fluctuating hot end temperature

Posted by appjaws1

|

fluctuating hot end temperature November 18, 2014 10:00AM |

Registered: 10 years ago Posts: 780 |

Strange, during a print the hot end temperature reduced from 193 to 168 and even though when I increased the set temp to 200 the temperature remained at 168-170.

The printer carried on printing and extruding even though the hot end was reading 169. I wonder if it is just a temperature reporting issue., I've got no way to measure the temperature of the hot end accurately.

It is not a firmware issue because I have tested with previous firmware versions.

This morning the Hot end as fluctuated between 200 and 173 over a 11 min period, now, after 15 mins, the temperature seems to be maintained +1.6C to -2.0C of the 193 set.

What is the normal range for fluctuations?

I have checked the heater and thermistor connections and they are OK.

What else can I try?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

The printer carried on printing and extruding even though the hot end was reading 169. I wonder if it is just a temperature reporting issue., I've got no way to measure the temperature of the hot end accurately.

It is not a firmware issue because I have tested with previous firmware versions.

This morning the Hot end as fluctuated between 200 and 173 over a 11 min period, now, after 15 mins, the temperature seems to be maintained +1.6C to -2.0C of the 193 set.

What is the normal range for fluctuations?

I have checked the heater and thermistor connections and they are OK.

What else can I try?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 18, 2014 02:32PM |

Registered: 10 years ago Posts: 14,672 |

May I assume you are running a single nozzle hot end, or you are referring to the first nozzle on a dual nozzle hot end? There are temperature reading errors for additional thermistors connected to a DueX4 expansion board.

If the thermistor concerned is connected to the main Duet board, then I can think of a few possibilities:

1. S factor set too low when using my or zpl's firmware, so that the head cannot maintain temperature at maximum allowed power.

2. A bad connection in the hot end heater wiring. Check all crimp connections and pin/socket pairs for scorching.

3. Ditto but on the Duet. Someone reported this kind of problem recently in another thread.

4. If you are using one of my hot end boards and the +3.3V or ground connection is lost, this may affect the temperature readings. Again, check the crimp connections.

Try setting the hot end to 200C, wait for it to settle, then waggle the hot end loom to see if you can make the reading change.

Edited 2 time(s). Last edit at 11/18/2014 02:33PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If the thermistor concerned is connected to the main Duet board, then I can think of a few possibilities:

1. S factor set too low when using my or zpl's firmware, so that the head cannot maintain temperature at maximum allowed power.

2. A bad connection in the hot end heater wiring. Check all crimp connections and pin/socket pairs for scorching.

3. Ditto but on the Duet. Someone reported this kind of problem recently in another thread.

4. If you are using one of my hot end boards and the +3.3V or ground connection is lost, this may affect the temperature readings. Again, check the crimp connections.

Try setting the hot end to 200C, wait for it to settle, then waggle the hot end loom to see if you can make the reading change.

Edited 2 time(s). Last edit at 11/18/2014 02:33PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 19, 2014 08:37AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

May I assume you are running a single nozzle hot end, or you are referring to the first nozzle on a dual nozzle hot end? There are temperature reading errors for additional thermistors connected to a DueX4 expansion board..

Yes at the moment I am running 1 nozzle with your control board

Quote

dc42

1. S factor set too low when using my or zpl's firmware, so that the head cannot maintain temperature at maximum allowed power..

I have tried various S settings but it appears that the code has no or little effect. My voltage is 12.4, this is some of the results:-

200 set - overshoot 5 - M301 P1 S0.45

150 set - overshoot 9.7 - M301 P1 S0.4

170 set - overshoot 9.3 - M301 P1 S0.3

Fitted new heater cartridge

60 set - overshoot 10.5 - M301 P1 S0.3

80 set - overshoot 9.8 - M301 P1 S0.9

110 set - overshoot 5.3 - M301 P1 S0.9

130 set - overshoot 11 - M301 P1 S1.5 - eventually reduces to 124.9 then 133.0 then 128.2 -- all this over a 15 min period.

So whatever I set the S parameter I get massive overshoot. I am assuming I am using the 301 and 305 codes correctly

From my config.

M301 P1 S0.75

M305 P0 H-5 L0

M305 P1 H50 L0

What does the "L" parameter do? Are there instructions anywhere?

