Poor layer adhesion?

Posted by Davek0974

|

Poor layer adhesion? June 13, 2014 11:00AM |

Registered: 10 years ago Posts: 776 |

I'm running PLA and just printed an enclosure box for a project, the dimensions were 100x100x50mm, split into a lid and base.

Wall and base thickness was 2.5mm, there are corner supports added for the cover screws.

It looks cosmetically great but i'm finding it very easy to split the walls, it appears that the PLA has not "bonded" intermittently??

It was printed at 195c/190c and bed at 65c/60c

First attempt was layer height 0.24mm, which took a while, second attempt was 0.36mm layer height.

I think infill was 40% or slic3r default whatever that was.

Any suggestions?

The last print was usable but you can feel the walls move a bit if stressed.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Wall and base thickness was 2.5mm, there are corner supports added for the cover screws.

It looks cosmetically great but i'm finding it very easy to split the walls, it appears that the PLA has not "bonded" intermittently??

It was printed at 195c/190c and bed at 65c/60c

First attempt was layer height 0.24mm, which took a while, second attempt was 0.36mm layer height.

I think infill was 40% or slic3r default whatever that was.

Any suggestions?

The last print was usable but you can feel the walls move a bit if stressed.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Poor layer adhesion? June 13, 2014 03:44PM |

Registered: 10 years ago Posts: 2,472 |

All prints are relatively weak in the Z direction, and layers will not bond to be as strong as the print is in the XY plane. You should orient your designs with that in mind - it is sometimes better to make an item in two or more pieces so as to get their orientations in the direction that needs the strength, and bolt/glue them together afterwards. You can experiment with different extruder temperatures and maybe block off the cooling air jet. A hotter extrusion will bond better, but also have a greater tendency to warp (which can also cause delamination) and has poorer bridging properties. You can also design in vertical ribs to provide greater strength to side walls - or make the walls thicker in general (though that can also promote warping).

Dave

(#106)

Dave

(#106)

|

Re: Poor layer adhesion? June 13, 2014 04:04PM |

Registered: 10 years ago Posts: 776 |

Ok, ta, I'll keep messing about.

Is it possible to print with 100% infill I.e. solid ?

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Is it possible to print with 100% infill I.e. solid ?

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Poor layer adhesion? June 13, 2014 05:22PM |

Registered: 10 years ago Posts: 101 |

I had been extruding PLA filament at 190c with great result - very strong. Then I bought a spool from another supplier, and got a very weak bond between the layers. After raising the temperature to 205c, the strencth of the bonds was back.

I'm currently printing some ABS-parts for the Ormerod with 0.95% fill with great results.They are very close to solid. I did not go to 1.0, because I was afraid it would affect the dimensions of the parts.

Please note, that most of the stiffness and strength of the printed parts comes from the perimeters (like in honey-comb plates). Therefore you will not gain much by using 1.0 fill. If you increase the number of perimeters to 6 or 8 on bigger parts, you will get much stiffer parts without using excess filament - not to mention tons of problems with warping. Just remember to increase the number of solid top/bottom-layers as well. This comes from basic static/mechanics calculations.

Best regards,

Carsten

I'm currently printing some ABS-parts for the Ormerod with 0.95% fill with great results.They are very close to solid. I did not go to 1.0, because I was afraid it would affect the dimensions of the parts.

Please note, that most of the stiffness and strength of the printed parts comes from the perimeters (like in honey-comb plates). Therefore you will not gain much by using 1.0 fill. If you increase the number of perimeters to 6 or 8 on bigger parts, you will get much stiffer parts without using excess filament - not to mention tons of problems with warping. Just remember to increase the number of solid top/bottom-layers as well. This comes from basic static/mechanics calculations.

Best regards,

Carsten

|

Re: Poor layer adhesion? June 14, 2014 03:29AM |

Registered: 10 years ago Posts: 776 |

Will try that

Thanks

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Thanks

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Poor layer adhesion? June 14, 2014 05:59AM |

Registered: 10 years ago Posts: 101 |

|

Re: Poor layer adhesion? June 14, 2014 10:27AM |

Registered: 10 years ago Posts: 859 |

If your using a Big Blue I'd suggest you run at a temp of 200' or 205' at the Walls with the Exhaust Pipe Uncovered to reduce the cooling air.

