Prusa i3 Rework - Inconsistent Layers / Sparseness on Narrow Segments

Posted by elahd

|

Prusa i3 Rework - Inconsistent Layers / Sparseness on Narrow Segments June 19, 2015 11:22AM |

Registered: 8 years ago Posts: 6 |

Hi--

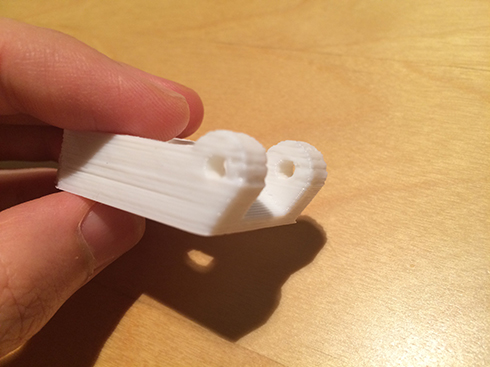

I'm running into issues with inconsistent layers, as seen in the photo. The picture is of the idler on the Prusa i3 Rework Extruder Upgrade.

I've tried:

* Extruder temperatures between 185 and 210 C.

* Print speeds between 20-40mms for perimiters / 30-60mms for fill

* Extruder DEFAULT_AXIS_STEPS_PER_UNIT between 550 and 600mms

* Cura's cold head lift function at 8 seconds minimum per layer

* Printing two idlers next to one another as alternative to cold head lift

No luck.

I'm also getting lots of stringiness and poorly filled layers on the idler's filament guide (not pictured). The stringiness is caused by my high exruder DEFAULT_AXIS_STEPS_PER_UNIT and cold head lift. If I reduce DEFAULT_AXIS_STEPS_PER_UNIT to ~500, the stringing goes away but consistency becomes sparse on infill in other layers.

Any ideas?

My setup:

* Prusa i3 Rework

* J-Head with .4mm nozzle (likely a knockoff - I bought it on eBay)

* PLA, 1.75mm

* Fan on at 100% for duration of print

* Heated bed at ~60 C, covered in kapton

* .3mm layer height

Any advice would be appreciated. Thanks!

Edited 2 time(s). Last edit at 06/19/2015 11:37AM by elahd.

I'm running into issues with inconsistent layers, as seen in the photo. The picture is of the idler on the Prusa i3 Rework Extruder Upgrade.

I've tried:

* Extruder temperatures between 185 and 210 C.

* Print speeds between 20-40mms for perimiters / 30-60mms for fill

* Extruder DEFAULT_AXIS_STEPS_PER_UNIT between 550 and 600mms

* Cura's cold head lift function at 8 seconds minimum per layer

* Printing two idlers next to one another as alternative to cold head lift

No luck.

I'm also getting lots of stringiness and poorly filled layers on the idler's filament guide (not pictured). The stringiness is caused by my high exruder DEFAULT_AXIS_STEPS_PER_UNIT and cold head lift. If I reduce DEFAULT_AXIS_STEPS_PER_UNIT to ~500, the stringing goes away but consistency becomes sparse on infill in other layers.

Any ideas?

My setup:

* Prusa i3 Rework

* J-Head with .4mm nozzle (likely a knockoff - I bought it on eBay)

* PLA, 1.75mm

* Fan on at 100% for duration of print

* Heated bed at ~60 C, covered in kapton

* .3mm layer height

Any advice would be appreciated. Thanks!

Edited 2 time(s). Last edit at 06/19/2015 11:37AM by elahd.

|

Re: Prusa i3 Rework - Inconsistent Layers / Sparseness on Narrow Segments June 22, 2015 05:28PM |

Registered: 10 years ago Posts: 581 |

Stringiness is cured by your retraction settings, not by steps per mm. The very first thing you need to do is calibrate your e-steps per mm, but the very-very first thing you need to do before that is to ensure that your extruder can extrude the same length of filament each and every time you ask it to. Mark off 120mm above the extruder, then extrude 100mm. Measure how much is left. Repeat. If the measurements are different, you need to get them consistent (normally by tweaking the guidler tension or reducing extrusion speed).

Once you've got that working, go on to the e steps per mm tuning guide on the reprap wiki. [reprap.org]

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

Once you've got that working, go on to the e steps per mm tuning guide on the reprap wiki. [reprap.org]

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Prusa i3 Rework - Inconsistent Layers / Sparseness on Narrow Segments June 24, 2015 10:36AM |

Registered: 8 years ago Posts: 6 |

|

Re: Prusa i3 Rework - Inconsistent Layers / Sparseness on Narrow Segments July 12, 2015 04:29PM |

Registered: 8 years ago Posts: 6 |

I solved the problem by doing a few things:

The photo shows 3 3Dbenchy prints. On the left is a print made with the J Head after tightening my motor and calibrating my cold end. In the middle is a print with the Lite6 using cold head lift. On the right is a print with the Lite6 with cold head lift off printed next to a tall chess piece to keep the extruder busy (and running) while some of the narrow portions of the 3Dbenchy cooled.

Thanks again for your help.

- First, my extruder motor was loose -- the screws must have loosened over time due to vibration -- so my motor wasn't making reliable contact with the main drive gear. I tightened the bolts and will check them regularly.

- Second, I calibrated my cold end at your suggestion by following this Thomas Sanladerer video guide.

- Third, I replaced my Chinese knockoff J Head extruder with an E3D Lite6. This, by far, made the biggest difference in print quality.

The photo shows 3 3Dbenchy prints. On the left is a print made with the J Head after tightening my motor and calibrating my cold end. In the middle is a print with the Lite6 using cold head lift. On the right is a print with the Lite6 with cold head lift off printed next to a tall chess piece to keep the extruder busy (and running) while some of the narrow portions of the 3Dbenchy cooled.

Thanks again for your help.

Sorry, only registered users may post in this forum.