Quote

dc42

2. A bad connection in the hot end heater wiring. Check all crimp connections and pin/socket pairs for scorching..

Took both boards out of the enclosure and all connections seem OK

Quote

dc42

3. Ditto but on the Duet. Someone reported this kind of problem recently in another thread..

All OK

Quote

dc42

4. If you are using one of my hot end boards and the +3.3V or ground connection is lost, this may affect the temperature readings. Again, check the crimp connections..

All OK

Quote

dc42

Try setting the hot end to 200C, wait for it to settle, then waggle the hot end loom to see if you can make the reading change.

This made no difference.

It's like there isn't enough power to heat the heater quick enough because it take a long time to reach temperature but then it overshoots and then under shoots by a large amount and takes a very long time to settle.

If I switch on the external fans, the temperature plummets and struggles to get back up to the set temperature.

When I have re-assembled the enclosure and boards I am going to change the whole hot end for my 2 nozzle version. That will tell me if it is your control board or something else on the duet.

Any other ideas?

Thanks again

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 19, 2014 09:01AM |

Registered: 10 years ago Posts: 665 |

Paul, I suggest you ensure your M304 parameters are okay. Have a look at this: [forums.reprap.org]

Edited 1 time(s). Last edit at 11/19/2014 09:02AM by zombiepantslol.

Edited 1 time(s). Last edit at 11/19/2014 09:02AM by zombiepantslol.

|

Re: fluctuating hot end temperature November 19, 2014 09:10AM |

Registered: 10 years ago Posts: 2,472 |

It sounds likely to me that your hotend heater is losing power intermittently. I would suspect either a bad connection somewhere (could be a bad solder joint on the Duet PC , or a faulty heater cartridge. Next time it happens feel all the connectors along the wire trail, as a poor connection will often overheat. Over the years I've found quite a few connection faults at the expense of a blistered finger!

, or a faulty heater cartridge. Next time it happens feel all the connectors along the wire trail, as a poor connection will often overheat. Over the years I've found quite a few connection faults at the expense of a blistered finger!

Dave

, or a faulty heater cartridge. Next time it happens feel all the connectors along the wire trail, as a poor connection will often overheat. Over the years I've found quite a few connection faults at the expense of a blistered finger!

, or a faulty heater cartridge. Next time it happens feel all the connectors along the wire trail, as a poor connection will often overheat. Over the years I've found quite a few connection faults at the expense of a blistered finger!Dave

|

Re: fluctuating hot end temperature November 19, 2014 10:46AM |

Registered: 10 years ago Posts: 780 |

Quote

zombiepantslol

Paul, I suggest you ensure your M304 parameters are okay. Have a look at this: [forums.reprap.org]

I am now totally confused (not hard to do>grin)

The above reference mentions M304 and M301 with H and L parameters for calibrating the hot end and bed temperatures. I have always had M305 in my config file as does your default config file. I have been using:-

M305 P2 H-55

M305 P1 H65

M305 P0 H5

and M301 P1 S0.7 as the parameter to adjust for overshoot.

So I have been trying to manipulate the temperatures with the wrong M code.

So do I follow the information from dc42 at [forums.reprap.org] and not use M305?

[forums.reprap.org] mentions using the same H and L parameters from M304 with the M301, so is this the correct format

M301 Hxx Lxx Sxx and M304 P1 Hxx Lxx M304 P2 Hxx Lxx

or should the S parameter be used with just M301 - M301 P0 Sxx M301 P1 Sxx M301 P2 Sxxas I originally had in my config?

Only M305 P0 Hxx has an effect on the bed cold temperature reading and only M305 P1 Hxx has an effect on the Hot end cold temperature reading.

The message log is showing:

M304 H0 L0

Heater 0 P:0.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

M301

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:0.70 W:180.0 B:30.0

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 19, 2014 10:51AM |

Registered: 10 years ago Posts: 665 |

|

Re: fluctuating hot end temperature November 19, 2014 12:00PM |

Registered: 10 years ago Posts: 780 |

Thanks for the reply.Quote

zombiepantslol

Yes sorry, I meant to say M305. I believe the code for ADC offsets changed some time ago... Do you have a chance to adjust your parameters with a few resistors?

