J-head hotend mount for the Ormerod

Posted by jstck

|

J-head hotend mount for the Ormerod August 26, 2014 06:19PM |

Registered: 10 years ago Posts: 378 |

For no other reason than "to see how it would work out", I decided to make a mount for the commonly found J-head hotend to fit the Ormerod. I got one for a different 3D printer project, and since I had some blockage issues with my original hotend I decided to give this a shot. Result is here.

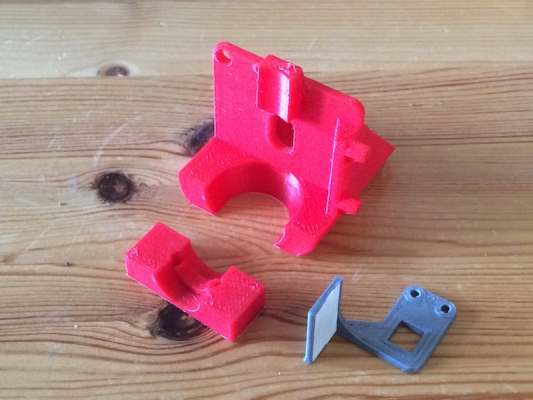

I got a cheap J-head hotend from Ebay a while back, as far as I can tell it is a Mk V nozzle holder and v5 hotend. The mount for it is a pretty simple block and a fan duct, and they clamp around the hotend nozzle holder and screw into the standard Ormerod X-carriage with a couple of M3x30 screws. The fan duct is modified from one designed for a Prusa, and fits a regular 40mm fan.

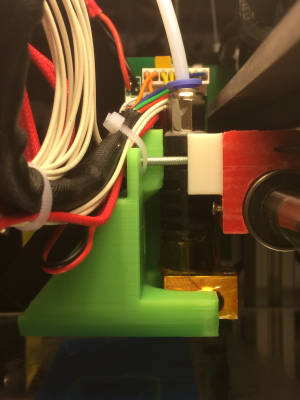

Here you can see the nozzle mount in white and the fan duct in green, with the J-head hotend in between. It has a push-fit connector for the Bowden tube, and since I got one with M5 thread I had to fix it in place with some high-temperature epoxy. Also the hotend has about half a meter of heater + thermistor wire that I didn't want to cut off just yet, so it's just coiled up.

The fan duct has mounting holes for dc42's sensor board. While the nozzle is in the same X/Y spot as the original one, it is about 20mm further down, so I changed dc42's sensor pad to match. It also means build height will be reduced by 20mm when using this.

As far as printing goes, it works quite well. I printed the first version on the old hotend, but after that I used this to "print itself", both PLA and ABS. Even when printing ABS the PEEK nozzle holder doesn't get very hot, the PLA parts I had on at the time seemed unmoved. For ABS, I just put some kapton tape under it to cover the cooling exhaust, but it seems to print well enough with no fan cooling whatsoever. The thermistor values need recalibrating, as temperatures are about 15-20 degrees too low (I just bumped up the temperature setting for now to print). Also the PID values for the heater are off, it overshoots a lot and oscillates a bit before settling. It is also clear the heater in this one is weaker, it takes at least twice as long to get the hotend up to temperature, and even when the thermistor reports it being there it takes a few more seconds before the plastic inside seems to melt properly.

More pictures and the parts files are on Thingiverse!

I got a cheap J-head hotend from Ebay a while back, as far as I can tell it is a Mk V nozzle holder and v5 hotend. The mount for it is a pretty simple block and a fan duct, and they clamp around the hotend nozzle holder and screw into the standard Ormerod X-carriage with a couple of M3x30 screws. The fan duct is modified from one designed for a Prusa, and fits a regular 40mm fan.

Here you can see the nozzle mount in white and the fan duct in green, with the J-head hotend in between. It has a push-fit connector for the Bowden tube, and since I got one with M5 thread I had to fix it in place with some high-temperature epoxy. Also the hotend has about half a meter of heater + thermistor wire that I didn't want to cut off just yet, so it's just coiled up.

The fan duct has mounting holes for dc42's sensor board. While the nozzle is in the same X/Y spot as the original one, it is about 20mm further down, so I changed dc42's sensor pad to match. It also means build height will be reduced by 20mm when using this.

