Mendal-Parts V10 Hot end

Posted by m0khz

|

Mendal-Parts V10 Hot end May 02, 2012 02:58AM |

Registered: 11 years ago Posts: 2 |

New to the group, and slowly building my Mendel clone, have recently purchased from Mendal-Parts.com, the V10 hot end (complete assembly), the quality of the parts a great, unfortunately I'm unable to find any build info (construction sequence) etc.

Any pointers wound be helpful, a picture would be great!

Regards

Kevin

Any pointers wound be helpful, a picture would be great!

Regards

Kevin

|

Re: Mendal-Parts V10 Hot end May 03, 2012 06:24AM |

Admin Registered: 12 years ago Posts: 2,569 |

You should ask on mendel-parts forums, for instance there : [www.mendel-parts.com]

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Mendal-Parts V10 Hot end May 06, 2012 05:16AM |

Registered: 11 years ago Posts: 2 |

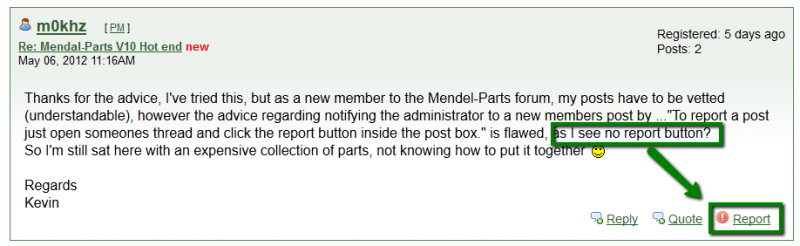

Thanks for the advice, I've tried this, but as a new member to the Mendel-Parts forum, my posts have to be vetted (understandable), however the advice regarding notifying the administrator to a new members post by ..."To report a post just open someones thread and click the report button inside the post box." is flawed, as I see no report button?

So I'm still sat here with an expensive collection of parts, not knowing how to put it together

Regards

Kevin

So I'm still sat here with an expensive collection of parts, not knowing how to put it together

Regards

Kevin

|

Re: Mendal-Parts V10 Hot end May 06, 2012 05:32AM |

Registered: 14 years ago Posts: 3,742 |

|

Re: Mendal-Parts V10 Hot end May 06, 2012 03:21PM |

Registered: 12 years ago Posts: 45 |

Hi!

The instructions will be included into the orca printer v0.42 manual. Go to their website and open the blog 2012. There's a link to the manual site. But there hasn't been posted any info about the hotend yet. If I were you, I would call Camiel and ask him if he can publish the part for the extruder/hotend next. I have to wait for my orca - probably I'll get it next weekend!

Edited 1 time(s). Last edit at 05/06/2012 03:26PM by lutjanus.

The instructions will be included into the orca printer v0.42 manual. Go to their website and open the blog 2012. There's a link to the manual site. But there hasn't been posted any info about the hotend yet. If I were you, I would call Camiel and ask him if he can publish the part for the extruder/hotend next. I have to wait for my orca - probably I'll get it next weekend!

Edited 1 time(s). Last edit at 05/06/2012 03:26PM by lutjanus.

|

Re: Mendal-Parts V10 Hot end May 21, 2012 04:47PM |

Registered: 12 years ago Posts: 45 |

Update: There are some photos of the new Orca V0.42 in the Mendel-Parts Forum. Also details about the V10 extruder / hotend.

http://www.mendel-parts.com/new_forum/phpBB3/viewtopic.php?f=34&t=8730

That should help you to assemble your extruder. I got my Orca V0.42 today :-) but it will take some days till I reach the part with the extruder.

Edited 1 time(s). Last edit at 05/21/2012 05:04PM by lutjanus.

http://www.mendel-parts.com/new_forum/phpBB3/viewtopic.php?f=34&t=8730

That should help you to assemble your extruder. I got my Orca V0.42 today :-) but it will take some days till I reach the part with the extruder.

