Not enough support (event with solid infill) for most top layer in v1.1.7 and github

Posted by imarin

|

Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 09, 2014 10:10AM |

Registered: 9 years ago Posts: 6 |

Hi!!

This is my first post in this community.

I am having a problem slicing this object with slic3r:

[www.thingiverse.com]

The problem I am having is that slic3r omits support in part of the are just below the top most layer, and then the top most layer "collapses" during print (you can see a hole a some strings over the hole). The rest of the object is perfect (front view is very nice, top view is like bumpy (ups and downs), like a roof that has not been maintained for 50 years). I am printing with ABS if that matters. The settings below work just fine with non-curved objects.

I have tried to force Slic3r to make the last 35 layers solid (the object's top surface is curved and needs 35 layers from start to end) in order to solve the problem, using the configuration below.

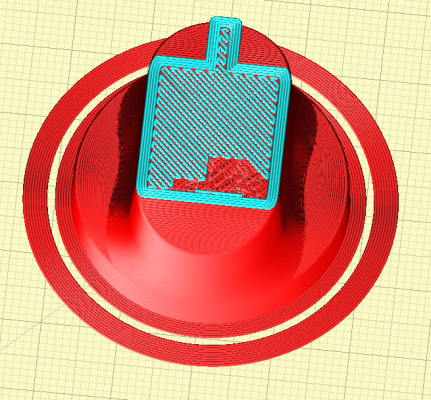

When I look at the generated gcode with pronterface, I see this:

Where support is omited, is where the "roof" colapses. Additionally, note that the file is symmetric with respect to the vertical axis, so it should not be a reason to omit support in the right part and not omit it in the left part, or to put it in the left part but omit it in the right part.

I do not know if this is a bug or not. I believe it is, but I am not a 3d printing expert. I think I give all the information needed to reproduce it. Let me know if I can help providing more information, and of course, if you have a solution for me I am very receptive!!!

Thanks!

imarin

Configuration:

This is my first post in this community.

I am having a problem slicing this object with slic3r:

[www.thingiverse.com]

The problem I am having is that slic3r omits support in part of the are just below the top most layer, and then the top most layer "collapses" during print (you can see a hole a some strings over the hole). The rest of the object is perfect (front view is very nice, top view is like bumpy (ups and downs), like a roof that has not been maintained for 50 years). I am printing with ABS if that matters. The settings below work just fine with non-curved objects.

I have tried to force Slic3r to make the last 35 layers solid (the object's top surface is curved and needs 35 layers from start to end) in order to solve the problem, using the configuration below.

When I look at the generated gcode with pronterface, I see this:

Where support is omited, is where the "roof" colapses. Additionally, note that the file is symmetric with respect to the vertical axis, so it should not be a reason to omit support in the right part and not omit it in the left part, or to put it in the left part but omit it in the right part.

I do not know if this is a bug or not. I believe it is, but I am not a 3d printing expert. I think I give all the information needed to reproduce it. Let me know if I can help providing more information, and of course, if you have a solution for me I am very receptive!!!

Thanks!

imarin

Configuration:

