Print bed surface review

Posted by dc42

|

Print bed surface review November 30, 2015 05:25PM |

Registered: 10 years ago Posts: 14,672 |

I've published a review of various print bed surfaces I have tried in my blog at [miscsolutions.wordpress.com]. Kapton, solvent cement/ABS juice, plain glass, BuiltTak, PrintBite and PEI are all discussed, in varying levels of detail.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Print bed surface review December 01, 2015 12:49AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

very good overview. Sadly you did not test BuildTak and some materials with ABS. This would have been quite interesting. The IR-sensors you mention are probably your boards? But many thanks for providing this as it helped me to show that it was not my fault that glass did not stick well for me with some sorts of PLA, for example.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

very good overview. Sadly you did not test BuildTak and some materials with ABS. This would have been quite interesting. The IR-sensors you mention are probably your boards? But many thanks for providing this as it helped me to show that it was not my fault that glass did not stick well for me with some sorts of PLA, for example.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Print bed surface review December 01, 2015 08:16AM |

Registered: 10 years ago Posts: 2,472 |

Yes, a good article, though I would disagree with your conclusion that you need a heated enclosure for ABS printing. I have printed exclusively with ABS pretty much since I got the Ormerod (exactly two years ago this month), and while warping was something I did battle with in the early days, I was able to prevent it completely on all but particularly difficult shapes without a heated chamber - and for those shapes I am able to make an ad-hoc heated chamber by covering the printer with a plastic bin-bag. The main things are to print in a room that is reasonably warm (above 20 deg C), and avoid draughts (e.g. just opening and closing a door rapidly during a print can cause it to warp). Try to avoid printing walled boxes with square corners. I have just printed all the parts for an Ormerod 2 for example, and apart from one part (Y-axis motor mount) that suffered a slight split (layer delamination), probably because my central heating switched off during the print, none of the parts were warped at all. The split was repaired easily with a bit of acetone.

For ABS printing, a more useful addition than a heated chamber would be a controllable cooling fan for overhangs and bridges. For parts with overhangs greater than 30 degrees or so I baby the print by blowing on the overhang section as its perimeters are printed, which gives a perfect result but is of course not very convenient. As for fumes - we have become a very risk-averse society and are advised to avoid things that present even miniscule risks as well as things that have not been properly assessed. As a result it has become very difficult to decide which warnings to take very seriously, which are real but acceptably low risks, and which can be dismissed as stupidly over-cautious (children must wear a safety helmet and goggles when playing conkers). If you want to be 100% safe, sure - never cross the road (carries a huge risk compared with many of the things we are advised against) and avoid barbeques (highly cancerous). The people who work in plastic injection moulding factories are exposed to far more plastic fumes during a year than is likely from hobbyist FFF printing (maybe there will be huge lawsuits in a few years similar to asbestos workers). This report may quantify the risk for a better informed decision [www.instructables.com]

If you use a soldering iron without a fume hood and extractor, from what I have read you are exposing yourself to far more hazardous gasses - and I've been doing that pretty frequently since the age of about 10 so maybe I'll suffer for it. I'm now a healthy 60 however, and so any problems I have in future is likely to be difficult to attribute to any particular lifestyle cause. I do however always try to avoid a surfeit of palfreys, which we all know is extremely unhealthy and has led to the death of at least one king.

Dave

Edited 1 time(s). Last edit at 12/01/2015 08:22AM by dmould.

For ABS printing, a more useful addition than a heated chamber would be a controllable cooling fan for overhangs and bridges. For parts with overhangs greater than 30 degrees or so I baby the print by blowing on the overhang section as its perimeters are printed, which gives a perfect result but is of course not very convenient. As for fumes - we have become a very risk-averse society and are advised to avoid things that present even miniscule risks as well as things that have not been properly assessed. As a result it has become very difficult to decide which warnings to take very seriously, which are real but acceptably low risks, and which can be dismissed as stupidly over-cautious (children must wear a safety helmet and goggles when playing conkers). If you want to be 100% safe, sure - never cross the road (carries a huge risk compared with many of the things we are advised against) and avoid barbeques (highly cancerous). The people who work in plastic injection moulding factories are exposed to far more plastic fumes during a year than is likely from hobbyist FFF printing (maybe there will be huge lawsuits in a few years similar to asbestos workers). This report may quantify the risk for a better informed decision [www.instructables.com]

If you use a soldering iron without a fume hood and extractor, from what I have read you are exposing yourself to far more hazardous gasses - and I've been doing that pretty frequently since the age of about 10 so maybe I'll suffer for it. I'm now a healthy 60 however, and so any problems I have in future is likely to be difficult to attribute to any particular lifestyle cause. I do however always try to avoid a surfeit of palfreys, which we all know is extremely unhealthy and has led to the death of at least one king.

