|

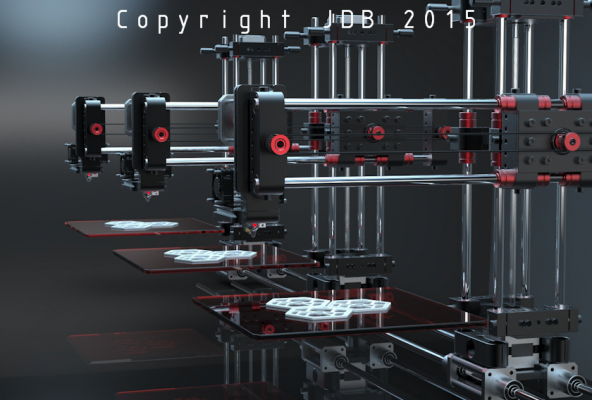

Four SCARA´s on one table? August 23, 2015 09:55AM |

Registered: 8 years ago Posts: 5,232 |

Hi guys,

inspired by the proposal of user " C0rpse", I had a vision of four SCARA bots sharing one big printbed.

TBH, I haven´t spent too much time searching for projects with the same idea, so forgive me if it had been discussed earlier.

I made some napkin sketches to show the options and want to discuss the feasibility with you.

Assumptions:

The part had to be split in 4 pieces and sliced/printed separately.

Z-height control:

Every SCARA would have it´s own controller plus one output pin and three input pins to share " layer done" status.

Whenever one bot is finished with it´s layer, it reads the layer done flags and set its own flag. If there are less than 3 flags set, the bot pauses the print and moves in a parking position.

The last bot finishing its duty, will see 3 valid flags, initiates the z-raise and then sets its own flag.

The other bots then see 3 valid flags too and resume their printing.

Collision control:

Every bot has a safe print area were collision with the other arms is impossible, but there is a zone were the arms can collide.

I see two options here:

1. The slicer would write the g-code in a way, that all bots start at one corner ( eg. bottom/left ) and end in the opposite corner.

A whole new slicing engine would be necessary.

2. The controller would have two more input pins and one output pin to signalize, it is printing in the collision zone.

The controller would pause the print, when it only sees a collision flag on the input and sets a flag " next one " to organize priority.

Any other controller trying to print in the collision zone would see the collision- and next one- flag and would wait until it is safe to print.

What do you think?

-Olaf

Edited 4 time(s). Last edit at 08/23/2015 10:04AM by o_lampe.

inspired by the proposal of user " C0rpse", I had a vision of four SCARA bots sharing one big printbed.

TBH, I haven´t spent too much time searching for projects with the same idea, so forgive me if it had been discussed earlier.

I made some napkin sketches to show the options and want to discuss the feasibility with you.

Assumptions:

The part had to be split in 4 pieces and sliced/printed separately.

Z-height control:

Every SCARA would have it´s own controller plus one output pin and three input pins to share " layer done" status.

Whenever one bot is finished with it´s layer, it reads the layer done flags and set its own flag. If there are less than 3 flags set, the bot pauses the print and moves in a parking position.

The last bot finishing its duty, will see 3 valid flags, initiates the z-raise and then sets its own flag.

The other bots then see 3 valid flags too and resume their printing.

Collision control:

Every bot has a safe print area were collision with the other arms is impossible, but there is a zone were the arms can collide.

I see two options here:

1. The slicer would write the g-code in a way, that all bots start at one corner ( eg. bottom/left ) and end in the opposite corner.

A whole new slicing engine would be necessary.

2. The controller would have two more input pins and one output pin to signalize, it is printing in the collision zone.

The controller would pause the print, when it only sees a collision flag on the input and sets a flag " next one " to organize priority.

Any other controller trying to print in the collision zone would see the collision- and next one- flag and would wait until it is safe to print.

What do you think?

-Olaf

Edited 4 time(s). Last edit at 08/23/2015 10:04AM by o_lampe.

|

Re: Four SCARA´s on one table? August 24, 2015 04:06AM |

Registered: 8 years ago Posts: 5,232 |

Last night, I revised the design and had the idea to use serial scara arms. This would reduce the collision zone.

