Bed adhesion and other questions

Posted by sedition

|

Bed adhesion and other questions November 23, 2014 01:11AM |

Registered: 9 years ago Posts: 6 |

Hi guys,

I've bumbled through my first few prints pretty well so far, only real problem is bed adhesion. The android test print had lifting underneath the head, then Nophead's Dial Gauge Bracket lifted at both ends. After some calibrating and adjusting I got about 10 layers in to this model before the corners lifted quite visibly. I've done the bed levelling and Z-Home calibration a couple of times over now, Z_HOME is at 203.9. I think I can work all of this out, and I'll likely revisit the calibration steps tomorrow to make sure I'm not missing something there, but I want to pose some questions here before I continue:

1a: What is the correct way to adjust the bed temperature? I've used a K Type thermocouple probe with the controls in Pronterface to test the bed (90 in Pronterface gets me 60C on the glass), but for the actual printing do I need to change settings inside Skeinforge?

1b: Do I correctly assume that Pronterface controls are for testing the machine and executing prints, and when a print starts the gcode takes over control of temperature and other things?

2: The white vinegar I've been using gets the glass looking clean with a kind of 'matte' surface. It doesn't 'squeak' like another poster here mentioned, but methylated spirits DOES squeak. Could the vinegar / glass cleaning be a factor in lack of adhesion here?

I'll likely have lots of questions so I'll keep posting here rather than starting a new thread each time. I have to say, Nophead's kit has been great from start to finish - well packaged, quickly shipping, very straight forward build. First print came out great considering the minimal calibration needed on a brand new machine built by a beginner. If anyone is deciding to pull the trigger on buying one, just do it.

EDIT: I should add I'm using the green PLA that came with Nophead's kit.

Edited 2 time(s). Last edit at 11/23/2014 01:51AM by sedition.

I've bumbled through my first few prints pretty well so far, only real problem is bed adhesion. The android test print had lifting underneath the head, then Nophead's Dial Gauge Bracket lifted at both ends. After some calibrating and adjusting I got about 10 layers in to this model before the corners lifted quite visibly. I've done the bed levelling and Z-Home calibration a couple of times over now, Z_HOME is at 203.9. I think I can work all of this out, and I'll likely revisit the calibration steps tomorrow to make sure I'm not missing something there, but I want to pose some questions here before I continue:

1a: What is the correct way to adjust the bed temperature? I've used a K Type thermocouple probe with the controls in Pronterface to test the bed (90 in Pronterface gets me 60C on the glass), but for the actual printing do I need to change settings inside Skeinforge?

1b: Do I correctly assume that Pronterface controls are for testing the machine and executing prints, and when a print starts the gcode takes over control of temperature and other things?

2: The white vinegar I've been using gets the glass looking clean with a kind of 'matte' surface. It doesn't 'squeak' like another poster here mentioned, but methylated spirits DOES squeak. Could the vinegar / glass cleaning be a factor in lack of adhesion here?

I'll likely have lots of questions so I'll keep posting here rather than starting a new thread each time. I have to say, Nophead's kit has been great from start to finish - well packaged, quickly shipping, very straight forward build. First print came out great considering the minimal calibration needed on a brand new machine built by a beginner. If anyone is deciding to pull the trigger on buying one, just do it.

EDIT: I should add I'm using the green PLA that came with Nophead's kit.

Edited 2 time(s). Last edit at 11/23/2014 01:51AM by sedition.

|

Re: Bed adhesion and other questions November 23, 2014 07:10AM |

Admin Registered: 17 years ago Posts: 7,879 |

The temperature is set in start_PLA.gcode in you Skeinforge settings folder. Yes the print is only controlled by the gcode unless you change it in pronterface while the print is running. Anything you do before the print starts has no effect.

The target temperature on the glass surface is just below the glass transition temperature of the plastic, so about 55C for PLA. The temperature below the PCB is about 15C higher so I set the temp to 70C. 90C is too high unless you are in a very cold room. The bottom layers plastic will be rubbery at that temperature and not able to hold its shape so it peels off.

It is not easy to get an accurate reading with a thermocouple because only one side of it is in contact with the glass so it reads low. I cover it with some ceramic cloth and then kapton tape to get a better reading but I prefer to use an IR thermometer for measuring the bed temperature.

To get more adhesion you can increase the temperature of the bed for just the first layer. E.g. 120 dropping to 70 at the start of the second layer. I don't think Skeinforge can do that but you can manually put it in the gcode or change it in pronterface when the first layer has finished.

Although lots of people recommend vinegar it doesn't work for me. I use acetone and more recently ethyl acetate and lint free wipes that are meant for solvents. Common mistakes are to use nail varnish remover instead of pure acetone or cloths that are affected by the solvent and leave a residue.

[www.hydraraptor.blogspot.com]

The target temperature on the glass surface is just below the glass transition temperature of the plastic, so about 55C for PLA. The temperature below the PCB is about 15C higher so I set the temp to 70C. 90C is too high unless you are in a very cold room. The bottom layers plastic will be rubbery at that temperature and not able to hold its shape so it peels off.

