Tuning printing parameters

Posted by aesuli

|

Tuning printing parameters January 28, 2014 05:37AM |

Registered: 10 years ago Posts: 19 |

Hi all,

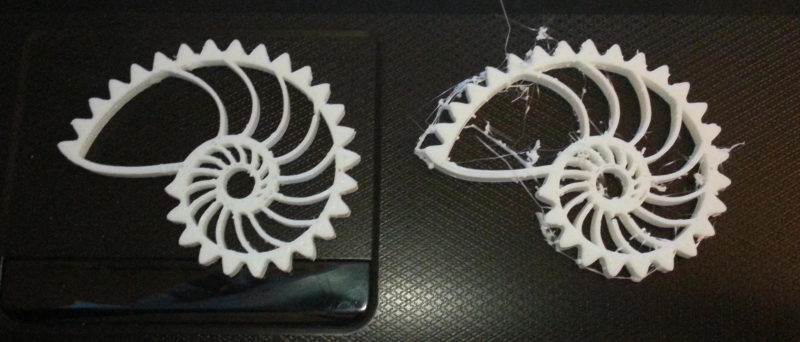

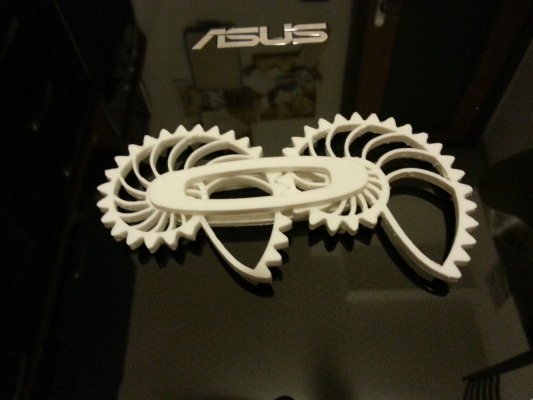

third evening printing, I printed the Nautilus gears.

They came out almost good but with a relevant amount of dribbles (I hope this is the proper English word for what you see in the picture, i.e., tiny filaments produced by the extruder when it moves from one point to another).

A bit of sanding cleaned it and made it nice.

I have generated the g-code for the printer using the last version of slic3r and the ormerod-0.5 profile downloaded from guthub.

Temperatures: extruder 205C (I'm using the white PLA from the kit), bed 65C.

The room temperature is 20C, umidity 60-70%.

Do you have any suggestion on how I should change the parameters (temperatures/slic3r) in order to improve print quality?

Thank you all, Andrea.

third evening printing, I printed the Nautilus gears.

They came out almost good but with a relevant amount of dribbles (I hope this is the proper English word for what you see in the picture, i.e., tiny filaments produced by the extruder when it moves from one point to another).

A bit of sanding cleaned it and made it nice.

I have generated the g-code for the printer using the last version of slic3r and the ormerod-0.5 profile downloaded from guthub.

Temperatures: extruder 205C (I'm using the white PLA from the kit), bed 65C.

The room temperature is 20C, umidity 60-70%.

Do you have any suggestion on how I should change the parameters (temperatures/slic3r) in order to improve print quality?

Thank you all, Andrea.

|

Re: Tuning printing parameters January 28, 2014 05:39AM |

Registered: 10 years ago Posts: 191 |

Hi Andrea,

did you increase extruder retraction to 2.4mm @ 45mm/s? You could also try lower temperatures both for the extruder and the heated bed.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

did you increase extruder retraction to 2.4mm @ 45mm/s? You could also try lower temperatures both for the extruder and the heated bed.

Markus

XBee & electronics blog: [lookmanowire.blogspot.com]

|

Re: Tuning printing parameters January 28, 2014 05:50AM |

Registered: 10 years ago Posts: 19 |

|

Re: Tuning printing parameters January 28, 2014 06:24AM |

Registered: 10 years ago Posts: 14,672 |

I use 4mm retraction, 198C for the first layer and 193C for the remaining layers. 205C and 200C were about right using the old firmware, which was overreading by about 7C @ around 200C. That was corrected at revision 0.53.

For the bed, I am currently using 75C for the first layer and 65C after that, but I am printing direct on glass. For printing on Kapton, I was using 60C.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

For the bed, I am currently using 75C for the first layer and 65C after that, but I am printing direct on glass. For printing on Kapton, I was using 60C.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tuning printing parameters January 28, 2014 08:51AM |

Registered: 10 years ago Posts: 19 |

|

Re: Tuning printing parameters January 28, 2014 10:26AM |

Registered: 10 years ago Posts: 14,672 |

I've not tried changing the print speed, but I have increased the extrusion max speed and acceleration, using these commands:

M201 X800 Y800 Z8 E350 ; set accelerations, reduce Z, increase E

M203 X3000 Y3000 Z180 E2700 ; increase max extruder speed

I did try increasing the max X and Y speeds, as high as 20000 at one time. Higher speeds seem OK but cause more vibration.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

M201 X800 Y800 Z8 E350 ; set accelerations, reduce Z, increase E

M203 X3000 Y3000 Z180 E2700 ; increase max extruder speed

I did try increasing the max X and Y speeds, as high as 20000 at one time. Higher speeds seem OK but cause more vibration.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.