I have a simple design in mind, where the arm is moved only by one stepper. A fishing line is pulling the printhead against the spring loaded elbow joint.

Another stepper turns the arm vertically. A mixup of a polar arm and a scara.

Try to make a drawing of it

-Olaf

I have a simple design in mind, where the arm is moved only by one stepper. A fishing line is pulling the printhead against the spring loaded elbow joint.

Another stepper turns the arm vertically. A mixup of a polar arm and a scara.

Try to make a drawing of it

-Olaf

|

Re: Four SCARA´s on one table? October 31, 2015 12:53PM |

Registered: 9 years ago Posts: 1,035 |

A CAD sketch would help visualizing the concept.It sounds interesting.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Four SCARA´s on one table? March 08, 2016 01:53AM |

Registered: 8 years ago Posts: 1,671 |

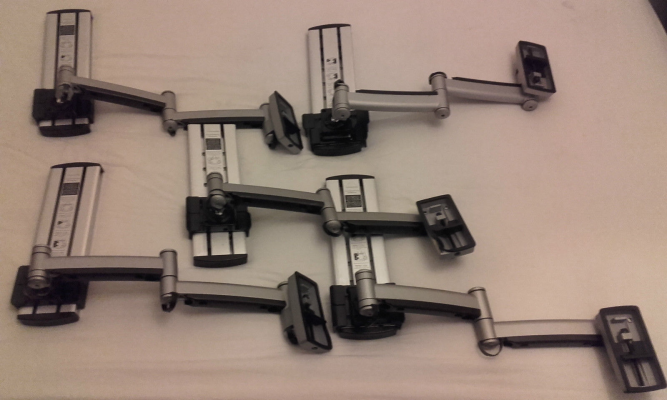

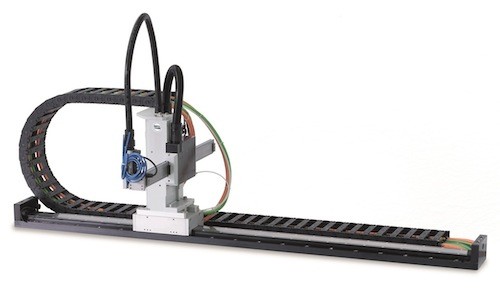

I just bought these to play with maybe I can make four scara's out of them.

Edited 1 time(s). Last edit at 03/08/2016 01:55AM by MechaBits.

Edited 1 time(s). Last edit at 03/08/2016 01:55AM by MechaBits.

|

Re: Four SCARA´s on one table? March 08, 2016 03:26AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Four SCARA´s on one table? March 08, 2016 06:08AM |

Registered: 9 years ago Posts: 1,035 |

I couldn't find anything with bearings in the joints when designing my scara. But I often thought about the LCD swiveling wall mounts.

Can't wait to see what you come up with.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Can't wait to see what you come up with.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Four SCARA´s on one table? March 08, 2016 07:33AM |

Registered: 8 years ago Posts: 1,671 |

it all rests on what I find in those joints...if I can add bearings, longer bolt, actuator points, i'm thinking some kinda rubber wheel to clamp arm, so it rolls as it swings, I wonder if the piece that mounts to the extrusion is plastic...but still might be able to use the extrusion as feet for my other printer...not sure but for a tenner I'm sure it will come in handy for something. But the more I read about scara's the less confident I get about making it work.

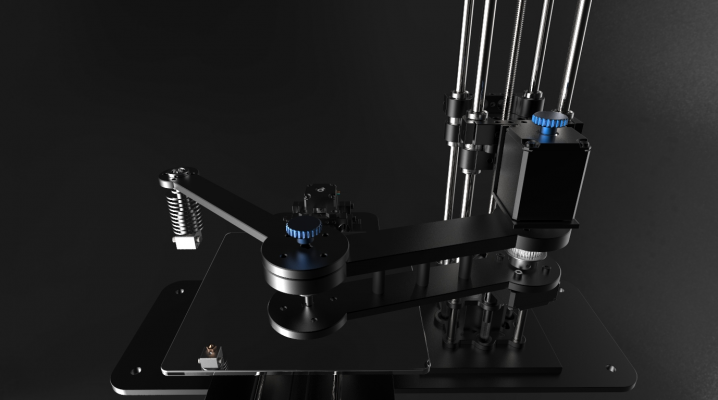

this is as far as I got before getting above parts, I realize the cogs are the wrong way round and there's still a lot to add, and it probably doesnt need the bed to move...but better minds than mine have already taught me enough to know it's going to be tricky...

