Help me with my doubts on buying a Omerod2

Posted by Vizual54

|

Re: Help me with my doubts on buying a Omerod2 December 19, 2014 07:33AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Vizual54

Got the O2 yesterday and started assembling it in the evening. Was oh so careful with the acrylic y-axis endplates since reading about people cracking them when putting the rods in. No worries though got the y and z axis assembled and started on the x axis yesterday.

Though when I was about to get going today I ran the y carriage back and fourth and suddenly heard a crack. Left endplate had shattered!!

Managed to glue it together to at least be able to continue building. At a closer inspection it seems like the hole for the rod in the y-idler-bracket and the acrylic part didn't line up and that probably put too much stress on the acrylic. Actually the y-idler-bracket was a really bad print compared with the other printed parts. Going to contact RRP tomorrow and see if they can send a new part.

I'm really sorry to hear that, and hope you are able to repair it well enough to get running over Christmas. I suppose that if need be it would be possible to make another plate with some sheet material (even plywood should work) and a few basic tools - the DXF files are available so you could print a paper pattern to stick onto the sheet and follow. Poorly printed parts can often be made to be adequate with a bit of filing and drilling - I bought a set of cheap needle files which are invaluable for finishing my prints. I am certain that many forum members would be willing to reprint any parts you may need to get you running ASAP, if you let us know your approximate location there may be someone close enough for you to collect, seeing that postal delivery is likely to be very slow at this time of year.

Dave

Edited 1 time(s). Last edit at 12/19/2014 07:34AM by dmould.

|

Re: Help me with my doubts on buying a Omerod2 December 19, 2014 02:00PM |

Registered: 9 years ago Posts: 32 |

|

Re: Help me with my doubts on buying a Omerod2 December 19, 2014 03:04PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Vizual54

I think that acrylic is a pretty bad choice for those parts since they only have one support which means there will be a lot of force on tje two bolts holding it to the printed parts. Maybe plywood or even better aluminium would be much better.

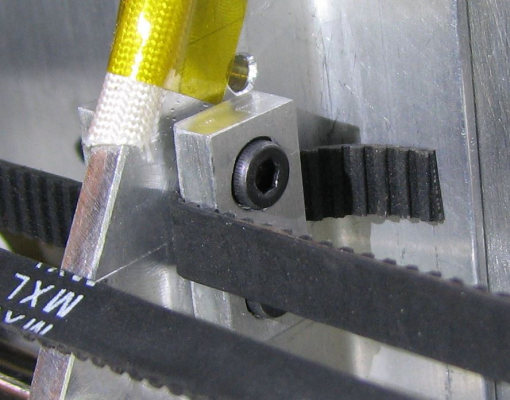

I agree and made these supporting end parts in aluminium

Problem is RepRapPro cannot laser cut aluminium in-house and want to keep the price of the printer down

More in this thread:

[forums.reprap.org]

Erik

|

Re: Help me with my doubts on buying a Omerod2 December 20, 2014 05:37AM |

Registered: 9 years ago Posts: 32 |

|

Re: Help me with my doubts on buying a Omerod2 December 20, 2014 06:45AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Vizual54

..Maybe I have to go buy a drill press after Christmas

Yes a drill press or access to one and a hacksaw is all you need - it don't have to be angled aluminium, I chose that because of the added sideway strength against the pull of the belt (belt now goes high pitch pling instead of low pitch ploing) -

- but on the other hand, aluminium is much stronger and stable than the PLA/Acrylic part so a flat length of aluminium will be much much better than the original - and I did print just fine with the original setup for a long time, as long as you do not move the printer and don't tighten the belt too much the ormerod prints just fine

..and if you have access to a 12mm drill bit, do yourself a favor and run it though the holes in the acrylic endparts to square the holes of (mine was cut in a angle as delivered and made the printer look silly)...and to make the 12mm smooth rods "float" in the holes, that will make the assembly much easier and the outside aluminium parts will arrest them sideways

And if you are not used to work with a drill press and chose to open the 12mm acrylic parts, please please do take care and make sure to arrest the parts on the bed of the drill press and lower the drill very very slow as it will try to grab and crack the acrylic for sure..

