Plastic Oozing from Hotend

Posted by logiwan992

|

Plastic Oozing from Hotend February 22, 2014 03:58PM |

Registered: 10 years ago Posts: 16 |

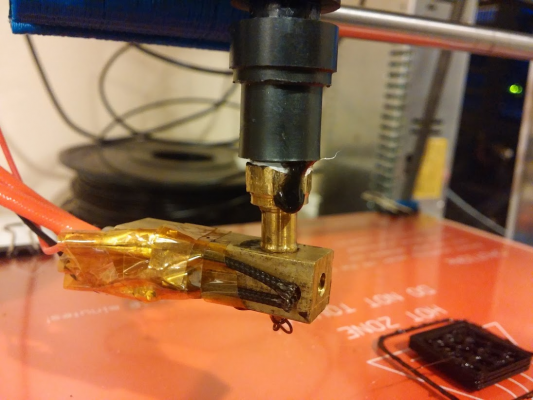

So I just got my prusa i3 up and running and got one good print out of it. On the second print though, plastic started oozing from where the brass nozzle screws into the black housing. Here is what I saw.

I just got this printer and it seems odd to have a problem like this right after getting it up and running. What could have caused this? Do I need to order a new hotend? Any help is greatly appreciated.

I just got this printer and it seems odd to have a problem like this right after getting it up and running. What could have caused this? Do I need to order a new hotend? Any help is greatly appreciated.

|

Re: Plastic Oozing from Hotend February 22, 2014 04:42PM |

Registered: 10 years ago Posts: 3 |

I just recently had my hot end start leaking. To fix it I took the brass piece apart like you did, cleaned off all plastic, then removed as much plastic from the hot end threads. I then wrapped the brass hot end in 1-2 layers of PTFE plubmers tape (it's about 1.00 USD at a local hardware store). It's worth a try and better than tossing the hot end in the trash.

|

Re: Plastic Oozing from Hotend February 22, 2014 06:06PM |

Registered: 10 years ago Posts: 16 |

Quote

jhenak

I just recently had my hot end start leaking. To fix it I took the brass piece apart like you did, cleaned off all plastic, then removed as much plastic from the hot end threads. I then wrapped the brass hot end in 1-2 layers of PTFE plubmers tape (it's about 1.00 USD at a local hardware store). It's worth a try and better than tossing the hot end in the trash.

Yeah I tried doing this but it started leaking again almost immediately. Is there anything else i can try to do? This is really frustrating.

|

Re: Plastic Oozing from Hotend February 22, 2014 09:16PM |

Registered: 10 years ago Posts: 1,381 |

A few ideas to consider:

It appears that you are using black filament.

If that is the case then try a natural uncolored filament.

Black filament has a high probability of having fillers, dirt, air, regrind, floor sweepings, etc blended into it.

You might be experiencing one jam after the another if there is dirt in or on the filament.

Try a larger orifice diameter, it might pass objects that would jam a smaller orifice.

In addition, you may have deformed threads, or the temperature is not reading correctly.

I see that the heater cartridge is orthogonal to the orifice, and fully embedded into the heater block, which is good, as that prolongs the life of the heater.

The hottest zone of the heater cartridge is located at the center of the cartridge, with the ends being not as hot.

Because of the orientation of the heater cartridge you may be running a higher temperature to achieve filament melt temperature, and the higher temperature of the block could be migrating up to the cold end.

Measure the temperature of the cold end at the threads to verify that it's not over heating.

It also looks like you are using a bespoke nozzle.

If you are the manufacturer of the nozzle, check the orifice diameter for size and burrs, and the length of the orifice land.

In general the land length should not be greater than 2 mm, and not less than 1 mm.

If the orifice land length is greater than 2 mm you may have more back pressure than what the sealing surface can hold.

The thermistor is also located on the far side of the heater block, opposite the heater cartridge.

This will cause the heater cartridge to run at a higher temperature.

Plastics will degrade, burn, and char at elevated temperatures, especially if it's not actively be extruded, burnt plastic could potentially block the orifice.

The thermistor should be located between the heat cartridge, and the orifice.

I suspect, but don't know that you might be operating the hot end at a temperature that it's not designed for.

Edited 1 time(s). Last edit at 02/22/2014 09:23PM by A2.

It appears that you are using black filament.

If that is the case then try a natural uncolored filament.

Black filament has a high probability of having fillers, dirt, air, regrind, floor sweepings, etc blended into it.

You might be experiencing one jam after the another if there is dirt in or on the filament.

Try a larger orifice diameter, it might pass objects that would jam a smaller orifice.

In addition, you may have deformed threads, or the temperature is not reading correctly.

I see that the heater cartridge is orthogonal to the orifice, and fully embedded into the heater block, which is good, as that prolongs the life of the heater.

The hottest zone of the heater cartridge is located at the center of the cartridge, with the ends being not as hot.

Because of the orientation of the heater cartridge you may be running a higher temperature to achieve filament melt temperature, and the higher temperature of the block could be migrating up to the cold end.

Measure the temperature of the cold end at the threads to verify that it's not over heating.

It also looks like you are using a bespoke nozzle.

If you are the manufacturer of the nozzle, check the orifice diameter for size and burrs, and the length of the orifice land.

In general the land length should not be greater than 2 mm, and not less than 1 mm.

If the orifice land length is greater than 2 mm you may have more back pressure than what the sealing surface can hold.

The thermistor is also located on the far side of the heater block, opposite the heater cartridge.

This will cause the heater cartridge to run at a higher temperature.

Plastics will degrade, burn, and char at elevated temperatures, especially if it's not actively be extruded, burnt plastic could potentially block the orifice.

The thermistor should be located between the heat cartridge, and the orifice.

I suspect, but don't know that you might be operating the hot end at a temperature that it's not designed for.

Edited 1 time(s). Last edit at 02/22/2014 09:23PM by A2.

|

Re: Plastic Oozing from Hotend February 23, 2014 12:12AM |

Registered: 10 years ago Posts: 16 |

So I added some ptfe tape to the threads and then sealed the outside with silicone sealant. I also tried printing at a lower temperature.

So far it is printing without any leaking.

Edited 1 time(s). Last edit at 02/23/2014 12:13AM by logiwan992.

So far it is printing without any leaking.

Edited 1 time(s). Last edit at 02/23/2014 12:13AM by logiwan992.

Sorry, only registered users may post in this forum.