Extrusion correctly calibrated - Top Layer not Solid

Posted by Ohmarinus

|

Extrusion correctly calibrated - Top Layer not Solid February 01, 2014 01:25PM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, I've correctly calibrated my E-steps, and have been printing a lot with my 2nd printer already, however, since I turned it into a 1.75mm bowden system instead of the 3mm system I had before, the infills on top layers are not closing the object well anymore.

No idea what to do to fix this.. I'm using Cura and have tried different infills and speeds and temperatures. However I think it's the software that is not calculating well how much filament needs to be extruded on the top layers. For example in the case of these images, it's the top layer that is resting on a bridged piece, so it should theoretically extrude a little more to get the lines closer to eachother.

Anyone knows any trick I can do to make it work? As you can see the side of the wall looks great and constant, so it's really not an E-step problem, it's perfectly extruding 100mm when I tell it to, it was off by only a little, I measured 99.99mm on five tries.

So stats:

- MendelMax

- 1.75mm J-head

- Bowden system

- Natural PLA

- E-steps calibrated near-perfectly

- Everything looks good and goes well except the few top layers

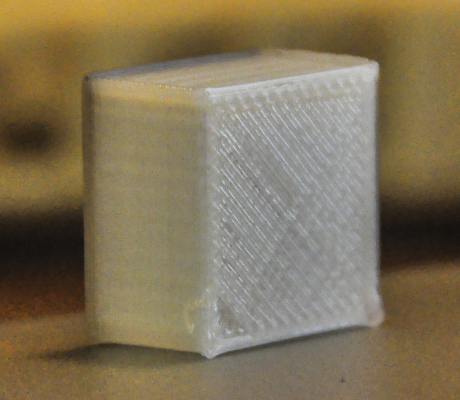

Top view of the hollow cube:

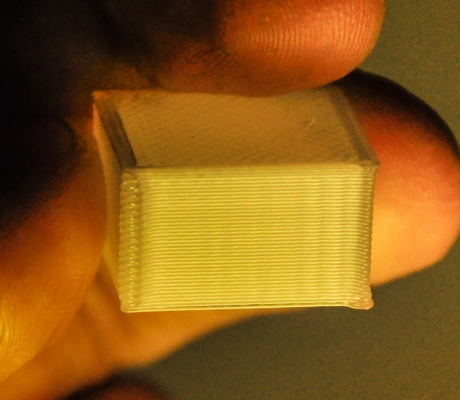

Side view of the cube:

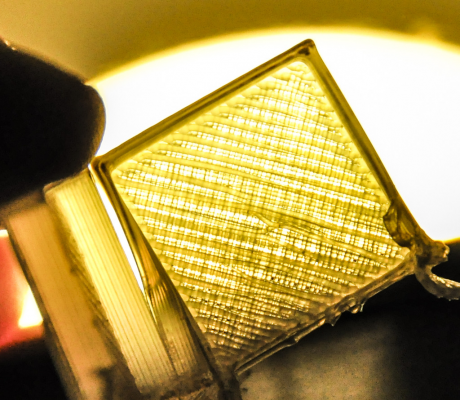

Top view from the inside:

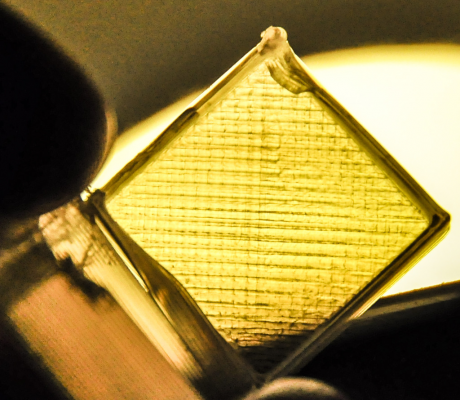

Bottom layer:

Edited 1 time(s). Last edit at 02/01/2014 01:40PM by Ohmarinus.

No idea what to do to fix this.. I'm using Cura and have tried different infills and speeds and temperatures. However I think it's the software that is not calculating well how much filament needs to be extruded on the top layers. For example in the case of these images, it's the top layer that is resting on a bridged piece, so it should theoretically extrude a little more to get the lines closer to eachother.

Anyone knows any trick I can do to make it work? As you can see the side of the wall looks great and constant, so it's really not an E-step problem, it's perfectly extruding 100mm when I tell it to, it was off by only a little, I measured 99.99mm on five tries.

So stats:

- MendelMax

- 1.75mm J-head

- Bowden system

- Natural PLA

- E-steps calibrated near-perfectly

- Everything looks good and goes well except the few top layers

Top view of the hollow cube:

Side view of the cube:

Top view from the inside:

Bottom layer:

Edited 1 time(s). Last edit at 02/01/2014 01:40PM by Ohmarinus.

|

Re: Extrusion correctly calibrated - Top Layer not Solid February 02, 2014 12:55AM |

Registered: 10 years ago Posts: 241 |

1: You can try more than 1 solid layer on the top. When you decrease the infill percentage, this leaves gaps that the next layer can sink down into. 2-3 layers can fill any gaps that get created.