If you have a scrapyard nearby you will find all the material you need and I'll bet much much more - I call the local one "the land of dreams", I try to remember every thing I see there and visualize what it can be used for

Happy modding! - the more work you put in yourself, the more you will like your printer and your prints

Erik

|

Re: Help me with my doubts on buying a Omerod2 January 02, 2015 07:48PM |

Registered: 9 years ago Posts: 32 |

Thought I should give a little update.

RRP replied before Christmas and is sending me a new acrylic and idler bracket, though it have not arrived yet.

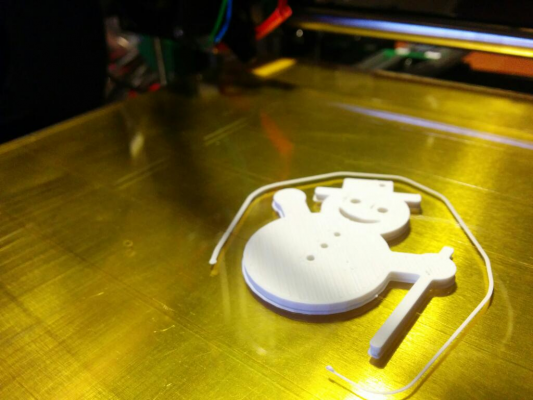

Anyway, some days after Christmas I tested to print the snowman and it came out surprisingly well.

My daughter immediately asked me to print three more

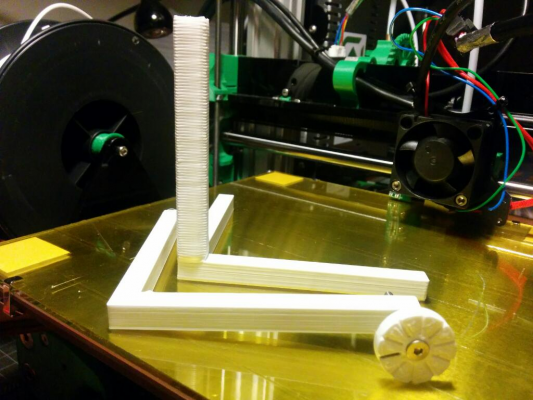

I have also printed the orthogonal compensation file which also came out quite ok. The z-axis is a bit thicker than x and y.

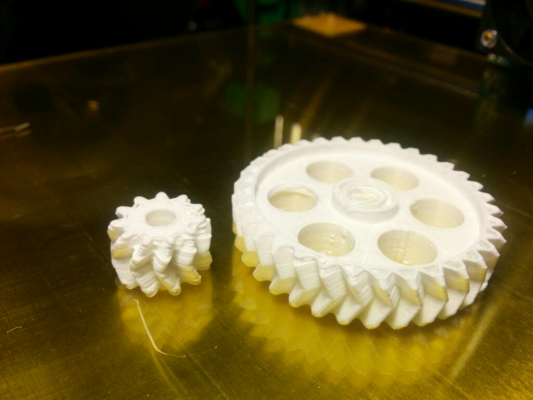

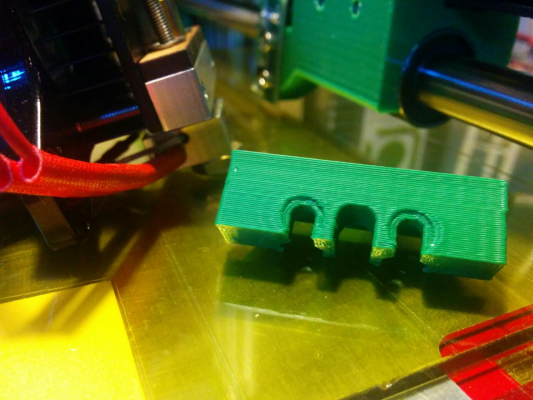

Since then I have upgraded to dc42's firmware and tried to print the herringbone gears for the extruder yesterday.

This did not come out very well though. The big gear is better than the small I have no idea why.

Made a new try today with the small gear and gears for the x-axis. This came out even worse.

I have used the standard ormerod0.5 slic3r presets with just a few modifications. What I don't understand is why the layers in the middle is very bad but the top layers is really ok. Also why the quality differs between the objects on the same layer level.

