PLA keep on curling up on exit on extruder head

Posted by sypher

|

PLA keep on curling up on exit on extruder head November 03, 2012 11:13PM |

Registered: 12 years ago Posts: 45 |

I am having a hard time trying to get my PLA to extrude evenly down as oppose to go against gravity and curl up as soon as it leave the printer head. If I use some left over plastic on the end it would be enough weight to pull and guide the strand down but without that the PLA would just curl up and form a mess at the exit. I am using some extra yellow 1.75mm PLA that came with my order from Ultimachine. I have clean the extruder head a few times now to remove the excess on the exterior and tried different temp range.

|

Re: PLA keep on curling up on exit on extruder head November 04, 2012 01:20AM |

Registered: 11 years ago Posts: 83 |

|

Re: PLA keep on curling up on exit on extruder head November 04, 2012 01:25AM |

Registered: 13 years ago Posts: 2,947 |

This is usually a sign that the nozzle hole is dirty. You need to clean out the nozzle exit hole on the inside.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: PLA keep on curling up on exit on extruder head November 04, 2012 05:35PM |

Registered: 12 years ago Posts: 283 |

Only very rarely does the filament come straight out of my novel. It tends to curl off to one side when the head is lifted clear of the bed. I would not be concerned if I was you. When printing, your head is fractions of a mm off the bed or previous layer so it can't go far! The first time I noticed this on my head I, like you, panicked. I stripped the head down and cleaned it. It made no difference. Try blowing it from different angles when extruding into free air. You'll notice that it send to pull towards the air flow.

Using ABSPrusa Mendel Zaphod with Pronterface and slic3r 1.3.0. Printing well with 3mm PLA and ABS through 2 x J Head Mk IV b and Wade Geared Exruders. Controlled using RAMPS1.4 board running Marlin_v1.1.9

Using ABSPrusa Mendel Zaphod with Pronterface and slic3r 1.3.0. Printing well with 3mm PLA and ABS through 2 x J Head Mk IV b and Wade Geared Exruders. Controlled using RAMPS1.4 board running Marlin_v1.1.9

|

Re: PLA keep on curling up on exit on extruder head November 09, 2012 02:46AM |

Registered: 12 years ago Posts: 45 |

|

Re: PLA keep on curling up on exit on extruder head November 24, 2012 08:22PM |

Registered: 12 years ago Posts: 45 |

I have been trying to figure this problem for some time now and really need some help with this. The machine mechanically runs ok but the extruder doesn't sync with the speed and has problem extruding the correct amount. After the first layer, it just leave a small dot of plastic only on top of the layer underneath it and does not connect or fill in 40% like I set in Splicer. I read some where that it could be firmware calibration or filament diameter not set correctly but I have double check that.

