Need Help & Advices. Non smooth edges print

Posted by valkiky

|

Need Help & Advices. Non smooth edges print July 18, 2013 03:57AM |

Registered: 10 years ago Posts: 5 |

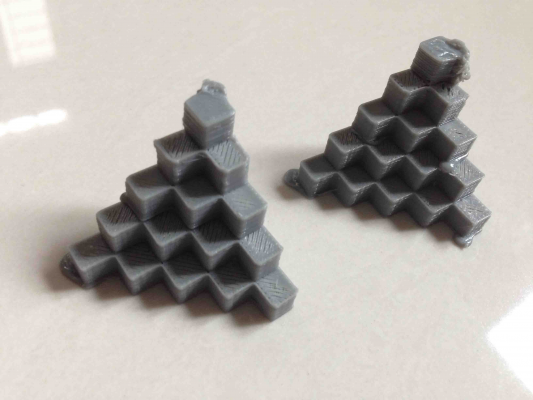

I keep getting non-smooth print on the edges / corner of my print.

The attached photo is printed with

layer height 0.3 mm

infill 0.8 mm

standard speed that comes with slic3r 0.9.10b (which I think is already pretty slow)

perimeter is 3

width is set to 0.42 mm

My Steps (X/Y/Z/E) has been calibrated to 50.7 / 50.7 / 2560 / 848

printed with Grey PLA at 185 degree and bed temperature on Mk2a at 60 degree.

(First layer is 190 noozle and 70 bed)

I have tried changing to faster speed and/or with lower infill (0.4), but always got those uneven corner print.

The object in the attached photo is also printed two copies on single run. (I was trying to give it more time before the extuder gets to the next layer, to give more time for the layer to cool off, especially on the layer that has only small area to print). The result is better printing one copy on single run)

I really don't know what else I need to tweak.

My unit is Mendelmax 1.5 with J-Head V hot end 0.5 mm nozzle

Would really appreciate any help/advice.

Thanks

mendelmax 1.5, sanguinololu 1.3a, with NEMA1.7, J-Head V hotend

A4988 Stepstick Drivers

The attached photo is printed with

layer height 0.3 mm

infill 0.8 mm

standard speed that comes with slic3r 0.9.10b (which I think is already pretty slow)

perimeter is 3

width is set to 0.42 mm

My Steps (X/Y/Z/E) has been calibrated to 50.7 / 50.7 / 2560 / 848

printed with Grey PLA at 185 degree and bed temperature on Mk2a at 60 degree.

(First layer is 190 noozle and 70 bed)

I have tried changing to faster speed and/or with lower infill (0.4), but always got those uneven corner print.

The object in the attached photo is also printed two copies on single run. (I was trying to give it more time before the extuder gets to the next layer, to give more time for the layer to cool off, especially on the layer that has only small area to print). The result is better printing one copy on single run)

I really don't know what else I need to tweak.

My unit is Mendelmax 1.5 with J-Head V hot end 0.5 mm nozzle

Would really appreciate any help/advice.

Thanks

mendelmax 1.5, sanguinololu 1.3a, with NEMA1.7, J-Head V hotend

A4988 Stepstick Drivers

|

Re: Need Help & Advices. Non smooth edges print July 18, 2013 09:51AM |

Registered: 11 years ago Posts: 1,320 |

|

Re: Need Help & Advices. Non smooth edges print July 23, 2013 03:05PM |

Registered: 11 years ago Posts: 157 |

I don't see the ooze problem that jbernardis does. What this looks like to me is a too-high esteps value. Pressure builds up in the nozzle as you extrude too much during a long perimeter, and once you're at the corner there's more room for plastic to leak out, and the nozzle is moving more slowly, allowing it to happen.

1) [reprap.org]

2) [reprap.org]

But first, I'd check the consistency of the filament diameter as it enters into the extruder. If it fluctuates, you've got no way to keep a consistent volume coming out of your extruder, other than buying better filament.

You might also have some serious z-wobble going on, but let's get that extrusion issue worked out first.

1) [reprap.org]

2) [reprap.org]

But first, I'd check the consistency of the filament diameter as it enters into the extruder. If it fluctuates, you've got no way to keep a consistent volume coming out of your extruder, other than buying better filament.

You might also have some serious z-wobble going on, but let's get that extrusion issue worked out first.

|

Re: Need Help & Advices. Non smooth edges print July 24, 2013 10:37PM |

Registered: 10 years ago Posts: 5 |

jbernardis, karmavore,

When the Hotend was heated to and stayed at 185 temperature (without doing any print), it does ooze continuously. I would say every 10 seconds it would ooze out a plastic string of several mm. I have to clean up the head many times before it start printing (wipe the head with toothbrush). Is this considered ooze problem ? I thought it is normal to ooze when not printing (but staying at printing temperature,185) ?

