Hybrid Delta-Cartesian

Posted by CellJeffe

|

Hybrid Delta-Cartesian June 25, 2014 12:18AM |

Registered: 10 years ago Posts: 37 |

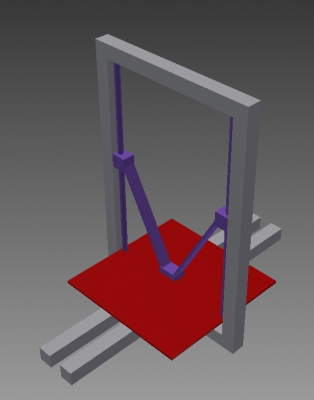

I have been dreaming up my next printer and wondered if anyone had built a hybrid delta-cartesian printer. I am thinking of Y-Z axes provided by two delta arms on either side and an X axis provided by a more traditional cartesian sliding plate underneath the two arms. The advantage over a standard 3-axis delta would be a rectangular build volume. The hybrid delta might have a slight advantage over a full cartesian because of the lighter extruder platform of the delta. Because of the lighter weight, the two vertical delta arms could use belts rather than lead-screws for vertical motion.

(I am certainly willing to bet that it has been contemplated before, but can't find any discussions on the merits.)

Thoughts?

(I am certainly willing to bet that it has been contemplated before, but can't find any discussions on the merits.)

Thoughts?

|

Re: Hybrid Delta-Cartesian June 25, 2014 02:44PM |

Registered: 10 years ago Posts: 172 |

|

Re: Hybrid Delta-Cartesian June 25, 2014 03:04PM |

Registered: 10 years ago Posts: 469 |

That looks like an awesome printer. Why not add a double table? The idea lends itself to a printer capable of doing a 500mmx300mmx500mm build volume. Huge prints here we come? You have mixed the high speed head of the delta with the capability of having a moving build table. Not bad!

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Hybrid Delta-Cartesian June 25, 2014 03:41PM |

Registered: 10 years ago Posts: 37 |

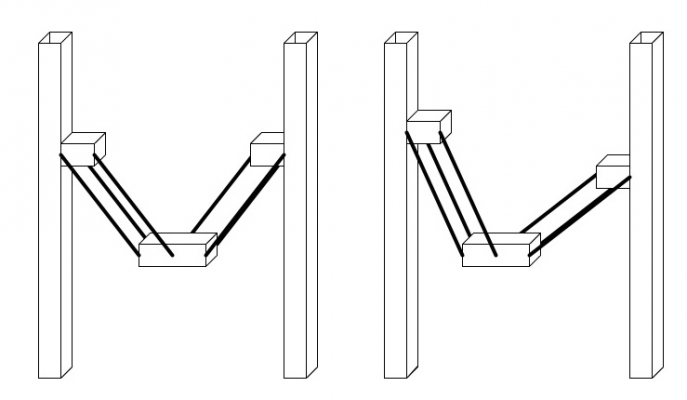

One would actually need 3 connections on at least one side to keep the extruder parallel to the plate. Two of the delta connecting rods would always form a parallelogram with the extruder plate. The other side could be 180 degree rotationally symmetric, so 6 arms in all between the sides and the extruder plate to keep things parallel.

And it would definitely need delta-style extra hight to get cartesian-style z-build volume. But hey, belts are cheap, a little extra extrusion would not cost that much more.

Edited 1 time(s). Last edit at 06/25/2014 03:45PM by CellJeffe.

And it would definitely need delta-style extra hight to get cartesian-style z-build volume. But hey, belts are cheap, a little extra extrusion would not cost that much more.

Edited 1 time(s). Last edit at 06/25/2014 03:45PM by CellJeffe.

|

Re: Hybrid Delta-Cartesian June 25, 2014 04:14PM |

Registered: 10 years ago Posts: 469 |

That can be done in reality with only two arms, however they have to have some torsional stability about them, the rest would have to be compensated for in the software.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Hybrid Delta-Cartesian June 28, 2014 10:48PM |

Registered: 9 years ago Posts: 1 |

|

Re: Hybrid Delta-Cartesian June 30, 2014 04:08PM |

Registered: 11 years ago Posts: 408 |

It s a vert good design !!