Right now it is set to 137.75 for extruder

Extruder Diameter set to 0.5mm

Using 1.75mm

Right now it is set to 137.75 for extruder

Extruder Diameter set to 0.5mm

Using 1.75mm

|

Re: PLA keep on curling up on exit on extruder head November 24, 2012 10:11PM |

Registered: 11 years ago Posts: 229 |

|

Re: PLA keep on curling up on exit on extruder head November 28, 2012 02:58AM |

Registered: 12 years ago Posts: 45 |

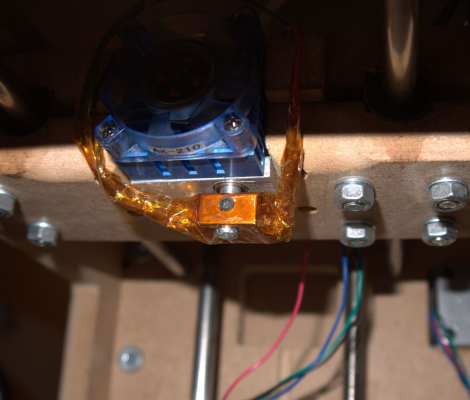

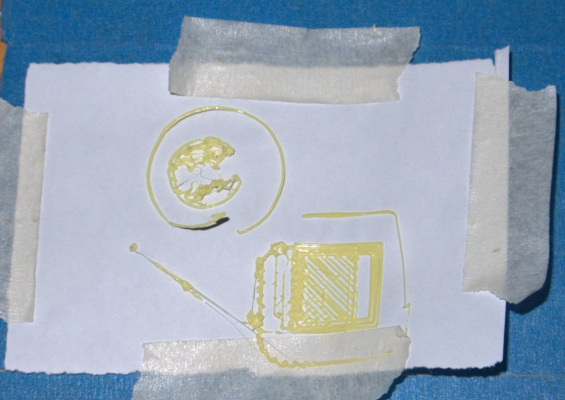

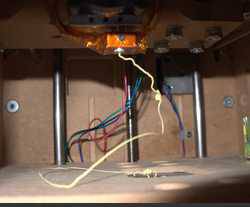

I haven't gotten far enough to let it do a full print because the first couple of layer is really bad...I uploaded these images to show you guys how bad and hopefully someone can lead me to the right path as I am stumped. Hey rogerw, I briefly look at your thread and we have similar problem but not quite. I do however need to manually have to pull and push it so it doesn't ooze out and create a blob. Current temp that it usually read are from 12-18 C

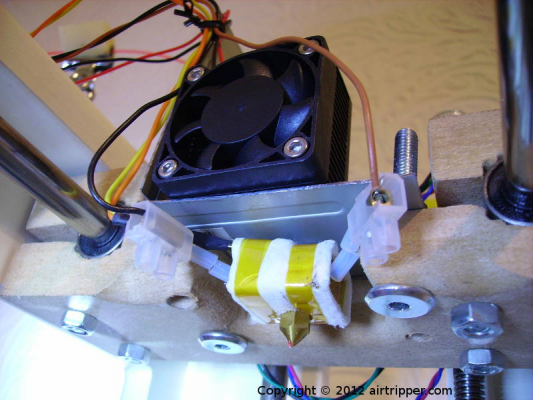

My setup and that blue fan attached to the heatsink isn't on because it would lower the temp too much

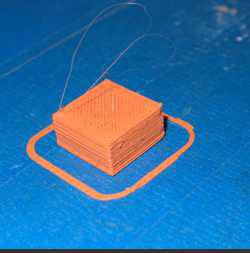

This bottom print is suppose to be that calibration cube in ReplicatorG but during the print, any layer aftter the first get shifted xx millimeter away, not sure why this problem is appearing again.

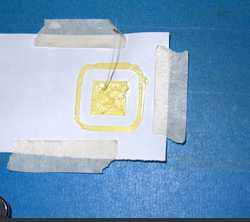

Hope this picture better describe the problem. The plastic would leave gaps in between the print then it start to bunch up and the extruder would drag some of them around and messing up the whole thing.

My setup and that blue fan attached to the heatsink isn't on because it would lower the temp too much

This bottom print is suppose to be that calibration cube in ReplicatorG but during the print, any layer aftter the first get shifted xx millimeter away, not sure why this problem is appearing again.

Hope this picture better describe the problem. The plastic would leave gaps in between the print then it start to bunch up and the extruder would drag some of them around and messing up the whole thing.

|

Re: PLA keep on curling up on exit on extruder head November 28, 2012 04:33AM |

Registered: 11 years ago Posts: 229 |

sypher - i agree. your photos do look different to mine. my problem i pretty sure (printing ok at the moment - touch wood) was that i was way too close to the bed - print a smear on the first layers. if it was fill it made it worst as if print heaps too close. the plastic had nowhere to go. i think the extruder was pretty good and kept pushing in until it was blocked.

i found when printing the calibration things that i had to go very slow or have the fan on so as not to get all still sticky.

but u sound like u have bigger problems if it is jumping to different x values on each layer - don't know much about the firmware stuff im afraid.

is it sticking to the paper? have u tried printing just to the blue tape instead?

roger.

Prusa 'Explorer' (3dStuffMaker), GEN6, J-head Mk III-B, Bowden Extruder, Marlin 1.0.0 RC2, Repitier-Host V0.84 and Slic3r 0.9.8, PLA. Live at Victoria, Australia.

i found when printing the calibration things that i had to go very slow or have the fan on so as not to get all still sticky.

but u sound like u have bigger problems if it is jumping to different x values on each layer - don't know much about the firmware stuff im afraid.

is it sticking to the paper? have u tried printing just to the blue tape instead?

roger.