don't hold your breath

Edited 2 time(s). Last edit at 03/08/2016 07:51AM by MechaBits.

this is as far as I got before getting above parts, I realize the cogs are the wrong way round and there's still a lot to add, and it probably doesnt need the bed to move...but better minds than mine have already taught me enough to know it's going to be tricky...

don't hold your breath

Edited 2 time(s). Last edit at 03/08/2016 07:51AM by MechaBits.

|

Re: Four SCARA´s on one table? March 08, 2016 07:42AM |

Registered: 9 years ago Posts: 1,035 |

Yes, making it work is the real issue. The rigidity must be high and the reduction mechanics must be backlash-free. In my early Lander design I could achieve that with spectra line in a bed-rock design but with gears you'll get very expensive for reduced backlash. Remember that whichever backlash you have at the source of motion, in your case the geared stepper, you will amplify it greatly at the end of each arm (it acts like a lever). That's why they use Harmonic Drives in these kinds of robots. It's backlash-free.

Another upped quality addition would be torsional bearings, some that are quite large and flat, to counter the vertical tilting/etc.

But your sketch looks promising.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Another upped quality addition would be torsional bearings, some that are quite large and flat, to counter the vertical tilting/etc.

But your sketch looks promising.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Four SCARA´s on one table? March 12, 2016 11:12PM |

Registered: 8 years ago Posts: 1,671 |

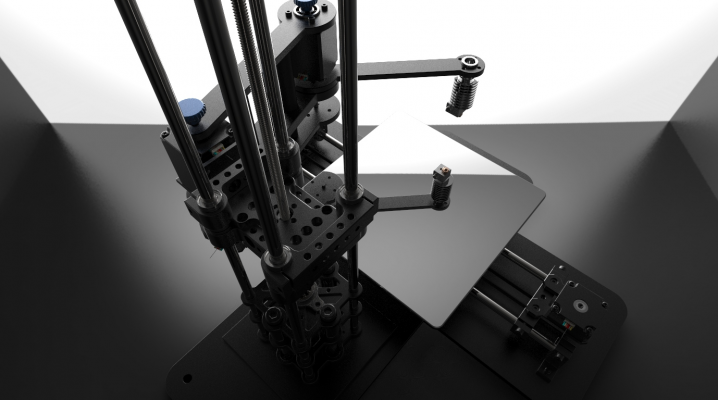

Imagine this monster on a table..

After mulling over the 5 arms for a day or 2(what a bargain), I think I'll be able to put them to use.

the alu profile has a spring mechanism inside, 3 settings of force, or disengaged,

the carriage slides quite smooth, a little play, but removed when things are in tension, load on arm,

whats good about these springs is, I can have a Z screw stopping the carriage from wanting to rise,

but have a fully loaded arm sort of weightless.

the carriage has a strong ball joint and can keep loaded arm level,

I disassembled arm joint to check out whats going on, reassembled many times, trying to get optimal fit with bearings I had...

and I managed to get it very smooth, finger touch, but if I get a few better bearings i could probably improve a little.

there are some places I could attach servo horn about inch away from pin center, but want to try out belts.

So i've not given up yet, want to take it a little further.

I have a part from an astral telescope I fitted to the end of the arm, which has a shaft for attaching motor to drive rotation,

so could be a nice tool holder, even if I could get this thing to be a 'mini milo', camera motion control rig, that would be a useful result.

who knows maybe I could use the spare arms in sarus arrangement for rise n fall table?

it has a 14mm D shaft in there(which has 8mm female each end) and brass bushes, so rotate the pin the arm will spin.

Unfortunately I ordered some extra pulleys with 5mm shaft not 8.... so more wait...but a 14mm shaft coupler would be the ideal,

14mm ID bearing options dont seem as prevalent as 15mm ones, might have to spend about £50 on bearings just to try them out, lets hope it's not a dead end.

