Is bed levelling working correctly?

Posted by appjaws1

|

Is bed levelling working correctly? July 17, 2014 06:14AM |

Registered: 10 years ago Posts: 780 |

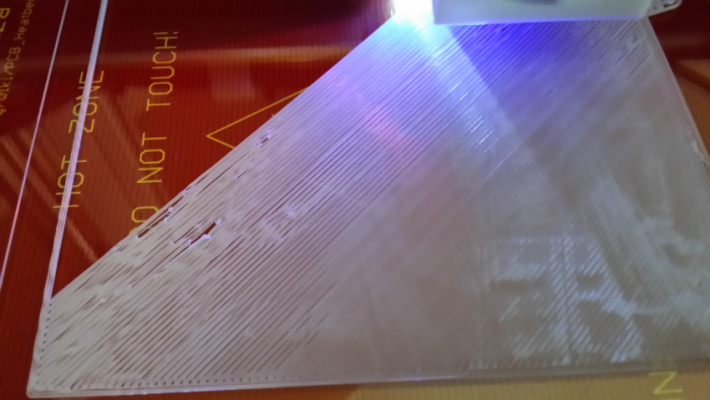

I have tried automatic bed levelling with dc42's latest probe and setbed.g. I have tried manual bed levelling using setman.g and whichever method I use I get similar results to the photo. As you can see the left hand corner towards the front of the bed is perfect but as the head moves towards the back right hand corner the lines of filament do not touch each other. So I think that the nozzle is too high.

This photo was as a result of using my setman.g file

This is my setman.g file, as you can see the bed is very close to being perfectly level with only +/- 0.1 at the front of the bed..

---------------------------------------------------------------------------------

M110

M140 S65 ; start heating the bed to 65C

M561 ; clear bed height transform

G91 ; relative positioning

G1 Z5 ; raise 5mm

G90 ; absolute positioning

G28 X0 Y0 ; home the X and Y axes

G1 Y200 F5000 ; get the head out of the way so we can clean the bed

M116 ; wait for bed temp to stabilise

;G4 P120000 ; want 2 more minutes when using the ultrasonic probe

M556 S74.5 X-0.56 Y0.18 Z0.267

; execute bed plane compensation procedure

G30 P0 X30 Y30 Z0.0

G30 P1 X30 Y175 Z0.0

G30 P2 X190 Y175 Z0.1

G30 P3 X190 Y30 Z-0.1 S

M92 X87.4890 Y87.4890 Z4000

G1 X100 Y100 ; now home the Z axis at the centre of the bed

M110

The bed levelling is quite good and represent a difference from front left to rear right of -0.1 I would have thought the compensation routine would iron out this small difference and produce a perfect print.

-------------------------------------------------------------------------------------------------------

This is my setbedg file

G30 P0 X30 Y30

G30 P1 X30 Y175

G30 P2 X190 Y175

G30 P3 X190 Y30

M92 X87.5766 Y87.5766 Z4000

M556 S74.5 X-0.56 Y0.18 Z0.267

M140 S65 ; start heating the bed to 65C

M561 ; clear bed height transform

G91 ; relative positioning

G1 Z5 ; raise 5mm

G90 ; absolute positioning

G28 X0 Y0 ; home the X and Y axes

G1 Y200 F5000 ; get the head out of the way so we can clean the bed

M116 ; wait for bed temp to stabilise

M104 S195;

G32 ; execute bed plane measurement procedure

G1 X100 Y107.5; now home the Z axis at the centre of the bed

G28 Z0

G1 Z5

---------------------------------------------------------------------------

These are the last 3 sets of readings of the Z probe

P0 1.55 1.55 1.55

P1 1.58 1.59 1.6

P2 1.34 1.28 1.19

P3 2.14 2.07 1.98

As you can see they are pretty consistent and represent a difference from front left to rear right of 0.38, which is a big difference from the manual settings.