Prusa 'Explorer' (3dStuffMaker), GEN6, J-head Mk III-B, Bowden Extruder, Marlin 1.0.0 RC2, Repitier-Host V0.84 and Slic3r 0.9.8, PLA. Live at Victoria, Australia.

|

Re: PLA keep on curling up on exit on extruder head November 29, 2012 09:07PM |

Registered: 12 years ago Posts: 45 |

Roger, I find that it stick better on paper than the blue masking tape. I am not sure why my print is jumping xx mm every few layer or so. What ever is causing that is in this gcode I uploaded if it is software related. It would normally extrude great for the first layer then it will struggle to fill in the gap and goes downhill from there.

I had some time to trouble shoot this some more and I think this is more of a hardware problem now. The filament isn't in snyc with the movement and isn't extruding fast enough even tho I set the temp to 190 for PLA. I tried maxing the flow rate and feed/mm in Repetier and I still got the same POS result. Is it possible that It could be that the heat isn't distributed evenly within the white tube and causing some section of the filament to melt faster and result in a irregular flow coming out? If that make sense. Anyway, I uploaded my gcode and would appreciate if someone can help me out with this.

I had some time to trouble shoot this some more and I think this is more of a hardware problem now. The filament isn't in snyc with the movement and isn't extruding fast enough even tho I set the temp to 190 for PLA. I tried maxing the flow rate and feed/mm in Repetier and I still got the same POS result. Is it possible that It could be that the heat isn't distributed evenly within the white tube and causing some section of the filament to melt faster and result in a irregular flow coming out? If that make sense. Anyway, I uploaded my gcode and would appreciate if someone can help me out with this.

|

Re: PLA keep on curling up on exit on extruder head November 29, 2012 09:31PM |

Registered: 11 years ago Posts: 229 |

sypher, im still having problems with mine as well. at the moment i try the following to try to clean out any blocked stuff in my nozzle.

1. extrude manually lots - ie. 100-200mm or so - mine too will curl up but then after a couple of 10, 20 even 30mm extrudes will run ok (i have 3mm PLA). at 205. (need to make sure you can do this well to start with i think).

2. then when i start printing i will get the first layer down ok (and fill) and then the second layer will start to morse code and then go good and the morse code again.

it is getting better. i find that it is best to just left it run as long as i can and see if it will come good . ie. sometimes the next layer

will run over the crap and make some good lines.

3. i try to print something very simple - like a solid 40mm cube with fill of 1.0 ie. just trying to get the stuff flowing without any fancy stuff (lots of straight lines, no stopping and starting and retracting and bridging for sparse fill).

i print at 30mm/min for perimeter (2 of) and 25mm/min for fill (solid). I turn the fan on after the first layer (which might be causing the problem).

4. I also have set my first layer and subsequent layers to the same temp (205) to try to rule out anything to do with the temp changing on the

change form the first layer to the second layer.

have you tried going really slow ie. 5mm/min ?

have you changed your layer height yet?

is the paper a flat enough surface?? or does it flop and float around? it doesn't look flat in the pictures. i find the head to the bed distance is the biggest thing to get right.

send some more pictures of how your 1 , 2 & 3 look

the circle thing in your photo looks too high from the paper - needs to be squashed on more - print a few extra skirts as well - instead of just 1 print 5 or 10...

Edited 9 time(s). Last edit at 11/29/2012 10:08PM by rogerw.

Prusa 'Explorer' (3dStuffMaker), GEN6, J-head Mk III-B, Bowden Extruder, Marlin 1.0.0 RC2, Repitier-Host V0.84 and Slic3r 0.9.8, PLA. Live at Victoria, Australia.

1. extrude manually lots - ie. 100-200mm or so - mine too will curl up but then after a couple of 10, 20 even 30mm extrudes will run ok (i have 3mm PLA). at 205. (need to make sure you can do this well to start with i think).

2. then when i start printing i will get the first layer down ok (and fill) and then the second layer will start to morse code and then go good and the morse code again.

it is getting better. i find that it is best to just left it run as long as i can and see if it will come good . ie. sometimes the next layer

will run over the crap and make some good lines.