Tomorrow I'll to go back a few steps and redo the calibration steps. I also have do some experiments with slic3r to learn what is happening. Do anyone have any good tips on basic settings to start from or are the ormerod0.5 OK?

RRP replied before Christmas and is sending me a new acrylic and idler bracket, though it have not arrived yet.

Anyway, some days after Christmas I tested to print the snowman and it came out surprisingly well.

My daughter immediately asked me to print three more

I have also printed the orthogonal compensation file which also came out quite ok. The z-axis is a bit thicker than x and y.

Since then I have upgraded to dc42's firmware and tried to print the herringbone gears for the extruder yesterday.

This did not come out very well though. The big gear is better than the small I have no idea why.

Made a new try today with the small gear and gears for the x-axis. This came out even worse.

I have used the standard ormerod0.5 slic3r presets with just a few modifications. What I don't understand is why the layers in the middle is very bad but the top layers is really ok. Also why the quality differs between the objects on the same layer level.

Tomorrow I'll to go back a few steps and redo the calibration steps. I also have do some experiments with slic3r to learn what is happening. Do anyone have any good tips on basic settings to start from or are the ormerod0.5 OK?

|

Re: Help me with my doubts on buying a Omerod2 January 03, 2015 03:37AM |

Registered: 10 years ago Posts: 14,672 |

I think that either you have a slack or slipping belt or a stepper motor is missing steps. So check the X and Y belt tensions, and check that the Y stepper motor current in the M906 command in config.g is set to 1000. Using a lower print speed may also help - to avoid having to re-slice you can use the slider in the web interface. You may also want to reduce the minimum X and Y speeds to 600mm/min or lower using the M566 command in config.g.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help me with my doubts on buying a Omerod2 January 03, 2015 05:46AM |

Registered: 9 years ago Posts: 42 |

I'm not an expert, but those pictures look more like an extrusion problem than an x/y steps missing problem (I would have thought that if you missed steps on X or Y you would end up with subsequent layers misaligned, where in the picture they appear to be aligned all the way up, just "lumpy".

When I first got my Ormerod I had issues with the gears on the extruder binding occasionally - increasing the current for the extruder to 1000 helped until I was able to print some herringbone gears to replace the originals. That could cause symptoms a bit like this.

Richard

When I first got my Ormerod I had issues with the gears on the extruder binding occasionally - increasing the current for the extruder to 1000 helped until I was able to print some herringbone gears to replace the originals. That could cause symptoms a bit like this.

Richard

|

Re: Help me with my doubts on buying a Omerod2 January 03, 2015 05:50AM |

Registered: 9 years ago Posts: 42 |

Forgot to say, in general I found the default slic3r settings from for Ormerod 0.5 work just fine, BUT for the herringbone extruder gear (the large one at least) you need to increase the infill (I think I put mine all the way to 100%) or it will be crushed when you try to tighten the hobbed bolt onto it.

Richard

Richard

|

Re: Help me with my doubts on buying a Omerod2 January 03, 2015 08:23AM |

Registered: 9 years ago Posts: 32 |

hanks for the tips!

I also thought that it was the extruder slipping or missing steps. Had problems during commissioning when I measured 100mm of filament and had to file some on the gears and also raise power to 1000.

I will check more tonight, especially x and y missing steps. The belt for the x-axis is pretty tight but the y-axis is a little bit loose. Since I broke and fixed one of the acrylic end pieces I don't dare tightening it too much. Hopefully the new one will arrive soon.

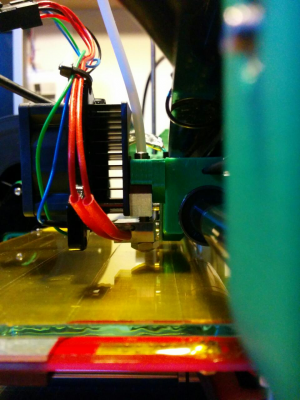

I also noticed this a moment ago:

As you can see the sensor is pretty straight but the hot end leans away from the x-axis pretty much. It appears as the mounting bolts for the hot end has digged into the printed part.

T

I also thought that it was the extruder slipping or missing steps. Had problems during commissioning when I measured 100mm of filament and had to file some on the gears and also raise power to 1000.