As far as printing goes, it works quite well. I printed the first version on the old hotend, but after that I used this to "print itself", both PLA and ABS. Even when printing ABS the PEEK nozzle holder doesn't get very hot, the PLA parts I had on at the time seemed unmoved. For ABS, I just put some kapton tape under it to cover the cooling exhaust, but it seems to print well enough with no fan cooling whatsoever. The thermistor values need recalibrating, as temperatures are about 15-20 degrees too low (I just bumped up the temperature setting for now to print). Also the PID values for the heater are off, it overshoots a lot and oscillates a bit before settling. It is also clear the heater in this one is weaker, it takes at least twice as long to get the hotend up to temperature, and even when the thermistor reports it being there it takes a few more seconds before the plastic inside seems to melt properly.

More pictures and the parts files are on Thingiverse!

|

Re: J-head hotend mount for the Ormerod August 27, 2014 03:20AM |

Registered: 10 years ago Posts: 176 |

|

Re: J-head hotend mount for the Ormerod August 27, 2014 03:40AM |

Registered: 10 years ago Posts: 94 |

|

Re: J-head hotend mount for the Ormerod August 27, 2014 04:30AM |

Registered: 10 years ago Posts: 378 |

OpenSCAD exports to a few formats (STL, OFF, DXF, CSG), but I have never used anything but STL which is as close to a "standard model format" as you can get in 3D printing. I would think most programs that can read IGES could import any of those other formats.

I made the fan duct and sensor pad in Sketchup, the fan duct since I only had an STL to work with and the sensor pad (which is parametric to begin with) because I was lazy. Making a parametric version of the sensor pad to match would be pretty simple, it is just moved down by 20mm and made 1.5mm wider. The sensor board is a little bit closer to the nozzle in the X direction, and I actually had the board touch the "bulge" on the aluminium X rib (the one for a possible Z rod coming straight out of the stepper motor) when doing X homing.

I printed ABS versions of the mounting parts using the PLA parts, turned out well. At least they didn't melt or anything.

I made the fan duct and sensor pad in Sketchup, the fan duct since I only had an STL to work with and the sensor pad (which is parametric to begin with) because I was lazy. Making a parametric version of the sensor pad to match would be pretty simple, it is just moved down by 20mm and made 1.5mm wider. The sensor board is a little bit closer to the nozzle in the X direction, and I actually had the board touch the "bulge" on the aluminium X rib (the one for a possible Z rod coming straight out of the stepper motor) when doing X homing.

I printed ABS versions of the mounting parts using the PLA parts, turned out well. At least they didn't melt or anything.

|

Re: J-head hotend mount for the Ormerod August 27, 2014 07:19AM |

Registered: 10 years ago Posts: 119 |

Great work John,

I have a Mendel with a J-head and I wanted to replace the controller on that with a Duet.

My initial thought was to try and mount the hot end/extruder from the Ormerod onto the Mendel.

But, I can now print your parts, test the J-head on the Ormerod with the Duet.

Once all is working then move the head, extruder driver and electronics over to the Mendel.

Looks like I will have to either add the thermister I use to the Duet code base, or swap it with the one used on the Ormerod.

I think the heater is also 12v compatible as well. So, it should be fairly easy.

Are there any other problems you noticed when installing the J-head, it looks like a complete description in your post above?

I have a Mendel with a J-head and I wanted to replace the controller on that with a Duet.

My initial thought was to try and mount the hot end/extruder from the Ormerod onto the Mendel.

But, I can now print your parts, test the J-head on the Ormerod with the Duet.

Once all is working then move the head, extruder driver and electronics over to the Mendel.

Looks like I will have to either add the thermister I use to the Duet code base, or swap it with the one used on the Ormerod.

I think the heater is also 12v compatible as well. So, it should be fairly easy.

Are there any other problems you noticed when installing the J-head, it looks like a complete description in your post above?

|

Re: J-head hotend mount for the Ormerod August 27, 2014 07:36AM |

Registered: 10 years ago Posts: 378 |

The thermistor and heater in the J-head are perfectly fine, it just needs a little bit of tuning. In my case it works well enough by just raising the print temperature value by 10-15 degrees. And while the hotend heats up slower than the stock one, it is still way quicker than the heated bed and therefore not really a practical problem.

