Prusa X Motor End Issue

Posted by Pawl

|

Prusa X Motor End Issue March 25, 2012 02:47AM |

Registered: 12 years ago Posts: 17 |

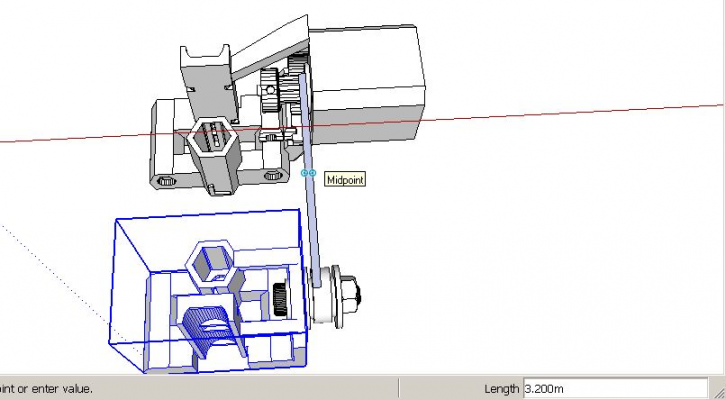

I think the X Motor End needs to be modified to allow the pulley to be more in line with the idler's 608 bearing. Even if the pulley was backwards and flush against the motor, only 3mm of belt would be able to fit on the 608 bearing. Here's a picture of what I'm talking about:

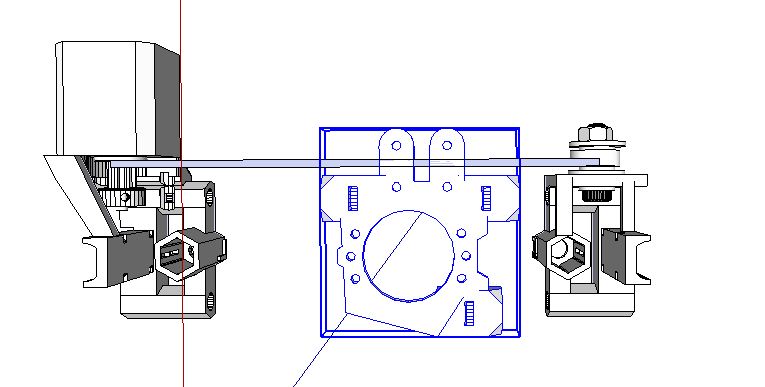

Here's my temporary fix (I added some washers between the motor and x end):

Edited 1 time(s). Last edit at 03/25/2012 02:50AM by Pawl.

Here's my temporary fix (I added some washers between the motor and x end):

Edited 1 time(s). Last edit at 03/25/2012 02:50AM by Pawl.

|

Re: Prusa X Motor End Issue March 25, 2012 08:29AM |

Registered: 13 years ago Posts: 1,780 |

Yes. I see this too in the Prusa iteration 2 that I'm currently building. But it looks like it's the x idler end that needs to be changed since the x carriage lines up with the x motor end. I printed my parts a few months ago (end of Nov or beginning of Dec) so it's possible that some parts have changed since then.

|

Re: Prusa X Motor End Issue March 25, 2012 06:57PM |

Registered: 12 years ago Posts: 17 |

Here's a picture of how it lines up with the x-carriage. The wall that the bolt sits against on the x-idler could move toward the rod ~7mm before the belt would be on top of the x-carriage's bolt hole. However, the motor can only move away from the rods ~4mm before the same thing happens (that's how much spacing you need with your washers - 4mm, 8 m3 washers, or 5 m4 washers).

If we're going to change the .scad files, moving the motor out and idler wall in would give us the most room.

|

Re: Prusa X Motor End Issue March 26, 2012 08:06AM |

Registered: 12 years ago Posts: 313 |

Pawl Wrote:

-------------------------------------------------------

> Here's my temporary fix (I added some washers

> between the motor and x end):

I had the same problem, but fixed it by adding just one washer in the bolt closest to the X carriage. That tilted the motor a tiny bit and made the belt run correctly without rubbing against anything. It's still a hack, though. Would be nicer to have everything line up correctly.

-------------------------------------------------------

> Here's my temporary fix (I added some washers

> between the motor and x end):

I had the same problem, but fixed it by adding just one washer in the bolt closest to the X carriage. That tilted the motor a tiny bit and made the belt run correctly without rubbing against anything. It's still a hack, though. Would be nicer to have everything line up correctly.

|

Re: Prusa X Motor End Issue March 26, 2012 05:28PM |

Registered: 13 years ago Posts: 1,780 |

I think using the printable bearing guide that comes with Prusa Iteration 2 helps since you'll only need one washer instead of 2. But instead of printing that one, use the one that I modified and posted in thingiverse.

|

Re: Prusa X Motor End Issue March 28, 2012 06:22AM |

Registered: 13 years ago Posts: 1,611 |

I had this issue too. I hacked the x-end-motor mount to create a 4mm spacer that is the same shape as the motor bracket. The belt is nicely aligned now. Another way to fix this is to use the x-rod adjusters in the motor end to 'turn' the whole motor mount a little, so the belt doesn't rub on the face of the motor.

|

Re: Prusa X Motor End Issue March 29, 2012 01:11AM |

Registered: 12 years ago Posts: 17 |

I think I fixed it. I'm going to use this on my new build and see if it fixes the problem: http://www.thingiverse.com/thing:20241

|

Re: Prusa X Motor End Issue March 29, 2012 09:39AM |

Registered: 13 years ago Posts: 1,611 |

|

Re: Prusa X Motor End Issue March 29, 2012 04:31PM |

Admin Registered: 15 years ago Posts: 1,470 |

Use two bearings on the x-idler, one washer between the bearings and the idler mount, and one washer on the other side. No fender washers necessary. Having two bearings make them stay perfectly straight, and you don't have to worry about the belt wandering off or rubbing on either side. That will also give you more room on the idler side, equivalent to moving the idler mount in a couple mm.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Prusa X Motor End Issue March 29, 2012 07:36PM |

Registered: 13 years ago Posts: 68 |

I think you have the exact same issue I have. The main problem for me is my rods arn't cut 99.99% correct. They are different by a few mm. So When you tighten that belt, combined with the super minimalistic design, the one side gets pulled in and the belts get out of alignment. I've not really found a solution except I added a second bearing on the x idler

|

Re: Prusa X Motor End Issue April 12, 2012 09:13AM |

Registered: 13 years ago Posts: 1,780 |

Sorry, only registered users may post in this forum.