After mulling over the 5 arms for a day or 2(what a bargain), I think I'll be able to put them to use.

the alu profile has a spring mechanism inside, 3 settings of force, or disengaged,

the carriage slides quite smooth, a little play, but removed when things are in tension, load on arm,

whats good about these springs is, I can have a Z screw stopping the carriage from wanting to rise,

but have a fully loaded arm sort of weightless.

the carriage has a strong ball joint and can keep loaded arm level,

I disassembled arm joint to check out whats going on, reassembled many times, trying to get optimal fit with bearings I had...

and I managed to get it very smooth, finger touch, but if I get a few better bearings i could probably improve a little.

there are some places I could attach servo horn about inch away from pin center, but want to try out belts.

So i've not given up yet, want to take it a little further.

I have a part from an astral telescope I fitted to the end of the arm, which has a shaft for attaching motor to drive rotation,

so could be a nice tool holder, even if I could get this thing to be a 'mini milo', camera motion control rig, that would be a useful result.

who knows maybe I could use the spare arms in sarus arrangement for rise n fall table?

it has a 14mm D shaft in there(which has 8mm female each end) and brass bushes, so rotate the pin the arm will spin.

Unfortunately I ordered some extra pulleys with 5mm shaft not 8.... so more wait...but a 14mm shaft coupler would be the ideal,

14mm ID bearing options dont seem as prevalent as 15mm ones, might have to spend about £50 on bearings just to try them out, lets hope it's not a dead end.

|

Re: Four SCARA´s on one table? March 13, 2016 04:28AM |

Registered: 9 years ago Posts: 1,035 |

They can do it now with cartesian printers: [vimeo.com] (Autodesk's Project Escher connects multiple 3D printers for faster, scalable large-format 3D printing). Maybe that can be of inspiration somehow.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Four SCARA´s on one table? March 13, 2016 06:10AM |

Registered: 8 years ago Posts: 1,671 |

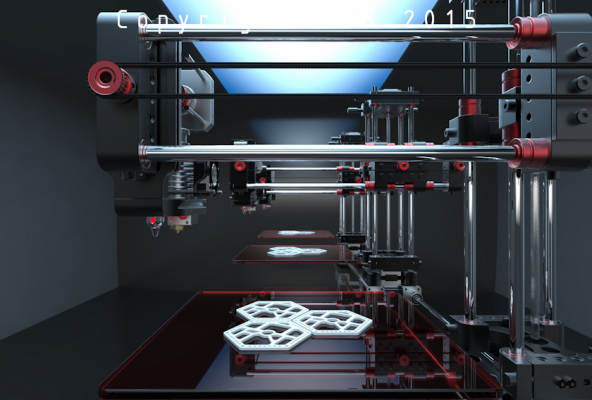

Yes I saw that and it reminded me of one of my renders(and the reason I had to do it all with smoke & mirrors)

But they have continuous bed, and much stronger frame, & more resources.

Having a large machine like that, that can work with multi materials additive & subtractive

can't come soon enough.

Maybe 4 machines like this would be a better solution than scara's, but still fun to play with the ideas.

[www.motioncontrol.com]

The endless permutations...the mind boggles, the possibilities of the promise, and the hope that it's just beyond the horizon...

just over the hill, turn left at the mountain, bypass an ocean of time, wait for the slow boat from china, look out for dragons, avoid the pit of procrastination, swing with the pendulum, lest you loose it on the roundabout.

Edited 6 time(s). Last edit at 03/13/2016 06:14PM by MechaBits.

But they have continuous bed, and much stronger frame, & more resources.

Having a large machine like that, that can work with multi materials additive & subtractive

can't come soon enough.

Maybe 4 machines like this would be a better solution than scara's, but still fun to play with the ideas.

[www.motioncontrol.com]

The endless permutations...the mind boggles, the possibilities of the promise, and the hope that it's just beyond the horizon...

just over the hill, turn left at the mountain, bypass an ocean of time, wait for the slow boat from china, look out for dragons, avoid the pit of procrastination, swing with the pendulum, lest you loose it on the roundabout.