Edited 1 time(s). Last edit at 05/21/2012 05:04PM by lutjanus.

|

Re: Mendal-Parts V10 Hot end May 31, 2012 08:34AM |

Registered: 12 years ago Posts: 9 |

|

Re: Mendal-Parts V10 Hot end May 31, 2012 10:32AM |

Registered: 13 years ago Posts: 60 |

They two brass threaded tubes should not be able to contact each other, as there should be a peek 'ledge' in the centre of the tube.

There needs be this bridge of peek between the two, otherwise the extruder ally will get too hot and melt the bearing/extruder plastics .

.

I believe that the peek's hole in x-section goes: m6 tapped hole from top to approx halfway down, then either 2 or 3.2mm hole (dep on 1.75 or 3mm filament) for about 3mm, then M6 tapped hole to bottom.

You need to make sure that they are tightly screwed together(without damaging the thread on the brass) and the lock collars are on tight - this will stop the extruder from leaking.

There is a youtube video by JamesHardiman01 on this http://www.youtube.com/watch?v=sR9l5O69MCM&feature=channel&list=UL

Note that there is 3 parts to this... hope it helps

There needs be this bridge of peek between the two, otherwise the extruder ally will get too hot and melt the bearing/extruder plastics

.

. I believe that the peek's hole in x-section goes: m6 tapped hole from top to approx halfway down, then either 2 or 3.2mm hole (dep on 1.75 or 3mm filament) for about 3mm, then M6 tapped hole to bottom.

You need to make sure that they are tightly screwed together(without damaging the thread on the brass) and the lock collars are on tight - this will stop the extruder from leaking.

There is a youtube video by JamesHardiman01 on this http://www.youtube.com/watch?v=sR9l5O69MCM&feature=channel&list=UL

Note that there is 3 parts to this... hope it helps

|

Re: Mendal-Parts V10 Hot end May 31, 2012 05:23PM |

Registered: 12 years ago Posts: 45 |

There is a small round piece of plastic coming with the kit. It is the same Material as the big plasticpart which connects the two pipe-pieces. Put one tube in, then the distance plastic part. Then the other tube. Now use the long drill to make a hole the distance-piece. This hole has now the exact size as the inner diameter of the pipes. I finished my extruder and it works brilliant. I will add some photos of the assembly in the next days.

Edited 2 time(s). Last edit at 05/31/2012 05:26PM by lutjanus.

Edited 2 time(s). Last edit at 05/31/2012 05:26PM by lutjanus.

|

Re: Mendal-Parts V10 Hot end June 01, 2012 10:21AM |

Registered: 12 years ago Posts: 45 |

OK, now here are some pictures:

Here are both pipe already installed and the "spacer"-plastic part is inserted between the pipes into the plastic cylinder. This creates a heat barrier so that the upper part stays colder.

Now use the long drill (for my 1,75mm extruder it is the 2mm size) and drill a hole into the spacer-plastic.

Add heater-block, nozzle and nuts...

Heating sensor and heater element added. Squeeze the heater block a bit (with a vise or strong pincer) - otherwise you can damage the screwhead of the small fixing screw when pulling tight.

The complete device...

All plastic parts for the V10 extruder. The bearing will be installed with a washer on each side (missing on the picture).

Mount all parts of the extruder axle as shown (and as it fits into the mounting block) I used 3,5,13 washers (from the left to the right side with the gear). File a small notch on the axle so that the fixing-screw of the gear doesn't slip (green arrow).

Everything fits.

Mount the axle and add the aluminium plate for the motor.

The complete extruder...

I hope that will help somewhat... ;-)

Edited 1 time(s). Last edit at 06/01/2012 10:39AM by lutjanus.

Here are both pipe already installed and the "spacer"-plastic part is inserted between the pipes into the plastic cylinder. This creates a heat barrier so that the upper part stays colder.

Now use the long drill (for my 1,75mm extruder it is the 2mm size) and drill a hole into the spacer-plastic.

Add heater-block, nozzle and nuts...