So do I follow dc42's instructions but use M305 instead of M304? and is M301 used for all heaters, including the bed?

Are there any up to date instructions, I'm still confused between M301 and M304 because as I understand it M301 takes the P parameter to indicate which heater, bed,1 or 2, so do I need M304? or can M301 Px Hxx Lxx Sxx be used instead?

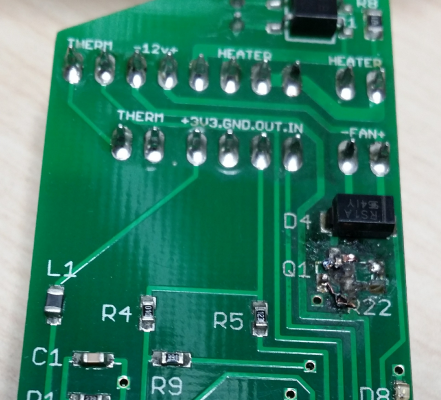

I've just blown up my dc42 single nozzle board R22 glowed and burnt out so I suppose this board is now a pile of junk. I still don't know how it happened but at least it will make me try the 2 nozzle board again to see if I can resolve the temperature issue.

Thanks for all help and advice

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 19, 2014 02:06PM |

Registered: 10 years ago Posts: 14,672 |

Hi Paul, sorry to hear you have damaged your board. However, if the damage is in the area of R22 (which is not fitted) then it means you connected the 12V supply wires the wrong way round, and the board can be repaired by replacing the diode and mosfet in that area. You can do this yourself, or send the board back to me and I will do it for £10+vat.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 19, 2014 02:12PM |

Registered: 10 years ago Posts: 14,672 |

In my firmware fork, M301and M304 do the same thing except that the H parameter defaults to 1 and 0 respectively. See [reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 19, 2014 02:36PM |

Registered: 10 years ago Posts: 2,472 |

Quote

dc42

Hi Paul, sorry to hear you have damaged your board. However, if the damage is in the area of R22 (which is not fitted) then it means you connected the 12V supply wires the wrong way round, and the board can be repaired by replacing the diode and mosfet in that area. You can do this yourself, or send the board back to me and I will do it for £10+vat.

Aren't they used only for the fan control? If so the fan can be wired permanently on, with the damaged components removed (in case they have failed in short-circuit) but not replaced.

Dave

|

Re: fluctuating hot end temperature November 19, 2014 06:39PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dmould

Aren't they used only for the fan control? If so the fan can be wired permanently on, with the damaged components removed (in case they have failed in short-circuit) but not replaced.

Dave

Yes, in fact the unpopulated R22 position is there so you can connect a 0 ohm resistor (or wire link) to bypass the fan control, as on the Kit 2 variant of my original board. So one option is to remove the diode and the remains of the mosfet, and then put a wire link across R22.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 20, 2014 02:48AM |

Registered: 10 years ago Posts: 14,672 |

Paul, what PSU are you using? Does the hot end temperature start to drop when the bed heater comes on? I'm wondering whether the 12V supply is drooping under load. This could be caused by loose 12V screw terminals on the Duet or the ATX board, or the PSU being on the way out.

Edited 1 time(s). Last edit at 11/20/2014 02:48AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 11/20/2014 02:48AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 20, 2014 10:33AM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

Quote

dmould

Aren't they used only for the fan control? If so the fan can be wired permanently on, with the damaged components removed (in case they have failed in short-circuit) but not replaced.

Dave

Yes, in fact the unpopulated R22 position is there so you can connect a 0 ohm resistor (or wire link) to bypass the fan control, as on the Kit 2 variant of my original board. So one option is to remove the diode and the remains of the mosfet, and then put a wire link across R22.

As you can see, the tracks have been destroyed, so probably the only option is to by pass the fan control with a wire link.

Looking at the photo could you tell me where I need to connect a wire link so that I can use the board again, all be it without fan control.

I completely caused this, when checking the wiring on the duet, I put the fan wires on the wrong pins. - that will teach me to double check before applying power.

I hope to calibrate the thermistors with some resistors but I can;t help thinking, something else is going on here, after all the machine has worked since end Feb 2014 without this heating problem.