3. i try to print something very simple - like a solid 40mm cube with fill of 1.0 ie. just trying to get the stuff flowing without any fancy stuff (lots of straight lines, no stopping and starting and retracting and bridging for sparse fill).

i print at 30mm/min for perimeter (2 of) and 25mm/min for fill (solid). I turn the fan on after the first layer (which might be causing the problem).

4. I also have set my first layer and subsequent layers to the same temp (205) to try to rule out anything to do with the temp changing on the

change form the first layer to the second layer.

have you tried going really slow ie. 5mm/min ?

have you changed your layer height yet?

is the paper a flat enough surface?? or does it flop and float around? it doesn't look flat in the pictures. i find the head to the bed distance is the biggest thing to get right.

send some more pictures of how your 1 , 2 & 3 look

the circle thing in your photo looks too high from the paper - needs to be squashed on more - print a few extra skirts as well - instead of just 1 print 5 or 10...

Edited 9 time(s). Last edit at 11/29/2012 10:08PM by rogerw.

Prusa 'Explorer' (3dStuffMaker), GEN6, J-head Mk III-B, Bowden Extruder, Marlin 1.0.0 RC2, Repitier-Host V0.84 and Slic3r 0.9.8, PLA. Live at Victoria, Australia.

|

Re: PLA keep on curling up on exit on extruder head November 29, 2012 09:51PM |

Registered: 11 years ago Posts: 229 |

looked at gcode

is your layer heigth OK?

did you comment out the M109 & M82

are you intentionally raising the head 0.5

anyway need to get point 1 above right first

Prusa 'Explorer' (3dStuffMaker), GEN6, J-head Mk III-B, Bowden Extruder, Marlin 1.0.0 RC2, Repitier-Host V0.84 and Slic3r 0.9.8, PLA. Live at Victoria, Australia.

is your layer heigth OK?

did you comment out the M109 & M82

are you intentionally raising the head 0.5

anyway need to get point 1 above right first

Prusa 'Explorer' (3dStuffMaker), GEN6, J-head Mk III-B, Bowden Extruder, Marlin 1.0.0 RC2, Repitier-Host V0.84 and Slic3r 0.9.8, PLA. Live at Victoria, Australia.

|

Re: PLA keep on curling up on exit on extruder head November 30, 2012 11:23PM |

Registered: 12 years ago Posts: 45 |

1. extrude manually lots - ie. 100-200mm or so - mine too will curl up but then after a couple of 10, 20 even 30mm extrudes will run ok (i have 3mm PLA). at 205. (need to make sure you can do this well to start with i think).

Going back to basic is a good place to start so here is the manual extrude (1.75mm PLA)

2. then when i start printing i will get the first layer down ok (and fill) and then the second layer will start to morse code and then go good and the morse code again.

it is getting better. i find that it is best to just left it run as long as i can and see if it will come good . ie. sometimes the next layer

will run over the crap and make some good lines.

These stepper motor sometime seem like they have a brain of its own. I once heard it started to do some synchronize song as weird as that was, it didn't sounded too bad. Have you try playing with the potentiometer on the control board? It improve the jump problem I was getting.

Lowering the speed does help improve the quality but still look like crap. I find that even at a slow speed it have trouble extruding at constant rate and put small dab of filament and will bunch up like before. At least it is getting better..

4. I also have set my first layer and subsequent layers to the same temp (205) to try to rule out anything to do with the temp changing on the

change form the first layer to the second layer.

Second attempt (on the right) with manual pushing and adjusting the platform result in a better print but it still end up suffering from the inconsistent filament flow problem. On both of the print they are set to really low speed (10/15 mm/s) and also lower the height in Slicer and kept the same temperature (190).

is the paper a flat enough surface?? or does it flop and float around? it doesn't look flat in the pictures. i find the head to the bed distance is the biggest thing to get right.

Well it start flat but once I leave it near the extruder, the heat from it start to warp the paper a bit but I don't think that affect the result too much. How much of a gap should I leave? I usually try to aim for paper thickness.

Going back to basic is a good place to start so here is the manual extrude (1.75mm PLA)

2. then when i start printing i will get the first layer down ok (and fill) and then the second layer will start to morse code and then go good and the morse code again.

it is getting better. i find that it is best to just left it run as long as i can and see if it will come good . ie. sometimes the next layer

will run over the crap and make some good lines.

