Inconsistent Y-axis position; solved.

Posted by Woodsmoke

|

Inconsistent Y-axis position; solved. March 23, 2013 01:12PM |

Registered: 13 years ago Posts: 39 |

Hi,

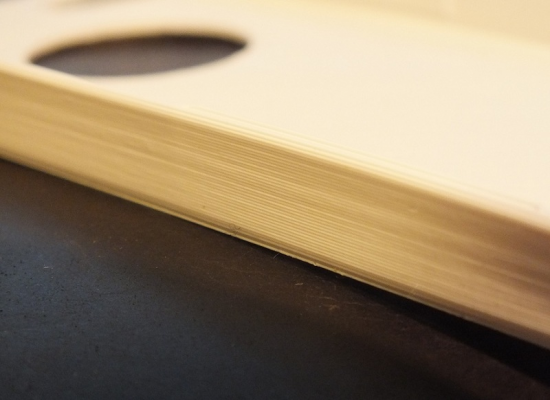

My Sturdy Mendel90 print bed struggles to retain consistent positioning from layer to layer, The effect is random and sometimes happens only slightly, or won't happen at all. When it does the result is poorly stacked filament on the Y axis:

This print was attempted at 32mm/s with 5mm/s jerk and 2000mm/s/s acceleration.

To begin with I checked for mechanical problems like belt slippage, loose pulleys, obstructions etc. but didn't find anything obvious.

Digging around online suggested it might be EMI on the Y end stop. Some careful repacking of the wiring to minimise cross talk seemed to do the trick and prints were better: Which is odd, I thought Marlin doesn't listen to end stops during a print?

A little while later the inconsistencies came back. I got frustrated and installed a 1/4" shielded stereo audio cable on the end stop. Besides looking cool it has had no real effect.

What else might cause this random realignment?

Mendel90sturdy / Azteeg X3 / Marlin RC1

Edited 2 time(s). Last edit at 03/25/2013 08:52AM by Woodsmoke.

My Sturdy Mendel90 print bed struggles to retain consistent positioning from layer to layer, The effect is random and sometimes happens only slightly, or won't happen at all. When it does the result is poorly stacked filament on the Y axis:

This print was attempted at 32mm/s with 5mm/s jerk and 2000mm/s/s acceleration.

To begin with I checked for mechanical problems like belt slippage, loose pulleys, obstructions etc. but didn't find anything obvious.

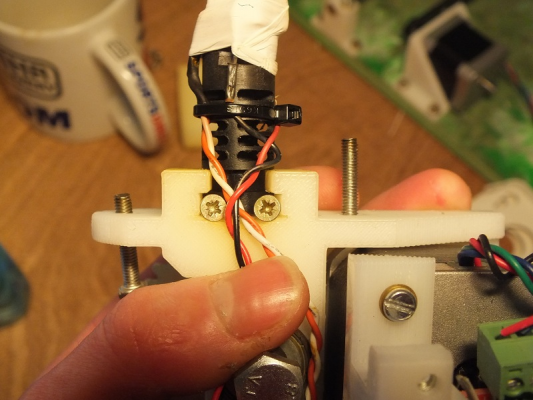

Digging around online suggested it might be EMI on the Y end stop. Some careful repacking of the wiring to minimise cross talk seemed to do the trick and prints were better: Which is odd, I thought Marlin doesn't listen to end stops during a print?

A little while later the inconsistencies came back. I got frustrated and installed a 1/4" shielded stereo audio cable on the end stop. Besides looking cool it has had no real effect.

What else might cause this random realignment?

Mendel90sturdy / Azteeg X3 / Marlin RC1

Edited 2 time(s). Last edit at 03/25/2013 08:52AM by Woodsmoke.

|

Re: Inconsistent Y-axis position March 25, 2013 08:51AM |

Registered: 13 years ago Posts: 39 |

245 degrees + the new short black J-Head might be asking rather a lot of the ABS push-fit socket you've designed.

How about a redesign of the around-the-nozzle cooling duct to direct air at the top of the peek section? As it is the duct prohibits other cooling fans being installed.

Edited 1 time(s). Last edit at 03/25/2013 08:51AM by Woodsmoke.

|

Re: Inconsistent Y-axis position March 25, 2013 12:43PM |

Admin Registered: 17 years ago Posts: 7,879 |

I run an extruder like that at 250C inside a box at 45C 24/7 for months on end without any problems. Your extruder will have been printed with it.

I have however changed the design to this: -

It allows the hot end to be removed and replaced in the event of a filament jam. The first design was catch 22 because you had to remove the filament to remove the hot end and you couldn't if it was jammed. Also if refitted it would not be tight enough press fitted a second time.

