Looking for some help some, tips

Posted by djinn5150

|

Looking for some help some, tips June 05, 2014 09:46AM |

Registered: 9 years ago Posts: 178 |

Hello all,

So first let me say I am new to the whole 3D printer world. I have built my first printer choosing the Smartrap. I have gotten everything working but with no consistency. I was able to get several calibration prints printed to within a .1

The problem comes when I try to print any replacement parts, specifically I really need a replacement x lm8 support, they tend to turn to swiss cheese. For instance last night I printed a lm8 bushing almost flawlessly, then turned around and ran the lm8 support through slic3r with the same settings the first few layers were nice then it just went bad for no apparent reason that I can tell. I was printing it vertically which I am sure makes a difference, but it was at about the screw hole that things went bad.

I had slicer set up at .25mm Layer height .4 infill /20 mm/s, 30 mm/s infill speed travel at 40 mms

Not sure what other info I need to provide for any help but can get anything without a problem.

Also I am using a knockoff j-head with a .4 nozzle.

thanks in advance.

So first let me say I am new to the whole 3D printer world. I have built my first printer choosing the Smartrap. I have gotten everything working but with no consistency. I was able to get several calibration prints printed to within a .1

The problem comes when I try to print any replacement parts, specifically I really need a replacement x lm8 support, they tend to turn to swiss cheese. For instance last night I printed a lm8 bushing almost flawlessly, then turned around and ran the lm8 support through slic3r with the same settings the first few layers were nice then it just went bad for no apparent reason that I can tell. I was printing it vertically which I am sure makes a difference, but it was at about the screw hole that things went bad.

I had slicer set up at .25mm Layer height .4 infill /20 mm/s, 30 mm/s infill speed travel at 40 mms

Not sure what other info I need to provide for any help but can get anything without a problem.

Also I am using a knockoff j-head with a .4 nozzle.

thanks in advance.

|

Re: Looking for some help some, tips June 05, 2014 10:38AM |

Registered: 10 years ago Posts: 229 |

|

Re: Looking for some help some, tips June 05, 2014 12:51PM |

Registered: 10 years ago Posts: 349 |

|

Re: Looking for some help some, tips June 05, 2014 01:46PM |

Registered: 9 years ago Posts: 178 |

Not sure how to post images from my google drive folder but the link is here Located in the "prints" folder

There is also a photo of the build in its current, albeit messy state.

My flow rate is set to default at 1, Have not had any "knocking" that I am aware of, a bit of whining here and there but not bad, I don't believe the filament is slipping but I am only a man I can be wrong(if you listen to my wife most likely I always am)

The filament I am using is 1.75mm black from JustPla purchased from amazon. My temps are set to run the first layer at 200 then following layers at 195.

The part basically disintegrated as I attempted to remove it from the print bed, yet the lm8 bushing(also in the picture file) is solid as a rock printed off the same slicer settings. Really hoping its not the print head. Going to try and scale the part down and print it again and see what happens.

thanks again for your help

There is also a photo of the build in its current, albeit messy state.

My flow rate is set to default at 1, Have not had any "knocking" that I am aware of, a bit of whining here and there but not bad, I don't believe the filament is slipping but I am only a man I can be wrong(if you listen to my wife most likely I always am)

The filament I am using is 1.75mm black from JustPla purchased from amazon. My temps are set to run the first layer at 200 then following layers at 195.

The part basically disintegrated as I attempted to remove it from the print bed, yet the lm8 bushing(also in the picture file) is solid as a rock printed off the same slicer settings. Really hoping its not the print head. Going to try and scale the part down and print it again and see what happens.

thanks again for your help

|

Re: Looking for some help some, tips June 05, 2014 02:26PM |

Registered: 10 years ago Posts: 349 |

|

Re: Looking for some help some, tips June 05, 2014 03:17PM |

Registered: 10 years ago Posts: 229 |

A couple of things. First, is that plain old fishing line your using? I know a lot of references mention "fishing line" but the type of fishing line that is supose to be used is called Spectra. It is a braided line made from this stuff. Nylon monoline will stretch and flex and will not give good results, it's too "springy". In this post, you can see the Spectra "fishing line" on my machine.

