Attaching PTFE hot end to Wade's extruder

Posted by picklemonkey

|

Attaching PTFE hot end to Wade's extruder October 14, 2012 08:08PM |

Registered: 11 years ago Posts: 16 |

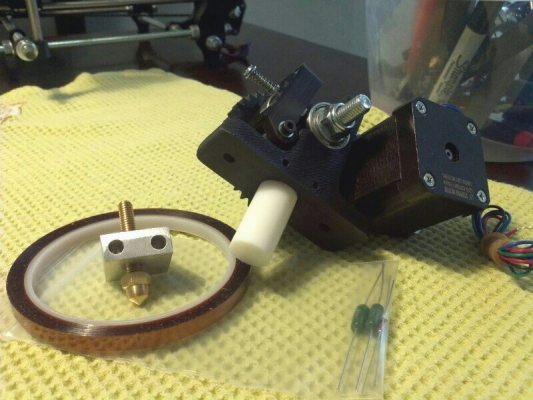

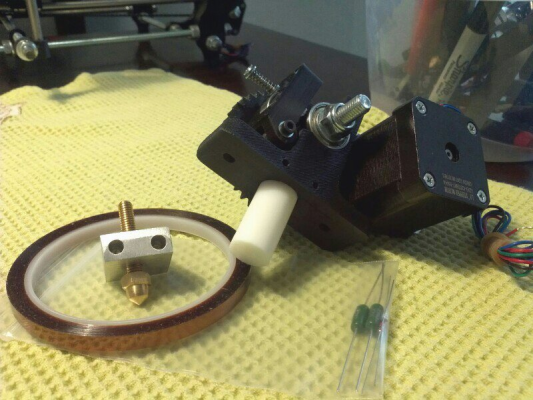

Hey guys, I'm a new reprapper and I'm trying to finish my first prusa i2. I have been working on this off and on for two months, and have been following the i2 assembly wiki page throughout my build. I sourced my kit from multiple sites, which has caused me many issues along the way, but I have managed to get through all steps up to the extruder. Now I'm a bit lost, though, because the wiki article says nothing about assembling the extruder! From what I can tell I have a Greg's hinged accessible Wade's extruder (I had to learn this from a lot of Google searches!), and a PTFE rod with an aluminum block/brass nozzle as shown on this site (again, not where I bought it, but what I've discovered to be my parts). The places I bought my parts are of no help in actually assembling the stuff.

The confusion I have is around attaching the PTFE rod to the bottom of the extruder--I can obviously fit the rod snugly into the bottom, as pictured, but I'm not sure how to actually affix it. I have seen pictures of others on the internet which have made me think I might be missing something (some wood piece?) that attaches the rod and extruder together, but am not certain. I have also read that it should be glued, but this doesn't sound right! It looks like I should maybe somehow screw into it through the holes on the extruder that are positioned on either side of the rod as shown. Is any of this right? Any other suggestions that I'm missing? I want to get this damn thing running already

Thank you in advance!

The confusion I have is around attaching the PTFE rod to the bottom of the extruder--I can obviously fit the rod snugly into the bottom, as pictured, but I'm not sure how to actually affix it. I have seen pictures of others on the internet which have made me think I might be missing something (some wood piece?) that attaches the rod and extruder together, but am not certain. I have also read that it should be glued, but this doesn't sound right! It looks like I should maybe somehow screw into it through the holes on the extruder that are positioned on either side of the rod as shown. Is any of this right? Any other suggestions that I'm missing? I want to get this damn thing running already

Thank you in advance!

|

Re: Attaching PTFE hot end to Wade's extruder October 14, 2012 08:10PM |

Registered: 11 years ago Posts: 16 |

Oh, also... does anybody know if the directions that I found on a2aprinter to build my hot end are the right steps for the parts shown in my photo? I'm a bit nervous to follow them/start drilling the PTFE rod until I know for sure it's what I need to do!

|

Re: Attaching PTFE hot end to Wade's extruder October 15, 2012 06:24AM |

Registered: 11 years ago Posts: 525 |

Howdy - the extruder body you have is designed to have a couple of screws run through the two holes you ask about. A lot of hot ends have a ring turnde into the top for either a separate locking plate (like the piece of wood you are thinking of, or perspex/acrylic). With this extruder the two screws lock into this recess in the hot end. If your extruder does not have the recessed ring you could just run a drill bit through the extruder with the hot end in place and that would cut a path for the self-tapper or machine screws you use.

The brass bolt with the alloy block is meant to screw into the bottom of the PTFE rod which should be drilled and tapped to take it. I think this type of hot end would want some type of sealant ot thread tape to prevent leakage around the threads.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

The brass bolt with the alloy block is meant to screw into the bottom of the PTFE rod which should be drilled and tapped to take it. I think this type of hot end would want some type of sealant ot thread tape to prevent leakage around the threads.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Attaching PTFE hot end to Wade's extruder October 15, 2012 11:34AM |

Registered: 12 years ago Posts: 972 |

It is mentioned in the forums [forums.reprap.org] that hotends where the PFTE piece is doing mechanical effort are prone to early failure. Yours seem designed so all the tension is supported by the PFTE block. It might be a good idea to have some external armature sharing the load (like a piece of wood, or ideally PEEK, and a couple of bolts pressing the threaded rod upwards, so there is no traction on the PFTE.