# generated by Slic3r 1.1.7 on Sun Nov 9 15:45:30 2014 avoid_crossing_perimeters = 1 bed_size = 200,200 bed_temperature = 80 bottom_solid_layers = 3 bridge_acceleration = 5000 bridge_fan_speed = 100 bridge_flow_ratio = 1 bridge_speed = 120 brim_width = 2 complete_objects = 1 cooling = 0 default_acceleration = 5000 disable_fan_first_layers = 1 dont_support_bridges = 1 duplicate_distance = 6 end_gcode = external_perimeter_speed = 12% external_perimeters_first = 0 extra_perimeters = 1 extruder_clearance_height = 20 extruder_clearance_radius = 80 extruder_offset = 0x0 extrusion_axis = E extrusion_multiplier = 1 extrusion_width = 0 fan_always_on = 0 fan_below_layer_time = 60 filament_diameter = 1.7 fill_angle = 45 fill_density = 40% fill_pattern = honeycomb first_layer_acceleration = 5000 first_layer_bed_temperature = 90 first_layer_extrusion_width = 0 first_layer_height = 400% first_layer_speed = 25% first_layer_temperature = 240 g0 = 0 gap_fill_speed = 80 gcode_arcs = 0 gcode_comments = 1 gcode_flavor = reprap infill_acceleration = 5000 infill_every_layers = 4 infill_extruder = 1 infill_extrusion_width = 0 infill_first = 0 infill_only_where_needed = 0 infill_speed = 240 interface_shells = 0 layer_gcode = layer_height = 0.075 max_fan_speed = 100 min_fan_speed = 35 min_print_speed = 10 min_skirt_length = 10 notes = nozzle_diameter = 0.34 only_retract_when_crossing_perimeters = 1 ooze_prevention = 0 output_filename_format = [input_filename_base].gcode overhangs = 1 perimeter_acceleration = 5000 perimeter_extruder = 1 perimeter_extrusion_width = 0 perimeter_speed = 240 perimeters = 4 post_process = print_center = 100,100 raft_layers = 0 resolution = 0 retract_before_travel = 2 retract_layer_change = 0 retract_length = 1 retract_length_toolchange = 10 retract_lift = 0 retract_restart_extra = 0 retract_restart_extra_toolchange = 0 retract_speed = 30 seam_position = nearest skirt_distance = 3 skirt_height = 1 skirts = 8 slowdown_below_layer_time = 30 small_perimeter_speed = 100% solid_fill_pattern = rectilinear solid_infill_below_area = 70 solid_infill_every_layers = 0 solid_infill_extrusion_width = 0 solid_infill_speed = 50% spiral_vase = 0 standby_temperature_delta = -5 start_gcode = support_material = 0 support_material_angle = 0 support_material_enforce_layers = 0 support_material_extruder = 1 support_material_extrusion_width = 0 support_material_interface_extruder = 1 support_material_interface_layers = 5 support_material_interface_spacing = 5 support_material_interface_speed = 100% support_material_pattern = rectilinear support_material_spacing = 8 support_material_speed = 120 support_material_threshold = 30 temperature = 230 thin_walls = 1 threads = 4 toolchange_gcode = top_infill_extrusion_width = 0 top_solid_infill_speed = 12% top_solid_layers = 35 travel_speed = 240 use_firmware_retraction = 0 use_relative_e_distances = 0 vibration_limit = 0 wipe = 1 z_offset = 0

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 10, 2014 09:21AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 11, 2014 08:53AM |

Registered: 9 years ago Posts: 6 |

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 12, 2014 08:56AM |

Registered: 10 years ago Posts: 2,472 |

It seems that the STL has some problems - I tried importing it into OpenScad and it failed. You can repair using [netfabb.azurewebsites.net]

I ran the STL through that service and it produced an STL which imports correctly into OpenScad, but I have not tried slicing it. The STL is too big to attach as one file, but I have split it and attached. If you download all 4 parts you can extract using the free application WinRar.

Or use the free NetFabb service I gave to fix the original STL yourself.

Dave

I ran the STL through that service and it produced an STL which imports correctly into OpenScad, but I have not tried slicing it. The STL is too big to attach as one file, but I have split it and attached. If you download all 4 parts you can extract using the free application WinRar.

Or use the free NetFabb service I gave to fix the original STL yourself.

Dave

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 12, 2014 11:45AM |

Registered: 9 years ago Posts: 6 |

Thanks a lot for your time.

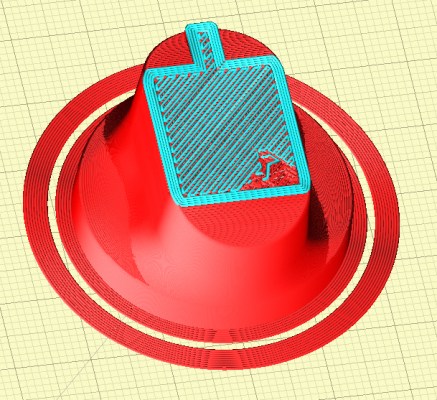

Slic3r still has problems slicing this one. See:

However, less problems, so I am going to try to actually print it.

If I have set the last 35 layers solid, it is weird that it does not "obey".

Would such a behaviour qualify like a bug the developer may be interested in taking a look to?

Thanks again,

imarin

Slic3r still has problems slicing this one. See:

However, less problems, so I am going to try to actually print it.

If I have set the last 35 layers solid, it is weird that it does not "obey".

Would such a behaviour qualify like a bug the developer may be interested in taking a look to?