Second thing is it looks like your layer height is too much for your nozzle diameter. Try dropping it back to 0.20 or less and make sure your esteps are correct for your Z. 200/195 sounds a bit hot to me, though it may take that for black that has a bunch of junk in it. I run both my black and green at 185 and have no problems. Have you tried extruding with a lower temp?

Mark

Second thing is it looks like your layer height is too much for your nozzle diameter. Try dropping it back to 0.20 or less and make sure your esteps are correct for your Z. 200/195 sounds a bit hot to me, though it may take that for black that has a bunch of junk in it. I run both my black and green at 185 and have no problems. Have you tried extruding with a lower temp?

Mark

|

Re: Looking for some help some, tips June 05, 2014 03:51PM |

Registered: 9 years ago Posts: 178 |

Yes it is a 45lb mono-filament, its what I had available at build. I will locate some spectra and replace that for sure. I am guessing that will have an effect on my steps so once thats done I will re-calibrate, Z steps are actually a little off after double checking the LM8 bushings, from what I can tell they should be 23.8mm tall and I just printed one at 23.14.

Once I get some new fishing line I will do some calibration prints dropping the layer height down and maybe lowering temp, 1 at a time of course. Then I will report back.

Thanks for the help

Once I get some new fishing line I will do some calibration prints dropping the layer height down and maybe lowering temp, 1 at a time of course. Then I will report back.

Thanks for the help

|

Re: Looking for some help some, tips June 05, 2014 06:41PM |

Registered: 11 years ago Posts: 791 |

Here are the images that didn't load because of permissions.

Bad Prints

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 05, 2014 06:58PM |

Registered: 9 years ago Posts: 80 |

I'm sure you were so excited to start printing after building your printer  but once you have your new fishing line installed, it would really save you a lot of filament in the long run if you do calibration tests.

but once you have your new fishing line installed, it would really save you a lot of filament in the long run if you do calibration tests.

I skipped those calibrations too as I was so excited to see it print but they will turn out much better if you do.

For example, experiment with flow rate. I don't know if a default of 1 flow rate worked for anybody but in my case, I'm currently printing at 0.8 despite accurately setting my filament diameter to 1.6 (that's the real diameter of the filament that I received). It looks like you need to turn your flow rate down a bit.

Congratulations on your new toy!

but once you have your new fishing line installed, it would really save you a lot of filament in the long run if you do calibration tests.

but once you have your new fishing line installed, it would really save you a lot of filament in the long run if you do calibration tests. I skipped those calibrations too as I was so excited to see it print but they will turn out much better if you do.

For example, experiment with flow rate. I don't know if a default of 1 flow rate worked for anybody but in my case, I'm currently printing at 0.8 despite accurately setting my filament diameter to 1.6 (that's the real diameter of the filament that I received). It looks like you need to turn your flow rate down a bit.

Congratulations on your new toy!

|

Re: Looking for some help some, tips June 05, 2014 07:35PM |

Registered: 9 years ago Posts: 178 |

New fishing line is installed and running calibration tests now. First 10mm cube came out ok, and definitely short on all axis. Will do one more them move up to a 25mm cube. I will most likely play with flow rate soon but want to minimize variables inbetween prints to find out what works etc etc, hopefully I wont be beating my head against the wall for too long.

Would someone be so kind as to describe "stepper knocking" Being a car guy all I can think of is like a rod knocking in an engine and that may not be the sound I need to be listening for.

Again thank you everyone that has chimed in here.

Would someone be so kind as to describe "stepper knocking" Being a car guy all I can think of is like a rod knocking in an engine and that may not be the sound I need to be listening for.

Again thank you everyone that has chimed in here.

|

Re: Looking for some help some, tips June 05, 2014 08:19PM |

Registered: 10 years ago Posts: 229 |

When your setting up your esteps for your x and y, your want to use this formula, if you haven't already -

Pi * (shaft dia + line dia) = Tc

Steps per rev * microstepping / Tc = esteps

So, for a 5 mm shaft and .3mm line we would have -

3.14159265359 * (5 + 0.3) = 16.650441064

and with a 1.8* step and 1/16 microstepping we then use -

200 * 16 / 16.650441064 = 192.187101092 or rounded to 192.19 esteps

Take your own measurements and do the math.