Overall, it was easier to get it running than I expected. I did a few generations of the various pieces until I got the dimensions right (screw holes too big or too small, and the sensor board being in slightly wrong position), but installing it and running it went smoothly and so far it is printing just fine.

I would expect there to be some variation in the exact dimensions of various J-head hotends, different versions and them being manufactured by different people. I just got the measurements from the drawings on the reprap wiki as well as just measuring things out on mine. Particularly the Z position of the fan duct assembly might need adjustment. While I made a version with "long holes" where the fan duct and sensor board can be adjusted a bit, things are of course more stable if you just have one set of small holes in the right place. It shouldn't be too much work changing it, and I might just for the fun of it make a parametric design out of it.

It's not like I would recommend everyone to go out buying J-head hotends and changing things out, but interchangeability of parts is never a bad thing, and that is the main reason I'm posting this.

Overall, it was easier to get it running than I expected. I did a few generations of the various pieces until I got the dimensions right (screw holes too big or too small, and the sensor board being in slightly wrong position), but installing it and running it went smoothly and so far it is printing just fine.

I would expect there to be some variation in the exact dimensions of various J-head hotends, different versions and them being manufactured by different people. I just got the measurements from the drawings on the reprap wiki as well as just measuring things out on mine. Particularly the Z position of the fan duct assembly might need adjustment. While I made a version with "long holes" where the fan duct and sensor board can be adjusted a bit, things are of course more stable if you just have one set of small holes in the right place. It shouldn't be too much work changing it, and I might just for the fun of it make a parametric design out of it.

It's not like I would recommend everyone to go out buying J-head hotends and changing things out, but interchangeability of parts is never a bad thing, and that is the main reason I'm posting this.

|

Re: J-head hotend mount for the Ormerod August 27, 2014 07:42AM |

Registered: 10 years ago Posts: 14,672 |

Quote

ezwul

Looks like I will have to either add the thermister I use to the Duet code base, or swap it with the one used on the Ormerod.

If you use my firmware fork, there is no need to change the code because you can use the M305 command to tell the firmware what the thermistor parameters are. See [reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: J-head hotend mount for the Ormerod August 27, 2014 07:53AM |

Registered: 10 years ago Posts: 378 |

|

Re: J-head hotend mount for the Ormerod August 27, 2014 08:19AM |

Registered: 10 years ago Posts: 119 |

Thanks for the pointer, I shall save all my settings and then swap the thermister from the J-head and work out its parameters as you suggested above.

What has just occured to me is the J-head is using 3mm filament, so I am going to have to see if the current extruder driver can cope or if I am going to have to print one of the Mendel Bowden extruders of RRPs other machines. My current Wades extruder is not a good substitute when used with bowden tube.

Suppose changing the J-head lining for 1.75mm is the best solution.

Otherwise has anyone put 3mm filament through the current Ormerod design?

I would think that these are the stopping points

1) The PTFE extruder drive feed tube, new tubing required + fittings

2) Distance between hob bolt and bearing, spring loaded extruder required

3) The PTFE bowden tube, new tubing required

4) PTFE brass fittings

5) The PTFE hot-end lining tube inside the hot end, new tubing required

6) Melt chamber in Hot-end

So only 4 and 5 worry me, if these can take the larger diameter?

Substitute different part for 4 and trial and error for 5 will prove this I suppose.

What has just occured to me is the J-head is using 3mm filament, so I am going to have to see if the current extruder driver can cope or if I am going to have to print one of the Mendel Bowden extruders of RRPs other machines. My current Wades extruder is not a good substitute when used with bowden tube.

Suppose changing the J-head lining for 1.75mm is the best solution.

Otherwise has anyone put 3mm filament through the current Ormerod design?

I would think that these are the stopping points

1) The PTFE extruder drive feed tube, new tubing required + fittings

2) Distance between hob bolt and bearing, spring loaded extruder required

3) The PTFE bowden tube, new tubing required

4) PTFE brass fittings

5) The PTFE hot-end lining tube inside the hot end, new tubing required

6) Melt chamber in Hot-end

So only 4 and 5 worry me, if these can take the larger diameter?