2: Using a good caliper, measure the ACTUAL size of the filament. If it's measuring 1.65mm, this will create a HUGE! difference in volume actually being extruded since your software may think it's 1.75mm.

2: Using a good caliper, measure the ACTUAL size of the filament. If it's measuring 1.65mm, this will create a HUGE! difference in volume actually being extruded since your software may think it's 1.75mm.

|

Re: Extrusion correctly calibrated - Top Layer not Solid February 02, 2014 04:31AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, the filament is actually slightly thicker than 1.75mm I am quite extensive when it comes to calibrating, a year ago when I built my first 3D-printer, I bought a digital caliper and now with the second machine I calibrated everything to the exact values.

1: I am using 3 solid layers on bottom and top (and 2 perimeters in the walls of the object)

2: Like I explained, it's slightly thicker even and of course I measure it almost every time I print to make sure there is not too much variation and it has always been 1.75mm or slightly thicker

That why I don't get that this isn't working

1: I am using 3 solid layers on bottom and top (and 2 perimeters in the walls of the object)

2: Like I explained, it's slightly thicker even and of course I measure it almost every time I print to make sure there is not too much variation and it has always been 1.75mm or slightly thicker

That why I don't get that this isn't working

|

Re: Extrusion correctly calibrated - Top Layer not Solid February 02, 2014 03:13PM |

Registered: 10 years ago Posts: 241 |

|

Re: Extrusion correctly calibrated - Top Layer not Solid February 02, 2014 04:19PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

KingRahl

It may be your nozzle diameter vs. extruded width. Just like filament size, nozzle diameters can vary slightly. I've been hearing good things about Cura but haven't tried it myself yet. (I've installed it some time ago). Have you tried another program to see if you get the same result?

Yup, Cura is about 50% faster than Slic3r with printing, because it does all print moves much more logical, Slic3r had worse performance on printed parts also, so I don't miss it. However, I feel like Slic3r handles the top layers a little bit better and bridging is also a little better, but still Cura wins hands down for now. You would like to use the plugin to lower the bed temp after the first layer

|

Re: Extrusion correctly calibrated - Top Layer not Solid February 09, 2014 05:30PM |

Admin Registered: 11 years ago Posts: 3,096 |

So after five minutes of looking where the printing issues forum had gone, I found it again haha!

Still battling this weird problem. My prints come out perfect, great walls, nice detail on all surfaces, round tops are good too, but Cura just doesn't want me to have nice infill on flat top layers.

Even slowed down printing to 60mm/s in Cura, no improvement. I hope someone can point me to the solution

Still battling this weird problem. My prints come out perfect, great walls, nice detail on all surfaces, round tops are good too, but Cura just doesn't want me to have nice infill on flat top layers.

Even slowed down printing to 60mm/s in Cura, no improvement. I hope someone can point me to the solution

|

Re: Extrusion correctly calibrated - Top Layer not Solid February 12, 2014 07:17AM |

Admin Registered: 11 years ago Posts: 3,096 |

The most interesting problem was occuring. I have had to re-calibrate the extruder?

Somehow it extruded only 95.87mm instead of 100mm, while, 2 weeks ago, I did the -exact- same procedure to calibrate and it would extrude a perfect 100mm when I asked it to. The filament size has not changed, I check it constantly with my digital caliper.

Can it be that different filament has a different 'squeezyness' to it so the effective diameter of the gear that pushes the filament gets reduced?

My prints have been looking absolutely superb except the top and finally today even the bottom layers would not develop correctly.

Or... can a stepper motor/driver fail and degrade in steps/mm?

Now printing my first test object, I've been having strange problems with this machine, I double-checked in the LCD screen if the new steps/mm were indeed saved and yes they were so I have no clue why it was suddenly under-extruding 5mm's of filament.

Somehow it extruded only 95.87mm instead of 100mm, while, 2 weeks ago, I did the -exact- same procedure to calibrate and it would extrude a perfect 100mm when I asked it to. The filament size has not changed, I check it constantly with my digital caliper.

Can it be that different filament has a different 'squeezyness' to it so the effective diameter of the gear that pushes the filament gets reduced?

My prints have been looking absolutely superb except the top and finally today even the bottom layers would not develop correctly.

Or... can a stepper motor/driver fail and degrade in steps/mm?

Now printing my first test object, I've been having strange problems with this machine, I double-checked in the LCD screen if the new steps/mm were indeed saved and yes they were so I have no clue why it was suddenly under-extruding 5mm's of filament.

Sorry, only registered users may post in this forum.