------------------------------------------------------------------------------------------------------------

Blog de GeeK: [www.zem.fr]

Reprap Prusa Mendel V2 pour 500€: [www.zem.fr]

------------------------------------------------------------------------------------------------------------

Blog de GeeK: [www.zem.fr]

Reprap Prusa Mendel V2 pour 500€: [www.zem.fr]

|

Re: Hybrid Delta-Cartesian June 30, 2014 05:50PM |

Registered: 10 years ago Posts: 37 |

Thanks all. Although I am surprised that I have not seen other hybrid deltas. I'm still working out some other fun design elements for this printer...

|

Re: Hybrid Delta-Cartesian July 01, 2014 07:36AM |

Registered: 11 years ago Posts: 408 |

Wtf?

------------------------------------------------------------------------------------------------------------

Blog de GeeK: [www.zem.fr]

Reprap Prusa Mendel V2 pour 500€: [www.zem.fr]

------------------------------------------------------------------------------------------------------------

Blog de GeeK: [www.zem.fr]

Reprap Prusa Mendel V2 pour 500€: [www.zem.fr]

|

Re: Hybrid Delta-Cartesian July 01, 2014 10:09AM |

Registered: 10 years ago Posts: 37 |

|

Re: Hybrid Delta-Cartesian July 01, 2014 03:04PM |

Registered: 10 years ago Posts: 172 |

Two arms won't cut it. The platform will still have a degree of freedom to rotate out of parallel with the bed if you don't have a parallel arm setup - at least on one carriage.

Also, having a moving bed in Y negates the high-speed advantaged gained by having X on a "delta-hybrid" platfrom. I3's, for instance, are limited, in X/Y, by the Y bed moving, not the X-carriage.

You would definitely gain speed in Z but how much is that really an advantage? I don't find myself needing a faster Z-axis on my I3. What scenarios would you need a faster Z? highly unlevel and fast printing?

Also, having a moving bed in Y negates the high-speed advantaged gained by having X on a "delta-hybrid" platfrom. I3's, for instance, are limited, in X/Y, by the Y bed moving, not the X-carriage.

You would definitely gain speed in Z but how much is that really an advantage? I don't find myself needing a faster Z-axis on my I3. What scenarios would you need a faster Z? highly unlevel and fast printing?

|

Re: Hybrid Delta-Cartesian July 01, 2014 03:36PM |

Registered: 10 years ago Posts: 37 |

Yes. I definitely need three arms per side to keep things parallel. Speed will certainly also be an issue with the moving build platform.

However, the design does have the advantage of only 3 motors for full X-Y-Z motion instead of 4 motors of a more traditional cartesian style printer. Instead of one motor/rail/belt for the X platform, two linear rails and 2 motors/lead screws in Z and one motor/belt/rail for Y, the hybrid would only use three motors/rails in total.

The other advantage is that with a much lighter Z axis, it can use belts or even rack and pinion drive on the Z axis instead of lead screws. A lighter Z-axis is less likely to fall down and go boom upon power loss.

With a hybrid design, there certainly are tradeoffs. The design would likely be as slow as a cartesian, but with thr rectangular build volume of a cartesian, and a few delta-style benefits (i.e. cheaper, lighter, simpler rail system and frame). But taller, and harder to program and level than a cartesian.

Edited 1 time(s). Last edit at 07/01/2014 03:37PM by CellJeffe.

However, the design does have the advantage of only 3 motors for full X-Y-Z motion instead of 4 motors of a more traditional cartesian style printer. Instead of one motor/rail/belt for the X platform, two linear rails and 2 motors/lead screws in Z and one motor/belt/rail for Y, the hybrid would only use three motors/rails in total.