I don't use the fan for printing ABS so I don't have it fitted. Some holes in the top of the duct might be a good idea for cooling the insulator, but I haven't had any problems printing PLA without a fan using a J-Head. The MK5 is a bit marginal with PLA though as you can get a jam in the grub screw at the top if the filament is not moving for a long period of time.

[www.hydraraptor.blogspot.com]

I have however changed the design to this: -

It allows the hot end to be removed and replaced in the event of a filament jam. The first design was catch 22 because you had to remove the filament to remove the hot end and you couldn't if it was jammed. Also if refitted it would not be tight enough press fitted a second time.

I don't use the fan for printing ABS so I don't have it fitted. Some holes in the top of the duct might be a good idea for cooling the insulator, but I haven't had any problems printing PLA without a fan using a J-Head. The MK5 is a bit marginal with PLA though as you can get a jam in the grub screw at the top if the filament is not moving for a long period of time.

[www.hydraraptor.blogspot.com]

|

Re: Inconsistent Y-axis position; solved. March 25, 2013 02:30PM |

Registered: 13 years ago Posts: 39 |

My last post was a somewhat accusational sorry. Just been sitting in from of my printer too long.

I have refitted the J Head once so that explains it, thanks. It continued printing PLA after the refit with no trouble, it was only when I tried ABS that the additional heat, or larger, hotter J Head? started loosening the extruder's grip. And the wobble symptoms appeared.

The revision looks great. Hope everyone held onto the extender in their precision manual toolsets.

Vis the Fan Duct, yes you want the option of controlling where the air goes so ABS doesn't delaminate on you and so on. This is largely redundant based on your greater experience with the J head but anyway:

Anyone interested should see it up on Thingiverse shortly.

woodsmoke

I have refitted the J Head once so that explains it, thanks. It continued printing PLA after the refit with no trouble, it was only when I tried ABS that the additional heat, or larger, hotter J Head? started loosening the extruder's grip. And the wobble symptoms appeared.

The revision looks great. Hope everyone held onto the extender in their precision manual toolsets.

Vis the Fan Duct, yes you want the option of controlling where the air goes so ABS doesn't delaminate on you and so on. This is largely redundant based on your greater experience with the J head but anyway:

Anyone interested should see it up on Thingiverse shortly.

woodsmoke

|

Re: Inconsistent Y-axis position March 28, 2013 04:30PM |

Registered: 11 years ago Posts: 250 |

hey Chris, what would it take to get one of the newer designs there?

(Just the piece printed here)

Thanks!

Chris

nophead Wrote:

-------------------------------------------------------

> I run an extruder like that at 250C inside a box

> at 45C 24/7 for months on end without any

> problems. Your extruder will have been printed

> with it.

>

> I have however changed the design to this:

> -[raw.github.com]

> bond/manual/extruder_hot_end_assembly.png

>

> It allows the hot end to be removed and replaced

> in the event of a filament jam. The first design

> was catch 22 because you had to remove the

> filament to remove the hot end and you couldn't if

> it was jammed. Also if refitted it would not be

> tight enough press fitted a second time.

>

> I don't use the fan for printing ABS so I don't

> have it fitted. Some holes in the top of the duct

> might be a good idea for cooling the insulator,

> but I haven't had any problems printing PLA

> without a fan using a J-Head. The MK5 is a bit

> marginal with PLA though as you can get a jam in

> the grub screw at the top if the filament is not

> moving for a long period of time.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

(Just the piece printed here)

Thanks!

Chris

nophead Wrote:

-------------------------------------------------------

> I run an extruder like that at 250C inside a box

> at 45C 24/7 for months on end without any

> problems. Your extruder will have been printed

> with it.

>

> I have however changed the design to this:

> -[raw.github.com]

> bond/manual/extruder_hot_end_assembly.png

>

> It allows the hot end to be removed and replaced

> in the event of a filament jam. The first design

> was catch 22 because you had to remove the

> filament to remove the hot end and you couldn't if

> it was jammed. Also if refitted it would not be

> tight enough press fitted a second time.

>

> I don't use the fan for printing ABS so I don't

> have it fitted. Some holes in the top of the duct

> might be a good idea for cooling the insulator,

> but I haven't had any problems printing PLA

> without a fan using a J-Head. The MK5 is a bit

> marginal with PLA though as you can get a jam in

> the grub screw at the top if the filament is not

> moving for a long period of time.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Sorry, only registered users may post in this forum.