Knocking is the sound you hear when the stepper can not push any more and it kicks back. the knocking sound comes from the tension being released when the stepper misses a step.

Mark

Pi * (shaft dia + line dia) = Tc

Steps per rev * microstepping / Tc = esteps

So, for a 5 mm shaft and .3mm line we would have -

3.14159265359 * (5 + 0.3) = 16.650441064

and with a 1.8* step and 1/16 microstepping we then use -

200 * 16 / 16.650441064 = 192.187101092 or rounded to 192.19 esteps

Take your own measurements and do the math.

Knocking is the sound you hear when the stepper can not push any more and it kicks back. the knocking sound comes from the tension being released when the stepper misses a step.

Mark

|

Re: Looking for some help some, tips June 05, 2014 08:35PM |

Registered: 9 years ago Posts: 178 |

Usually I could follow that...maybe I have just been at this too long....

Usually I could follow that...maybe I have just been at this too long....But what I have been doing is just this print a 10mm cube, measure then apply this formula

10/actual size * old step = New stepp

for instance my last print

10/9.7 * 182.59011 = 184.434455

My shafts are 5mm, my fishing line is .43 I am going to walk away for a minute so maybe my brain can process what you are telling me, then I'll look again after this print finishes.

On another note are you guys printing right on the glass or using blue painters tape, I cannot for the life of me get this pla to stick to the glass on its own. I did harvest it out of a scanner so maybe that has something to do with it.

And for what its worth, I have not noticed any knocking.

|

Re: Looking for some help some, tips June 05, 2014 09:05PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

Usually I could follow that...maybe I have just been at this too long....

But what I have been doing is just this print a 10mm cube, measure then apply this formula

10/actual size * old step = New stepp

for instance my last print

10/9.7 * 182.59011 = 184.434455

My shafts are 5mm, my fishing line is .43 I am going to walk away for a minute so maybe my brain can process what you are telling me, then I'll look again after this print finishes.

On another note are you guys printing right on the glass or using blue painters tape, I cannot for the life of me get this pla to stick to the glass on its own. I did harvest it out of a scanner so maybe that has something to do with it.

And for what its worth, I have not noticed any knocking.

Clean your glass and then get some watered down (just enough water to make it paintable) PVA wood glue and coat your glass with a heavy coat and let it dry completely.

Don't force dry it, best toleave it overnight until it goes clear. Maybe a second coat is a good idea too, you want the glue to be fairly thick when dried.

You can then print on this surface many times and the PLA will stick down very well. Use a knife to carefully lift your print off, being careful to not damage the glue surface.

Ordinary window glass is OK to use for a print bed, I use 3mm glass which actually measures about 2,8mm. It is very cheap and easy to find.

The knocking sound comes from a motor that is being over driven and is missing steps. This is quiet common for direct drive extruders. You either need to adjust the pressure applied to the filament, reduce the speed of the print, use a more powerful motor, or change to a geared extruder (best option)

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 05, 2014 09:08PM |

Registered: 10 years ago Posts: 229 |

|

Re: Looking for some help some, tips June 05, 2014 09:37PM |

Registered: 9 years ago Posts: 178 |

Awesome I'll try both, probably the aquanet first since I believe there is a can in the wife's bag of tricks

My brain finally kicked in and I came up with the same thing, rounded up at 187.586 but will probably go up to .59, did another print and it was within .15. Being how the last few calibration tests went so well I am going to attempt the x-lm8 support again. the one I have is I believe from the original design and it is just loose as a goose, especially up front. I have aquarium air hose somewhat clamping it down now but its not going to last much longer I am sure. I am sure it will be a couple hours to knock this one out, wish me luck. And thank you again you all have been awesome, I must say its been awhile to be in a forum and not be told were the search boxes are when looking for help.