It is not easy to get an accurate reading with a thermocouple because only one side of it is in contact with the glass so it reads low. I cover it with some ceramic cloth and then kapton tape to get a better reading but I prefer to use an IR thermometer for measuring the bed temperature.

To get more adhesion you can increase the temperature of the bed for just the first layer. E.g. 120 dropping to 70 at the start of the second layer. I don't think Skeinforge can do that but you can manually put it in the gcode or change it in pronterface when the first layer has finished.

Although lots of people recommend vinegar it doesn't work for me. I use acetone and more recently ethyl acetate and lint free wipes that are meant for solvents. Common mistakes are to use nail varnish remover instead of pure acetone or cloths that are affected by the solvent and leave a residue.

[www.hydraraptor.blogspot.com]

|

Re: Bed adhesion and other questions November 23, 2014 03:33PM |

Registered: 9 years ago Posts: 6 |

|

Re: Bed adhesion and other questions November 23, 2014 06:00PM |

Admin Registered: 17 years ago Posts: 7,879 |

If you want to watch it change tick it but I find that sometimes causes comms errors while printing so my advice is not to.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Bed adhesion and other questions November 24, 2014 03:43AM |

Registered: 9 years ago Posts: 6 |

I switched to acetone today as per your advice, and made some good progress with bed adhesion. All of the first 5 prints were the Android robot, as it arrived on the SD card:

First print after cleaning with acetone peeled from the bed, but noticeably less. From memory this was the default 60 degrees, no changed made from Pronterface.

Second print I started with the bed at 120 for the first layer, 90 thereafter as per your advice - slightly less peeling.

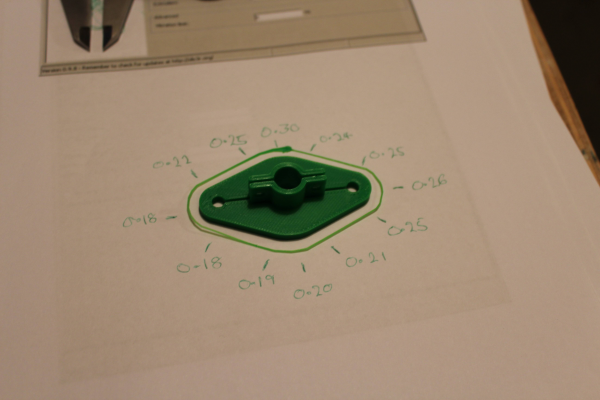

Third, fourth, and fifth prints were at 90, 95 and 100 degrees respectively through the entire print. The fifth at 100 degrees finally adhered perfectly, and the skirt measurements were closer (bit still varying by +/- 0.05mm) to the 0.3mm. So I re-printed your X Carriage Dial Gauge Mount - VERY happy with the result this time.

I took a bunch of measurements of the skirt - I have a feeling I still need to make a tiny adjustment to get the X axis level. Rather than jumping into that headlong, could I ask you to advise where I should go from here, what calibration steps I should take if any?

First print after cleaning with acetone peeled from the bed, but noticeably less. From memory this was the default 60 degrees, no changed made from Pronterface.

Second print I started with the bed at 120 for the first layer, 90 thereafter as per your advice - slightly less peeling.

Third, fourth, and fifth prints were at 90, 95 and 100 degrees respectively through the entire print. The fifth at 100 degrees finally adhered perfectly, and the skirt measurements were closer (bit still varying by +/- 0.05mm) to the 0.3mm. So I re-printed your X Carriage Dial Gauge Mount - VERY happy with the result this time.

I took a bunch of measurements of the skirt - I have a feeling I still need to make a tiny adjustment to get the X axis level. Rather than jumping into that headlong, could I ask you to advise where I should go from here, what calibration steps I should take if any?

|

Re: Bed adhesion and other questions November 24, 2014 05:31AM |

Registered: 10 years ago Posts: 541 |

I would discard the 0.3mm measurement as that is the starting point of the line and will be thicker. The average of the measurements at 2, 4 and 8 (think of a clock face) will give you an idea of your first layer thickness.

Regarding bed preparation, I am one of the folks who gets on well with pure white vinegar. I occasionally wipe the glass over with Isopropanol alcohol before cleaning with the vinegar (I suspect that Acetone would work as a substitute for IPA).

Getting the first layer height correct (to within +/-0.01mm) seems to be critical to the success of pure white vinegar as a bed preparation but it does work very well.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Regarding bed preparation, I am one of the folks who gets on well with pure white vinegar. I occasionally wipe the glass over with Isopropanol alcohol before cleaning with the vinegar (I suspect that Acetone would work as a substitute for IPA).

