Print bed material sticking

Posted by dantyas

|

Print bed material sticking December 13, 2015 03:50PM |

Registered: 8 years ago Posts: 14 |

Hello all,

This is my first post so bare with me...

I have built my first printer I have printed a few models but I am having the same problem. The model sticking fast to the print bed.

The heated print bed is aluminium, however I was advised to use yellow decorators tape on the bed to aid adhesion, using the tape does stop such problems as curling, however its very difficult to then remove the model from the bed.

So I ask the community what should i do? should I add another material to the bed when printing?

Also how did you guys level your print bed and calibrate you print head I am new to all this and any advise would be very welcome !!!

Thank you

Edited 2 time(s). Last edit at 12/13/2015 03:59PM by dantyas.

This is my first post so bare with me...

I have built my first printer I have printed a few models but I am having the same problem. The model sticking fast to the print bed.

The heated print bed is aluminium, however I was advised to use yellow decorators tape on the bed to aid adhesion, using the tape does stop such problems as curling, however its very difficult to then remove the model from the bed.

So I ask the community what should i do? should I add another material to the bed when printing?

Also how did you guys level your print bed and calibrate you print head I am new to all this and any advise would be very welcome !!!

Thank you

Edited 2 time(s). Last edit at 12/13/2015 03:59PM by dantyas.

|

Re: Print bed material sticking December 13, 2015 05:31PM |

Registered: 8 years ago Posts: 778 |

Temperature, correctly adjusted first layer height, speed and the tape itself affects how the plastic will or won't stick.

You did not mention what material you use but give clear craft glue a chance.

Use the stuff that uses methanol or ethanol as a solvent, not the ones for kids that are water based and washable.

Clean the bed and apply a thin layer of glue using a spatula, knife or ruler.

Wait until the layer is dry and appliy another one 90° to the first - again let fully dry, should only take 5 minutes anyway.

Print with low speeds for the first layer and all should stick.

The glue can be ruese several times and actually increases in bonding strenght.

If you need to apply a new layer of fix damages use alcohol and make up pads to clean or smooth the bad areas, apply a new coat of glue where required.

You did not mention what material you use but give clear craft glue a chance.

Use the stuff that uses methanol or ethanol as a solvent, not the ones for kids that are water based and washable.

Clean the bed and apply a thin layer of glue using a spatula, knife or ruler.

Wait until the layer is dry and appliy another one 90° to the first - again let fully dry, should only take 5 minutes anyway.

Print with low speeds for the first layer and all should stick.

The glue can be ruese several times and actually increases in bonding strenght.

If you need to apply a new layer of fix damages use alcohol and make up pads to clean or smooth the bad areas, apply a new coat of glue where required.

|

Re: Print bed material sticking December 14, 2015 11:26AM |

Registered: 8 years ago Posts: 14 |

Thank you for taking the time to respond its appreciated. My apologies for not mentioning the material I'm currently using PLA

I'll take what you've said on-board and have a go! just to clarify I am applying the glue directly to the aluminium bed?

As for speeds I'll have to have a look at my software, figure out how to do that.

Thanks again

I'll take what you've said on-board and have a go! just to clarify I am applying the glue directly to the aluminium bed?

As for speeds I'll have to have a look at my software, figure out how to do that.

Thanks again

|

Re: Print bed material sticking December 14, 2015 04:24PM |

Registered: 11 years ago Posts: 5,780 |

Blue painter's tape on an unheated bed usually works well for PLA, no glue, no hairspray, or other slop required.

If you wipe it with IPA before printing it seems to work best.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you wipe it with IPA before printing it seems to work best.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Print bed material sticking December 14, 2015 06:43PM |

Registered: 8 years ago Posts: 778 |

I tried the glue on a lot of surfaces and so far it works great, just let it dry first and do a peel test.

If the glue goess of like a big sheet it is no good, if the glue needs alcohol to be removed it is good.

But as siad by our dentist, PLA should not be an issue, if it is then mostly the printer calibration and print settings are to blame.

If the glue goess of like a big sheet it is no good, if the glue needs alcohol to be removed it is good.

But as siad by our dentist, PLA should not be an issue, if it is then mostly the printer calibration and print settings are to blame.

|

Re: Print bed material sticking December 15, 2015 06:24AM |

Registered: 8 years ago Posts: 14 |

|

Re: Print bed material sticking December 15, 2015 07:59AM |

Registered: 8 years ago Posts: 778 |

If you use PLA and think all settings are good but the stuff refuses to stick on your tape:

Get some alcohol or methylated spirit, 200 or 300 grid sandpaper and if in doubt fresh air.

First press the tape firmly onto the surface - you can on the back of some glas what is required to get an even adhesion.

Now use a lint free cloth that you wet with the alcohol and wipe over the tape, you should see it changing color slightly once the protective layer is done and actual paper gets wet.

Wait until the surface appear to be dry and with slight pressure sand down the tape a bit so it looks really rough.

Blow off any dust and let the tape fully dry - use the heated bed or a hair dryer if you are in hurry or in a cold room.

If your PLA now still refuse to stick (in fact it should be quite hard to get it off!) it means you have a serious calibration problem or totally wrong print settings for the first layer.

