Corner warping ABS

Posted by brucehvn

|

Corner warping ABS September 06, 2015 06:51PM |

Registered: 10 years ago Posts: 231 |

I've got a weird problem I haven't seen before. I'm starting a new roll of ABS filament. It's Shaxon brand from Fry's Electronics. I haven't used it before and I see mixed reviews of it. Some people seem to think it's fine, others say it's crap. This printer has been in service now for about a year and a half, so I've done many prints on it.

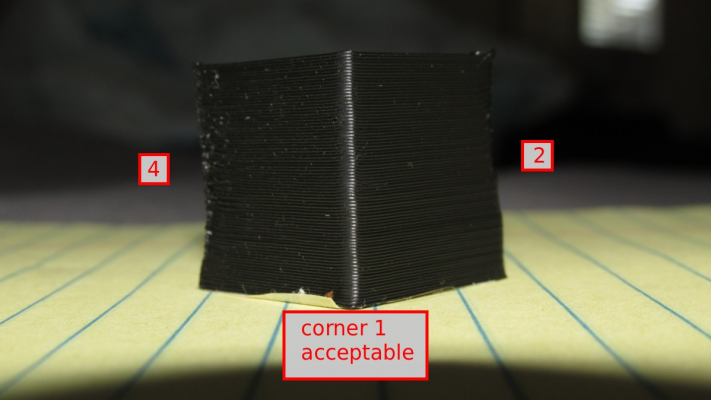

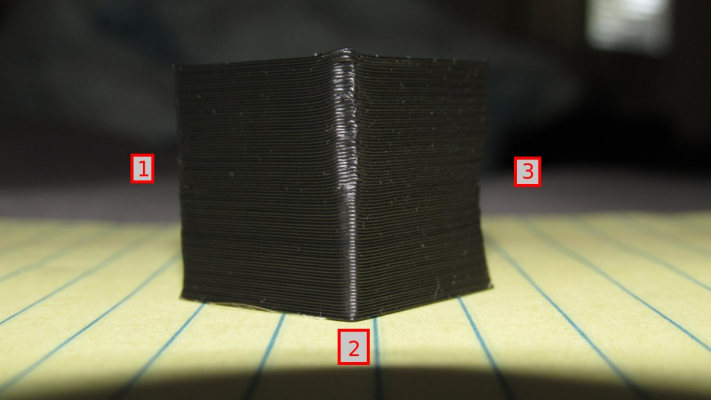

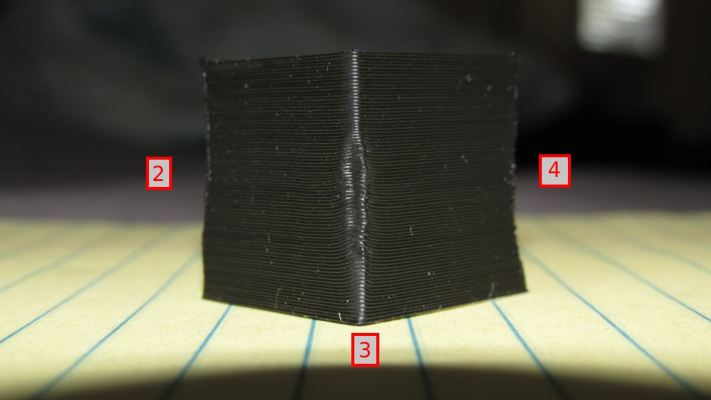

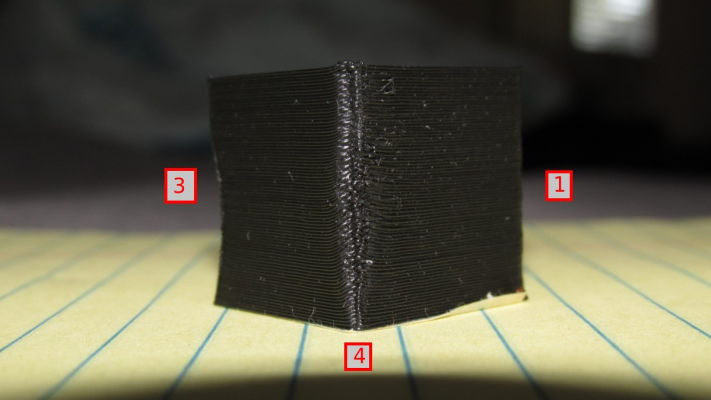

Anyway, I've been trying to get things calibrated with the new filament. I had already done the temperature tests and settled on 240C as about the right temperature, but based on what I'm seeing, I could be wrong. The attached photos show a print of a 20mm cube, 20mm tall. I've attached one photo for each corner of the print. I seem to be getting sort of random warping, but only on the corners and sometimes mid print and not at the bottom where you would expect to see warping due to not sticking to the bed, etc. The weird thing is one corner prints almost perfectly, and the other 3 have this weird problem. It seems to be a little hit or miss as well. I printed the same cube at about 40mm high while doing temperature tests and saw very little of this. I'm not ruling out temperature as an issue. My choice of 240 was based on printing a cube at changing temperatures every 20 layers or so and seeing this warping. But now I see the warping at my chosen temp, so maybe that wasn't the best indicator.

This is a prusa i3 variant with an E3Dv5 hot end. The important Slic3r settings are as follows:

Perimeters: 2

Layer Ht: .248

First Layer Ht: .32

Solid Layers (top/bot): 2/2

Infill: 20% rectlinear

Speeds

Perimeter: 20

External Perimeters: 65%

Infill: 40

Solid Infill: 60%

First Layer Extrusion Temp: 245C

Extrustion Temp: 240C

First Layer Bed Temp: 115C

Bed Temp: 85C

Marlin Firmware configuration highlights:

I'm using purple glue stick for the adhesion which has worked very well for me in the past. I don't see any warping of the bottom layers from the bed. The previous roll of black filament I was using, I was printing at 237C which seemed to be the sweet spot.

Edited 1 time(s). Last edit at 09/06/2015 06:53PM by brucehvn.