Remember that the second fill in the wall section has to be hot enough to meld with the first perimeter.

When running Pronterface you can actualy raise and lower the HotEnd Temp while printing manualy, as well as control the Fan if you have it connected correctly using the M106 code.

If you have a single Fan on your BigBlue and it's connected to the Secondary Fan pins then don't run it below M106 S70 as you won't have air blowing throu the HeatSink if you reduce it lower.

If you have two Fans the Second one can be set to M106 S0 while doing the walls (M106 S0 turns the secondary Fan off...M106 S255 turns it Full On).

You can also let Slic3r control the fan, but again remember to set the Minimum to around S70 with a single Fan (you might be able to go a little lower dependant on your Fan, but you'd need to feel the HeatSink while it is running to check it is cool).

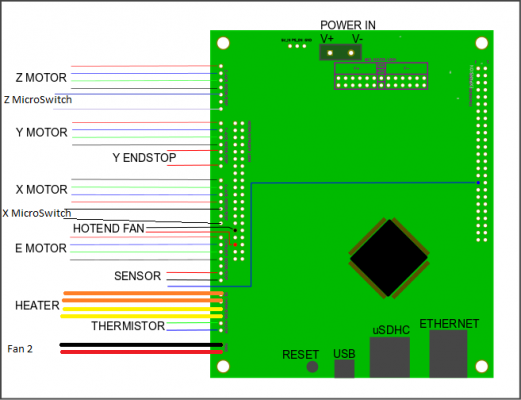

If your curious about the controlable Fan then it's marked on this Duet Diagram below... (As FAN2). Just move the fan wires over, but do check your Slic3r settings if you do this.... Else you might find the fan is turned off and the Ormerod would look very strainge with the HotEnd whipping around, slowly melting.....

Edited 1 time(s). Last edit at 06/14/2014 10:31AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Remember that the second fill in the wall section has to be hot enough to meld with the first perimeter.

When running Pronterface you can actualy raise and lower the HotEnd Temp while printing manualy, as well as control the Fan if you have it connected correctly using the M106 code.

If you have a single Fan on your BigBlue and it's connected to the Secondary Fan pins then don't run it below M106 S70 as you won't have air blowing throu the HeatSink if you reduce it lower.

If you have two Fans the Second one can be set to M106 S0 while doing the walls (M106 S0 turns the secondary Fan off...M106 S255 turns it Full On).

You can also let Slic3r control the fan, but again remember to set the Minimum to around S70 with a single Fan (you might be able to go a little lower dependant on your Fan, but you'd need to feel the HeatSink while it is running to check it is cool).

If your curious about the controlable Fan then it's marked on this Duet Diagram below... (As FAN2). Just move the fan wires over, but do check your Slic3r settings if you do this.... Else you might find the fan is turned off and the Ormerod would look very strainge with the HotEnd whipping around, slowly melting.....

Edited 1 time(s). Last edit at 06/14/2014 10:31AM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Poor layer adhesion? June 14, 2014 12:16PM |

Registered: 10 years ago Posts: 776 |

Trying 4 perimeters and 4 solid top and bottom layers now.

I have not ventured into the big blue arena yet, I'm still running the standard z head with noisy fan

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I have not ventured into the big blue arena yet, I'm still running the standard z head with noisy fan

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Poor layer adhesion? June 14, 2014 12:51PM |

Registered: 10 years ago Posts: 859 |

hihihihi in the Big Blue I suggest to people to use rubber 'o' rings to rubber mount the fan/s.

If using two fans like I do, one sits ontop of the other to give it that extra puff of air when needed....

And Big Blue bridges in 360' not just up and down the X axis...

If I stick with the Ormerod, which I probably will, I maybe doing an even better version in the coming months. But it's good as is for now...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

If using two fans like I do, one sits ontop of the other to give it that extra puff of air when needed....

And Big Blue bridges in 360' not just up and down the X axis...

If I stick with the Ormerod, which I probably will, I maybe doing an even better version in the coming months. But it's good as is for now...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Sorry, only registered users may post in this forum.