Head sag worse because of wiring?

Posted by ZeAllan

|

Head sag worse because of wiring? February 13, 2014 02:37PM |

Registered: 10 years ago Posts: 46 |

Hi,

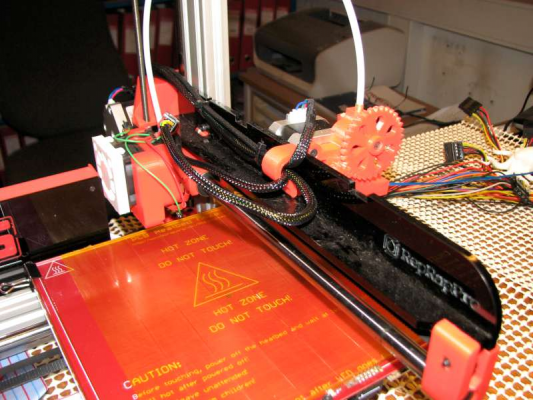

Sometimes the print head cabling is lower than the print head when held in place by the extruder clip. That led me to try attaching the cabled loosely to the bowden cable in order do avoid it catching a tall print.

The next print was then ruined after an hour by what looks like the worst case of head sag to date. The obvious guess is that the cable actually pushes the fan enclosure a little downwards when positioned in this way compared to normally when the centre of gravity is more towards the end of the X axis instead of right on the fan.

The question that I feel like examining now is if I could move the cabling away from where it could catch tall prints AND prevent head sag by putting adding some sort of tower to the extruder clip and attaching the cabling loosely to that using a rubber band to neutralize its weight.

Any thoughts?

/Allan

Edited 1 time(s). Last edit at 02/13/2014 02:56PM by ZeAllan.

Sometimes the print head cabling is lower than the print head when held in place by the extruder clip. That led me to try attaching the cabled loosely to the bowden cable in order do avoid it catching a tall print.

The next print was then ruined after an hour by what looks like the worst case of head sag to date. The obvious guess is that the cable actually pushes the fan enclosure a little downwards when positioned in this way compared to normally when the centre of gravity is more towards the end of the X axis instead of right on the fan.

The question that I feel like examining now is if I could move the cabling away from where it could catch tall prints AND prevent head sag by putting adding some sort of tower to the extruder clip and attaching the cabling loosely to that using a rubber band to neutralize its weight.

Any thoughts?

/Allan

Edited 1 time(s). Last edit at 02/13/2014 02:56PM by ZeAllan.

|

Re: Head sag worse because of wiring? February 13, 2014 03:28PM |

Registered: 10 years ago Posts: 1,230 |

Hi Allan

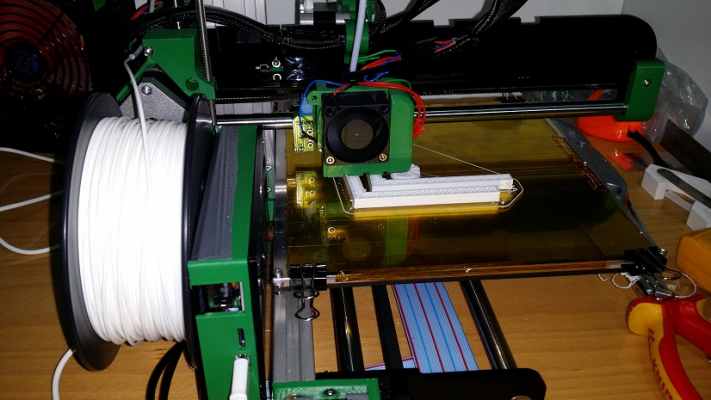

Why not put them all under extruder clip like this?

Its a very bad idea to attach anything to the filament tube as the variating downward pressure along the x-axis on the nozzle is bad enough as it is, not even cable guy has been able to fix this problem for me...yet!

Erik

Why not put them all under extruder clip like this?