I checked the retraction setting in the slic3r 0910b, by default it is enabled with 1 mm retraction length and retraction speed of 30 mm/s. So the print in the picture was print with retraction enabled. or should I change it faster and retract more length ?

I checked the consistency of the filament, it range from 2.98 - 3.11.

Karmavore, I will recheck the E-Steps again. I do sometimes hear a kriek kriek sound from the extruder motor, but am not sure what it is. Maybe that is the motor skip step ?

FYI

The following is the Extruder used:

Greg's Wade Reloaded Extruder with Herringbone Gear [www.thingiverse.com]

With NEMA1.7 Motor

use with 3 mm Grey PLA Filament.

I wonder what other people that used the same Extruder+Gear+NEMA1.7+3mm filament ended up with their E-Steps?

I do appreciate the advices and the time to help me.

Thanks

When the Hotend was heated to and stayed at 185 temperature (without doing any print), it does ooze continuously. I would say every 10 seconds it would ooze out a plastic string of several mm. I have to clean up the head many times before it start printing (wipe the head with toothbrush). Is this considered ooze problem ? I thought it is normal to ooze when not printing (but staying at printing temperature,185) ?

I checked the retraction setting in the slic3r 0910b, by default it is enabled with 1 mm retraction length and retraction speed of 30 mm/s. So the print in the picture was print with retraction enabled. or should I change it faster and retract more length ?

I checked the consistency of the filament, it range from 2.98 - 3.11.

Karmavore, I will recheck the E-Steps again. I do sometimes hear a kriek kriek sound from the extruder motor, but am not sure what it is. Maybe that is the motor skip step ?

FYI

The following is the Extruder used:

Greg's Wade Reloaded Extruder with Herringbone Gear [www.thingiverse.com]

With NEMA1.7 Motor

use with 3 mm Grey PLA Filament.

I wonder what other people that used the same Extruder+Gear+NEMA1.7+3mm filament ended up with their E-Steps?

I do appreciate the advices and the time to help me.

Thanks

|

Re: Need Help & Advices. Non smooth edges print July 25, 2013 11:53PM |

Registered: 10 years ago Posts: 5 |

Hi,

Following instruction on Triffid Hunter Calibration Guide

I calibrated my E-Steps to 800. My calculated E was 720 but after extruding 100mm of filament, it only went through 90mm, and so my new E-Steps is 720x100/90 and I got 800. After that, I tried extruding another 100mm and the filament went in exactly 100mm (from Ruler Reading).

-- 0.5% of 800 is 4 STEPS.

I start from 800, go to 804, 808, 812, 816, they all look the same to me, I can still see little gap in between the infill line. So I just thought 800 is already good. Because I'm also afraid if I go higher, it will contradict with the first Re-Calculated E-Steps, won't it?

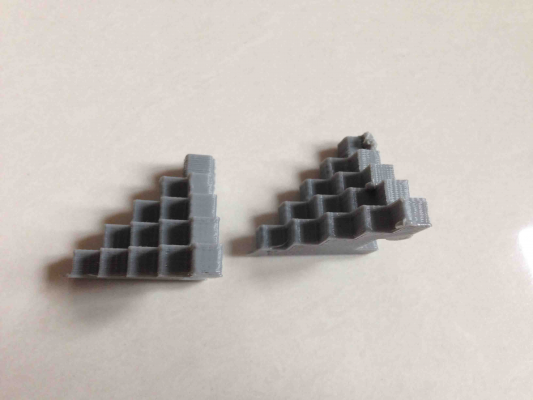

The attached 5mm Cubes was printed with

Layer Height 0.2 mm

Width 0.28 mm

infill 0.95 Rectiliner

Extraction is 3 mm ( I tried changing from 1 to 3 mm)

Perimeter is 1

Filament Diameter is 3.06 mm (Filament width range from 2.98 - 3.11)

Multiplication is 0.8 (based on the last time I measured the printed thin wall hollow cube)

Printing Speed is the default setting from slic3r 0910b

These were printed 2 copies on single run.

I notice the following:

1. There was a drop of filament at the start of printing Perimeter of the Object (Right after it finished doing the skirt and moving to printing the Perimeter of the object). Printing temperature of layer 1 is 185, with bed at 70. This drop happened almost on all of my prints. (wonder if anybody got this problem too)

2. at layer height approximately 10mm (right after 2 steps of 5mm cube, going for the third steps of 5mm cube), there was another drop of filement, and I noticed there is kind of higher gap between the layer. (probably this is what Karmavore mentioned that I might have some Z problem?)

3. I think the highest Cube was printed badly because of No Fan is installed in my printer and so those layers are printed too fast.