Quote

3.14159265359 * (5 + 0.43)=17.058848109

then for 1/16th steps and 1.8* per step -

200*16/17.058848109=187.585936609 esteps or rounded to 187.59 esteps per mm

My brain finally kicked in and I came up with the same thing, rounded up at 187.586 but will probably go up to .59, did another print and it was within .15. Being how the last few calibration tests went so well I am going to attempt the x-lm8 support again. the one I have is I believe from the original design and it is just loose as a goose, especially up front. I have aquarium air hose somewhat clamping it down now but its not going to last much longer I am sure. I am sure it will be a couple hours to knock this one out, wish me luck. And thank you again you all have been awesome, I must say its been awhile to be in a forum and not be told were the search boxes are when looking for help.

|

Re: Looking for some help some, tips June 05, 2014 10:22PM |

Registered: 9 years ago Posts: 178 |

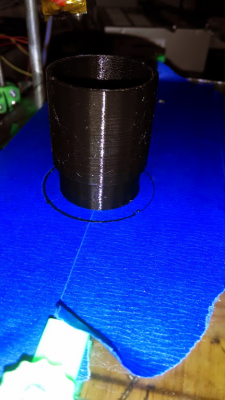

Well might be hard to tell but looks like its delaminating as it prints...  any thoughts?

any thoughts?

any thoughts?

any thoughts?; generated by Slic3r 1.0.0RC3 on 2014-06-05 at 18:19:52 ; layer_height = 0.2 ; perimeters = 4 ; top_solid_layers = 3 ; bottom_solid_layers = 3 ; fill_density = 1 ; perimeter_speed = 30 ; infill_speed = 30 ; travel_speed = 30 ; nozzle_diameter = 0.4 ; filament_diameter = 1.75 ; extrusion_multiplier = 1 ; perimeters extrusion width = 0.40mm ; infill extrusion width = 0.67mm ; solid infill extrusion width = 0.67mm ; top infill extrusion width = 0.67mm ; first layer extrusion width = 0.50mm

|

Re: Looking for some help some, tips June 06, 2014 09:49AM |

Registered: 9 years ago Posts: 178 |

Well would ya look at that I think I figured it out, this was a 2+ hour print and came out wonderfully. It really helps if your air conditioning isn't blowing across the print bed.

I have a whole other slew of problems with this print but I think its in the modeling more then the printers fault.

Was expecting a 2mm sidewall at the top, got 2.01mm; 3.87mm at the bottom, 3.9. z fell short at 43 of 44.5. The problem is my diameters are about 2 mm short on both ends.

Could it be shrinkage? Or is there something I need to know about printing circles?

Anyway THANK YOU ALL!!! Especially markstephen

|

Re: Looking for some help some, tips June 06, 2014 12:53PM |

Registered: 10 years ago Posts: 814 |

|

Re: Looking for some help some, tips June 06, 2014 08:42PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

Well would ya look at that I think I figured it out, this was a 2+ hour print and came out wonderfully. It really helps if your air conditioning isn't blowing across the print bed.

I have a whole other slew of problems with this print but I think its in the modeling more then the printers fault.

Was expecting a 2mm sidewall at the top, got 2.01mm; 3.87mm at the bottom, 3.9. z fell short at 43 of 44.5. The problem is my diameters are about 2 mm short on both ends.

Could it be shrinkage? Or is there something I need to know about printing circles?

Anyway THANK YOU ALL!!! Especially markstephen

Hey! that is looking much better, you are getting there.

Are you using M5 thread for lifting the Z?

If so a small tip that can make a difference on tall objects.

Try and make the multiplier of the steps as close as you can to a full step. OK this needs a bit of explanation.

M5 gives a travel distance of 0.8mm per turn, so try and work out what you need for your layer height that will work in with that.

Any very small discrepancy will add up over a tall object, so the more accuracy you can get the better the object final size will be.

Some people are setting a layer height of 0.25mm while if you were to use 0.24mm there would be no part steps needed (either lost or added to)

Quick way to work it out, how many times will 8 divide into the layer height exactly ( leave the decimal out to make it clearer to see)

8x3=24 so using 0.24 would be the better layer height to use.

Works for me pretty good.