The power supply I am using seems rock solid under load and maintains the set voltage during the heating cycle, it was one in the range of power supplies suggested earlier in the forum

again thanks for all the help

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 20, 2014 11:08AM |

Registered: 10 years ago Posts: 14,672 |

Hi Paul, I think that board could still be salvaged. The upper pad and lower left pad for Q1 look OK to me, and a short wire link could be run from the lower right pin of the replacement Q1 to the PCB trace just below the R of R22.

To have the fan run permanently, the simplest option is to remove D4 in case it has failed short circuit, then add a wire from the fan - output pin to the 12V - input pin. You can find the schematic here [github.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

To have the fan run permanently, the simplest option is to remove D4 in case it has failed short circuit, then add a wire from the fan - output pin to the 12V - input pin. You can find the schematic here [github.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 21, 2014 07:56AM |

Registered: 10 years ago Posts: 780 |

@zombiepantslol and @dc42

Please confirm that I have interpreted the Reprap Wiki G-code document correctly as applied by both firmware's

I need to issue M301 codes to correct for heater power, I notice that the heater number is decided by the "H" parameter and that the "P" parameter is to switch to PID instead of bang-bang for heater control, so is the following correct?

M301 H0 S1.0 - bed heater

M301 H1 P1 S0.9 - extruder 1

M301 H2 P1 S0.9 - extruder 2

I then need the M305 code to set the thermistors, where the "P" parameter is the heater number, "H" is the ADC High end correction, "L" is the Low end correction, "T" is the 25C resistance, R is the series resistance and "B" is the Beta value (not sure what this is), so is the following correct?

M305 P0 T100000 R1000 B4200 Hxx Lxx - bed heater

M305 P1 T100000 R1000 B4200 Hxx Lxx - extruder 1

M305 P2 T100000 R1000 B4200 Hxx Lxx - extruder 2

and M304 is not used.

Thanks for any clarification

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Please confirm that I have interpreted the Reprap Wiki G-code document correctly as applied by both firmware's

I need to issue M301 codes to correct for heater power, I notice that the heater number is decided by the "H" parameter and that the "P" parameter is to switch to PID instead of bang-bang for heater control, so is the following correct?

M301 H0 S1.0 - bed heater

M301 H1 P1 S0.9 - extruder 1

M301 H2 P1 S0.9 - extruder 2

I then need the M305 code to set the thermistors, where the "P" parameter is the heater number, "H" is the ADC High end correction, "L" is the Low end correction, "T" is the 25C resistance, R is the series resistance and "B" is the Beta value (not sure what this is), so is the following correct?

M305 P0 T100000 R1000 B4200 Hxx Lxx - bed heater

M305 P1 T100000 R1000 B4200 Hxx Lxx - extruder 1

M305 P2 T100000 R1000 B4200 Hxx Lxx - extruder 2

and M304 is not used.

Thanks for any clarification

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 21, 2014 08:12AM |

Registered: 10 years ago Posts: 14,672 |

That is mostly correct. The S factor in M301 is for reducing heater power, to compensate for using heater cartridges more powerful than average, or a supply voltage higher than 12V. Otherwise, set the S factor to 1.0 and leave it there unless you get serious overshoot using the default PID values. The P, I and D factors in the M301 command are the usual PID constants, but the P factor can also be used to switch between PID and bang-bang control.

Edited 1 time(s). Last edit at 11/21/2014 08:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 11/21/2014 08:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 21, 2014 08:17AM |

Registered: 10 years ago Posts: 665 |

|

Re: fluctuating hot end temperature November 21, 2014 08:51AM |

Registered: 10 years ago Posts: 780 |

Still don't understand.

In dc42's 057u firmware where the instructions for adjusting the H and L parameters are, it refers to M301 but the Reprap Wiki says that in M301 the "H" parameter identifies the heater number.

extract for dc42'instructions:-

. I have added optional parameters L and H to the M301 (set hot end PID parameters) and M304 (set bed PID parameters) commands. These allow the offset and gain errors inherent in the SAM3X ADC to be corrected. The values you set are stored to flash memory, so they survive power down cycles and resets, but not re-flashing the firmware (which sets both values to zero). You can use positive or negative values, integer or fractional. The H parameter affects mostly the low-temperature readout, and the L parameter affects mostly the high-temperature readout. To determine the correct values for your Duet board:

so my question is How is the heater number identified?

the instructions go on to say:-

The parameters you use for the hot end should also be correct for the bed, so when you have determined the correct hot end parameters, send an M304 command with the same H and L parameters. However, you can use different M301 and M304 parameters if you wish.

