Hobbed bolt slippage on long prints

Posted by Pappy588

|

Hobbed bolt slippage on long prints December 18, 2013 10:10AM |

Registered: 10 years ago Posts: 2 |

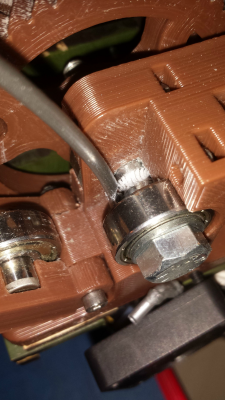

I've been having issues with my Makerfarm Prusa i3 using a .35mm J-Head with a Greg's extruder for the last few weeks. It prints small, quick prints ok but if my print goes for 6 hours or so the hobbed bolt begins to slip and inevitably digs its way almost all the way through the PLA filament.

I am running the PLA I bought from makerfarm at 195c temps(used to use 185, the higher temp doesn't seem to help much with these long prints). I have the springs that came with the supplied Greg's extruder and I tighten the bolts down completely(this actually helped a lot but still wont last through long prints). I also have a fan blowing on the PEEK section of the nozzle. I also clean the hobbed bolt's teeth out everytime this happens.

I am printing on basically stock Slic3r settings and I measure the filament before each print.

Any suggestions would be greatly appreciated! Let me know if you guys need more detailed information!

Edited 2 time(s). Last edit at 12/18/2013 10:27AM by Pappy588.

I am running the PLA I bought from makerfarm at 195c temps(used to use 185, the higher temp doesn't seem to help much with these long prints). I have the springs that came with the supplied Greg's extruder and I tighten the bolts down completely(this actually helped a lot but still wont last through long prints). I also have a fan blowing on the PEEK section of the nozzle. I also clean the hobbed bolt's teeth out everytime this happens.

I am printing on basically stock Slic3r settings and I measure the filament before each print.

Any suggestions would be greatly appreciated! Let me know if you guys need more detailed information!

Edited 2 time(s). Last edit at 12/18/2013 10:27AM by Pappy588.

|

Re: Hobbed bolt slippage on long prints December 18, 2013 04:38PM |

Registered: 10 years ago Posts: 10 |

Maybe it is a height issue. Once you're too high your filament is blocked somewhere.

Otherwise, for the other tips I have in mind, you've already done it (tight springs, fan on peek, …)

Are you sure the FAN is running 100% and not obstructed ?

I have to say that I still have to print long stuff, I never reached 6h yet … maybe I'll face the dame issues as you.

Cheers,

Régis.

Otherwise, for the other tips I have in mind, you've already done it (tight springs, fan on peek, …)

Are you sure the FAN is running 100% and not obstructed ?

I have to say that I still have to print long stuff, I never reached 6h yet … maybe I'll face the dame issues as you.

Cheers,

Régis.

|

Re: Hobbed bolt slippage on long prints December 19, 2013 09:39AM |

Registered: 10 years ago Posts: 2 |

|

Re: Hobbed bolt slippage on long prints December 29, 2013 01:26AM |

Registered: 11 years ago Posts: 11 |

a little background, I have 6 printers running just about every day for 10 hours each day making parts for people on Ebay. I have been doing that for about a year. I have seen your problem many times. It comes down to one of these two problems or a combination of both.

1. Filament is a tiny bit too big. Even though it says 1.75mm or 3mm it rarely is exactly on target. Even as the spool is being used there is a variation in size. What happens is the filament can get too fat, and is too hard for the hobbed bolt to push through the hot end. When it runs into resistance it stops, and the bolt just digs into the side. Print failed. Solution, disassemble your hot end, and use a drill to make the inside plastic tube of the hot end a little bit bigger so if you get fat filament it won't jam.

2. Your hot end gets too hot. If the print gets going for a long long time the heat can travel up the hot end on the inside and get your filament too hot before it gets to the melting chamber. Then it swells, slowing down the filament, leading to the same problem as mentioned above. Solution, make sure you have not blocked any cooling vanes with capton tape, and or use a cooling fan. You can also drill out your inside tube so if it does swell, the print can just keep going as mentioned above.

Hope that helps

1. Filament is a tiny bit too big. Even though it says 1.75mm or 3mm it rarely is exactly on target. Even as the spool is being used there is a variation in size. What happens is the filament can get too fat, and is too hard for the hobbed bolt to push through the hot end. When it runs into resistance it stops, and the bolt just digs into the side. Print failed. Solution, disassemble your hot end, and use a drill to make the inside plastic tube of the hot end a little bit bigger so if you get fat filament it won't jam.

2. Your hot end gets too hot. If the print gets going for a long long time the heat can travel up the hot end on the inside and get your filament too hot before it gets to the melting chamber. Then it swells, slowing down the filament, leading to the same problem as mentioned above. Solution, make sure you have not blocked any cooling vanes with capton tape, and or use a cooling fan. You can also drill out your inside tube so if it does swell, the print can just keep going as mentioned above.

Hope that helps

|

Re: Hobbed bolt slippage on long prints December 29, 2013 10:46AM |

Registered: 11 years ago Posts: 560 |

|

Re: Hobbed bolt slippage on long prints December 29, 2013 11:23PM |

Registered: 11 years ago Posts: 1,592 |

Sorry, only registered users may post in this forum.