Thanks again,

imarin

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 12, 2014 03:11PM |

Registered: 10 years ago Posts: 2,472 |

I've looked at the fixed STL I posted by cutting sections with OpenScad, and I cannot see any voids or other irregularities, so I think that it must be a Slic3r bug. Slic3r is free software and the developers have no obligation or financial incentive to fix bugs, so while there is no harm in reporting such issues, it's pot-luck as to whether you can interest anyone in fixing it - a perfectly legitimate response is, "the source code is freely available, so you can fix it yourself". It's the main reason I decided to buy some commercial slicing software, where if I come across a bug, I have access to support and eventually the right to demand either a fix, a viable workaround or my money back! You could try other free slicing software. Cura for example has less options than Slic3r but does a good job, especially in adding support. You could also try different (older) versions of Slic3r, as I have found each version has a different set of bugs!

Addendum: I've just looked at your settings, and it may be worth trying with a standard recangular fill instead of honeycomb.

Dave

Edited 1 time(s). Last edit at 11/12/2014 03:15PM by dmould.

Addendum: I've just looked at your settings, and it may be worth trying with a standard recangular fill instead of honeycomb.

Dave

Edited 1 time(s). Last edit at 11/12/2014 03:15PM by dmould.

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 12, 2014 05:08PM |

Registered: 10 years ago Posts: 208 |

There are no (serious) issues with the model.

It's a Slic3r issue (you may call it bug). Due to the shape of the top and the very thin layer height, it gets confused about what the "top layer" is.

I sliced the model in Simplify3D and there are 35 layers at the top of any part of the... top of the knob (including where it goes from round to, say, rectangle on the lower part).

An workaround will be to print with 100% infill (some more filament and time, and still some slicing issues but not affecting the top) and/or increase the layer height.

I would go for 0.15-0.2 mm and use some acetone to get an "injection molded" look and feel

Or try the Kisslicer free.

Obviously, you can report the bug on github.

It's a Slic3r issue (you may call it bug). Due to the shape of the top and the very thin layer height, it gets confused about what the "top layer" is.

I sliced the model in Simplify3D and there are 35 layers at the top of any part of the... top of the knob (including where it goes from round to, say, rectangle on the lower part).

An workaround will be to print with 100% infill (some more filament and time, and still some slicing issues but not affecting the top) and/or increase the layer height.

I would go for 0.15-0.2 mm and use some acetone to get an "injection molded" look and feel

Or try the Kisslicer free.

Obviously, you can report the bug on github.

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 13, 2014 09:05AM |

Registered: 10 years ago Posts: 2,472 |

Out of interest I sliced the STL using Simplify3D and printed it in ABS with 0.2mm layer height and 40% infill. It printed perfectly (taking 35 minutes), though the top required a light sanding and a polish with an acetone soaked cloth to get rid of the layer steps and a smooth finish. I may try it with a smaller layer height - I have not tried printing below 0.2mm (I doubt the improvement is worth the additional time, not only for the increased number of layers but the fact that thin layers require a lower speed to prevent the extrusion breaking up).

Dave

Dave

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 13, 2014 10:15AM |

Registered: 9 years ago Posts: 6 |

Thanks a lot!! You give me advice and you even printed it!!

In my first trials I was using 0.15 mm. Reducing the layer height to 0.075 mm it really made a difference (without any acetone used).

I have used acetone to treat ABS parts. But I have never used it with a cloth soaked in acetone, but using a acetone vapor bath (using a baby bottle warmer that uses water to tranfer the heat to the bottle, a glass jar, the piece hung to the top of the jar with a hook and closing the jar). The problem I have with that is that it gives a shinny glossy finish, while I am looking for a matte finish. Nevertheless I will try with a soaked cloth, just to see how it goes.

I have printed the file from yesterday. This is the result:

Apart from that ugly circle (the printer stops the nozzle there for some seconds before finishing the print, I think it is a printer problem). You can see that it still collapses in the areas where no infill is set below (where in pronterface you can see that it fails to put infill). I think I will report the bug. Showing this thread and having the files available, if the developer is motivated to solve it, he will at least have a way to consistently reproduce the problem.

P.S.: I have just applied acetone with a cloth to a piece. Thanks for the tip. It is much less glossy finish than with the acetone vapor bath!!! Very useful for what I want to achieve!!!

In my first trials I was using 0.15 mm. Reducing the layer height to 0.075 mm it really made a difference (without any acetone used).