I will check more tonight, especially x and y missing steps. The belt for the x-axis is pretty tight but the y-axis is a little bit loose. Since I broke and fixed one of the acrylic end pieces I don't dare tightening it too much. Hopefully the new one will arrive soon.

I also noticed this a moment ago:

As you can see the sensor is pretty straight but the hot end leans away from the x-axis pretty much. It appears as the mounting bolts for the hot end has digged into the printed part.

T

|

Re: Help me with my doubts on buying a Omerod2 January 03, 2015 10:22AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Vizual54

It appears as the mounting bolts for the hot end has digged into the printed part.

That is a common problem, I'm surprised that RRP haven't fixed it. Here [www.thingiverse.com] is my version of the nozzle mount, which has holes instead of slots for the mounting screws.

Edited 1 time(s). Last edit at 01/04/2015 07:07PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help me with my doubts on buying a Omerod2 January 04, 2015 02:00PM |

Registered: 9 years ago Posts: 32 |

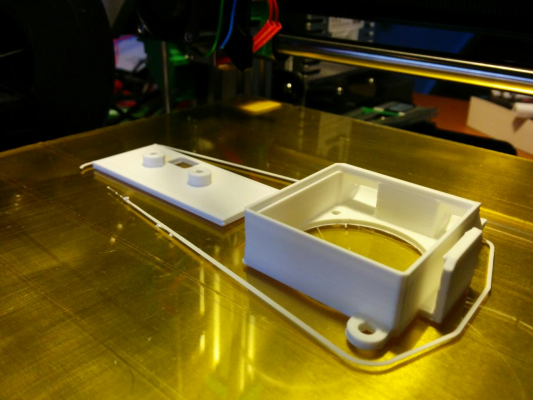

Fixed the sag of the nozzle and tried leveling the print bed a little bit better. Though I'm having a hard time getting it level in all corners, hopefully its because of the broken end plate.

Also redid the z-homing distance and noticed that I had M558 P1 in the config.g must have forgot to change that to M558 P2.

Printed the one-piece fan duct and insulator for dc42s hot end board that I will mount soon.

Seems like its working much better now. Haven't tried the herringbone gears yet though.

Thanks for the help!

Edited 1 time(s). Last edit at 01/04/2015 02:01PM by Vizual54.

Also redid the z-homing distance and noticed that I had M558 P1 in the config.g must have forgot to change that to M558 P2.

Printed the one-piece fan duct and insulator for dc42s hot end board that I will mount soon.

Seems like its working much better now. Haven't tried the herringbone gears yet though.

Thanks for the help!

Edited 1 time(s). Last edit at 01/04/2015 02:01PM by Vizual54.

|

Re: Help me with my doubts on buying a Omerod2 January 05, 2015 03:59AM |

Registered: 10 years ago Posts: 780 |

I found that the hot end temperature was quite critical when printing these gears, especially the small gear.

Try reducing the temperature by a few degrees and see if that helps.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Try reducing the temperature by a few degrees and see if that helps.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Help me with my doubts on buying a Omerod2 January 05, 2015 08:42AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Vizual54

Fixed the sag of the nozzle and tried leveling the print bed a little bit better. Though I'm having a hard time getting it level in all corners, hopefully its because of the broken end plate.

I expect it is the broken end plate causing that issue. If the two Y ground rods that the plate is holding are not exactly parallel, it will not be possible to get all 4 corners of the bed to the same height because the front of the bed will move up and down relative to the back of the bed as you move the bed from side to side (Y direction).

Dave

|

Re: Help me with my doubts on buying a Omerod2 January 05, 2015 12:04PM |

Registered: 9 years ago Posts: 42 |

Quote

dmould

If the two Y ground rods that the plate is holding are not exactly parallel, it will not be possible to get all 4 corners of the bed to the same height because the front of the bed will move up and down relative to the back of the bed as you move the bed from side to side (Y direction).

Dave

That is really useful (and timely) information! I've been having terrible trouble trying to level my bed, and was convinced that the bed was warped - but now I see that in fact the problem is that my Y rods are not quite parallel.

Thanks - you've saved me a lot of effort trying to build a new bed!

Richard

Sorry, only registered users may post in this forum.