Heating sensor and heater element added. Squeeze the heater block a bit (with a vise or strong pincer) - otherwise you can damage the screwhead of the small fixing screw when pulling tight.

The complete device...

All plastic parts for the V10 extruder. The bearing will be installed with a washer on each side (missing on the picture).

Mount all parts of the extruder axle as shown (and as it fits into the mounting block) I used 3,5,13 washers (from the left to the right side with the gear). File a small notch on the axle so that the fixing-screw of the gear doesn't slip (green arrow).

Everything fits.

Mount the axle and add the aluminium plate for the motor.

The complete extruder...

I hope that will help somewhat... ;-)

Edited 1 time(s). Last edit at 06/01/2012 10:39AM by lutjanus.

|

Re: Mendal-Parts V10 Hot end June 04, 2012 05:19AM |

Registered: 12 years ago Posts: 9 |

Lucastar,

thanks - I was all but certain that the 2 brass pieces needed to be separated out by something, but could not see how to do it with V10. I had overlooked the video because V9 looked rather different. It turns out that the top part of V10 differs from the top part of V9 in one small but important way - the use of a small disc of PEEK. See below for details.

lutjanus,

thanks - those are very clear and helpful instructions/photos. I have now built my extruder after a bit of head-scratching. If I'd had your photos it would have been a matter of minutes to put it together. One note for others following in our footsteps - it seems that the metal base plate for the extruder has an upper and lower side. If you mount the extruder & hot end to it the wrong way up the holes for the top of the extruder, the toothed wheel, and the top of the hot end will not line up correctly.

The difference between V9 and V10

The V9 had, as Lucastar pointed out, a ledge built into the centre of the PEEK to keep the 2 brass tubes apart. The V10 has a completely tapped PEEK outer, and is delivered with a *small* disk of PEEK that you need to place inbetween the 2 brass tubes. After phoning Camiel yesterday it seems that I am not the only one who has overlooked the disc and he may change things in the future. Anyway, a couple of discs are now in the post for me, so I should be able to put my hotend together tomorrow.

and he may change things in the future. Anyway, a couple of discs are now in the post for me, so I should be able to put my hotend together tomorrow.

When I put my hotend together, I'll take a picture of the above and post it up.

thanks - I was all but certain that the 2 brass pieces needed to be separated out by something, but could not see how to do it with V10. I had overlooked the video because V9 looked rather different. It turns out that the top part of V10 differs from the top part of V9 in one small but important way - the use of a small disc of PEEK. See below for details.

lutjanus,

thanks - those are very clear and helpful instructions/photos. I have now built my extruder after a bit of head-scratching. If I'd had your photos it would have been a matter of minutes to put it together. One note for others following in our footsteps - it seems that the metal base plate for the extruder has an upper and lower side. If you mount the extruder & hot end to it the wrong way up the holes for the top of the extruder, the toothed wheel, and the top of the hot end will not line up correctly.

The difference between V9 and V10

The V9 had, as Lucastar pointed out, a ledge built into the centre of the PEEK to keep the 2 brass tubes apart. The V10 has a completely tapped PEEK outer, and is delivered with a *small* disk of PEEK that you need to place inbetween the 2 brass tubes. After phoning Camiel yesterday it seems that I am not the only one who has overlooked the disc

and he may change things in the future. Anyway, a couple of discs are now in the post for me, so I should be able to put my hotend together tomorrow.

and he may change things in the future. Anyway, a couple of discs are now in the post for me, so I should be able to put my hotend together tomorrow.

When I put my hotend together, I'll take a picture of the above and post it up.

|

Re: Mendal-Parts V10 Hot end June 07, 2012 08:46AM |

Registered: 12 years ago Posts: 9 |

Here's a picture of the PEEK core that you need to put inside the PEEK outer:

Edited 1 time(s). Last edit at 06/07/2012 08:50AM by cranberry.