M305 is not mentioned.

dc42 referred me to:- In my firmware fork, M301and M304 do the same thing except that the H parameter defaults to 1 and 0 respectively. See [reprap.org].

zombiepantslol said:- I meant to say M305. I believe the code for ADC offsets changed some time ago...

and referred me to:-Have a look at this: [forums.reprap.org]

So the documentation is a little confusing.

Is the Reprap Wiki wrong?

Is the heater identified by the "P" parameter in M301, M304 and M305?

Do I need to use M301, M304 and M305?

What exactly do I need to set up my heaters correctly? Please provide the correct entries that I can put in my config file.

Thanks for your time, Am I the only user confused by this or am I missing some documentation that explains things more clearly?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

In dc42's 057u firmware where the instructions for adjusting the H and L parameters are, it refers to M301 but the Reprap Wiki says that in M301 the "H" parameter identifies the heater number.

extract for dc42'instructions:-

. I have added optional parameters L and H to the M301 (set hot end PID parameters) and M304 (set bed PID parameters) commands. These allow the offset and gain errors inherent in the SAM3X ADC to be corrected. The values you set are stored to flash memory, so they survive power down cycles and resets, but not re-flashing the firmware (which sets both values to zero). You can use positive or negative values, integer or fractional. The H parameter affects mostly the low-temperature readout, and the L parameter affects mostly the high-temperature readout. To determine the correct values for your Duet board:

so my question is How is the heater number identified?

the instructions go on to say:-

The parameters you use for the hot end should also be correct for the bed, so when you have determined the correct hot end parameters, send an M304 command with the same H and L parameters. However, you can use different M301 and M304 parameters if you wish.

M305 is not mentioned.

dc42 referred me to:- In my firmware fork, M301and M304 do the same thing except that the H parameter defaults to 1 and 0 respectively. See [reprap.org].

zombiepantslol said:- I meant to say M305. I believe the code for ADC offsets changed some time ago...

and referred me to:-Have a look at this: [forums.reprap.org]

So the documentation is a little confusing.

Is the Reprap Wiki wrong?

Is the heater identified by the "P" parameter in M301, M304 and M305?

Do I need to use M301, M304 and M305?

What exactly do I need to set up my heaters correctly? Please provide the correct entries that I can put in my config file.

Thanks for your time, Am I the only user confused by this or am I missing some documentation that explains things more clearly?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 21, 2014 09:23AM |

Registered: 10 years ago Posts: 14,672 |

Paul, subsequent to implementing M301 in version 0.57u, RepRapPro and I came to an agreement on how M301 and M305 should work. So the 0.57u instructions are not correct for 0.65 and later series firmware, and the wiki is correct.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 21, 2014 09:31AM |

Registered: 10 years ago Posts: 665 |

Hi Paul, here's a short clarification:

M301 and M304 set PID parameters for individual heaters: These two codes do act the same way, but if you don't specify any heater with the 'H' parameter, M301 will adjust heater number 1 (first nozzle heater) and M304 will adjust heater number 0 (hot bed). Any other specified parameters are used to control the temperature internally in the firmware. The "S" parameter dc42 introduced a while ago is only used to scale the final heater PWM signal generated by the PID controller, which is the reason why it may be specified using these two codes.

M305 adjusts the physical heater parameters, such as temperature reading values (thermistor resistance, beta value and ADC offsets [H/L parameters]).

In general it is a good idea to rely on the information provided by the RepRap G-Code article as dc42 already said. That page doesn't include our changes for M0 yet, but I'll add this piece of information sometime soon.

You may put these codes in your config.g file:

And then run these codes once and restart your Ormerod (please note it will reset your Flash values once and it will only work when using my firmware fork):

I hope that helps.

Edited 2 time(s). Last edit at 11/21/2014 09:33AM by zombiepantslol.

