dialing in seams and edges (w/ KISSlicer)

Posted by Amsterdamman

|

dialing in seams and edges (w/ KISSlicer) September 13, 2014 06:49AM |

Registered: 9 years ago Posts: 146 |

Hi All,

Finally my Ormerod1 is working fairly consistently and with few failures. Now I'm trying to get the prints better, esp since I want to print my Ormerod2 parts! Attached is a photo of three 1cm3 blocks I made last night. Left is #1 and middle is #9 I do use KISSlicer far right is from Slic3r. Realizing most users seems to use Slic3r I also made one with Slic3r just to see the difference, and it is a better final shape, but the print was twice as long as well and I prefer the paths and interface method KISSlicer uses. The final product is key, so I would give up and use Slic3r if it is the only method that works.

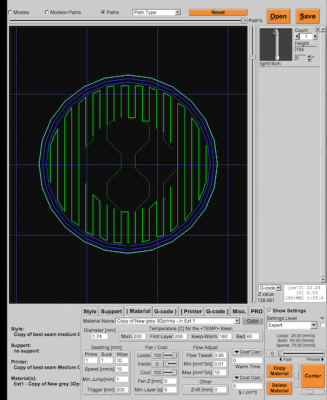

I was trying different fields between test #1 and #9 but found the last MISC tab had the most effect on the print seam. Seam hiding didn't help, so I lowered the Oversampling resolution from 0.125 to 0.05 and dropped the crowning threshold from 1 to 0.5 but It still isn't quite as good as Slic3r though... Attached are screenshots of my KISSLicer fields.

Also the base of the piece flares slightly compared to Slic3r. Any suggestions for fields to play with or other methods to improve the KISSlicer results?

Thanks all for any help your willing to offer!!

Kimon ~ The Amsterdamman

Finally my Ormerod1 is working fairly consistently and with few failures. Now I'm trying to get the prints better, esp since I want to print my Ormerod2 parts! Attached is a photo of three 1cm3 blocks I made last night. Left is #1 and middle is #9 I do use KISSlicer far right is from Slic3r. Realizing most users seems to use Slic3r I also made one with Slic3r just to see the difference, and it is a better final shape, but the print was twice as long as well and I prefer the paths and interface method KISSlicer uses. The final product is key, so I would give up and use Slic3r if it is the only method that works.

I was trying different fields between test #1 and #9 but found the last MISC tab had the most effect on the print seam. Seam hiding didn't help, so I lowered the Oversampling resolution from 0.125 to 0.05 and dropped the crowning threshold from 1 to 0.5 but It still isn't quite as good as Slic3r though... Attached are screenshots of my KISSLicer fields.

Also the base of the piece flares slightly compared to Slic3r. Any suggestions for fields to play with or other methods to improve the KISSlicer results?

Thanks all for any help your willing to offer!!

Kimon ~ The Amsterdamman

|

Re: dialing in seams and edges (w/ KISSlicer) September 13, 2014 09:04AM |

Registered: 10 years ago Posts: 1,230 |

Hi Kimon

The perimeters that don't reach in the corners - is it start or the ending point that is lacking or both? - hard to see from your picture

Did you use the exact same settings in slic3r and kisslicer?

Material - First layer temp. of 255C do seem a bit excessive and will carry up some layers, my PLA settings are 185/57 all the way

I would try with Prime and Suck at 0 and 4 or 5mm, Speed 45mm/sec

Erik

The perimeters that don't reach in the corners - is it start or the ending point that is lacking or both? - hard to see from your picture

Did you use the exact same settings in slic3r and kisslicer?

Material - First layer temp. of 255C do seem a bit excessive and will carry up some layers, my PLA settings are 185/57 all the way

I would try with Prime and Suck at 0 and 4 or 5mm, Speed 45mm/sec

Erik

|

Re: dialing in seams and edges (w/ KISSlicer) September 13, 2014 09:13AM |

Registered: 9 years ago Posts: 146 |

the KISSlicer temps don't seem to do anything. I run 200c and 60c bed

I tried to use the same in Slic3r - .30 layer etc, but the speeds are set faster in Slic3r and run slower....

I THINK the end was the bigger issue. It runs counter clockwise on the last outer edge - so that seems to make the end a bigger issue than the start. But they both has some issues to start with.

I notice it seems to get worse with the height, esp on #1 I lowered the speed increase per level but it didnt seem to affect it

Thanks!

Socrates ~ The Amsterdamman

slic3r-1.2.9

I tried to use the same in Slic3r - .30 layer etc, but the speeds are set faster in Slic3r and run slower....

I THINK the end was the bigger issue. It runs counter clockwise on the last outer edge - so that seems to make the end a bigger issue than the start. But they both has some issues to start with.