Edited 6 time(s). Last edit at 03/13/2016 06:14PM by MechaBits.

|

Re: Four SCARA´s on one table? March 21, 2016 12:45PM |

Registered: 8 years ago Posts: 1,671 |

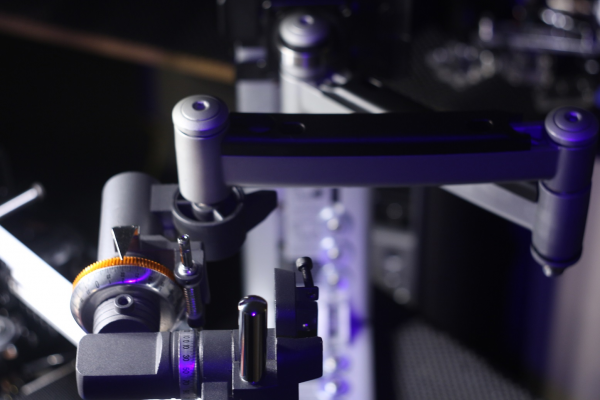

So Close but yet so far from anything functional.

|

Re: Four SCARA´s on one table? March 21, 2016 01:53PM |

Registered: 9 years ago Posts: 1,035 |

you have a talent for making "Kickstarter"-like photos  ...keep up...we're eager to see more.

...keep up...we're eager to see more.

Edited 1 time(s). Last edit at 03/21/2016 03:31PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

...keep up...we're eager to see more.

...keep up...we're eager to see more.Edited 1 time(s). Last edit at 03/21/2016 03:31PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Four SCARA´s on one table? March 21, 2016 02:31PM |

Registered: 8 years ago Posts: 1,671 |

What the hells a Likstarter ?

I have many more pics, dont really want to post all to blog unless I can find a better way,

long post of pics are a little ...long...cant be bothered to keep adding galleries,

need a better more dynamic way embedded in post, will have to see whats new in latest lightroom.

I have many more pics, dont really want to post all to blog unless I can find a better way,

long post of pics are a little ...long...cant be bothered to keep adding galleries,

need a better more dynamic way embedded in post, will have to see whats new in latest lightroom.

|

Re: Four SCARA´s on one table? March 21, 2016 03:32PM |

Registered: 9 years ago Posts: 1,035 |

I meant Kickstarter ...corrected  . I mean they are very well done, with mood and all ... almost like a marketing promo. I like them...quite artistic.

. I mean they are very well done, with mood and all ... almost like a marketing promo. I like them...quite artistic.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

. I mean they are very well done, with mood and all ... almost like a marketing promo. I like them...quite artistic.

. I mean they are very well done, with mood and all ... almost like a marketing promo. I like them...quite artistic.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Four SCARA´s on one table? March 21, 2016 04:26PM |

Registered: 8 years ago Posts: 1,671 |

I thought it was some new twitter LikList net Lingo that I hadnt heard,

the great thing about pictures is "click" done...most the pics I take are just as I see things,

opportunistic moments, not done much studio work, so it's fun to be able to control the set, the rest of the place is a tip

even more fun when its for your own machine design, these things evolving into something real rather than rendered,

interesting to see how the design has to change to accommodate new parts, it is a closed feedback loop (but I suppose open to suggestions)

I've spent so long making images in the computer, presided over many a 12 hour render,

having your own MechaTronic Puppets to work with is great, they look/pose just how want them,

people blink twitch or move, and it can be a little trickier to get the right angle, at the same time as everything else is in place,

but yeah experimenting with a little set design for a short noir sci-fi movie...it's feeding a number of neurons with the right endorphins

...

Edited 1 time(s). Last edit at 03/22/2016 04:45AM by MechaBits.

the great thing about pictures is "click" done...most the pics I take are just as I see things,

opportunistic moments, not done much studio work, so it's fun to be able to control the set, the rest of the place is a tip

even more fun when its for your own machine design, these things evolving into something real rather than rendered,

interesting to see how the design has to change to accommodate new parts, it is a closed feedback loop (but I suppose open to suggestions)

I've spent so long making images in the computer, presided over many a 12 hour render,

having your own MechaTronic Puppets to work with is great, they look/pose just how want them,

people blink twitch or move, and it can be a little trickier to get the right angle, at the same time as everything else is in place,

but yeah experimenting with a little set design for a short noir sci-fi movie...it's feeding a number of neurons with the right endorphins

...