Get some alcohol or methylated spirit, 200 or 300 grid sandpaper and if in doubt fresh air.

First press the tape firmly onto the surface - you can on the back of some glas what is required to get an even adhesion.

Now use a lint free cloth that you wet with the alcohol and wipe over the tape, you should see it changing color slightly once the protective layer is done and actual paper gets wet.

Wait until the surface appear to be dry and with slight pressure sand down the tape a bit so it looks really rough.

Blow off any dust and let the tape fully dry - use the heated bed or a hair dryer if you are in hurry or in a cold room.

If your PLA now still refuse to stick (in fact it should be quite hard to get it off!) it means you have a serious calibration problem or totally wrong print settings for the first layer.

|

Re: Print bed material sticking December 15, 2015 08:47AM |

Registered: 8 years ago Posts: 14 |

Thank you for the replies,

I think the print/ first layer settings is the primary problem if I'm honest, this is my first build and also my first time using a printer so I'm fairly clueless on the topic, I'm using the software repetier,

What settings should I be changing and what too? any advice would be greatly appreciated.

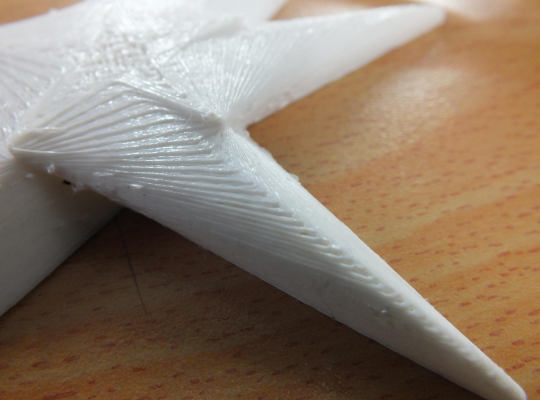

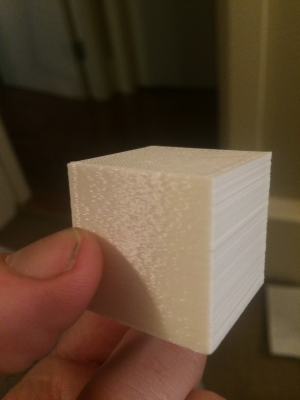

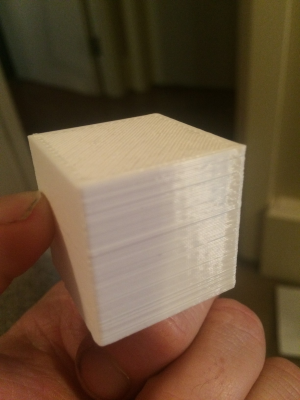

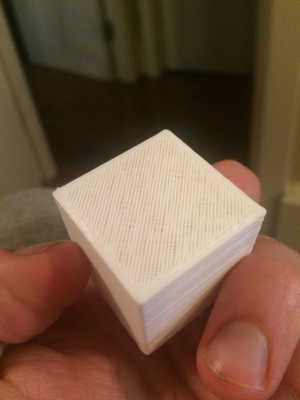

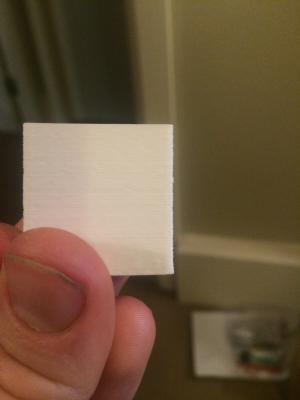

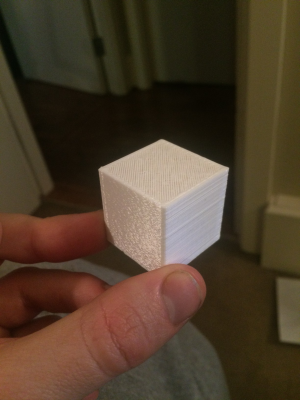

I've included images of my first print

I think the print/ first layer settings is the primary problem if I'm honest, this is my first build and also my first time using a printer so I'm fairly clueless on the topic, I'm using the software repetier,

What settings should I be changing and what too? any advice would be greatly appreciated.

I've included images of my first print

|

Re: Print bed material sticking December 15, 2015 09:15AM |

Registered: 8 years ago Posts: 778 |

You need to calibrate your extruder stepping and / or your multiplier to start with.

Only if the extruder really pushes out 10cm when asked so you can make useful finetuning in the print settings.

And for the testing stick to simple infill patterns, like retangular as it helps to identiy problems.

Your curled snake might look fancy but can't assist in troubleshooting.

Here is a good guide to get started with the printer calibration:

http://reprap.org/wiki/Triffid_Hunter's_Calibration_Guide

Only if the extruder really pushes out 10cm when asked so you can make useful finetuning in the print settings.

And for the testing stick to simple infill patterns, like retangular as it helps to identiy problems.

Your curled snake might look fancy but can't assist in troubleshooting.