I notice it seems to get worse with the height, esp on #1 I lowered the speed increase per level but it didnt seem to affect it

Thanks!

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: dialing in seams and edges (w/ KISSlicer) September 14, 2014 05:34AM |

Registered: 9 years ago Posts: 146 |

Hi Reppers!

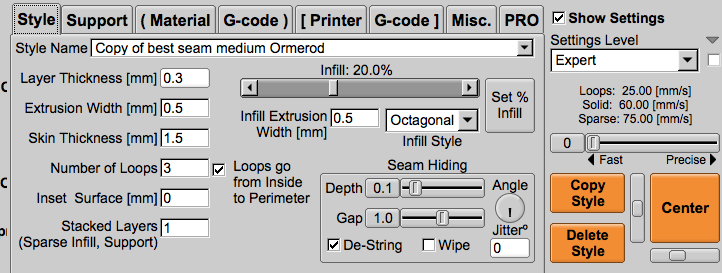

I updated to KISSlicer 1.4.5.10 and had MUCH better results! Attached are screenshots of my current settings. I changed the temps etc. as suggested. Attached is a photo of the test 1 cm cubes. Left is 1st test with old KISSlicer, middle is Slic3r and right is new 1.4 KISSlicer. The seam is much improved and I think better than Slic3r now.

My only complaint in the first three layers are slightly too large and create a mild flare at the base. Any idea which setting may correct this? I also attached the simple .stll for the 1cm3 cube.

Socrates ~ The Amsterdamman

slic3r-1.2.9

I updated to KISSlicer 1.4.5.10 and had MUCH better results! Attached are screenshots of my current settings. I changed the temps etc. as suggested. Attached is a photo of the test 1 cm cubes. Left is 1st test with old KISSlicer, middle is Slic3r and right is new 1.4 KISSlicer. The seam is much improved and I think better than Slic3r now.

My only complaint in the first three layers are slightly too large and create a mild flare at the base. Any idea which setting may correct this? I also attached the simple .stll for the 1cm3 cube.

Socrates ~ The Amsterdamman

slic3r-1.2.9

Attachments:

open | download - Screen Shot 2014-09-14 at 11.20.15 AM.png (64.4 KB)

open | download - Screen Shot 2014-09-14 at 11.20.02 AM.png (67.7 KB)

open | download - Screen Shot 2014-09-14 at 11.19.39 AM.png (82.4 KB)

open | download - photo (14).JPG (509 KB)

open | download - 1cm3.stl (684 bytes)

open | download - Screen Shot 2014-09-14 at 11.20.15 AM.png (64.4 KB)

open | download - Screen Shot 2014-09-14 at 11.20.02 AM.png (67.7 KB)

open | download - Screen Shot 2014-09-14 at 11.19.39 AM.png (82.4 KB)

open | download - photo (14).JPG (509 KB)

open | download - 1cm3.stl (684 bytes)

|

Re: dialing in seams and edges (w/ KISSlicer) September 14, 2014 07:05AM |

Registered: 9 years ago Posts: 146 |

i found the "seam angle" on style tab had the greatest effect and a 45degree to top right made the real bad seam.

Straight down made the best seams. I tried straight up - was poor, to left - similar to down and 45 to top right - default - very very bad.

So KISSlicer 1.4.5.10 is a great improvement, but make sure you change the seam angle to straight down.

[groups.google] com/forum/#!msg/kisslicer-refugee-camp/UBI5gPxyc0o/qNe3GjLEkjIJ

Socrates ~ The Amsterdamman

slic3r-1.2.9

Straight down made the best seams. I tried straight up - was poor, to left - similar to down and 45 to top right - default - very very bad.

So KISSlicer 1.4.5.10 is a great improvement, but make sure you change the seam angle to straight down.

[groups.google] com/forum/#!msg/kisslicer-refugee-camp/UBI5gPxyc0o/qNe3GjLEkjIJ

Socrates ~ The Amsterdamman

slic3r-1.2.9

|

Re: dialing in seams and edges (w/ KISSlicer) September 19, 2014 06:38AM |

Registered: 9 years ago Posts: 146 |

Using the paths view it is possible to see how the seam meets, graphically my seam looked best at a Depth of 0.1 - this also printed a near perfect seam! My seam is set at the straight down angle. Using the graphic display you can see a slight gap in the infill wall, but the outer perimeter is well aligned. Slide the top slider to show the moment the seam forms and the side slider to see different heights of the model. .

Socrates ~ The Amsterdamman

slic3r-1.2.9

Socrates ~ The Amsterdamman

slic3r-1.2.9

Sorry, only registered users may post in this forum.