solution to 2 nozzle height adjustment

Posted by appjaws1

|

solution to 2 nozzle height adjustment September 08, 2014 08:51AM |

Registered: 10 years ago Posts: 780 |

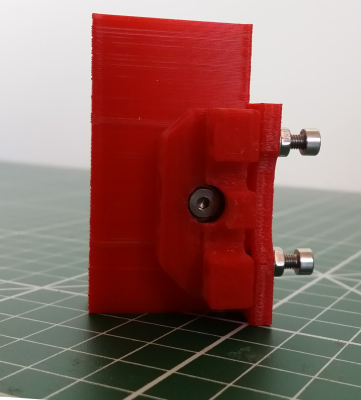

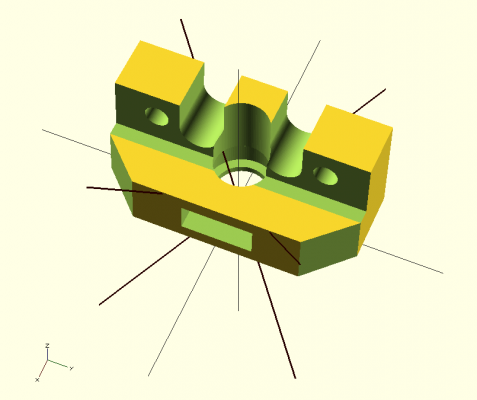

I found it very difficult, during assembly of my 2 nozzle set-up to ensure that the heights of the 2 nozzles would be the same.

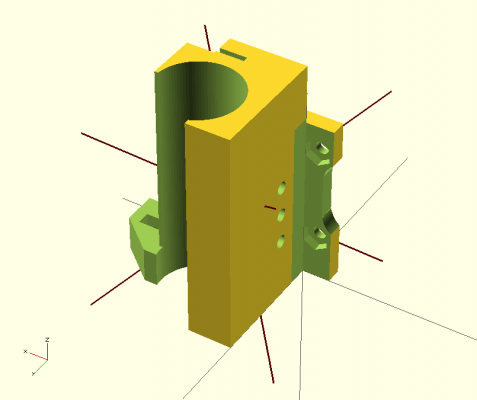

So I have designed a rotating nozzle holder that can be adjusted when fitted to the modified X-carriage.

The nozzle is based on dc42's 3 degree design and the X-carriage is based on dc42's design

The other advantage of this design is that it can be adapted to include some sort of actuator to automatically lift the non active nozzle, but at the moment with my extra cooling and the nozzles adjusted correctly I do not have a drag issue.

It is a bit fiddly to lock the adjusting screws once the correct heights are made, I wonder if there is an alternative that would provide a secure lock of the screws in that confined space?

I have attached the scad files for anybody who would like to try this adjustment

Have fun

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

So I have designed a rotating nozzle holder that can be adjusted when fitted to the modified X-carriage.

The nozzle is based on dc42's 3 degree design and the X-carriage is based on dc42's design

The other advantage of this design is that it can be adapted to include some sort of actuator to automatically lift the non active nozzle, but at the moment with my extra cooling and the nozzles adjusted correctly I do not have a drag issue.

It is a bit fiddly to lock the adjusting screws once the correct heights are made, I wonder if there is an alternative that would provide a secure lock of the screws in that confined space?

I have attached the scad files for anybody who would like to try this adjustment

Have fun

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: solution to 2 nozzle height adjustment September 08, 2014 09:32AM |

Registered: 9 years ago Posts: 138 |

|

Re: solution to 2 nozzle height adjustment September 09, 2014 10:46AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: solution to 2 nozzle height adjustment September 10, 2014 04:23AM |

Registered: 10 years ago Posts: 780 |

Quote

dmould

Maybe a spring instead of a lock nut would do the trick?

Dave

(#106)

Thank you Dave, that seems to have done the trick.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: solution to 2 nozzle height adjustment September 10, 2014 08:47AM |

Registered: 10 years ago Posts: 119 |

Hi Paul

With your Design, have you had any problems with the fan duct?

Presumably the head is adjusted to make the nozzles level, which is dependant on how well the match is between the hot ends after they are screwed into the heatsink.

If the nozzles are now parallel to the bed this presumably means the heatsink and nozzles on the underside of the fan duct are also slightly off level (one side higher than the other)?

Presumably this difference is so small it is negligable compared to the 1-2mm the fan outlets are above the heated nozzles.

What is your procedure for levelling?

Do you loosen both bolts.

Lower the head assembly allowing the heads to naturally level out on the bed

Tighten the screws to hold the head level or another method?

Another thought, the hot bed must be mechanically level otherwise the nozzles will be out at different points on the bed(sloping bed), so not a good idea to use auto bed compensation, unless the nozzles are adjusted over the same place on the bed (to within a few mm)

Sorry brain is racing through all sorts of scenarios, just wondering if you have seen any of this affect your prints or if I am over complicating the setup.

Lloyd

P.S. Did you post both parts of the new head assembly above or the same part twice, good design though.

With your Design, have you had any problems with the fan duct?

Presumably the head is adjusted to make the nozzles level, which is dependant on how well the match is between the hot ends after they are screwed into the heatsink.