Anyway, I've been trying to get things calibrated with the new filament. I had already done the temperature tests and settled on 240C as about the right temperature, but based on what I'm seeing, I could be wrong. The attached photos show a print of a 20mm cube, 20mm tall. I've attached one photo for each corner of the print. I seem to be getting sort of random warping, but only on the corners and sometimes mid print and not at the bottom where you would expect to see warping due to not sticking to the bed, etc. The weird thing is one corner prints almost perfectly, and the other 3 have this weird problem. It seems to be a little hit or miss as well. I printed the same cube at about 40mm high while doing temperature tests and saw very little of this. I'm not ruling out temperature as an issue. My choice of 240 was based on printing a cube at changing temperatures every 20 layers or so and seeing this warping. But now I see the warping at my chosen temp, so maybe that wasn't the best indicator.

- Corner 1 is about the best I would want. Very straight all the way up and it looks very good overall.

- Corner 2 is normal up to about 1/3 of the way up the print, then the corner starts lifting and gradually gets worse.

- Corner 3 starts lifting almost immediately at the bottom, gets worse in the middle, then straightens out and prints fine for about the last third of the print.

- Corner 4 is the seam layer. It starts warping towards the bottom and has varying degrees of warp pretty much through the whole print.

This is a prusa i3 variant with an E3Dv5 hot end. The important Slic3r settings are as follows:

Perimeters: 2

Layer Ht: .248

First Layer Ht: .32

Solid Layers (top/bot): 2/2

Infill: 20% rectlinear

Speeds

Perimeter: 20

External Perimeters: 65%

Infill: 40

Solid Infill: 60%

First Layer Extrusion Temp: 245C

Extrustion Temp: 240C

First Layer Bed Temp: 115C

Bed Temp: 85C

Marlin Firmware configuration highlights:

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,724.394}

#define DEFAULT_MAX_FEEDRATE {500, 500, 2, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,100,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 15.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

I'm using purple glue stick for the adhesion which has worked very well for me in the past. I don't see any warping of the bottom layers from the bed. The previous roll of black filament I was using, I was printing at 237C which seemed to be the sweet spot.

Edited 1 time(s). Last edit at 09/06/2015 06:53PM by brucehvn.

Sorry, only registered users may post in this forum.