Edited 1 time(s). Last edit at 06/07/2012 08:50AM by cranberry.

|

Re: Mendal-Parts V10 Hot end June 13, 2012 04:46AM |

Registered: 12 years ago Posts: 45 |

|

Re: Mendal-Parts V10 Hot end July 02, 2012 02:35PM |

|

Re: Mendal-Parts V10 Hot end July 10, 2012 03:17PM |

Registered: 11 years ago Posts: 25 |

Dear Lutjanus,

Thank you for the very clear photos of the v10 hotend for Orca 0.42, was wondering wether you had any idea/ photos of where the scratch-felt piece goes.

According to orca042BOM they are to put under "feet" to prevent damage and use under motor in v10 extruder.

"EDITED 12th JULY

Not to worry, I just realised where it goes!!

Edited 1 time(s). Last edit at 07/12/2012 01:50PM by magicmodel.

3D Printing never sleeps

MAGICMODEL

Thank you for the very clear photos of the v10 hotend for Orca 0.42, was wondering wether you had any idea/ photos of where the scratch-felt piece goes.

According to orca042BOM they are to put under "feet" to prevent damage and use under motor in v10 extruder.

"EDITED 12th JULY

Not to worry, I just realised where it goes!!

Edited 1 time(s). Last edit at 07/12/2012 01:50PM by magicmodel.

3D Printing never sleeps

MAGICMODEL

|

Re: Mendal-Parts V10 Hot end August 03, 2012 05:59AM |

Registered: 11 years ago Posts: 2 |

Hi !

I didn't see this topic before so we assembled our orca v0.42's hotend "intuitively" and of course made lots of mistakes. We had plastic leaking so we tried to disassemble everyhting to see what was wrong but everything broke. We have to get a new hotend v10 asap but Mendel-parts.com seems to be the only place to get them. As of today, the website in not accessible, and a few days ago everything was Out of stock.

Do you guys have any idea of where I could get replacement parts ? Even if I can't find the exact same Hotend v10, which one could I use instead ?

When we get a new one we'll make sure to follow the great instructions above !

Thank you.

I didn't see this topic before so we assembled our orca v0.42's hotend "intuitively" and of course made lots of mistakes. We had plastic leaking so we tried to disassemble everyhting to see what was wrong but everything broke. We have to get a new hotend v10 asap but Mendel-parts.com seems to be the only place to get them. As of today, the website in not accessible, and a few days ago everything was Out of stock.

Do you guys have any idea of where I could get replacement parts ? Even if I can't find the exact same Hotend v10, which one could I use instead ?

When we get a new one we'll make sure to follow the great instructions above !

Thank you.

|

Re: Mendal-Parts V10 Hot end August 03, 2012 07:46AM |

Registered: 12 years ago Posts: 9 |

Oliver,

I managed to damage the driven wheel for my V10 hot end ( over-tightened the grub screw and split the plastic ).

I have ordered a Wade's extruder and a new J-head hotend. This will require me to change the x-carriage to fit them, but I think should give more consistent feeding/fewer jams than the V10 hot end.

There are several people on EmakerShop offering kits/printed parts/vitamins if you also want to swap extruders and hot ends.

I managed to damage the driven wheel for my V10 hot end ( over-tightened the grub screw and split the plastic ).

I have ordered a Wade's extruder and a new J-head hotend. This will require me to change the x-carriage to fit them, but I think should give more consistent feeding/fewer jams than the V10 hot end.

There are several people on EmakerShop offering kits/printed parts/vitamins if you also want to swap extruders and hot ends.

|

Re: Mendal-Parts V10 Hot end August 03, 2012 12:17PM |

Registered: 11 years ago Posts: 2 |

|

Re: Mendal-Parts V10 Hot end August 06, 2012 11:41AM |

Registered: 12 years ago Posts: 9 |

I can't say for definite at the moment, but I hope it will at most require me to drill some holes in the metal plate that makes up the X-carriage. It may however mean that I need to make up a new plate if things don't fit, and drill holes to accept the bearing holders, extruder and hotend.

Sorry, only registered users may post in this forum.