These stepper motor sometime seem like they have a brain of its own. I once heard it started to do some synchronize song as weird as that was, it didn't sounded too bad. Have you try playing with the potentiometer on the control board? It improve the jump problem I was getting.

Lowering the speed does help improve the quality but still look like crap. I find that even at a slow speed it have trouble extruding at constant rate and put small dab of filament and will bunch up like before. At least it is getting better..

4. I also have set my first layer and subsequent layers to the same temp (205) to try to rule out anything to do with the temp changing on the

change form the first layer to the second layer.

Second attempt (on the right) with manual pushing and adjusting the platform result in a better print but it still end up suffering from the inconsistent filament flow problem. On both of the print they are set to really low speed (10/15 mm/s) and also lower the height in Slicer and kept the same temperature (190).

is the paper a flat enough surface?? or does it flop and float around? it doesn't look flat in the pictures. i find the head to the bed distance is the biggest thing to get right.

Well it start flat but once I leave it near the extruder, the heat from it start to warp the paper a bit but I don't think that affect the result too much. How much of a gap should I leave? I usually try to aim for paper thickness.

|

Re: PLA keep on curling up on exit on extruder head December 15, 2012 05:26PM |

Registered: 11 years ago Posts: 40 |

From youtube message

You are not getting enough plastic out of the nozzle for the feed rate set. This will cause the plastic to be pulled, dragged and stretched across the bed surface. The extruder system shipped with the Sumpod does not perform to expectations and as prompted me and others to upgrade.

You may want to start with this Airtripper's Bowden Extruder

And get this MK7 Drive Gear Pully

or this (second choice) Raptor Filament Drive Gear

Once the new bits are in place you can start to trouble shoot the hot end, be prepared to replace that as well.

Get the extruder system sorted out, including the hot end, and you'll have a high performance machine.

Bookmark my blog airtripper.com for plenty of Sumpod stuff and Sumpod stuff to come.

Blog - [airtripper.com]

Extrude Filament Force Sensor - [airtripper.com]

Quote

sypher

Hi, I remember you from way back when Richard first started launching on Indiegogo. I am having some problem trying to get my system to extrude consistently. I have the first batch of extruder and wondering if that maybe is the problem. Just wondering if you can maybe take a look at my thread that I made on reprap.com below. I have been working on this for over a year now and would appreciate your input. Thanks.

[forums.reprap.org]

You are not getting enough plastic out of the nozzle for the feed rate set. This will cause the plastic to be pulled, dragged and stretched across the bed surface. The extruder system shipped with the Sumpod does not perform to expectations and as prompted me and others to upgrade.

You may want to start with this Airtripper's Bowden Extruder

And get this MK7 Drive Gear Pully

or this (second choice) Raptor Filament Drive Gear

Once the new bits are in place you can start to trouble shoot the hot end, be prepared to replace that as well.

Get the extruder system sorted out, including the hot end, and you'll have a high performance machine.

Bookmark my blog airtripper.com for plenty of Sumpod stuff and Sumpod stuff to come.

Blog - [airtripper.com]

Extrude Filament Force Sensor - [airtripper.com]

|

Re: PLA keep on curling up on exit on extruder head December 16, 2012 10:22PM |

Registered: 12 years ago Posts: 45 |

Airtripper Wrote:

-------------------------------------------------------

> You are not getting enough plastic out of the

> nozzle for the feed rate set. This will cause the

> plastic to be pulled, dragged and stretched across

> the bed surface. The extruder system shipped with

> the Sumpod does not perform to expectations and as

> prompted me and others to upgrade.

>

> You may want to start with this Airtripper's

> Bowden Extruder

> And get this MK7 Drive Gear Pully

> or this (second choice) Raptor Filament Drive

> Gear

>

> Once the new bits are in place you can start to

> trouble shoot the hot end, be prepared to replace

> that as well.

>

> Get the extruder system sorted out, including the

> hot end, and you'll have a high performance

> machine.

>

> Bookmark my blog airtripper.com for plenty of

> Sumpod stuff and Sumpod stuff to come.