------------------------------------------------------------------------

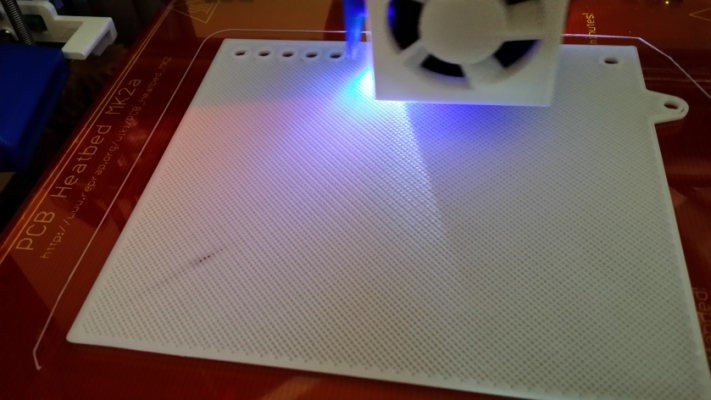

I should have tried without any compensation, but now the print is on layer 6 and is looking good so I am reluctant to stop it, I have already wasted so much filament, This is my 5th attempt at the new enlarged duet and X4 enclosure, the others were worse than the photo and the nozzle must have got caught because steps were missed in the X direction.

This is as of layer 6

I will have to put up with the very poor finish that will be the face seen of the enclosure.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

This photo was as a result of using my setman.g file

This is my setman.g file, as you can see the bed is very close to being perfectly level with only +/- 0.1 at the front of the bed..

---------------------------------------------------------------------------------

M110

M140 S65 ; start heating the bed to 65C

M561 ; clear bed height transform

G91 ; relative positioning

G1 Z5 ; raise 5mm

G90 ; absolute positioning

G28 X0 Y0 ; home the X and Y axes

G1 Y200 F5000 ; get the head out of the way so we can clean the bed

M116 ; wait for bed temp to stabilise

;G4 P120000 ; want 2 more minutes when using the ultrasonic probe

M556 S74.5 X-0.56 Y0.18 Z0.267

; execute bed plane compensation procedure

G30 P0 X30 Y30 Z0.0

G30 P1 X30 Y175 Z0.0

G30 P2 X190 Y175 Z0.1

G30 P3 X190 Y30 Z-0.1 S

M92 X87.4890 Y87.4890 Z4000

G1 X100 Y100 ; now home the Z axis at the centre of the bed

M110

The bed levelling is quite good and represent a difference from front left to rear right of -0.1 I would have thought the compensation routine would iron out this small difference and produce a perfect print.

-------------------------------------------------------------------------------------------------------

This is my setbedg file

G30 P0 X30 Y30

G30 P1 X30 Y175

G30 P2 X190 Y175

G30 P3 X190 Y30

M92 X87.5766 Y87.5766 Z4000

M556 S74.5 X-0.56 Y0.18 Z0.267

M140 S65 ; start heating the bed to 65C

M561 ; clear bed height transform

G91 ; relative positioning

G1 Z5 ; raise 5mm

G90 ; absolute positioning

G28 X0 Y0 ; home the X and Y axes

G1 Y200 F5000 ; get the head out of the way so we can clean the bed

M116 ; wait for bed temp to stabilise

M104 S195;

G32 ; execute bed plane measurement procedure

G1 X100 Y107.5; now home the Z axis at the centre of the bed

G28 Z0

G1 Z5

---------------------------------------------------------------------------

These are the last 3 sets of readings of the Z probe

P0 1.55 1.55 1.55

P1 1.58 1.59 1.6

P2 1.34 1.28 1.19

P3 2.14 2.07 1.98

As you can see they are pretty consistent and represent a difference from front left to rear right of 0.38, which is a big difference from the manual settings.

------------------------------------------------------------------------

I should have tried without any compensation, but now the print is on layer 6 and is looking good so I am reluctant to stop it, I have already wasted so much filament, This is my 5th attempt at the new enlarged duet and X4 enclosure, the others were worse than the photo and the nozzle must have got caught because steps were missed in the X direction.