Substitute different part for 4 and trial and error for 5 will prove this I suppose.

|

Re: J-head hotend mount for the Ormerod August 27, 2014 10:11AM |

Registered: 10 years ago Posts: 378 |

I think most extruders can be adapted for a bowden tube with those push-in fittings. In any case, if you have the hardware there are lots of models available to print out to make a bowden extruder drive.I didn't know you could just insert a liner to use 1.75mm filament in a 3mm hotend, but maybe that would work. A PTFE tube with 3mm outer and 2mm inner diameter (same kind of tubing as the filament guide supplied with the ormerod) perhaps.

The opposite path, adapting the regular Ormerod hotend for 3mm filament, I think is not possible. Basically every part along the filament path would need replacing. If you take out the PTFE liner inside the hotend nozzle a 3mm filament could maybe fit, but from what I gather the liner does serve a thermal purpose preventing the filament from melting too high up. To fit a liner for a 3mm filament you would either need a completely new nozzle (that would be thicker, requiring a different cooling block), or drilling out the existing one so it would be scary thin. To make a 3mm-filament Ormerod, it would be better to get whatever 3mm hotend you like and make a compatible mount for it, and just adapt some bowden extruder to have the same mounting bracket.

The opposite path, adapting the regular Ormerod hotend for 3mm filament, I think is not possible. Basically every part along the filament path would need replacing. If you take out the PTFE liner inside the hotend nozzle a 3mm filament could maybe fit, but from what I gather the liner does serve a thermal purpose preventing the filament from melting too high up. To fit a liner for a 3mm filament you would either need a completely new nozzle (that would be thicker, requiring a different cooling block), or drilling out the existing one so it would be scary thin. To make a 3mm-filament Ormerod, it would be better to get whatever 3mm hotend you like and make a compatible mount for it, and just adapt some bowden extruder to have the same mounting bracket.

|

Re: J-head hotend mount for the Ormerod August 27, 2014 02:51PM |

Registered: 10 years ago Posts: 176 |

|

Re: J-head hotend mount for the Ormerod August 27, 2014 02:55PM |

Registered: 9 years ago Posts: 138 |

|

Re: J-head hotend mount for the Ormerod August 27, 2014 05:01PM |

Registered: 10 years ago Posts: 378 |

Quote

VortyZA

What would be the advantage of 3mm over 1.75mm?

Depends mostly on what hardware or filament you already have, as it is easier to stick to one size. Also some specialized filament types may only be available in one size or the other. While extruders and hotends need to be designed a little bit differently, both work just as well.

Quote

muggi

What are the advantages of a j-head compare to the original ormerod hot end?

The J-head seems to do well without any fan-cooling (or very little), and it is easy to find cheaply on ebay and a lot of other resellers of 3D printer parts, just from being more common. Print quality wise, I don't think there is any difference really.

|

Re: J-head hotend mount for the Ormerod August 28, 2014 02:54PM |

Registered: 10 years ago Posts: 9 |

Good work! I had been about to work on something similar and this cuts more than half the work away from it with minor modifications! I had the idea of doing a direct drive extruder to print ninjaflex with as the filament seems to not work well with bowden setups.

Also a note to anyone who decides to purchase a J head from ebay, I've read warnings from the creator of the original one about cheap ebay knockoffs of the authentic j-head having jamming problems after some time(good method of identification would be the internal PTFE liner being red to know if it was manufactured by hotends.com) , so hopefully you got your hands on an authentic one or at least got lucky with one that does not give you problems!

Also a note to anyone who decides to purchase a J head from ebay, I've read warnings from the creator of the original one about cheap ebay knockoffs of the authentic j-head having jamming problems after some time(good method of identification would be the internal PTFE liner being red to know if it was manufactured by hotends.com) , so hopefully you got your hands on an authentic one or at least got lucky with one that does not give you problems!

|

Re: J-head hotend mount for the Ormerod August 28, 2014 06:19PM |

Registered: 10 years ago Posts: 378 |

Sorry, only registered users may post in this forum.