M301 and M304 set PID parameters for individual heaters: These two codes do act the same way, but if you don't specify any heater with the 'H' parameter, M301 will adjust heater number 1 (first nozzle heater) and M304 will adjust heater number 0 (hot bed). Any other specified parameters are used to control the temperature internally in the firmware. The "S" parameter dc42 introduced a while ago is only used to scale the final heater PWM signal generated by the PID controller, which is the reason why it may be specified using these two codes.

M305 adjusts the physical heater parameters, such as temperature reading values (thermistor resistance, beta value and ADC offsets [H/L parameters]).

In general it is a good idea to rely on the information provided by the RepRap G-Code article as dc42 already said. That page doesn't include our changes for M0 yet, but I'll add this piece of information sometime soon.

You may put these codes in your config.g file:

; M304 S1.0 ; bed heater - no need for this line, because the hot bed isn't driven by PWM M301 S0.9 ; extruder 1 (no need for H1) M301 H2 P1 S0.9 ; extruder 2 (needs H2 for third heater) M305 P0 Hxx Lxx ; bed heater (M305 always requires P parameter, i.e. heater index) M305 P1 Hxx Lxx ; extruder 1 M305 P2 Hxx Lxx ; extruder 2

And then run these codes once and restart your Ormerod (please note it will reset your Flash values once and it will only work when using my firmware fork):

M502 M500

I hope that helps.

Edited 2 time(s). Last edit at 11/21/2014 09:33AM by zombiepantslol.

|

Re: fluctuating hot end temperature November 21, 2014 09:46AM |

Registered: 10 years ago Posts: 780 |

Further observations.

I connected to Pronterface and checked the M codes.

Connecting...

Printer is now online.

>>>M304 H0

SENDING:M304

Heater 0 P:-1.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

>>>M304 H1

SENDING:M304 H1

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:0.60 W:180.0 B:30.0

>>>M301

SENDING:M301

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:0.60 W:180.0 B:30.0

>>>M301 H0

SENDING:M301 H0

Heater 0 P:-1.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

>>>M301 H1 S1

SENDING:M301 H1 S1

>>>M301 H1

SENDING:M301 H1

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:1.00 W:180.0 B:30.0

>>>M305 P0

SENDING:M305 P0

T:10000.0 B:3988.0 R:1000.0 L:0.0 H:10.0

>>>M305 P1

SENDING:M305 P1

T:100000.0 B:4138.0 R:1000.0 L:0.0 H:32.0

So the "H and L" parameters only apply to M305 codes and the heater is selected by the "P" parameter

The M301 or M304 codes can have the "S" parameter applied and the heater selected by the "H" parameter.

So just as a final check before I enter anything on my ormerod is the following correct for all firmware versions

M301 H0 S1.0 - bed heater, M301 H1 P1 S1 - extruder 1, M301 H2 P1 S1 - extruder 2

or use

M304 H0 S1.0 - bed heater, M304 H1 P1 S1 - extruder 1, M304 H2 P1 S1 - extruder 2

and

M305 P0 Hxx Lxx - bed heater, M305 P1 Hxx Lxx - extruder 1, M305 P2 Hxx Lxx - extruder 2

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I connected to Pronterface and checked the M codes.

Connecting...

Printer is now online.

>>>M304 H0

SENDING:M304

Heater 0 P:-1.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

>>>M304 H1

SENDING:M304 H1

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:0.60 W:180.0 B:30.0

>>>M301

SENDING:M301

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:0.60 W:180.0 B:30.0

>>>M301 H0

SENDING:M301 H0

Heater 0 P:-1.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

>>>M301 H1 S1

SENDING:M301 H1 S1

>>>M301 H1

SENDING:M301 H1

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:1.00 W:180.0 B:30.0

>>>M305 P0

SENDING:M305 P0

T:10000.0 B:3988.0 R:1000.0 L:0.0 H:10.0

>>>M305 P1

SENDING:M305 P1

T:100000.0 B:4138.0 R:1000.0 L:0.0 H:32.0

So the "H and L" parameters only apply to M305 codes and the heater is selected by the "P" parameter

The M301 or M304 codes can have the "S" parameter applied and the heater selected by the "H" parameter.

