Bent y motor mount problem

Posted by Chaisaeng

|

Bent y motor mount problem May 15, 2014 04:15AM |

Registered: 10 years ago Posts: 76 |

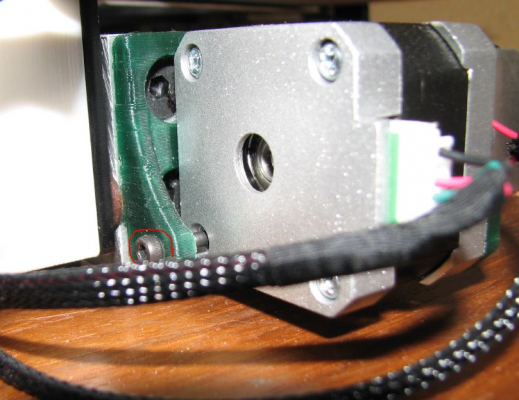

Any one having this problem? I just reprint it an replace in my ormerod

but still thinking of reinforce it to mor rigid. The bent was due to heat generated from the motor over long period of continuous printing

The belt tension pull it so it will be seen prominently while it still installed in the printer.

Anyone having idea to reinforce it so it will stay square with few effort.

but still thinking of reinforce it to mor rigid. The bent was due to heat generated from the motor over long period of continuous printing

The belt tension pull it so it will be seen prominently while it still installed in the printer.

Anyone having idea to reinforce it so it will stay square with few effort.

|

Re: Bent y motor mount problem May 15, 2014 06:52AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Chaisaeng

...The belt tension pull it so it will be seen prominently while it still installed in the printer.

Anyone having idea to reinforce it so it will stay square with few effort.

thinking out loud here, the y-motor-bracket will alway give against the belt pull, no matter how solid the printed part is - better to use metal, we have the steel rods - design and print a support part for the two acrylic y-axis-end-plate (in the full length off) then use the 12mm y-rods against the belt pull - at the end point of the 12mm rods, make room for a nut and bolt to adjust against the ends of the steel rods (the steel rods are rough cut and of different size) - then we have something solid to hold rest the y-motor bracket against

Erik

|

Re: Bent y motor mount problem May 15, 2014 06:57AM |

Registered: 10 years ago Posts: 14,672 |

If you stand the Ormerod feet on Paul's anti-vibration mounts or jack them up in some other way, then the y-motor will be higher off the ground. That would allow you to add a triangular fillet to the plastic part underneath the motor.

Edited 1 time(s). Last edit at 05/15/2014 07:24AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 05/15/2014 07:24AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bent y motor mount problem May 15, 2014 07:02AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Bent y motor mount problem May 15, 2014 02:11PM |

Registered: 10 years ago Posts: 76 |

|

Re: Bent y motor mount problem May 15, 2014 03:18PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Chaisaeng

Thanks for all suggestion. .I think of something Erik do strengthen on both side of acrylic part

with square aluminum and maybe cutting another square aluminum for motor mount.

Another take could be to make a base plate of e.g. 4 mm aluminum - or maybe plywood would do if chosen a bit thicker - then mount this under the y-aluminum extrusion with 3mm T-nuts and screws, you would have to make a cut-out for the printed z-axis support part and ditto for the bed heater cable, the dimension could be something like 400x100mm, if you make it more than 100mm in the X direction you would also have to make out-cuts for the feet of the acrylic end parts to go through as they are a bit (4mm afair) under the level of the y-extrusion - or you could just chop 4mm of the acrylic parts (I did)

Then use this strong-against-belt-pull base plate to mount your supports for the acrylic end parts on - and another upside of a base plate would be the support of the heating bed cables

..and then put some handles on both side of the base plate for lifting the ormerod, better than carrying it in the z-axis

I may have to order a hardware kit and start all over again as there is so many different ways you can mod this thing :-)

Erik

|

Re: Bent y motor mount problem May 16, 2014 08:19AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Chaisaeng

Thanks for all suggestion. .I think of something Erik do strengthen on both side of acrylic part

with square aluminum and maybe cutting another square aluminum for motor mount.

..but you will IMHO be better off and your time better spend making angled aluminum supports for the acrylic parts bolted to the y-extrusion, then you will get horizontal strength against the pull of the y-belt and vertical strength to keep the bed stable - two for the price of one, what's not to like? :-)

Erik

|

Re: Bent y motor mount problem May 16, 2014 08:21AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Bent y motor mount problem May 16, 2014 09:30AM |

Registered: 10 years ago Posts: 76 |

Quote

dmould

Quite possibly the unmodified part printed in ABS instead of PLA would be sufficient. ABS won't get soft due to the motor getting hot, and I think it is also a stronger plastic.

Dave

(#106)

ABS will be quite flexible so the belt tension may pull it making the thin motor mount arm bent.

It may not affect by heat generated by the motor but i think original design may need to modified to have it thicker or may be add some support underneath as DC42 suggest.

Edited 1 time(s). Last edit at 05/16/2014 09:31AM by Chaisaeng.

|

Re: Bent y motor mount problem May 16, 2014 09:51AM |

Registered: 10 years ago Posts: 1,230 |

The back screw is what really holds the stepper in position, if you moved the motor out a bit there would be room for making the angle adjustable to compensate for the sag, not perfect I know..

Erik

Erik

Sorry, only registered users may post in this forum.