Dave

Edited 1 time(s). Last edit at 12/01/2015 08:22AM by dmould.

|

Re: Print bed surface review December 01, 2015 11:02PM |

Registered: 9 years ago Posts: 1,699 |

Hello Dave,

For soldering I switched to lead free solder. For companies only this solder is allowed in Germany since 2007. For that reason and for my healthy I switched to lead free at home, too.

I do not think that you need a chamber for ABS printing. it seems to be more important to prevent backlash somehow and to have a good print surface. I have only a problem that the edges tends to warp but at the moment bridges and overhangs looks very good even without a second cooling fan. The same is for PLA (both regarding my Ormerod 2). Maybe this is the problem. My Ormerod 1 is not able to print bridges and overhangs in this good quality. So maybe I need a fan with reduced power. However in 3-4 weeks I will start to design my own cartesian printer model which will optionally have a chamber. As it will be optionally I will be able to compare the results

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

For soldering I switched to lead free solder. For companies only this solder is allowed in Germany since 2007. For that reason and for my healthy I switched to lead free at home, too.

I do not think that you need a chamber for ABS printing. it seems to be more important to prevent backlash somehow and to have a good print surface. I have only a problem that the edges tends to warp but at the moment bridges and overhangs looks very good even without a second cooling fan. The same is for PLA (both regarding my Ormerod 2). Maybe this is the problem. My Ormerod 1 is not able to print bridges and overhangs in this good quality. So maybe I need a fan with reduced power. However in 3-4 weeks I will start to design my own cartesian printer model which will optionally have a chamber. As it will be optionally I will be able to compare the results

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Print bed surface review December 02, 2015 03:50AM |

Registered: 10 years ago Posts: 14,672 |

My experience is that without a warm chamber it is impossible to print ABS parts more than a few mm high without warping. I had some fairly successful ABS prints using 2 plastic bags over the printer to form a makeshift heated chamber, relying on the heat from the bed to keep it warm. But the ABS fumes or more probably the particulates emitted gave me a nasty cough for a few days, and that's why I started taking the health warnings about printing ABS more seriously. So I am sticking to PLA and PETG until I have a filtered chamber.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Print bed surface review December 02, 2015 04:45AM |

Registered: 10 years ago Posts: 275 |

Hi

@ Dave

I had intoxication from ABS fume years ago.... so.. I can't feel safe with ABS.

I consider it an imperceptibly slow poisoning.(very dangerous)

I know that I must die.... but for now I prefer to print PLA only

@dc42

as always thanks

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

@ Dave

I had intoxication from ABS fume years ago.... so.. I can't feel safe with ABS.

I consider it an imperceptibly slow poisoning.(very dangerous)

I know that I must die.... but for now I prefer to print PLA only

@dc42

as always thanks

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Print bed surface review December 02, 2015 07:24AM |

Registered: 10 years ago Posts: 2,472 |

Well, my experience certainly appears to be very different. I have several ABS prints that are over 100mm high that have not warped. Square-cornered hollow shapes are a problem however. If I need to print something that is too prone to warping or that I cannot orientate on the build plate without large overhangs, bridges or excessive support, I split it into sections and glue them together. A big advantage of ABS is that it can quickly and easily be chemically welded by using acetone as a "glue," forming a bond that is as strong as a solid piece. I've made the frames for a complex aerial (Lindenblad) that are over 1m long using that technique, and a pair of large parabolic dishes (good WiFi connection over a path of almost 1 km!).

Whether it is the filament brand (3D Filaprint) or hotend temperature (235 deg C) or something else I don't know, but I can barely smell anything during an ABS print (and nor can other people) - it certainly doesn't cause any irritation whatsoever.

Dave

Whether it is the filament brand (3D Filaprint) or hotend temperature (235 deg C) or something else I don't know, but I can barely smell anything during an ABS print (and nor can other people) - it certainly doesn't cause any irritation whatsoever.