Hi, can you clarify something? On your blog you mention that the unit came ready and work right out of the box and from the picture on this page, beside the hot bed and hot end, we have the same setup. Could the problem be something else like the heat distributions on the hot end? When I pull out my filament after letting it cool off a bit, I can see that there is uneven warping on the filament at where the aluminum block is located. Read somewhere that filament need a certain pressure to come out of the hot end and due to the warping/stretching of the filament, there was a gap and what could have cause the problem. Just a theory and would kinda make sense as to why the first couple of layer look great but then it start to trickle filament down.

I would actually try your version of extruder on thingiverse out but I can't print one myself and they don't ship (ebay alternative work?). Wondering if the one your currently using is the second batch of hotend from Richard because the one on his site look different.

Edited 1 time(s). Last edit at 12/16/2012 10:25PM by sypher.

-------------------------------------------------------

> You are not getting enough plastic out of the

> nozzle for the feed rate set. This will cause the

> plastic to be pulled, dragged and stretched across

> the bed surface. The extruder system shipped with

> the Sumpod does not perform to expectations and as

> prompted me and others to upgrade.

>

> You may want to start with this Airtripper's

> Bowden Extruder

> And get this MK7 Drive Gear Pully

> or this (second choice) Raptor Filament Drive

> Gear

>

> Once the new bits are in place you can start to

> trouble shoot the hot end, be prepared to replace

> that as well.

>

> Get the extruder system sorted out, including the

> hot end, and you'll have a high performance

> machine.

>

> Bookmark my blog airtripper.com for plenty of

> Sumpod stuff and Sumpod stuff to come.

Hi, can you clarify something? On your blog you mention that the unit came ready and work right out of the box and from the picture on this page, beside the hot bed and hot end, we have the same setup. Could the problem be something else like the heat distributions on the hot end? When I pull out my filament after letting it cool off a bit, I can see that there is uneven warping on the filament at where the aluminum block is located. Read somewhere that filament need a certain pressure to come out of the hot end and due to the warping/stretching of the filament, there was a gap and what could have cause the problem. Just a theory and would kinda make sense as to why the first couple of layer look great but then it start to trickle filament down.

I would actually try your version of extruder on thingiverse out but I can't print one myself and they don't ship (ebay alternative work?). Wondering if the one your currently using is the second batch of hotend from Richard because the one on his site look different.

Edited 1 time(s). Last edit at 12/16/2012 10:25PM by sypher.

|

Re: PLA keep on curling up on exit on extruder head December 17, 2012 08:04PM |

Registered: 11 years ago Posts: 40 |

Quote

sypher

Hi, can you clarify something? On your blog you mention that the unit came ready and work right out of the box and from the picture on this page, beside the hot bed and hot end, we have the same setup. Could the problem be something else like the heat distributions on the hot end?

I got the original hot end working and got some good prints out of it, but I later had problems when I come to use a new real of filament. Had I wrote the blog post as an experienced 3d printer owner, the blog post would have been very different. Even though I got good prints out of the printer, the maximum speed I could print was like 10 times slower than other printers out there.

Quote

syther

When I pull out my filament after letting it cool off a bit, I can see that there is uneven warping on the filament at where the aluminum block is located. Read somewhere that filament need a certain pressure to come out of the hot end and due to the warping/stretching of the filament, there was a gap and what could have cause the problem. Just a theory and would kinda make sense as to why the first couple of layer look great but then it start to trickle filament down.

I scrapped the Sumpod hot ends a long time ago, they just did not work reliably or not at all, and more trouble than they are worth. Basically, the PTFE tube is not providing enough thermal barrier to stop the filament from swelling under the heat higher up hot end tube. This eventually slows extrusion and lead to nozzle jamming.

Changing the hot end will work for you and you will be able to print your own extruder upgrade. I can't recommend any hot end at present but I have a new one for testing now and I'll have another one to test after Xmas. If the tests are good I may be able to recommend either hot end. They are cheap as well, but high spec. A review will be put on the blog.

Quote

sypher

I would actually try your version of extruder on thingiverse out but I can't print one myself and they don't ship (ebay alternative work?). Wondering if the one your currently using is the second batch of hotend from Richard because the one on his site look different.