Its a very bad idea to attach anything to the filament tube as the variating downward pressure along the x-axis on the nozzle is bad enough as it is, not even cable guy has been able to fix this problem for me...yet!

Erik

|

Re: Head sag worse because of wiring? February 13, 2014 04:17PM |

Registered: 10 years ago Posts: 46 |

That's where I had them first. I'm experimenting with a plate full of [www.thingiverse.com] printed one at a time next to each other at different temperatures -- but the more I print beyond the middle of the plate, the lower the cable sinks, so if unattended, it ends up hanging low enough to catch the objects I printed first.

Point taken about attaching to the bowden tube, though. Perhaps the "tower" idea could work with the cabling in the current position instead, and the tower mounted in the outer rib cutout instead...

/Allan

Point taken about attaching to the bowden tube, though. Perhaps the "tower" idea could work with the cabling in the current position instead, and the tower mounted in the outer rib cutout instead...

/Allan

|

Re: Head sag worse because of wiring? February 13, 2014 05:21PM |

Registered: 10 years ago Posts: 14,672 |

Allan, I find it hard to understand how your cables could be sagging (when not attached to the bowden cable), assuming you tie-wrapped the fan/heater/thermistor cables to the top of the heatsink as in the instructions. Can you post a photo?

Edited 1 time(s). Last edit at 02/13/2014 05:22PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 02/13/2014 05:22PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Head sag worse because of wiring? February 13, 2014 06:12PM |

Registered: 10 years ago Posts: 46 |

Actually that might be what caused the problem if I'm the only one having it. :-)

Looking at the assembly instructions again I remember that I got confused about the images not showing what the text said most of the places in the hot-end section, and attaching to the heat sink somehow felt wrong because of the way some of the wires (especially from the fan and the thermistor) went around the whole assembly. I ended up attaching the bundle to the eye on the side of the fan casing instead, as done in at least one of the pictures in the assembly instructions -- and later adding the Z sensor harness to the same bundle, making the whole bundle run more or less out and away from the fan instead of along the X axis.

I've now tied it to the sink and so far it looks as if it carries itself better this way when leave it under the extruder clip like in Eriks photo. Just wondering if the movement of the connector is wearing in the long run...

Thanks for the help! ;-)

/Allan

Looking at the assembly instructions again I remember that I got confused about the images not showing what the text said most of the places in the hot-end section, and attaching to the heat sink somehow felt wrong because of the way some of the wires (especially from the fan and the thermistor) went around the whole assembly. I ended up attaching the bundle to the eye on the side of the fan casing instead, as done in at least one of the pictures in the assembly instructions -- and later adding the Z sensor harness to the same bundle, making the whole bundle run more or less out and away from the fan instead of along the X axis.

I've now tied it to the sink and so far it looks as if it carries itself better this way when leave it under the extruder clip like in Eriks photo. Just wondering if the movement of the connector is wearing in the long run...

Thanks for the help! ;-)

/Allan

|

Re: Head sag worse because of wiring? February 13, 2014 06:44PM |

Registered: 10 years ago Posts: 14,672 |

You appear to have the 6-way connector off to the right of the head. I guess your fan must have had long wires. My 6-way connector is just above the heatsink, held there by the cable tie around the hot end wires going into it, so its weight is supported by the hot end.

Edited 1 time(s). Last edit at 02/13/2014 06:44PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 02/13/2014 06:44PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Head sag worse because of wiring? February 14, 2014 02:29AM |

Registered: 10 years ago Posts: 1,230 |

Quote

ormerod168

...Its a very bad idea to attach anything to the filament tube as the variating downward pressure along the x-axis on the nozzle is bad enough as it is...

Erik

The visual:

[forums.reprap.org]

|

Re: Head sag worse because of wiring? February 14, 2014 07:59PM |

Registered: 10 years ago Posts: 46 |

I wonder if the length of the filament tube could be increased to reduce the pull from the Extruder connection...