I have used acetone to treat ABS parts. But I have never used it with a cloth soaked in acetone, but using a acetone vapor bath (using a baby bottle warmer that uses water to tranfer the heat to the bottle, a glass jar, the piece hung to the top of the jar with a hook and closing the jar). The problem I have with that is that it gives a shinny glossy finish, while I am looking for a matte finish. Nevertheless I will try with a soaked cloth, just to see how it goes.

I have printed the file from yesterday. This is the result:

Apart from that ugly circle (the printer stops the nozzle there for some seconds before finishing the print, I think it is a printer problem). You can see that it still collapses in the areas where no infill is set below (where in pronterface you can see that it fails to put infill). I think I will report the bug. Showing this thread and having the files available, if the developer is motivated to solve it, he will at least have a way to consistently reproduce the problem.

P.S.: I have just applied acetone with a cloth to a piece. Thanks for the tip. It is much less glossy finish than with the acetone vapor bath!!! Very useful for what I want to achieve!!!

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 13, 2014 12:47PM |

Registered: 10 years ago Posts: 2,472 |

I always give my prints a rub over with an acetone cloth or paper towel. Not only to improve the finish, but I have found that the acetone soaks between the layers and causes them to melt together, creating a much stronger part along the Z axis. Try printing a tall thin vertical column and you will be able to snap it easily because the layer bonds are fairly weak. Now rub down a similar column with acetone (or dip in acetone) and let it dry for an hour or two, then snap it, and you will feel the difference. Acetone is also an excellent glue to join parts together or repair a print. Hold the separate parts in place with elastic bands or clips, then run some acetone along the joints between the parts using a syringe & needle, and leave overnight. The thin acetone gets pulled into the joint by capillary action, giving a large chemical weld area and an invisible join (if you are careful enough). It is often preferable to print a design in several parts later glued together than to print it in one piece, because each piece can then be printed in the most favourable orientation, in sections that do not need support and/or are less likely to warp.

(Obviously this applies only to ABS parts)

Dave

(Obviously this applies only to ABS parts)

Dave

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 13, 2014 02:27PM |

Registered: 9 years ago Posts: 6 |

Thanks so much for the acetone treatment leson!!! It is really something I was wanting to learn about.

I have applied several "rubs with acetone" to the piece and it is looking better and better.

I had this problem of weak in z direction. I will really consider rubbing with acetone next time.

Thank you so much for this post,

imarin.

I have applied several "rubs with acetone" to the piece and it is looking better and better.

I had this problem of weak in z direction. I will really consider rubbing with acetone next time.

Thank you so much for this post,

imarin.

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github November 14, 2014 01:46PM |

Registered: 9 years ago Posts: 6 |

I have posted the bug in Github:

[github.com]

In the meantime I am having success with this part using Cura.

Thanks a lot for your help and support,

imarin

[github.com]

In the meantime I am having success with this part using Cura.

Thanks a lot for your help and support,

imarin

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github December 26, 2014 04:56AM |

Registered: 13 years ago Posts: 228 |

Hello. imarin, that happens because you've set Combine infill every 4 layers. If you set it back to 1 the issue will disappear.

Edit: there's still something with that little layer height 0.075 used with that number of perimeters that causes the Top Solid Layers option not to be honored completely in the sloping region. I'll investigate.

Edited 1 time(s). Last edit at 12/26/2014 07:33AM by Sound.

Edit: there's still something with that little layer height 0.075 used with that number of perimeters that causes the Top Solid Layers option not to be honored completely in the sloping region. I'll investigate.

Edited 1 time(s). Last edit at 12/26/2014 07:33AM by Sound.

|

Re: Not enough support (event with solid infill) for most top layer in v1.1.7 and github December 26, 2014 08:39AM |

Registered: 10 years ago Posts: 208 |

It happens also to me for many parts with low slope to have the number of top solid layers not fulfilled in some regions. The worst thing is that in certain circumstances (I didn't find any rule), nor more perimeters are added, hence the external surface is compromised (holes).

I'm normally using 20% infill, 2-4 perimeters, infill on every layer, 0.1-0.2 mm layer height, so nothing spectacular.

If there is something like the top of a head, it happens that only the top of the top is considered to be... top, and areas between the forehead and the beginning of the topped volume may suffer from this.

I'm normally using 20% infill, 2-4 perimeters, infill on every layer, 0.1-0.2 mm layer height, so nothing spectacular.

If there is something like the top of a head, it happens that only the top of the top is considered to be... top, and areas between the forehead and the beginning of the topped volume may suffer from this.

Sorry, only registered users may post in this forum.