This is as of layer 6

I will have to put up with the very poor finish that will be the face seen of the enclosure.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Is bed levelling working correctly? July 17, 2014 06:43AM |

Registered: 10 years ago Posts: 14,672 |

Strange that the nozzle looks to be too high even at the centre of the bed where you homed it after setting bed compensation.

The way I test auto bed compensation is to place an obstacle a few mm high in one of the corners before I execute G32. Then I remove the obstacle, run circle.g or square.g, and watch to see if the head rises to avoid the missing obstacle.

Another test you can do is to prepare a gcode file comprising five shallow cylinders or cubes, one at each corner of the bed and one at the centre.

Edited 1 time(s). Last edit at 07/17/2014 07:37AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The way I test auto bed compensation is to place an obstacle a few mm high in one of the corners before I execute G32. Then I remove the obstacle, run circle.g or square.g, and watch to see if the head rises to avoid the missing obstacle.

Another test you can do is to prepare a gcode file comprising five shallow cylinders or cubes, one at each corner of the bed and one at the centre.

Edited 1 time(s). Last edit at 07/17/2014 07:37AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is bed levelling working correctly? July 17, 2014 07:27AM |

Registered: 10 years ago Posts: 2,472 |

You could also try making the probe's trigger height 0.05mm lower - this will cause the entire print area to be slightly lower, so you'll get some squashing in the places that presently print just right, but that's preferable to printing too high (so long as it is not too squashed).

Dave

(#106)

Dave

(#106)

|

Re: Is bed levelling working correctly? July 17, 2014 09:00AM |

Registered: 10 years ago Posts: 780 |

Thank you both,

I will do some testing when my enclosure is finished, another 3hr 43 mins to go.

Using dc42's probe the difference of P3 and P4 from P0 is 0.36 and -0.43 respectively(just using the third set of numbers), compared with my manual paper measurement of 0.1 and-0.1

This seems to be a big discrepancy, any thoughts?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I will do some testing when my enclosure is finished, another 3hr 43 mins to go.

Using dc42's probe the difference of P3 and P4 from P0 is 0.36 and -0.43 respectively(just using the third set of numbers), compared with my manual paper measurement of 0.1 and-0.1

This seems to be a big discrepancy, any thoughts?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Is bed levelling working correctly? July 17, 2014 09:16AM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

Using dc42's probe the difference of P3 and P4 from P0 is 0.36 and -0.43 respectively(just using the third set of numbers), compared with my manual paper measurement of 0.1 and-0.1

This seems to be a big discrepancy, any thoughts?

Paul

Are you certain that 0.1 and -0.1 are accurate values? I don't find using paper very accurate for this kind of measurement, so I use RRP's approach of rolling the shank of a drill between the bed and the nozzle. Also, from the photo you posted earlier, I would have said that your manual bed adjustment of 0.1mm was insufficient.

The IR probe reading could be affected by other objects in the vicinity of the sensor head, such as bed clips or bed edges. So it might be worth trying again with the bed probing coordinates moved in by another 5 or 10mm from each edge.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is bed levelling working correctly? July 17, 2014 09:33AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

The IR probe reading could be affected by other objects in the vicinity of the sensor head, such as bed clips or bed edges. So it might be worth trying again with the bed probing coordinates moved in by another 5 or 10mm from each edge.

Thanks for that, I'll certainly give a try to the drill shank and bring the co-ordinates in by 5mm.

As I said in the other thread, I wonder if part of my problem is the wings on my single nozzle hot end reflecting light..

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Is bed levelling working correctly? July 17, 2014 10:11AM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

As I said in the other thread, I wonder if part of my problem is the wings on my single nozzle hot end reflecting light..

Paul

Reflected light from a wing close to the sensor will affect the trigger height and may make it more sensitive to the bed surface (because the light reflected by the bed surface has to compete with light reflected from the wing). However, for a constant surface, the effect should be consistent. Whether the wing actually makes a difference depends on how close it is to the IR emitters and phototransistor. Both have very directional characteristics; but I already observed that light reflected off the PCB was a problem, before I put the big capacitor there.

Edited 1 time(s). Last edit at 07/17/2014 10:13AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.