I can see how a rubber band from above might worsen the weight difference along the axis in your numbers, since the pull would be biggest where the difference is smallest. On the other hand, using the two remaining cutouts instead, with a "weak" rubber band in each, might counteract the extra force from the middle position more than in the outer positions...

But, provided the X rib is stiff and straight enough, shouldn't the weight be more constant that it is in your measurements, and therefore less of an issue? With my printer, at least for now, it is the bed that needs adjustment first of all (visibly bendy wood underneath), and i'm hoping to try out a few simple ideas within the next week.

Since the cable is attached to the head anyway, the weight of the cable as well as whatever force the bending of the cable exerts ought to vary as the head moves along the X axis, and the way it is running normally, I expect it to have a slight twisting effect on the X carriage also (not sure if that is a problem).

I haven't got a precise scale yet, but I'll have to try some measurements without the cables and with them in the normal position vs. on the filament tube once I get one. My theory until the numbers are in is that the weight of the cable on the head just might be more constant in the tube position, and that the total weight on the tube is probably not that much different.

/Allan

|

Re: Head sag worse because of wiring? February 14, 2014 08:56PM |

Registered: 10 years ago Posts: 859 |

My wires are cable tied at the top of the heat sink like every one else, but my extruder feeder is closer to the pillar, as I found I had your problem.

I also found that doing up the two fan screws, while lifting the fan ducting, raised the ducting by about 2mm by accident...

Don't put cable ties on the PTFE tubing... It hates the added pressure... I found this one out the hard way....

(excuse the gaffer tape... It was taken before my little pillar mods to the Duet box...see tips thread below if interested).

Kim

Building tips

Edited 2 time(s). Last edit at 02/14/2014 08:58PM by KimBrown.

|

Re: Head sag worse because of wiring? February 15, 2014 03:05PM |

Registered: 10 years ago Posts: 46 |

Small update: I got a scale today, and tried a quick and unstructured experiment: Found the point where the nozzle touches the scale, moved it up 1mm and there was no weight on the scale anymore. Compared the weight reading in three positions across the x axis. my bed is a little lower in the inner X position, but probably only .1 to .2mm.

The unscientific observation seems to be that between having the cable run along the X rib as it should, and having it attached to the filament tube (note: Loosely attached to, to hold the cable in position, not tied to. See the image in my first post) made no big difference in the outer positions, but seemed to reduce the weight in the middle by 10g. I haven't tried detaching the cables al the way to see what that does.

I only have a difference of around 10g added weight when the filament tube is not attached to the extruder, by the way.

As I said: Completely unscientific - and probably not terribly precise measurements. I'm leaving the cables in the "official" position for now, after all the warnings - but remain not really convinced. :-)

By the way: My bed had 1.2mm misalignment. Since I found blue tape and a cold bed to work best most of the time anyway, I found four washers that were almost 1.1mm and attached those along the back side of the glass plate near the lowest corner. Better solutions are on the way, but now I can get on with bigger prints at least (and I have an extra glass plate if I need to print heated).

/Allan

The unscientific observation seems to be that between having the cable run along the X rib as it should, and having it attached to the filament tube (note: Loosely attached to, to hold the cable in position, not tied to. See the image in my first post) made no big difference in the outer positions, but seemed to reduce the weight in the middle by 10g. I haven't tried detaching the cables al the way to see what that does.

I only have a difference of around 10g added weight when the filament tube is not attached to the extruder, by the way.

As I said: Completely unscientific - and probably not terribly precise measurements. I'm leaving the cables in the "official" position for now, after all the warnings - but remain not really convinced. :-)

By the way: My bed had 1.2mm misalignment. Since I found blue tape and a cold bed to work best most of the time anyway, I found four washers that were almost 1.1mm and attached those along the back side of the glass plate near the lowest corner. Better solutions are on the way, but now I can get on with bigger prints at least (and I have an extra glass plate if I need to print heated).

/Allan

Sorry, only registered users may post in this forum.