Discovery about layer strength (adhesion)

Posted by tmorris9

|

Discovery about layer strength (adhesion) May 20, 2014 03:49AM |

Registered: 11 years ago Posts: 1,171 |

So I make a lot of GoPro mounts and while I have never had one break while mounted I worry about the layer strength since it's thin fingers and I can squeeze them and break them.

Well tonight while refining a design I had an epiphany. You see I always relied on perimeters for strength figuring the aligned layering was best but I thought maybe only a few perimeters and solid infill would be better than trying to make it solid with perimeters. This may be old news to some but I have been printing over 2.5 years now and never have seen or thought about this.

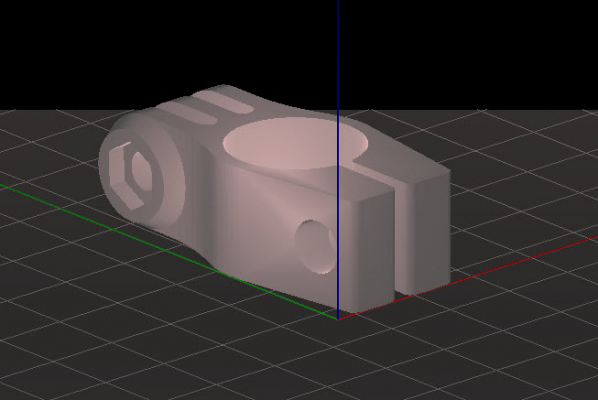

In the attached image I show where I purposely broke 2 mounts The one on the left had 2 perimeters and solid infill while the one on the right had 4 perimeters and solid infill Basically the infill can be seen as the white stripe in the middle. The white shows where the layers were connected best. The one on the left was much harder to break and in fact I had to use pliers where the other one broke by pinching it against the other wall with only my fingers

Well tonight while refining a design I had an epiphany. You see I always relied on perimeters for strength figuring the aligned layering was best but I thought maybe only a few perimeters and solid infill would be better than trying to make it solid with perimeters. This may be old news to some but I have been printing over 2.5 years now and never have seen or thought about this.

In the attached image I show where I purposely broke 2 mounts The one on the left had 2 perimeters and solid infill while the one on the right had 4 perimeters and solid infill Basically the infill can be seen as the white stripe in the middle. The white shows where the layers were connected best. The one on the left was much harder to break and in fact I had to use pliers where the other one broke by pinching it against the other wall with only my fingers

|

Re: Discovery about layer strength (adhesion) May 20, 2014 08:08AM |

Registered: 10 years ago Posts: 790 |

Not at all old news to me, you've given me new information.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Discovery about layer strength (adhesion) May 20, 2014 10:48AM |

Registered: 10 years ago Posts: 11 |

I noticed this as well when making a go-pro mount - then I decided to flip it so that it was printing the "fingers" on it's side, longitudinally. If you think solid layers are strong - this orientation was MUCH stronger! My concern was probably similar to yours - "I don't want to lose my GoPro if the mount breaks!"

-This is of course dependent on what your final design looks like, but you could always use rafting/support to force this side-oriented print.

-This is of course dependent on what your final design looks like, but you could always use rafting/support to force this side-oriented print.

|

Re: Discovery about layer strength (adhesion) May 20, 2014 05:46PM |

Registered: 11 years ago Posts: 1,171 |

I had actually designed one so the fingers were separate and laying flat on the heated bed and then used ABS to glue them together. This was the strongest way possible but messy and not good looking. I am really surprised at the strength improvement of my new settings. I won't worry about my mounts breaking anymore. Just a side note, I have actually broken original GoPro made mounts by squeezing them too hard when not attached to another mount. I can't do that with my new prints so that's something.

|

Re: Discovery about layer strength (adhesion) May 22, 2014 10:14AM |

Registered: 10 years ago Posts: 239 |

another thing to experiment with is to use 2 or 3 perimeters, 1-10% infill, solid infill every 3 or 4 layers then set the bridge flow ratio high like 10-15. Basically you are creating a 3-4 layer cavity then filling it on the 5th layer but not to the point were its smooth but has an irregular surface so the process can happen again, interlocking with the previous 3-4 layers. I have got this right several times and it essentially makes a solid part that wont delaminate. Just as anything else it takes some fiddling to get it right though

|

Re: Discovery about layer strength (adhesion) May 22, 2014 11:25PM |

Registered: 11 years ago Posts: 1,171 |

Strange, 2 days later I printed the same file with the same gcode and this time it was easy to break again.

Now I am really confused. The one that printed strong (2 actually) are very strong yet the same gcode file and the same filament now print one that is fragile.

Edited 1 time(s). Last edit at 05/22/2014 11:26PM by tmorris9.

Now I am really confused. The one that printed strong (2 actually) are very strong yet the same gcode file and the same filament now print one that is fragile.

Edited 1 time(s). Last edit at 05/22/2014 11:26PM by tmorris9.

|

Re: Discovery about layer strength (adhesion) May 23, 2014 06:18PM |

Registered: 11 years ago Posts: 205 |

|

Re: Discovery about layer strength (adhesion) May 23, 2014 06:24PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Discovery about layer strength (adhesion) May 23, 2014 10:24PM |

Registered: 11 years ago Posts: 1,171 |

|

Re: Discovery about layer strength (adhesion) May 23, 2014 10:26PM |

Registered: 11 years ago Posts: 1,171 |

Quote

A2

You need to orientate the object as mobile chernobyl depicted/suggested, as this places the fibers in tension. The way you have it printing the fibers are in shear when an orthogonal load is applied.

I do understand this but I am looking at the bigger picture. Some objects have thin parts in multiple directions or if you want to print without support. There should be a better way to improve layer adhesion, this part is just a very good test for this.

|

Re: Discovery about layer strength (adhesion) May 23, 2014 11:00PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Discovery about layer strength (adhesion) May 24, 2014 03:19AM |

Registered: 11 years ago Posts: 1,171 |

Thanks but I am trying to find a true fix not a compromised work around that limits how things are made. But I did have another little Eureka moment tonight. I think the cause of easy breakage (delamination) is too much cooling while printing. Then I thought I may have had the speed turned up in Repetier when I originally printed the good mount and had the normal speed later when I reprinted it and it broke.. So I turned off cooling all together in Slic3r and printed it. It's ugly as heck due to the speed / heat but I can't break it even with pliers. So, I am now on a quest to find the ideal "cooling" temperature so that parts look good but are strong. My printer originally came with default slic3r settings that had the cooling speed down to 1mms. Right now I am trying a print with cooling set to 40mms and so far it looks pretty good.

Once I do some testing and come to a conclusion I will return and post more.

Thanks for all the help, sometimes just posting the facts make you see things more clearly and find the solution.

Once I do some testing and come to a conclusion I will return and post more.

Thanks for all the help, sometimes just posting the facts make you see things more clearly and find the solution.

|

Re: Discovery about layer strength (adhesion) May 25, 2014 08:18AM |

Registered: 10 years ago Posts: 239 |

There appears to be a fairly small window between enough heat in the part to get really good layer bonding and too much heat causing distortion. Ideally the whole part should be fused together at once I think. I like A2's suggestion of internal structures. I don't see it as a band aid, more like a strategy for addressing the short comings of a laminated object.

Sorry, only registered users may post in this forum.