Dave

|

Re: Print bed surface review December 02, 2015 08:15AM |

Registered: 9 years ago Posts: 1,699 |

I know that there are many differences between the manufacturer regarding the fumes. A German one ads with this for example.

HIPS is much more recognizable than ABS.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

HIPS is much more recognizable than ABS.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Print bed surface review December 02, 2015 09:23AM |

Registered: 9 years ago Posts: 106 |

Quote

dc42

I've published a review of various print bed surfaces I have tried in my blog...

Thanks for this, very informative read. I wish you'd included hair spray though, as I'm thinking of getting a can on my next groceries shop to see if I can improve ABS adhesion for objects with small footprints... :-)

Quote

dmould

As for fumes - we have become a very risk-averse society and are advised to avoid things that present even miniscule risks as well as things that have not been properly assessed. As a result it has become very difficult to decide which warnings to take very seriously, which are real but acceptably low risks, and which can be dismissed as stupidly over-cautious...

Thankyouthankyouthankyouthankyouthankyou!! If this were Facebook, I'd be clicking "like" on this post! I have to deal with this on an everyday basis. More and more common use chemicals are newly found to be dangerous in some way or other. In many if not most of these cases it is due to more sensitive instrumentation (to detect their presence in the first place) and better methods of isolating their contribution to some pathology from its background rate. The thing is, the background is tiny by definition so even if you determine that a particular substance contributes such and such a proportion of said background, it is still a tiny effect. Yet that is enough for a substance to be classified as a carcinogen. Which is why the recent scare about red meats being carcinogenic is a lot of over-hyped (by tabloid media) bull excrement.

This is not to belittle well-documented acute and chronic health effects some materials have on (some) people. For example, sulfur dioxide induces asthma attacks in some people (while I like its smell) and long-term exposure to n-hexane is associated with peripheral neuropathy (which is why it is sometimes replaced by heptane in industrial settings). But these are well-documented and established relationships. What you get from the media is at best misleading and most often over-blown hype.

All I'm saying is that you should take any health warnings from the media with a pinch (or tub) of salt. Work place and HSE warnings are more believable but even those can be just an exercise in minimizing a background which is tiny to start with (see above). I suspect a lot of HSE directives have more to do with avoiding litigation than with real risk, but that's another rant. If some fumes give you a headache, then by all means open the window, and avoid future exposure to those fumes. It doesn't mean they'll affect the next person in the same way. If you're soldering for a living then it's probably good practice to avoid breathing the fumes (mostly flux and absolutely vanishingly tiny amounts of lead particulates) because of possible chronic effects way down the line. If you only solder stuff very occasionally, you'll be absolutely fine using lead solder in a confined room.

Call me a cowboy (or old-fashioned) but when I was growing up, I had access to toxic, carcinogenic, pyrophoric, radioactive, flammable, and corrosive materials since the age of about 11-12 (had a chemistry lab in the basement). All of those were sourced from either chemistry teachers, pharmacies or even completely legally from major chemical suppliers. Today, you wouldn't let even a postgrad near some of these without a lot of training and form-filling. By all accounts I should be dead or dying from cancer, radiation poisoning, heart and/or multiple organ failure, burns or whatever. As it happens, I guess I had enough common sense back then to still be alive today (and still a research chemist). Common sense seems a vanishing faculty today and appears to be inversely proportional to the propensity to litigate... The practical implementations of health and safety warnings also vary from place to place, which is confusing but goes to show they are not absolutes to live by. For example, hydrofluoric acid was a "no no" where I used to work in industry ("don't even ask about ordering or using it, you can't, period, find a way around it") while where I work now (academia) it is not a huge problem (need training and filling in some forms). On the other hand, for cyanide work back in industry, you would just sign out the 1 kg potassium cyanide tub from stores, put up a warning sign on the lab door and get on with it. If I wanted to use cyanides (even on a small scale) now, I'd still be filling in risk assessment forms come next Christmas. Incidentally, hydrofluoric acid is one of the dodgy things I was playing around with in the basement when I was 13 or so.