Here is a good guide to get started with the printer calibration:

http://reprap.org/wiki/Triffid_Hunter's_Calibration_Guide

|

Re: Print bed material sticking December 15, 2015 10:11AM |

Registered: 8 years ago Posts: 14 |

|

Re: Print bed material sticking December 15, 2015 05:06PM |

Registered: 8 years ago Posts: 14 |

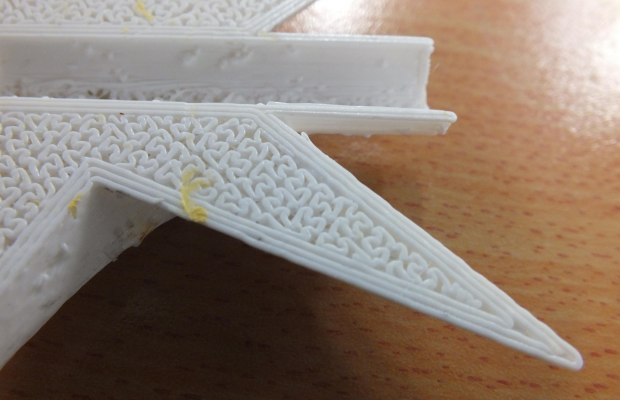

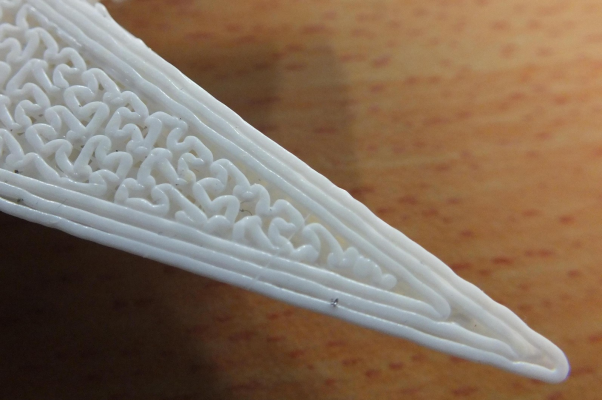

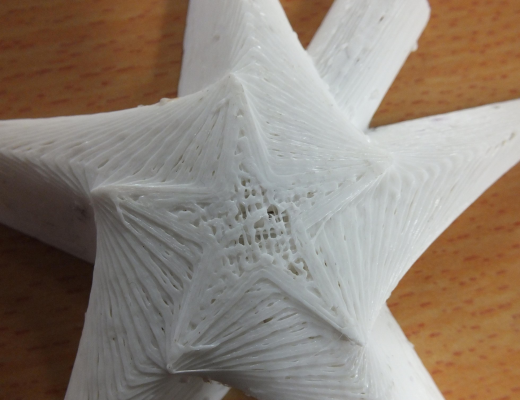

Firstly thanks for the ongoing advice the last round was great, I took your advice and applied the settings and got much better results, spent some time calibrating the bed making sure it was level.

but...

there's still some issues, the wall facing the front of the printer is great, the two side walls however are more heavily lines and rough and the top is see through and fairly poor.

Please see images and offer advice as you see fit,

thanks again.

but...

there's still some issues, the wall facing the front of the printer is great, the two side walls however are more heavily lines and rough and the top is see through and fairly poor.

Please see images and offer advice as you see fit,

thanks again.

|

Re: Print bed material sticking December 15, 2015 05:19PM |

Registered: 8 years ago Posts: 778 |

Not sure what infill and how much overlap you used but if the infill is not going into the perimeters too much I would say you have a problem with your belt on the Y-axis.

I had similar patterns on me sides and tried it all, including reducing jerk and acceleration to a crawl.

But the real solution was to lube the sides of the belts with some silicone grease.

On my printer the belts are hold on the bearings with big washers, the belt grinds on them and in return that caused vibrations on my build table.

Linear bearings that are very badly aligned and dry can cause a similar problem.

The top infill seems to suffer from under extrusion or too thin extrusion width.

Try to set the top solid infill to at least 25% more than the nozzle diameter, if stll no complete infill increase the extrusion slightly.

You can test quicker by printing with 100% infill - making sure the first layer is really flat.

If the infill has gaps increase the extrusion by about 5%, if the infill is pushed out and over the lines slightly then reduce the extrusion by about 5%.

You want the infill to show no gaps and no plastic being pushed over the lines either.

I had similar patterns on me sides and tried it all, including reducing jerk and acceleration to a crawl.

But the real solution was to lube the sides of the belts with some silicone grease.

On my printer the belts are hold on the bearings with big washers, the belt grinds on them and in return that caused vibrations on my build table.

Linear bearings that are very badly aligned and dry can cause a similar problem.

The top infill seems to suffer from under extrusion or too thin extrusion width.

Try to set the top solid infill to at least 25% more than the nozzle diameter, if stll no complete infill increase the extrusion slightly.

You can test quicker by printing with 100% infill - making sure the first layer is really flat.

If the infill has gaps increase the extrusion by about 5%, if the infill is pushed out and over the lines slightly then reduce the extrusion by about 5%.

You want the infill to show no gaps and no plastic being pushed over the lines either.

Sorry, only registered users may post in this forum.