If the nozzles are now parallel to the bed this presumably means the heatsink and nozzles on the underside of the fan duct are also slightly off level (one side higher than the other)?

Presumably this difference is so small it is negligable compared to the 1-2mm the fan outlets are above the heated nozzles.

What is your procedure for levelling?

Do you loosen both bolts.

Lower the head assembly allowing the heads to naturally level out on the bed

Tighten the screws to hold the head level or another method?

Another thought, the hot bed must be mechanically level otherwise the nozzles will be out at different points on the bed(sloping bed), so not a good idea to use auto bed compensation, unless the nozzles are adjusted over the same place on the bed (to within a few mm)

Sorry brain is racing through all sorts of scenarios, just wondering if you have seen any of this affect your prints or if I am over complicating the setup.

Lloyd

P.S. Did you post both parts of the new head assembly above or the same part twice, good design though.

|

Re: solution to 2 nozzle height adjustment September 10, 2014 09:44AM |

Registered: 10 years ago Posts: 780 |

Quote

ezwul

With your Design, have you had any problems with the fan duct?.

No but I am using my own design hot end assembly.

Quote

ezwul

Presumably the head is adjusted to make the nozzles level, which is dependant on how well the match is between the hot ends after they are screwed into the heatsink. .

Yes the two nozzles need to be as close to the same level as possible.

Quote

ezwul

If the nozzles are now parallel to the bed this presumably means the heatsink and nozzles on the underside of the fan duct are also slightly off level (one side higher than the other)?

Presumably this difference is so small it is negligable compared to the 1-2mm the fan outlets are above the heated nozzles..

I have had to lower the heater block by putting washers between the insulator and the nozzle mount, eventually I will make the nozzle mount thicker. All so, I only have 12mm between nozzles but of course any difference in height is amplified at the ends of the fan duct.

Quote

ezwul

What is your procedure for levelling?

Do you loosen both bolts.

Lower the head assembly allowing the heads to naturally level out on the bed

Tighten the screws to hold the head level or another method?.

That is how I did it but the movement of the screws are quite sensitive and it is easy to over tighten. So it is really important to recheck the levels with a piece of paper, the same as recommended for Z height zeroing.

Quote

ezwul

Another thought, the hot bed must be mechanically level otherwise the nozzles will be out at different points on the bed(sloping bed), so not a good idea to use auto bed compensation, unless the nozzles are adjusted over the same place on the bed (to within a few mm).

I always Z0 in the certer of the bed and am using 5 point bed compensation

Quote

ezwul

Sorry brain is racing through all sorts of scenarios, just wondering if you have seen any of this affect your prints or if I am over complicating the setup..

I am still testing and the results look good.

Quote

ezwul

P.S. Did you post both parts of the new head assembly above or the same part twice, good design though.

You are quite right, attached are the correct files.

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: solution to 2 nozzle height adjustment September 10, 2014 10:02AM |

Registered: 10 years ago Posts: 119 |

|

Re: solution to 2 nozzle height adjustment September 21, 2014 01:49PM |

Registered: 9 years ago Posts: 138 |

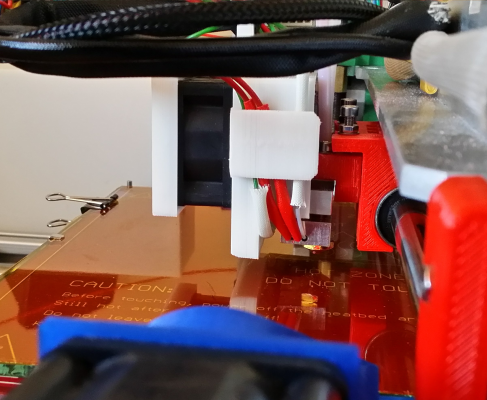

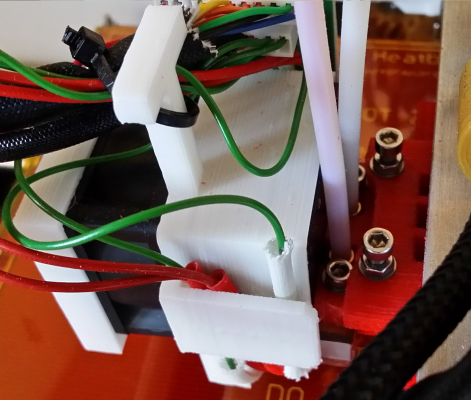

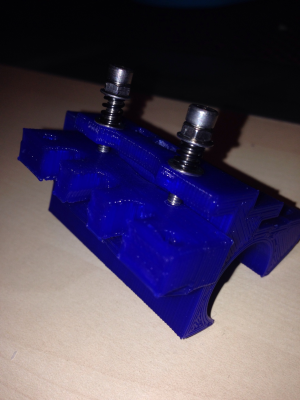

Hi paul,

i like your idea very much, so u modded the scad file to mach the dc42/davek heatsinkblock.

Here is a picture mounted together.

i like your idea very much, so u modded the scad file to mach the dc42/davek heatsinkblock.

Here is a picture mounted together.

|

Re: solution to 2 nozzle height adjustment September 21, 2014 02:10PM |

Registered: 10 years ago Posts: 780 |

Sorry, only registered users may post in this forum.