So just as a final check before I enter anything on my ormerod is the following correct for all firmware versions

M301 H0 S1.0 - bed heater, M301 H1 P1 S1 - extruder 1, M301 H2 P1 S1 - extruder 2

or use

M304 H0 S1.0 - bed heater, M304 H1 P1 S1 - extruder 1, M304 H2 P1 S1 - extruder 2

and

M305 P0 Hxx Lxx - bed heater, M305 P1 Hxx Lxx - extruder 1, M305 P2 Hxx Lxx - extruder 2

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 21, 2014 10:01AM |

Registered: 10 years ago Posts: 665 |

Quote

appjaws1

So just as a final check before I enter anything on my ormerod is the following correct for all firmware versions

M301 H0 S1.0 - bed heater, M301 H1 P1 S1 - extruder 1, M301 H2 P1 S1 - extruder 2

or use

M304 H0 S1.0 - bed heater, M304 H1 P1 S1 - extruder 1, M304 H2 P1 S1 - extruder 2

and

M305 P0 Hxx Lxx - bed heater, M305 P1 Hxx Lxx - extruder 1, M305 P2 Hxx Lxx - extruder 2

Paul

I haven't checked if the official RRP firmware already supports the M301/M304 S parameter, but they do work with both dc42's and my firmware fork. At least your 'P' parameters are wrong though, they should have a value of 10 for both nozzle heaters (H1, H2). Also see my post above.

|

Re: fluctuating hot end temperature November 21, 2014 11:53AM |

Registered: 10 years ago Posts: 780 |

Thank you dc42 and zombiepantslol for your expertise and patience

I have repaired dc42's control board and wired a link so that the fan is on at all times.

I don't know how I change the P value to 1 instead of 10. I now have it set at 10 and the heater has much more power and reaches target with only a slight overshoot.

I have set up the H and L parameters using resistors and put the details in my config file.

However I still have a problem, if I or the gcode file starts up the external cooling then the hot end looses temperature and can not maintain the set temperature. Even with only 30% cooling the hot end struggles.

In the near past I could run the cooling at 100% and the hot end temperature would be maintained.

What else could be causing this loss of power, I have checked all crimps, connections and wiring, could the duet board be faulty? If so how can I check if that is indeed the problem?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have repaired dc42's control board and wired a link so that the fan is on at all times.

I don't know how I change the P value to 1 instead of 10. I now have it set at 10 and the heater has much more power and reaches target with only a slight overshoot.

I have set up the H and L parameters using resistors and put the details in my config file.

However I still have a problem, if I or the gcode file starts up the external cooling then the hot end looses temperature and can not maintain the set temperature. Even with only 30% cooling the hot end struggles.

In the near past I could run the cooling at 100% and the hot end temperature would be maintained.

What else could be causing this loss of power, I have checked all crimps, connections and wiring, could the duet board be faulty? If so how can I check if that is indeed the problem?

Paul

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 21, 2014 01:04PM |

Registered: 10 years ago Posts: 2,472 |

Quote

appjaws1

Thank you dc42 and zombiepantslol for your expertise and patience

I have repaired dc42's control board and wired a link so that the fan is on at all times.

I don't know how I change the P value to 1 instead of 10. I now have it set at 10 and the heater has much more power and reaches target with only a slight overshoot.

I have set up the H and L parameters using resistors and put the details in my config file.

However I still have a problem, if I or the gcode file starts up the external cooling then the hot end looses temperature and can not maintain the set temperature. Even with only 30% cooling the hot end struggles.

In the near past I could run the cooling at 100% and the hot end temperature would be maintained.

What else could be causing this loss of power, I have checked all crimps, connections and wiring, could the duet board be faulty? If so how can I check if that is indeed the problem?

Paul

It is extremely unlikely to be a fault on the Duet. Any high-resistance on the Duet board itself (including a faulty or under-driven FET) that is enough to cause the heater to be underpowered would result in the fault dissipating enough power to reveal itself via a smoke signal! In fact any poor connections anywhere will heat up quite a bit, allowing you to detect them by feeling the connectors after the heater has been on for a while. Don't forget to check whether the main 12V supply terminal blocks are getting hot (indicating loose terminal screws). Loose connections anywhere along the high current paths are quite serious, because they can heat up enough to cause major damage or even a fire.

