Changing wheel on the fly

Posted by ormerod168

|

Changing wheel on the fly February 28, 2015 02:42PM |

Registered: 10 years ago Posts: 1,230 |

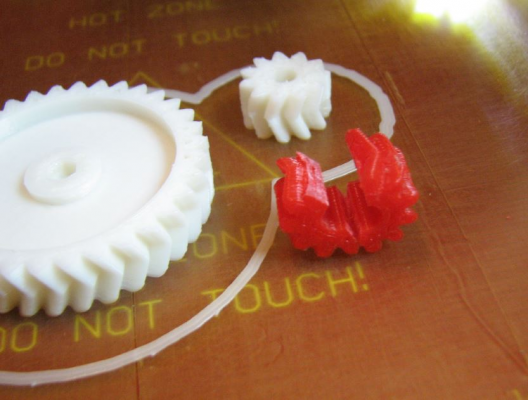

So I was happily printing a new set of extruder gear wheels in ABS when I heard a cracking sound, the stepper extruder wheel split, now what's the odds of that happening...

Paused and made a quick and dirty mount of a new one, pressed the gear wheel on the stepper axle with a c-clamp and restarted the print, thank you for the extra parts Mario, saved my print :-)

Erik

Paused and made a quick and dirty mount of a new one, pressed the gear wheel on the stepper axle with a c-clamp and restarted the print, thank you for the extra parts Mario, saved my print :-)

Erik

|

Re: Changing wheel on the fly February 28, 2015 03:07PM |

Registered: 10 years ago Posts: 665 |

|

Re: Changing wheel on the fly February 28, 2015 03:50PM |

Registered: 10 years ago Posts: 1,230 |

The broken one was PLA, should have changes that one long ago as I do print a lot of ABS and it has taken a lot of heat

The new one in ABS seems to hold just fine, had a bit of doubt about it holding on to the very small flat on the axle as ABS is more soft and springy than PLA, have marked the flat to the gear wheel with a pen so to keep an eye on it not moving

Erik

The new one in ABS seems to hold just fine, had a bit of doubt about it holding on to the very small flat on the axle as ABS is more soft and springy than PLA, have marked the flat to the gear wheel with a pen so to keep an eye on it not moving

Erik

|

Re: Changing wheel on the fly March 01, 2015 02:56AM |

Registered: 9 years ago Posts: 1,159 |

Quote

ormerod168

The broken one was PLA, should have changes that one long ago as I do print a lot of ABS and it has taken a lot of heat

The new one in ABS seems to hold just fine, had a bit of doubt about it holding on to the very small flat on the axle as ABS is more soft and springy than PLA, have marked the flat to the gear wheel with a pen so to keep an eye on it not moving

Erik

Erik

It might be worth seeing if a wages gear would work they are 9 tooth herringbone (Looks same as your's) but it has a raised flange which has a screw clamp on it for the Motor shaft or modify the ormerod one?

Doug

|

Re: Changing wheel on the fly March 01, 2015 09:38AM |

Registered: 10 years ago Posts: 1,230 |

Hi Doug

Yes that would be better, found one but not ideal as the extruder gear wheel would have to be moved out a bit and I do like to have that up close the the bearing, the axle is only 3mm and not very strong - would prefer the screw clamp on the other side (away from the stepper)

The one printed in ABS seems to hold up nicely so far..

9 Tooth Herringbone Gear with Large Base

[www.thingiverse.com]

..and another thing I did not expect - was adjusting the front hight of the bed when I accidentally "shorted" the screw against the led on the heatbed, this is not something I would worry about as I did isolation test the aluminium bed with 1150VAC against the wirings, standard procedure after repair - but the ATX shut down, two cups of coffe later (I needed that) I flipped the switch and everything was roses - did a forensic on the screw, washer and solder, no burn marks, no sign of sparks flying, most have been static electricity that got to the ATX and made it shut down

Erik

Yes that would be better, found one but not ideal as the extruder gear wheel would have to be moved out a bit and I do like to have that up close the the bearing, the axle is only 3mm and not very strong - would prefer the screw clamp on the other side (away from the stepper)

The one printed in ABS seems to hold up nicely so far..

9 Tooth Herringbone Gear with Large Base

[www.thingiverse.com]

..and another thing I did not expect - was adjusting the front hight of the bed when I accidentally "shorted" the screw against the led on the heatbed, this is not something I would worry about as I did isolation test the aluminium bed with 1150VAC against the wirings, standard procedure after repair - but the ATX shut down, two cups of coffe later (I needed that) I flipped the switch and everything was roses - did a forensic on the screw, washer and solder, no burn marks, no sign of sparks flying, most have been static electricity that got to the ATX and made it shut down

Erik

|

Re: Changing wheel on the fly March 01, 2015 04:26PM |

Registered: 10 years ago Posts: 2,472 |

Quote

ormerod168

The broken one was PLA, should have changes that one long ago as I do print a lot of ABS and it has taken a lot of heat

The new one in ABS seems to hold just fine, had a bit of doubt about it holding on to the very small flat on the axle as ABS is more soft and springy than PLA, have marked the flat to the gear wheel with a pen so to keep an eye on it not moving

Erik

I printed new extruder gears in ABS (herringbone design) and (touch wood) they have been fine for over a year and about 12kg of filament. I put 2 or 3 small drops of 3 in 1 oil on them about once a month.

Dave

Sorry, only registered users may post in this forum.

Out of curiosity, did you print that broken red part with PLA or ABS?

Out of curiosity, did you print that broken red part with PLA or ABS?