The hot end I'm currently using is a modded Mendel Parts V9 (an expensive poor copy). The best print speed I can get out of this is 16mm/s, which is not good enough. The hot ends from Richard have not been proven to work, at least on par with other proven hot ends.

My extruder is available on ebay but I reckon your existing extruder will work well enough to print your own with a new hot end. If you wait for my hot end tests I might have one to recommend with attachment brackets and fan worked out to fit the Sumpod. I only have a Dremel, a drill and some tin snips so nothing complicated involved.

|

Re: PLA keep on curling up on exit on extruder head December 19, 2012 02:42AM |

Registered: 12 years ago Posts: 45 |

Just manage to push out a finished calibration block below. Not bad for having to continuously assist the stepper motor for almost 1 and a half hour. Beside a sore thumb, I am pleased with the end result. Found out that it is often a hit and miss with this system and require a lot of supervision so I am looking forward to your recommendation ASAP. Just curious as to which two kit are you looking at? Great blog btw, still going through every article!

|

Re: PLA keep on curling up on exit on extruder head December 19, 2012 06:49PM |

Registered: 11 years ago Posts: 40 |

Quote

sypher

Found out that it is often a hit and miss with this system and require a lot of supervision so I am looking forward to your recommendation ASAP. Just curious as to which two kit are you looking at?

I've been working on one of the hot ends today but not had a chance to get it printing due to it being a bit late for the noise. It has jammed solid on a couple of tests but ramping the temperature up, quickly got the extruder going again. When it extrudes, it extrudes very easily. I've just got to find the right temperature that works best for this filament I'm using.

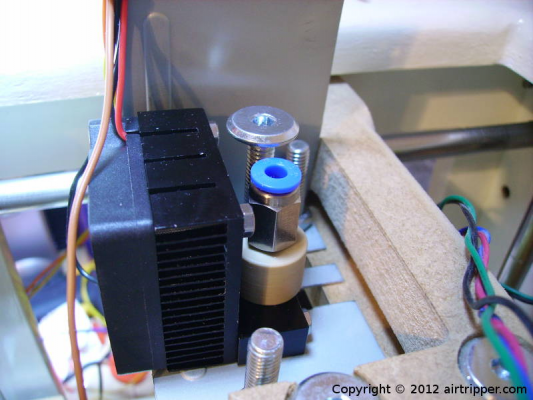

I'll report more later, and I've attached a couple of images of the hot end. It's a QU-BD MBE Extruder V9, but converted to a bowden type extruder.

Mark

Blog - [airtripper.com]

Extrude Filament Force Sensor - [airtripper.com]

|

Re: PLA keep on curling up on exit on extruder head January 07, 2013 12:11AM |

Registered: 12 years ago Posts: 45 |

Hi Mark, any update on when you would be comfortable recommending an alternative hotend for all Sumpod user? Haven't seen any update on your blog and my current heat resistor lead broke off during a print a few weeks ago and this seem like the perfect time to retire the hotend. Looking to order something this week in case they need some lead time and have something arrive here to work on before the end of this month. If anyone for that matter know any reliable 1.75mm hotend that they would recommend then I would love to hear more about it. Thanks.

|

Re: PLA keep on curling up on exit on extruder head January 08, 2013 06:02PM |

Registered: 11 years ago Posts: 40 |

Well, the QU-BD MBE Extruder V9 did not work with the 1.75 PLA I had. It seems that the stainless steel barrel was not smooth enough to force the filament swell down to the melt chamber. The filament just gripped solid inside the barrel.

I got another hot end delivered today which is the J-Head MK-IV Hot end. It needs some assembly and a bracket designed and printed, and since it will be for 1.75mm PLA, I need to fit a fan as well.

It will be a few days before I get any test results.

In case you did not know, there is an unofficial Sumpod forum you might be interested in [sumpod.proboards.com]

I got another hot end delivered today which is the J-Head MK-IV Hot end. It needs some assembly and a bracket designed and printed, and since it will be for 1.75mm PLA, I need to fit a fan as well.

It will be a few days before I get any test results.

In case you did not know, there is an unofficial Sumpod forum you might be interested in [sumpod.proboards.com]

Sorry, only registered users may post in this forum.