KISSLicer Is Up To The Challenge: Wade's Big Gear

Posted by Garry Bartsch

|

KISSLicer Is Up To The Challenge: Wade's Big Gear July 21, 2014 03:33PM |

Registered: 10 years ago Posts: 363 |

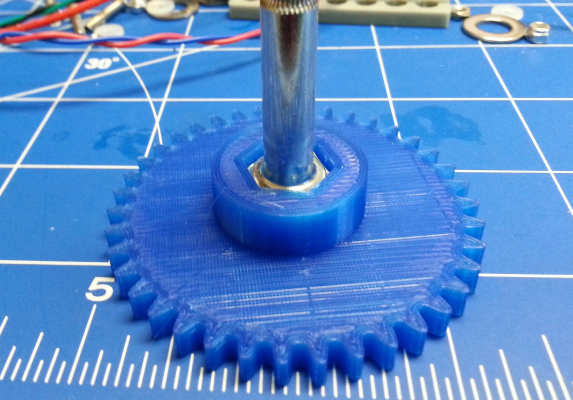

I just wanted to show that KISSlicer can slice the Wade's gear so the bolt flats are perfect. This was sliced at 3 loops; perimeter first.

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear July 21, 2014 06:40PM |

Registered: 9 years ago Posts: 41 |

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear July 22, 2014 06:30PM |

Registered: 10 years ago Posts: 363 |

The M3 and M4 nuts fit perfectly into the top poly holes and loosely into the side poly holes.

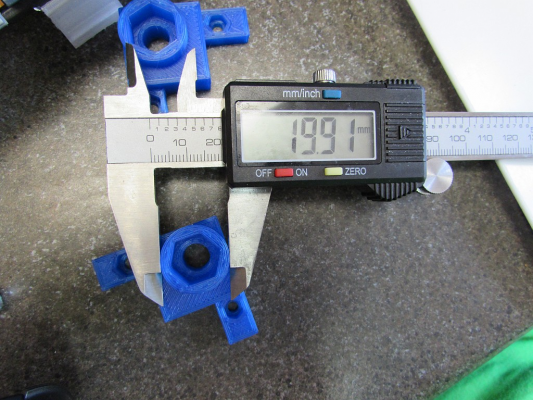

The diameter of the cylinder measures 19.9mm rather than the 20mm it is designed at. I should print the part and see how Skeinforge slices the cylinder.

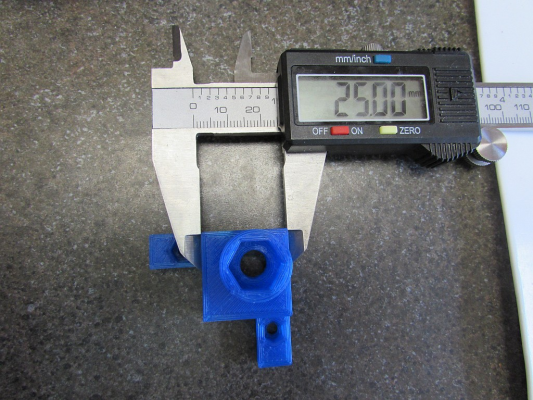

The square section are pretty good as per the photos.

Since there is no cal.scad with the larger poly hole I loaded cal.stl into IronCad and measured 13.337mm across the flats (I will assume this measurement is good since the squares measure 25mm and 40mm right on using the software). My cheap digital calipers measure 13.5mm across the flats of the printed part. The bolt I used for this test is 12.9mm across the flats. Indeed it is a sloppy fit.

Is this OK?

The diameter of the cylinder measures 19.9mm rather than the 20mm it is designed at. I should print the part and see how Skeinforge slices the cylinder.

The square section are pretty good as per the photos.

Since there is no cal.scad with the larger poly hole I loaded cal.stl into IronCad and measured 13.337mm across the flats (I will assume this measurement is good since the squares measure 25mm and 40mm right on using the software). My cheap digital calipers measure 13.5mm across the flats of the printed part. The bolt I used for this test is 12.9mm across the flats. Indeed it is a sloppy fit.

Is this OK?

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear August 31, 2014 12:09PM |

Registered: 12 years ago Posts: 227 |

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear August 31, 2014 03:46PM |

Registered: 10 years ago Posts: 363 |

I'm going from memory here but I know the 3mm PLA was RepRapper blue, 0.2mm layer height, 0.4mm J-Head that comes with the Mendel90 kit. I might have set the extrusion width to 0.5mm but can't remember for sure. Likely 20-25mm/sec. My e-steps/mm were calculated as close as possible and then I further tweaked the flow in KISSlicer till it is perfect. I can print row after row of solid layers and never build up too much plastic (or lay down too little).

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear September 02, 2014 09:20AM |

Registered: 12 years ago Posts: 227 |

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear September 02, 2014 09:27AM |

Registered: 11 years ago Posts: 180 |

|

Re: KISSLicer Is Up To The Challenge: Wade's Big Gear September 03, 2014 12:16PM |

Registered: 10 years ago Posts: 363 |

@karabas

I haven't tried with ABS. The only thing I have made so far with ABS is a replacement Wade's block. ABS is tougher to print with for me since I need to ask for more help when working with it (I'm have a disability) so I have stuck to PLA so far. But I would love to use it more and see how accurately it would make objects. The Wade's block works fine but the nut traps were tight and so was the 22mm bearing holes. But the print was a one time go with almost zero calibration since the existing Wade's block was almost shot and I just needed to get the print done. That was sliced with KISSlicer.

@danlad1631

I'd love to share the files but they are such a mess and full of different materials and experimental settings, etc. I'm wondering if I could break out relevant sections? Which settings do you want to see?

I haven't tried with ABS. The only thing I have made so far with ABS is a replacement Wade's block. ABS is tougher to print with for me since I need to ask for more help when working with it (I'm have a disability) so I have stuck to PLA so far. But I would love to use it more and see how accurately it would make objects. The Wade's block works fine but the nut traps were tight and so was the 22mm bearing holes. But the print was a one time go with almost zero calibration since the existing Wade's block was almost shot and I just needed to get the print done. That was sliced with KISSlicer.

@danlad1631

I'd love to share the files but they are such a mess and full of different materials and experimental settings, etc. I'm wondering if I could break out relevant sections? Which settings do you want to see?

Sorry, only registered users may post in this forum.