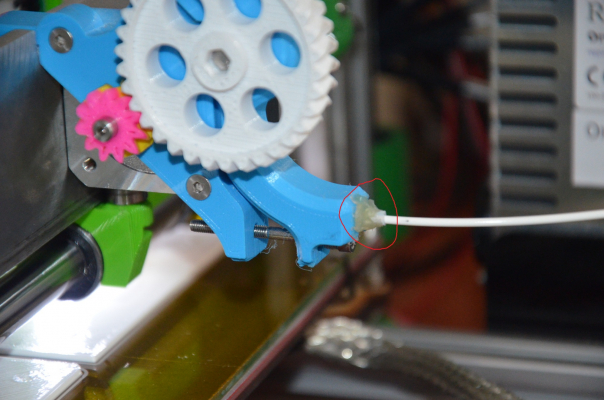

Spring-loaded extruder PTFE liner fastening

Posted by spiff

|

Spring-loaded extruder PTFE liner fastening August 31, 2015 07:02AM |

Registered: 10 years ago Posts: 45 |

Hi all.

I recently printed MasonStonehenge's Spring-loaded extruder, since my original ormerod extruder was getting somewhat squeaky, as others have reported (I haven't printed that much yet, so it is not worn through yet, but I thought I would replace the extruder before it failed).

I use the version with room for a PTFE liner, and I cut a piece of the PTFE feeder tube that came with the Ormerod, but which I never used, because I have my filament on a separate holder, feeding directly into the extruder (hanging on the X-arm).

Unfortunately, I am experiencing problems getting this PTFE to stay in the feeder part. Especially when retracting the filament, the PTFE tends to come out as well. Did anyone experience this problem as well, and what have you done to prevent it? I have been thinking about drilling a small hole through the feeder part, near the filament inlet, and putting in a thin wire to hold the PTFE tube in place. Alternatively, maybe a drop of glue is sufficient (although not as easy to remove).

Any suggestions?

Mikkel Holm Olsen

AKA Spaceman Spiff

I recently printed MasonStonehenge's Spring-loaded extruder, since my original ormerod extruder was getting somewhat squeaky, as others have reported (I haven't printed that much yet, so it is not worn through yet, but I thought I would replace the extruder before it failed).

I use the version with room for a PTFE liner, and I cut a piece of the PTFE feeder tube that came with the Ormerod, but which I never used, because I have my filament on a separate holder, feeding directly into the extruder (hanging on the X-arm).

Unfortunately, I am experiencing problems getting this PTFE to stay in the feeder part. Especially when retracting the filament, the PTFE tends to come out as well. Did anyone experience this problem as well, and what have you done to prevent it? I have been thinking about drilling a small hole through the feeder part, near the filament inlet, and putting in a thin wire to hold the PTFE tube in place. Alternatively, maybe a drop of glue is sufficient (although not as easy to remove).

Any suggestions?

Mikkel Holm Olsen

AKA Spaceman Spiff

|

Re: Spring-loaded extruder PTFE liner fastening August 31, 2015 07:16AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

I have nearly the same problem but I am using not the original one. I have remixed the Feeder-part and the motor-part I use the holder for the Ormerod MK2 (even though I have a MK1). I also use another tube, I think it was something like LDPE. The difference is that the inner hole is slightly bigger (2.5mm) and the material with all its properties of course.

I did not fix it yet, but why do not use super glue? For what reason you should have to remove the tube? Okay my tube is a little bit cheaper that is why I choosed it (normally for compressed air). If in doubt just reprint one as I have some Extruders in spare like most printed parts.

Edited 1 time(s). Last edit at 08/31/2015 07:17AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I have nearly the same problem but I am using not the original one. I have remixed the Feeder-part and the motor-part I use the holder for the Ormerod MK2 (even though I have a MK1). I also use another tube, I think it was something like LDPE. The difference is that the inner hole is slightly bigger (2.5mm) and the material with all its properties of course.

I did not fix it yet, but why do not use super glue? For what reason you should have to remove the tube? Okay my tube is a little bit cheaper that is why I choosed it (normally for compressed air). If in doubt just reprint one as I have some Extruders in spare like most printed parts.

Edited 1 time(s). Last edit at 08/31/2015 07:17AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Spring-loaded extruder PTFE liner fastening August 31, 2015 07:38AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Spring-loaded extruder PTFE liner fastening August 31, 2015 09:41AM |

Registered: 9 years ago Posts: 638 |

I used hot glue gun to glue it into place( but it will not stick to PTFE since it so slipery,i dought super glue will stick to it aswell) but it does provide a tighter fit so the tube stays inside the hole while retracting.it does come out a bit if i remove the filament but not with retraction.

Edited 1 time(s). Last edit at 08/31/2015 09:46AM by Darathy.

Edited 1 time(s). Last edit at 08/31/2015 09:46AM by Darathy.

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 03:20AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

this might work but I think it is too much visible and not very good to look at. Even though I have no woman but I would say WAF = 0.

Before I try something on my own: Is there any reason against super glue? Should I have to remove the tube at any time? And if so: why? I have bought 1 meter of the LDPE tube so it should be enough for exchanging the feeder if needed several times.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

this might work but I think it is too much visible and not very good to look at. Even though I have no woman but I would say WAF = 0.