I suggest that you put a voltmeter across the heater cartridge when it is cold, then set a temperature above 100 deg. The cartridge should then receive full voltage (12V or whatever your PSU is supplying). That will prove that the firmware is commanding full power (as it should when heating from cold). If you have fitted DC42's sensor board you should then be able to tell by the brightness of the LED how much power the heater is being fed by the firmware controlled PWM. If the fan cools the hotend by as much as 10 degrees, I would expect you to see the LED at its full brightness. If it is not, then the PID parameters are not tuned correctly. If it is at full power but the hotend cannot maintain the temperature, then it is either a faulty cartridge or the air stream is misdirected so it is blowing directly onto the hot block instead of just below the nozzle.

Dave

|

Re: fluctuating hot end temperature November 21, 2014 02:06PM |

Registered: 10 years ago Posts: 14,672 |

Quote

appjaws1

However I still have a problem, if I or the gcode file starts up the external cooling then the hot end looses temperature and can not maintain the set temperature. Even with only 30% cooling the hot end struggles.

Paul

Do you really have the S factor in the M301 or M304 commands for your nozzle heater(s) set to 0.6? If so, then your heaters will be limited to 60% of full power, which might explain why they struggle when the cooling fan is on.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 21, 2014 02:55PM |

Registered: 10 years ago Posts: 780 |

Quote

dc42

Quote

appjaws1

However I still have a problem, if I or the gcode file starts up the external cooling then the hot end looses temperature and can not maintain the set temperature. Even with only 30% cooling the hot end struggles.

Paul

Do you really have the S factor in the M301 or M304 commands for your nozzle heater(s) set to 0.6? If so, then your heaters will be limited to 60% of full power, which might explain why they struggle when the cooling fan is on.

No during all of my messing around they got set to 0.6 but as you can see I have reset them to 1.0

SENDING:M301 H0

Heater 0 P:10.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

SENDING:M301

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:1.00 W:180.0 B:30.0

SENDING:M304

Heater 0 P:10.00 I:5.000 D:500.00 T:2.70 S:1.00 W:255.0 B:5.0

SENDING:M304 H1

Heater 1 P:1.00 I:0.100 D:100.00 T:0.40 S:1.00 W:180.0 B:30.0

Do the other parameters look right?

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 21, 2014 04:09PM |

Registered: 10 years ago Posts: 14,672 |

The heater 1 P factor looks far too low. The default value is 10. I suggest you comment out the M301 and M304 commands in config.g so as to revert to the defaults, and see how well that works.

Heater 0 P factor is usually set to -1 to select bang-bang control for the bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Heater 0 P factor is usually set to -1 to select bang-bang control for the bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fluctuating hot end temperature November 22, 2014 11:56AM |

Registered: 10 years ago Posts: 780 |

!!!!!!!!!! PROBLEM SOLVED !!!!!!!!!

It appears that all of my recent temperature problems were self inflicted.

I was confused by the inconsistent identifying of heaters, in my case Bed, Nozzle 1 and Nozzle 2, some M codes identify by "H" parameter and others by "P" parameters. So if like me you issue M301 P1 Hxx (thinking P1 refers to the first nozzle) you in fact set the heater to a very low power.

So to stop others from making my mistake, M305 has it's heaters identified by a "P" parameter and M301 and M304 has it's heaters identified by a "H" parameter.

I would have thought that we should have a consistent naming convention throughout the Reprap machines. - perhaps in time.

Anyway thank you all who have helped, especially dc42, dmould and zombiepantslol

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

It appears that all of my recent temperature problems were self inflicted.

I was confused by the inconsistent identifying of heaters, in my case Bed, Nozzle 1 and Nozzle 2, some M codes identify by "H" parameter and others by "P" parameters. So if like me you issue M301 P1 Hxx (thinking P1 refers to the first nozzle) you in fact set the heater to a very low power.

So to stop others from making my mistake, M305 has it's heaters identified by a "P" parameter and M301 and M304 has it's heaters identified by a "H" parameter.

I would have thought that we should have a consistent naming convention throughout the Reprap machines. - perhaps in time.

Anyway thank you all who have helped, especially dc42, dmould and zombiepantslol

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: fluctuating hot end temperature November 22, 2014 06:09PM |

Registered: 10 years ago Posts: 14,672 |

I agree, a consistent parameter letter for the heater number would be better. Generally, P is used for the heater number. However, M301 and M304 were already using P for the PID proportional constant, so we had to use H for the heater number for those codes.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.