Right, rant over, should probably go back to work. Just to say that I completely agree with your assessment of today's society being way over-cautious. Reminds me of one of those internet memes I read somewhere: "all those health freaks are gonna feel right silly when they're in hospital at 80 dying from nothing"... :-)

Bart

|

Re: Print bed surface review December 03, 2015 06:45AM |

Registered: 8 years ago Posts: 443 |

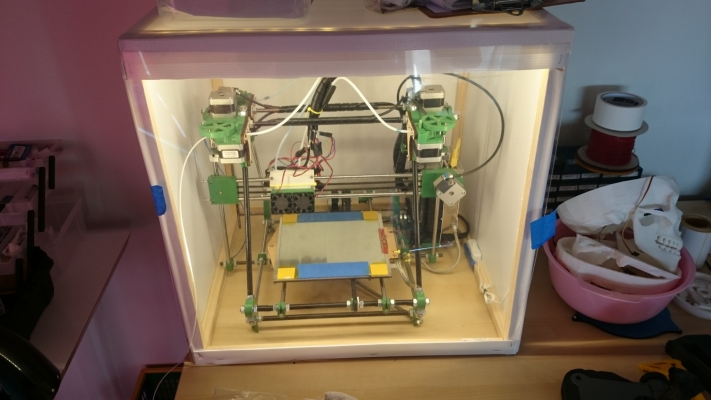

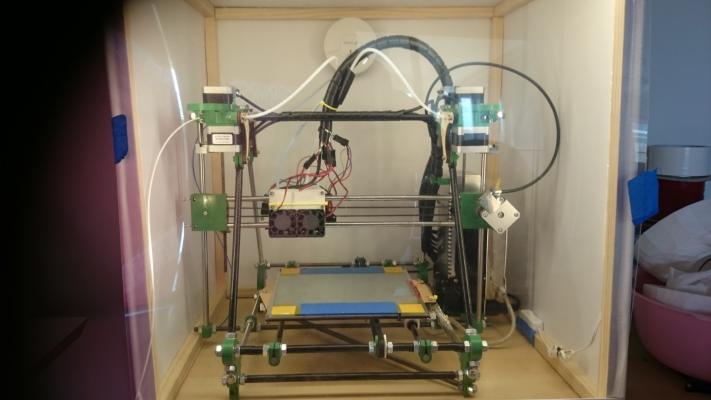

Built a chamber for printing ABS on my Mendel 3...... before I got warping and cracking, after perfect prints.... definitely recommend a chamber for ABS

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Print bed surface review December 03, 2015 06:51AM |

Registered: 10 years ago Posts: 94 |

Very intressting, I am planning to heat my build chamber as well.Quote

bgkdavis

Built a chamber for printing ABS on my Mendel 3...... before I got warping and cracking, after perfect prints.... definitely recommend a chamber for ABS

What temperature are you running inside the chamber?

Is it a bowden system? If so is there a problem with temperature of filament?

Are you running more than one nozzle?

What are you using to heat the chamber?

Kind reg Joar

|

Re: Print bed surface review December 03, 2015 06:12PM |

Registered: 8 years ago Posts: 443 |

No additional heating, the chamber already contains multiple heat sources, if anything Ill need to add cooling or an extractor fan, or move the electronics outside the chamber.

What I have added inside the chamber is LED light strips and a smoke alarm.

The construction is really simple, its basically a 550x500x500 box the three walls and top are made from corrugated plastic board which is stapled onto 16mm square baton, with a clear plastic flap on the front, and i just used white duct tape to tidy the corners, it takes no more than an hour to build from basic hardware

The filament currently just feeds trough the front flap, but Ill be adding a hole in the side at a later date.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

What I have added inside the chamber is LED light strips and a smoke alarm.

The construction is really simple, its basically a 550x500x500 box the three walls and top are made from corrugated plastic board which is stapled onto 16mm square baton, with a clear plastic flap on the front, and i just used white duct tape to tidy the corners, it takes no more than an hour to build from basic hardware

The filament currently just feeds trough the front flap, but Ill be adding a hole in the side at a later date.

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Print bed surface review December 04, 2015 01:46PM |

Registered: 9 years ago Posts: 638 |

|

Re: Print bed surface review December 04, 2015 05:29PM |

Registered: 8 years ago Posts: 443 |

The bed mounts,carraige and hot end (white parts) are ABS, the rest is stock PLA

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

Sorry, only registered users may post in this forum.