filament does not break when the extruder stops in general. The filament is molten so it just stretches and also pulls more molten platic out of the nozzle so you can stretch it about 300mm before it becomes thin enough to break.

[www.hydraraptor.blogspot.com]

You don't say which plastic. If it HDPE and it does not stick to HDPE board then it is not hot enough or the nozzle is too high. Measure the diameter of the extruded filament and set the nozzle to 0.8 times that above the bed. Extrude at a temperature of twice the melting point - ambient. I.e. about 240C for HDPE in a room at 20C.

Which electronics and which thermistor are you using? You will have problems at high temps with the 10K termistor on the orginal electronics. Switching to 100K should fix that.

The filament does not break when the extruder stops in general. The filament is molten so it just stretches and also pulls more molten platic out of the nozzle so you can stretch it about 300mm before it becomes thin enough to break.

[www.hydraraptor.blogspot.com]

|

Re: Almost Done!!! February 19, 2008 01:14AM |

Registered: 16 years ago Posts: 622 |

Nophead,

I'll try the .8 times the diameter setting thing. I'm already using the 100k thermistor--bought about 10 of them--but I think I have my cap set wrong or just have the wrong cap in there.

Yes, the filament doesn't break but at 1mm extrusion diameter it tends to pull things off the board when it moves. Not cool

Andy,

Yeah, I was wondering about that whole heat thing too. Could be that you are right. I'll have to just swap down to a smaller extruder nozzle.

Demented

I'll try the .8 times the diameter setting thing. I'm already using the 100k thermistor--bought about 10 of them--but I think I have my cap set wrong or just have the wrong cap in there.

Yes, the filament doesn't break but at 1mm extrusion diameter it tends to pull things off the board when it moves. Not cool

Andy,

Yeah, I was wondering about that whole heat thing too. Could be that you are right. I'll have to just swap down to a smaller extruder nozzle.

Demented

|

Re: Almost Done!!! March 08, 2008 10:19PM |

Registered: 16 years ago Posts: 622 |

A few picture updates as I've been away for awhile.

I'm only going to post the links. I don't like uploading the pictures here.

[picasaweb.google.com]

I've got quite a hand-full of those bits of printed plastic. No inter-layer adhesion so I have some work cut out still. Got the wrong capacitor-thermistor combo going and I still have to get that ironed out.

Here I have my z-axis setup but not yet wired.

[picasaweb.google.com]

A few close ups

[picasaweb.google.com]

[picasaweb.google.com]

And here is how I insulated my thermal barel

[picasaweb.google.com]

[picasaweb.google.com]

[picasaweb.google.com]

[picasaweb.google.com]

And here is the finished build that is "almost" functional.

[picasaweb.google.com]

It melts plastic and moves correctly. It just doesn't get the plastic hot enough!

I've also been working on the schools RepStrap. I have a web site set up through Google Pages. Nothing special but it talks about what we are doing. I like that kind of thing when I step through forums.

[oitreprap.googlepages.com]

That site isn't finished but it has some interesting pictures.

Just thought I'd post something.

Demented

I'm only going to post the links. I don't like uploading the pictures here.

[picasaweb.google.com]

I've got quite a hand-full of those bits of printed plastic. No inter-layer adhesion so I have some work cut out still. Got the wrong capacitor-thermistor combo going and I still have to get that ironed out.

Here I have my z-axis setup but not yet wired.

[picasaweb.google.com]

A few close ups

[picasaweb.google.com]

[picasaweb.google.com]

And here is how I insulated my thermal barel

[picasaweb.google.com]

[picasaweb.google.com]

[picasaweb.google.com]

[picasaweb.google.com]

And here is the finished build that is "almost" functional.

[picasaweb.google.com]

It melts plastic and moves correctly. It just doesn't get the plastic hot enough!

I've also been working on the schools RepStrap. I have a web site set up through Google Pages. Nothing special but it talks about what we are doing. I like that kind of thing when I step through forums.

[oitreprap.googlepages.com]

That site isn't finished but it has some interesting pictures.

Just thought I'd post something.

Demented

|

Re: Almost Done!!! March 09, 2008 06:03AM |

Admin Registered: 17 years ago Posts: 7,879 |

Hi Demented,

That's looking impressive. The magnetic Z-axis is a neat trick. What sort of magnets did you use?

On the insulation of the barrel: I have found that it's not a good idea to insulate the PTFE bit as the temperature you need to run HDPE at is close to the temperature PTFE seems to go soft at. Unless you are running a fan, you don't really need the insulation.

Regarding the rats nest of wires. Although it looks untidy, electrically it is better than running wires in neat bundles as there is less crosstalk between wires and on average the wires are shorter because they can run point to point.

[www.hydraraptor.blogspot.com]

That's looking impressive. The magnetic Z-axis is a neat trick. What sort of magnets did you use?

On the insulation of the barrel: I have found that it's not a good idea to insulate the PTFE bit as the temperature you need to run HDPE at is close to the temperature PTFE seems to go soft at. Unless you are running a fan, you don't really need the insulation.

Regarding the rats nest of wires. Although it looks untidy, electrically it is better than running wires in neat bundles as there is less crosstalk between wires and on average the wires are shorter because they can run point to point.

[www.hydraraptor.blogspot.com]

|

Re: Almost Done!!! March 13, 2008 10:46PM |

Registered: 16 years ago Posts: 622 |

nophead,

The magnets are of unknown origin and type. I didn't make the setup, I scavanged it from an old broke down landing vessel--cough: universal stereoplotter--that the last survey team left on Gideon Prime. Bastards left it none-to-clean either! ;-)

As to the insulation...Good point. I'll de-wrap mine before I get the darn thing up to temp. Suppose this means I'll have to run the heater profiler again...damn.

Yes, but how much cross-talk was I likely to get anyway? When I run the wires again I'm just going to leave them in the shielded Cat5e cabling to make it even nicer. I hope it doesn't hurt because the rat's nest really bugs me! ...a lot!

Demented

The magnets are of unknown origin and type. I didn't make the setup, I scavanged it from an old broke down landing vessel--cough: universal stereoplotter--that the last survey team left on Gideon Prime. Bastards left it none-to-clean either! ;-)

As to the insulation...Good point. I'll de-wrap mine before I get the darn thing up to temp. Suppose this means I'll have to run the heater profiler again...damn.

Yes, but how much cross-talk was I likely to get anyway? When I run the wires again I'm just going to leave them in the shielded Cat5e cabling to make it even nicer. I hope it doesn't hurt because the rat's nest really bugs me! ...a lot!

Demented

|

Re: Almost Done!!! March 13, 2008 11:01PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Almost Done!!! March 13, 2008 11:03PM |

Registered: 16 years ago Posts: 622 |

Sorry, only registered users may post in this forum.