Before I try something on my own: Is there any reason against super glue? Should I have to remove the tube at any time? And if so: why? I have bought 1 meter of the LDPE tube so it should be enough for exchanging the feeder if needed several times.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 04:19AM |

Registered: 10 years ago Posts: 14,672 |

I guess it needs some sort of clamp to hold it in place.

btw does anyone know why we use 4mmx2mm PTFE tube for the Bowden, but 3mmx2mm for the inlet?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

btw does anyone know why we use 4mmx2mm PTFE tube for the Bowden, but 3mmx2mm for the inlet?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 04:31AM |

Registered: 9 years ago Posts: 1,699 |

I am using 4 mm.

It seems that OD4 is standard for 1.75 mm as you get it everywhere like E3D extruder, chinese replika and so on. All bowden type extruder seems to use this. It is harder to get a OD3 tube. If I had known this before I would not have needed to modify the feeder as Robotdigg supllies the small tube and other pneumatic fittings with a thread of 6 mm instead of 5 mm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

It seems that OD4 is standard for 1.75 mm as you get it everywhere like E3D extruder, chinese replika and so on. All bowden type extruder seems to use this. It is harder to get a OD3 tube. If I had known this before I would not have needed to modify the feeder as Robotdigg supllies the small tube and other pneumatic fittings with a thread of 6 mm instead of 5 mm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 07:43AM |

Registered: 8 years ago Posts: 12 |

This looks like a useful mod, as several people have said. My problem is that the supplied gear set (Ormerod 2) has a slightly elliptical large gear. I've got it fettled to a state where it feeds ok. The spring loaded version will accomodate the ellipticality but that might make the grip on the filament slacken off.

I haven't yet worked out a way of independently varying gear mesh and filament grip! It would certainly mean moving the idler bearing off the motor. One find day...!

I haven't yet worked out a way of independently varying gear mesh and filament grip! It would certainly mean moving the idler bearing off the motor. One find day...!

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 08:28AM |

Registered: 10 years ago Posts: 45 |

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 08:34AM |

Registered: 9 years ago Posts: 638 |

Quote

MetalBasher

This looks like a useful mod, as several people have said. My problem is that the supplied gear set (Ormerod 2) has a slightly elliptical large gear. I've got it fettled to a state where it feeds ok. The spring loaded version will accomodate the ellipticality but that might make the grip on the filament slacken off.

I haven't yet worked out a way of independently varying gear mesh and filament grip! It would certainly mean moving the idler bearing off the motor. One find day...!

You can try printing these: [forums.reprap.org] they are better then the stock but i still suggest getting the spring loaded version.

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 08:41AM |

Registered: 10 years ago Posts: 45 |

Quote

MetalBasher

This looks like a useful mod, as several people have said. My problem is that the supplied gear set (Ormerod 2) has a slightly elliptical large gear. I've got it fettled to a state where it feeds ok.

If you can print, I would suggest you print a new set of gears.

Quote

MetalBasher

The spring loaded version will accomodate the ellipticality but that might make the grip on the filament slacken off.

I haven't yet worked out a way of independently varying gear mesh and filament grip! It would certainly mean moving the idler bearing off the motor. One find day...!

I spent some time thinking about this. If the hinge was in the same place as the motor axle, the grip of the gears would be constant, but that placement of the hinge is probably not easy. But if the hobbed wheel and hinge was on opposite sides of the motor axle, the gear mesh would not change a lot when filament thickness changes.

But the 4 reels of filament I have here are all between 1.70 and 1.75, so I doubt that such a small change in filament thickness will give problems with the gear mesh.

I also think this is a classic case of "Don't let perfect get in the way of better": There may still be some (at least theoretical) improvements that can be done, but it is certainly a much better extruder than the original that came with the Ormerod.

Mikkel Holm Olsen

AKA Spaceman Spiff

|

Re: Spring-loaded extruder PTFE liner fastening September 01, 2015 02:45PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dc42

..btw does anyone know why we use 4mmx2mm PTFE tube for the Bowden, but 3mmx2mm for the inlet?

Don't know but a 3mmx2mm bowden would be more elastic, stretch more, shrink the inner diameter more, might even pinch the filament if on the large side

Had one spool where the filament got stuck, was 1,95mm

Erik

|

Re: Spring-loaded extruder PTFE liner fastening September 10, 2015 02:41PM |

Registered: 8 years ago Posts: 12 |

Thanks, spiff and others for suggestions. Plenty to keep me busy. Still getting symptoms of y-axis backlash with belt adjusted to RRP's spec. Isn't adjusting y belt tension a pita?!

Bob

New to 3D printing; long experience making things of metal the 19th century way. Slowly trying to get into the 21st century.

Bob

New to 3D printing; long experience making things of metal the 19th century way. Slowly trying to get into the 21st century.

|

Re: Spring-loaded extruder PTFE liner fastening September 10, 2015 05:59PM |

Registered: 9 years ago Posts: 638 |

Quote

MetalBasher

Thanks, spiff and others for suggestions. Plenty to keep me busy. Still getting symptoms of y-axis backlash with belt adjusted to RRP's spec. Isn't adjusting y belt tension a pita?!

Bob

You can try my tensioning mod if you like: [www.thingiverse.com]

Sorry, only registered users may post in this forum.