Here are a few photos of prints using this method. I am actually using a couple of my i3 machines to print these are they can print 275mm tall, but the same principle works for the SmartRap too.

This vase is 275mm tall, no problems with the print at all.

The final height of this piece will be 265mm tall. Coming out pretty good so far.

Another shot of the same piece being printed.

You might notice that this printer has built-in fans and Creed LEDs that follow the work piece as it is being printed.

I haven't worked out how to do that with the SmartRap yet, but that would be a nice feature as it works so well on my i3 (my design, not an original i3 machine)

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 06, 2014 11:13PM |

Registered: 10 years ago Posts: 814 |

|

Re: Looking for some help some, tips June 07, 2014 12:35AM |

Registered: 9 years ago Posts: 178 |

Awesome tips regpye, thanks. Those are some beautiful prints there, Hopefully one day I'll have mine dialed in enough to print parts for a mendel of some sorts. It's still giving me issues but I am almost certain its user error and slic3r settings more then anything. I am not using a m5 sadly they are hard to come by in my neck of the woods and didn't wan't to order another part but I am using 10/32 threaded rod and I am guessing the .8 comes from the pitch of the m5, I'll have to see if I can find the info on this rod I'm using until I can get ahold of some m5.

I have been pondering on the lights as well, I have a very hard time seeing the part in the shadows and some light would be a welcome addition.

At this point if I can just get the much needed "upgrades" done I will be 1 happy camper. My front Y plate has begun to sag from pressure from the weight of the glass and the heat generated by the stepper motors. I am also getting a wonderfull vibration at print but when I travel its almost silent, I cant seem to figure that out either but I am learning lots and have loads of fun playing in my scrap pile

I have been pondering on the lights as well, I have a very hard time seeing the part in the shadows and some light would be a welcome addition.

At this point if I can just get the much needed "upgrades" done I will be 1 happy camper. My front Y plate has begun to sag from pressure from the weight of the glass and the heat generated by the stepper motors. I am also getting a wonderfull vibration at print but when I travel its almost silent, I cant seem to figure that out either but I am learning lots and have loads of fun playing in my scrap pile

|

Re: Looking for some help some, tips June 07, 2014 01:53AM |

Registered: 10 years ago Posts: 229 |

The metric pitch on a 10-32 thread is .794 mm real close to .8 but over a distance can throw you off as your esteps works out to 4,030.22670025 / mm. Not so good trying to match an imperial thread to a metric based unit. There are not any standard imperial threads that will work out to even steps on a metric based system. Your best bet is to go for the metric thread and be done with it.

|

Re: Looking for some help some, tips June 07, 2014 02:38AM |

Registered: 11 years ago Posts: 791 |

Quote

markstephen

The metric pitch on a 10-32 thread is .794 mm real close to .8 but over a distance can throw you off as your esteps works out to 4,030.22670025 / mm. Not so good trying to match an imperial thread to a metric based unit. There are not any standard imperial threads that will work out to even steps on a metric based system. Your best bet is to go for the metric thread and be done with it.

Yes I totally agree,it will never be any good with imperial, too many variances

In Australia we went all metric years ago, and being an old fella, I still remember the feet and inches, but I certainly wouldn't want to go back to that, metric is so much easier.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 07, 2014 02:49AM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

Awesome tips regpye, thanks. Those are some beautiful prints there, Hopefully one day I'll have mine dialed in enough to print parts for a mendel of some sorts. It's still giving me issues but I am almost certain its user error and slic3r settings more then anything. I am not using a m5 sadly they are hard to come by in my neck of the woods and didn't wan't to order another part but I am using 10/32 threaded rod and I am guessing the .8 comes from the pitch of the m5, I'll have to see if I can find the info on this rod I'm using until I can get ahold of some m5.

I have been pondering on the lights as well, I have a very hard time seeing the part in the shadows and some light would be a welcome addition.