However, Back to the original issue (non-smooth edge Print) .. the edge of these prints looks better.

I will try on another print.

|

Re: Need Help & Advices. Non smooth edges print July 30, 2013 11:11AM |

Registered: 10 years ago Posts: 5 |

Hi again,

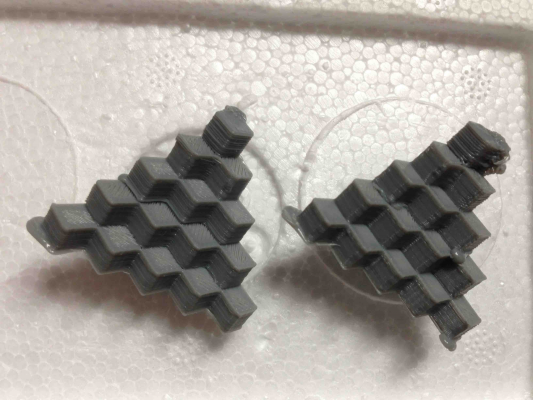

Following up tweaking my mendelmax 1.5 unit, I post the following result.

I printed simple object (Minecraft Creeper Body), which is just simple square object with a hole in the middle.

I keep getting ooze problem at the side and corner. especially if it is printing small area layer.

I attached 2 print trial (both print seperately), and both had ooze on the layer with small area I think.

Both are printed with 0.3 layer height.

Really need help and advice to what I should do.

Am really confuse with what I should do. Is this normal ?

Would really appreciate any thoughts and help.

Following up tweaking my mendelmax 1.5 unit, I post the following result.

I printed simple object (Minecraft Creeper Body), which is just simple square object with a hole in the middle.

I keep getting ooze problem at the side and corner. especially if it is printing small area layer.

I attached 2 print trial (both print seperately), and both had ooze on the layer with small area I think.

Both are printed with 0.3 layer height.

Really need help and advice to what I should do.

Am really confuse with what I should do. Is this normal ?

Would really appreciate any thoughts and help.

|

Re: Need Help & Advices. Non smooth edges print July 30, 2013 04:16PM |

Registered: 11 years ago Posts: 157 |

I can't say that I've experience what you're experiencing, so keep in mind I'm just guessing.

It's clear that your printer works very well for at least a little while, and when it screws up, it seems to do so in the same spots, but those spots differ among prints. This seems odd to me. Here are a couple things I'd explore:

1. How steady does your extruder temperature stay? Once it is locked in on a temp, I'd expect it to hang within +/- .5 degrees. Does it vary more than that? If so, it could be pushing more into the extruder when it is cold, and having more come out again when it is hot. (Having some ooze while to heat and stationary is normal, though.) Have you run the PID tuning with Marlin?

2. What do your acceleration settings in Marlin look like? They come as 9,000 mm/sec^2 by default, and you'll probably want to bring them way down. I'd suggest going all the way down to 1,200, then bringing them back up as your printer can handle it. I currently run at 2,000 for the X&Y.

Good luck.

It's clear that your printer works very well for at least a little while, and when it screws up, it seems to do so in the same spots, but those spots differ among prints. This seems odd to me. Here are a couple things I'd explore:

1. How steady does your extruder temperature stay? Once it is locked in on a temp, I'd expect it to hang within +/- .5 degrees. Does it vary more than that? If so, it could be pushing more into the extruder when it is cold, and having more come out again when it is hot. (Having some ooze while to heat and stationary is normal, though.) Have you run the PID tuning with Marlin?

2. What do your acceleration settings in Marlin look like? They come as 9,000 mm/sec^2 by default, and you'll probably want to bring them way down. I'd suggest going all the way down to 1,200, then bringing them back up as your printer can handle it. I currently run at 2,000 for the X&Y.

Good luck.

|

Re: Need Help & Advices. Non smooth edges print July 30, 2013 06:29PM |

Registered: 10 years ago Posts: 47 |

Use the same diligence you used to calibrate your extruder in checking the calibration of X, Y, and especially Z movement. I think your Z travel is a little short. Also, I have found that if I got slightly higher than my measured filament diameter, I avoid this kind of excess plastic.

So, if you measure a filament diameter range of 2.7-2.78, try printing at 2.82. So with your measurements, try 3.15

But, i'll bet your Z travel is the big problem. If you're not moving up far enough, you squish down the extruded plastic and it can blob out of the edge like that.

So, if you measure a filament diameter range of 2.7-2.78, try printing at 2.82. So with your measurements, try 3.15

But, i'll bet your Z travel is the big problem. If you're not moving up far enough, you squish down the extruded plastic and it can blob out of the edge like that.

Sorry, only registered users may post in this forum.