That said, you may get hours of trouble-free operation if you just tap the PFTE (if not already tapped) and screw the threaded rod in place.

That said, you may get hours of trouble-free operation if you just tap the PFTE (if not already tapped) and screw the threaded rod in place.

|

Re: Attaching PTFE hot end to Wade's extruder October 15, 2012 11:51AM |

Registered: 11 years ago Posts: 16 |

Thank you, Wired1. I saw some PTFE tape on the end of some of the rods on other pictures and assumed I had to use it on all connections.

Here's a picture I found on the net showing the bottom of my extruder:

[www.thingiverse.com]

Just to make sure I understand you, you're saying that with this particular extruder I don't need a separate locking plate, and that I should just get two small self-tapping screws and screw directly into the PTFE rod through the extruder's pilot holes on the side. Is that right?

Edited 1 time(s). Last edit at 10/15/2012 11:52AM by picklemonkey.

Here's a picture I found on the net showing the bottom of my extruder:

[www.thingiverse.com]

Just to make sure I understand you, you're saying that with this particular extruder I don't need a separate locking plate, and that I should just get two small self-tapping screws and screw directly into the PTFE rod through the extruder's pilot holes on the side. Is that right?

Edited 1 time(s). Last edit at 10/15/2012 11:52AM by picklemonkey.

|

Re: Attaching PTFE hot end to Wade's extruder October 15, 2012 11:58AM |

Registered: 11 years ago Posts: 16 |

Misan, thank you... that's exactly the concern that I have.. The piece of PEEK (or wood) is what I had seen in other images, but am not sure of what exactly I'd need to make/how I'd get it/how I'd affix it. If I went this route, how would I attach the bolts in such a way that they're pushing the rod upwards? I think this would be easier for me to understand if I had a photo... I'll try to google some in the meantime.

|

Re: Attaching PTFE hot end to Wade's extruder October 15, 2012 12:52PM |

Registered: 12 years ago Posts: 972 |

Maybe you can get some inspiration from here: [reprap.org]

I do not know how much rod will go inside the PFTE block in your extruder, so putting the wood/PEEK part before the heater block maybe not be possible. If that were the case, maybe you can locate it below the heater block ...

I do not know how much rod will go inside the PFTE block in your extruder, so putting the wood/PEEK part before the heater block maybe not be possible. If that were the case, maybe you can locate it below the heater block ...

|

Re: Attaching PTFE hot end to Wade's extruder October 15, 2012 10:41PM |

Registered: 11 years ago Posts: 525 |

Spend a bit of time going through all these and you might find one that is similar [reprap.org]

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

|

Re: Attaching PTFE hot end to Wade's extruder October 18, 2012 10:05PM |

Registered: 11 years ago Posts: 16 |

Can I use copper wire to attach the hot end to the board, or do I use niChrome... or does it matter? I received a 20 gauge, .5mm^2 copper wire in my kit but see mixed reviews on the forum, and nothing really explains which or why. Some say it's fine, some say niChrome, some say 16 gauge or bigger, etc. Is there a standard? Will I hurt anything if I go with this 20 gauge copper?

Edited 1 time(s). Last edit at 10/18/2012 10:18PM by picklemonkey.

Edited 1 time(s). Last edit at 10/18/2012 10:18PM by picklemonkey.

|

Re: Attaching PTFE hot end to Wade's extruder October 19, 2012 01:34AM |

Registered: 12 years ago Posts: 972 |

I guess this copper wire is to connect the hotend heater (your seem to be based on nicrome wire) to your electronics. You need thicker wire as it carries much more current than, let's say, the thermistor wires. If you use thinner wires they will heat up and your hotend may not reach the desired temperature.

|

Re: Attaching PTFE hot end to Wade's extruder October 19, 2012 11:39AM |

Registered: 11 years ago Posts: 477 |

As misan said, you need to use normal insulated wire to feed the hotend. The hot-end's heater, on the other hand, would either be a power resistor or nichrome, depending on the design. Nichrome is considered "resistance wire", whereas the feed wire is desired to be as low resistance as possible (within reason) to eliminate electrical losses in that feed wire prior to reaching the load (the hot-end's heater).

The Jhead I purchased uses a 5.6 ohm resistor, which implies a normal load current for the heater of 2-3A (12V/5.6ohm = 2.14A). 20ga wire should be ok for feed to the hot-end. (losses in a 5 foot length of 20ga @ 2.14A is roughly 0.2V (0.1V for the supply-side, and 0.1V for the return)

Needless to say, your feed should be stranded wire since it needs to be flexible

The Jhead I purchased uses a 5.6 ohm resistor, which implies a normal load current for the heater of 2-3A (12V/5.6ohm = 2.14A). 20ga wire should be ok for feed to the hot-end. (losses in a 5 foot length of 20ga @ 2.14A is roughly 0.2V (0.1V for the supply-side, and 0.1V for the return)

Needless to say, your feed should be stranded wire since it needs to be flexible

|

Re: Attaching PTFE hot end to Wade's extruder October 19, 2012 04:23PM |

Registered: 11 years ago Posts: 525 |

The Nicrome is the heating element so it gets wrapped around the business end of the hot end. You probably got some crimp ferules to connect it to the flexible plastic coated copper wires that run back to your control board as it is probably too hot to solder them on.

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

_________________________________________________________________________________________

Richmond, New Zealand

Thingiverse ~ YouTube

Sorry, only registered users may post in this forum.