At this point if I can just get the much needed "upgrades" done I will be 1 happy camper. My front Y plate has begun to sag from pressure from the weight of the glass and the heat generated by the stepper motors. I am also getting a wonderfull vibration at print but when I travel its almost silent, I cant seem to figure that out either but I am learning lots and have loads of fun playing in my scrap pile

Yes the pitch of an M5 gives a forward movement of 0.8mm per turn. M6 is even better, it is 1mm per turn. Some of my i3s have M6 because I wanted to see if it were any better and in some ways it is because M6 is usually straighter than M5, the 1:1 ratio is so easy to work with too.

One drawback is that M6 is stronger and if there is any wobble through the rod being a little bent, the rod can't flex as easy as the M5. That makes the M5 a bit better in that respect, but only if the top end is floating, that is not set in a bearing to stop the wiggle of the end. It is much better to have that Z rod able to wiggle at its free end so that no pressure is put on the linear rods. If this wiggle is transferred to the linear bearings it will make the print head wiggle too, and then you know what happens to the print.

I didn't like the Y design at all, it just didn't sit right with me having so much load on one side, so that is why I redesigned the split Y section and balanced out the load across the whole carriage or bed. It made a huge difference to the machine, and then of course I couldn't stop there and redesigned the whole of the machine again and again ha..ha.. lots of fun. I will have another one to show you guys soon.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 07, 2014 12:24PM |

Registered: 10 years ago Posts: 349 |

Thanks once again Reg these tips are very useful. In regard to M5 rods i like to add that i noticed that INOX threaded rods are usually pretty good. And the galvanised ones are very bad, the thread is not as smooth as the INOX (it feels rough in your fingers) and a wobble is already visual as well (at least in my local hardware store..)

Impressive prints BTW

Impressive prints BTW

|

Re: Looking for some help some, tips June 07, 2014 08:21PM |

Registered: 9 years ago Posts: 178 |

So much knowledge...thanks again guys I'll hunt down a M5 and shoot for INOX. Things are going ok now, If i can get my strings and circle problems under control I will be a happy camper for a while. Circles are consistently undersized and I have yet to understand why. Everything else in the model is x/y wise is spot on Z is off but we already know why I am having problems there. Thank you again to you all, this is definitley becoming my favorite new hobby

|

Re: Looking for some help some, tips June 07, 2014 08:23PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Thanks once again Reg these tips are very useful. In regard to M5 rods i like to add that i noticed that INOX threaded rods are usually pretty good. And the galvanised ones are very bad, the thread is not as smooth as the INOX (it feels rough in your fingers) and a wobble is already visual as well (at least in my local hardware store..)

Impressive prints BTW

Stainless steel thread is the very best, but it is expensive compared to zinc coated. Plain steel is not too bad, however it is not so easy to find here, maybe you have better supplies where you are.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 07, 2014 08:27PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

So much knowledge...thanks again guys I'll hunt down a M5 and shoot for INOX. Things are going ok now, If i can get my strings and circle problems under control I will be a happy camper for a while. Circles are consistently undersized and I have yet to understand why. Everything else in the model is x/y wise is spot on Z is off but we already know why I am having problems there. Thank you again to you all, this is definitley becoming my favorite new hobby

I noticed that Slic3r was making under sized holes, and I changed to Cura and haven't seen the problem any more. Cura makes faster prints too and also I like the support stand better as well.

I think Slic3r has a better top finish, but is too slow for me.

Cura is very much easier to use too in my books.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 07, 2014 09:24PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Thanks once again Reg these tips are very useful. In regard to M5 rods i like to add that i noticed that INOX threaded rods are usually pretty good. And the galvanised ones are very bad, the thread is not as smooth as the INOX (it feels rough in your fingers) and a wobble is already visual as well (at least in my local hardware store..)

Impressive prints BTW

Here is another print for you to look at'

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 08, 2014 12:49AM |

Registered: 9 years ago Posts: 178 |

I tried Cura and got 1 good print out of it, I really like the simplicity of the interface but for some reason It seems I need to calibrate the z-offset almost every print, and since the 1st print with cura I cannot get it to actually lay anything down on the bed, its always just a smidge too high for some reason and nothing sticks. I'll figure it out someday. On another note I did get my little 16x2 LCD up and running today so there's that  Always improving

Always improving

Always improving

Always improving

Sorry, only registered users may post in this forum.