Hobbed bolt: groove necessary?

Posted by Rich K.

|

Hobbed bolt: groove necessary? October 05, 2014 06:50PM |

Registered: 9 years ago Posts: 254 |

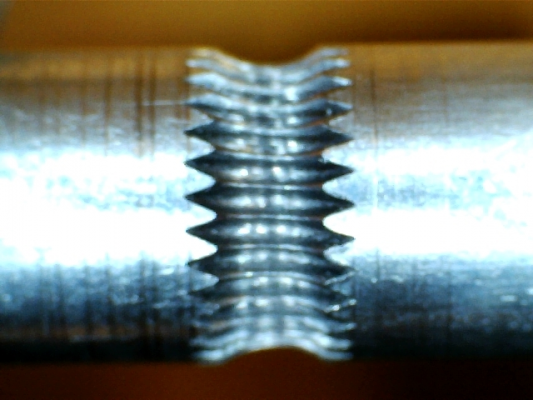

The bolt I have for my extruder is an EBay purchase, I think from Geetech. The hobbing is nice and neat, but there is no groove in the bolt: the hobbing is directly on the surface diameter of the bolt. Is that groove necessary, especially if I am using 3mm filament? Or do I need to try to re-hob the bolt myself after cutting a groove?

If I DO re-hob the bolt, what size tap should I use? I live in the USA, so SAE taps are more common, but I can get metrics from work, if necessary, though the selection is somewhat limited.

If I DO re-hob the bolt, what size tap should I use? I live in the USA, so SAE taps are more common, but I can get metrics from work, if necessary, though the selection is somewhat limited.

|

Re: Hobbed bolt: groove necessary? October 06, 2014 04:52AM |

Admin Registered: 17 years ago Posts: 7,879 |

The ones I make are hobbed with an M5 tap to a depth of 1mm. I don't cut a groove first but I hob it with a CNC lathe.

Since hobbing with a tap always results in a groove I have never tried one without a groove in a Wade's. I have tested splined and knurled shafts and they do work to a lesser extent [hydraraptor.blogspot.com.es]

[www.hydraraptor.blogspot.com]

Since hobbing with a tap always results in a groove I have never tried one without a groove in a Wade's. I have tested splined and knurled shafts and they do work to a lesser extent [hydraraptor.blogspot.com.es]

[www.hydraraptor.blogspot.com]

|

Re: Hobbed bolt: groove necessary? October 06, 2014 06:31PM |

Registered: 9 years ago Posts: 254 |

This is the bolt I have (though not from the same seller):

Geetech hobbed bolt - EBay)

It was one of my early purchases - all I knew was I needed an 8mm hobbed bolt for my extruder. Think it will work?

Edited 1 time(s). Last edit at 10/06/2014 06:31PM by Rich K..

Geetech hobbed bolt - EBay)

It was one of my early purchases - all I knew was I needed an 8mm hobbed bolt for my extruder. Think it will work?

Edited 1 time(s). Last edit at 10/06/2014 06:31PM by Rich K..

|

Re: Hobbed bolt: groove necessary? October 07, 2014 11:26AM |

Admin Registered: 17 years ago Posts: 7,879 |

I don't know but I think it is worth trying before getting something else. My experiments with splines worked but had less grip than a hobbed bolt.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.