Edited 1 time(s). Last edit at 03/22/2016 04:45AM by MechaBits.

|

Re: Four SCARA´s on one table? April 15, 2016 08:22AM |

Registered: 15 years ago Posts: 376 |

An interesting idea to have many SCARA arms together. It seems that you may be confused as to what you want to achieve as you are discussing two very alternative approaches.

1) 4 SCARAs in one build area. This will require a bit more programming for collision detection, but this would be quite interesting to do. The only advantage you are really getting is reduced build time. If you want a larger print area and are not interested in rapid builds, just build a larger SCARA or place the SCARA base on a linear rail (This is done a lot in industry particularly on automotive assembly lines). The strange shaped build area of a SCARA is a limitation, so for large builds a cartesian is probably a better way to go.

2) SCARA robots in series. This is much simpler to develop, but if you are making one offs you don't achieve any faster build times . This is only an advantage if you are making many similar parts (i.e in production line ) and each station needs to do a different operation. If you are producing many of the same parts, using them in parallel (ie each robot making 1 complete part) is better as this is a more reliable system. This is because one failed print scraps one part. With an in line approach one failed print scraps all parts that pass through that station.

This is a really interesting concept you are trying and hasn't been explored enough in the reprap community, so I encourage you to continue. My qualifications are in Production Engineering, so if you want any help deciding on whats the best configuration for what you want to achieve let me know.

Helium Frog Website

1) 4 SCARAs in one build area. This will require a bit more programming for collision detection, but this would be quite interesting to do. The only advantage you are really getting is reduced build time. If you want a larger print area and are not interested in rapid builds, just build a larger SCARA or place the SCARA base on a linear rail (This is done a lot in industry particularly on automotive assembly lines). The strange shaped build area of a SCARA is a limitation, so for large builds a cartesian is probably a better way to go.

2) SCARA robots in series. This is much simpler to develop, but if you are making one offs you don't achieve any faster build times . This is only an advantage if you are making many similar parts (i.e in production line ) and each station needs to do a different operation. If you are producing many of the same parts, using them in parallel (ie each robot making 1 complete part) is better as this is a more reliable system. This is because one failed print scraps one part. With an in line approach one failed print scraps all parts that pass through that station.

This is a really interesting concept you are trying and hasn't been explored enough in the reprap community, so I encourage you to continue. My qualifications are in Production Engineering, so if you want any help deciding on whats the best configuration for what you want to achieve let me know.

Helium Frog Website

|

Re: Four SCARA´s on one table? April 16, 2016 04:00AM |

Registered: 8 years ago Posts: 5,232 |

Thanks a lot for the encouragement to move on, but I will not be able to do so myself. ( time and financial reasons )

I'm posting all my ideas in hope to find some interested people to build them or merge them into their own projects.

The multi color idea is new to me, but we would have no mixing function, only a four color/material option.

You are right when you say the risk of failure on a multi extruder printer is higher, but with my approach you'd have the choice of printing bigger parts or multiple identical parts.

IMHO the risk of a extruder jam or clogging is related to the amount of filament extruded ( and the filament quality ), which would be the same with one extruder or four extruders.

Overheating steppers or stepper drivers are just a consequence of misconception/bad adjustment. So this source of failure can be eliminated. ( same as filament quality )

I'm posting all my ideas in hope to find some interested people to build them or merge them into their own projects.

The multi color idea is new to me, but we would have no mixing function, only a four color/material option.

You are right when you say the risk of failure on a multi extruder printer is higher, but with my approach you'd have the choice of printing bigger parts or multiple identical parts.

IMHO the risk of a extruder jam or clogging is related to the amount of filament extruded ( and the filament quality ), which would be the same with one extruder or four extruders.

Overheating steppers or stepper drivers are just a consequence of misconception/bad adjustment. So this source of failure can be eliminated. ( same as filament quality )

Sorry, only registered users may post in this forum.