The other advantage is that with a much lighter Z axis, it can use belts or even rack and pinion drive on the Z axis instead of lead screws. A lighter Z-axis is less likely to fall down and go boom upon power loss.

With a hybrid design, there certainly are tradeoffs. The design would likely be as slow as a cartesian, but with thr rectangular build volume of a cartesian, and a few delta-style benefits (i.e. cheaper, lighter, simpler rail system and frame). But taller, and harder to program and level than a cartesian.

Edited 1 time(s). Last edit at 07/01/2014 03:37PM by CellJeffe.

|

Re: Hybrid Delta-Cartesian July 01, 2014 04:08PM |

Registered: 10 years ago Posts: 790 |

I know of more 3 motor cartesians than 4 motor, where are you grabbing this information? I've got a 3 motor cart. myself and have no issue related to not enough motors.Quote

CellJeffe

However, the design does have the advantage of only 3 motors for full X-Y

Don't see how it's lighter than other options are possible with, but I also can't recall a single event where a bed has fallen on power loss, belt and especially not screw.Quote

CellJeffe

The other advantage is that with a much lighter Z axis, it can use belts or even rack and pinion drive on the Z axis instead of lead screws. A lighter Z-axis is less likely to fall down and go boom upon power loss.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Hybrid Delta-Cartesian July 01, 2014 04:11PM |

Registered: 10 years ago Posts: 790 |

The only advantage I see in this is a more scalable Z-axis, but a Delta can already do that much. Maybe even go so far as to say a faster Z-axis will allow a higher Z lift on retract for more impact avoidance on move. I find what I can do with my cartesian most sufficient for that, though.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Hybrid Delta-Cartesian July 03, 2014 05:19PM |

Registered: 10 years ago Posts: 37 |

Quote

MrDoctorDIV

I know of more 3 motor cartesians than 4 motor, where are you grabbing this information? I've got a 3 motor cart. myself and have no issue related to not enough motors.Quote

CellJeffe

However, the design does have the advantage of only 3 motors for full X-Y-Z

Yeah, good call. I was mostly thinking of Prusa/Mendel-style cartesians when I wrote that. In fact, I have a 3-axis-motor SmartRap right in front of me and gave it the short shrift! I have seen H-bots and core-xy cartesians with 3 motors, along with the Wally. Now I'm curious about your design.

One of the other motivations (besides reduced carriage hardware) was that I was thinking of how one might make a printer with all rack-and-pinion drives. I switched my SmartRap X&Y axes over from string to GT2 belts to herringbone R&P and have been quite impressed with the smoothness of the printouts from R&P. The hybrid delta was my initial answer for a larger/sturdier all R&P printer (R&P on Z too). Motor/pinion at the top of each arm to lift a rack connected to a carriage lower down. (Just don't stare down at the printer from above or risk getting poked in the eye by a rising rack end.)

Part of experimentation is being smart enough to know why something probably won't work, but being stupid enough to try it anyway - as long as it doesn't turn into a "here, hold my beer" Darwin award.

I might still try the hybrid delta just for the heck of it. It's all fun and games until somebody puts an eye out.

|

Re: Hybrid Delta-Cartesian July 03, 2014 10:09PM |

Registered: 11 years ago Posts: 979 |

This would be a fun build. Check out this video for some inspiration. It shows a very similar idea.

Edited 1 time(s). Last edit at 07/03/2014 10:09PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

Edited 1 time(s). Last edit at 07/03/2014 10:09PM by nicholas.seward.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

|

Re: Hybrid Delta-Cartesian July 04, 2014 10:57AM |

Registered: 10 years ago Posts: 790 |

I can see use in lack of leadscrews, yeah. That's actually a fair use for it, cutting cost. I have seen other non-leadscrew systems, however, and still question if this would be a real solution beyond what is already here. Especially since you are greatly reducing Z axis resolution.

Other than that, I'd say go for it. We may not see a current real use, but one might come around.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Other than that, I'd say go for it. We may not see a current real use, but one might come around.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Sorry, only registered users may post in this forum.