Getting the first layer height correct (to within +/-0.01mm) seems to be critical to the success of pure white vinegar as a bed preparation but it does work very well.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: Bed adhesion and other questions November 24, 2014 10:54AM |

Registered: 9 years ago Posts: 2 |

I had similar problems and found that applying a thin layer of a children's arts and crafts glue sticks (Elmer's glue sticks here is the states) made a world of difference. Put it on before the glass heats up for the best results. I do it before each print, but suspect this is overkill. After too many applications it builds up and can leave a textured finish on the base of your part as well as start to mess up your Z-axis bed height calibration. I clean my build plate by running it under the faucet, gently scraping it with a putty knife then wiping down with denatured alcohol (mineral spirits).

Also with parts like the one above having the thin shelf makes them more prone to peeling action. Try using a brim instead of the skirt. 4-5mm would be plenty for that piece. I'm not sure how to set this up in skeinforge, but it's straightforward in both slic3r and cura. Check out Repetier Host for build plate layout and slicing as it has a slightly less intimidating interface and has all three slicers built in. You still have to learn to adjust setting with skeinforge, but it will give you much more dimensionally accurate prints than the other two. You can also set the skirt distance to 0 and doing 5 or 6 loops to create a similar brim-type feature. Also that big of a temp difference between your first layer and the rest of the part could be more harm than help in my eyes as once the build plate and part cool down a little the difference in the rate of thermal expansion between the glass and the plastic starts to create a shearing force between the edges of your part and the bed.

Cheers,

Matt

Also with parts like the one above having the thin shelf makes them more prone to peeling action. Try using a brim instead of the skirt. 4-5mm would be plenty for that piece. I'm not sure how to set this up in skeinforge, but it's straightforward in both slic3r and cura. Check out Repetier Host for build plate layout and slicing as it has a slightly less intimidating interface and has all three slicers built in. You still have to learn to adjust setting with skeinforge, but it will give you much more dimensionally accurate prints than the other two. You can also set the skirt distance to 0 and doing 5 or 6 loops to create a similar brim-type feature. Also that big of a temp difference between your first layer and the rest of the part could be more harm than help in my eyes as once the build plate and part cool down a little the difference in the rate of thermal expansion between the glass and the plastic starts to create a shearing force between the edges of your part and the bed.

Cheers,

Matt

|

Re: Bed adhesion and other questions November 24, 2014 07:33PM |

Registered: 9 years ago Posts: 6 |

Thanks heaps for the input guys.

I'll hold off judgement until I've done a few more prints, but I think the 100 degree constant bed temp is the answer. Is there anything to be aware of if I stick with that? Also, is it possible that the ~15 degrees Celsius temperature of my workshop could be a factor here?

With bed levelling, I don't think the perfectionist in me will rest until I get it licked. I found this print on Thingiverse which I'm going to work with, and probably get a non-digital calliper to ensure the cheap digital isn't sabotaging the effort.

I just installed it, looks great - I'll give it a run this afternoon. If I like it, this will be a complete substitute for Pronterface + Skeinforge, correct? One program rather than two?

I'll hold off judgement until I've done a few more prints, but I think the 100 degree constant bed temp is the answer. Is there anything to be aware of if I stick with that? Also, is it possible that the ~15 degrees Celsius temperature of my workshop could be a factor here?

With bed levelling, I don't think the perfectionist in me will rest until I get it licked. I found this print on Thingiverse which I'm going to work with, and probably get a non-digital calliper to ensure the cheap digital isn't sabotaging the effort.

Quote

Caliprints

Check out Repetier Host for build plate layout and slicing as it has a slightly less intimidating interface and has all three slicers built in. You still have to learn to adjust setting with skeinforge, but it will give you much more dimensionally accurate prints than the other two.

I just installed it, looks great - I'll give it a run this afternoon. If I like it, this will be a complete substitute for Pronterface + Skeinforge, correct? One program rather than two?

|

Re: Bed adhesion and other questions November 24, 2014 09:23PM |

Registered: 9 years ago Posts: 2 |

Glad you found the software useful! I actually still use pronterface for the printer interface. When I connect to my Mendel90 using repetier I get '7 commands waiting' or 6, 8, etc and don't get any error of this sort with pronterface so I continued to run my printer off that instead.

The low ambient temp could definitely have an effect like that. When it was hot this summer I had to do a lot of my ABS printing without using any enclosure as it would simply get too hot and the layers couldn't cool in time for the next one. Maybe try a cardboard enclosure with no lid. Even just a 1 ft tall barrier would help with any drafts in your workspace.

If you continue to have trouble after a precise bed leveling, try the glue stick trick. It can be used on ABS and other materials as well with similar success.

Edited 2 time(s). Last edit at 11/24/2014 09:59PM by Caliprints.

The low ambient temp could definitely have an effect like that. When it was hot this summer I had to do a lot of my ABS printing without using any enclosure as it would simply get too hot and the layers couldn't cool in time for the next one. Maybe try a cardboard enclosure with no lid. Even just a 1 ft tall barrier would help with any drafts in your workspace.

If you continue to have trouble after a precise bed leveling, try the glue stick trick. It can be used on ABS and other materials as well with similar success.

Edited 2 time(s). Last edit at 11/24/2014 09:59PM by Caliprints.

Sorry, only registered users may post in this forum.