Greg's SmartRap Build

Posted by zackary

|

Greg's SmartRap Build June 21, 2014 02:21PM |

Registered: 9 years ago Posts: 20 |

Hi Everyone,

Great forum and really sound advice - much of it is a little over my head though.

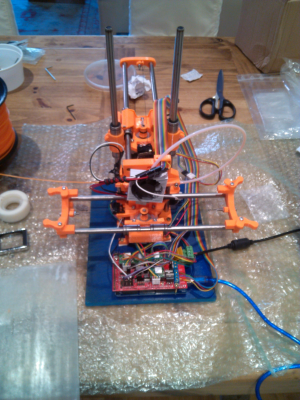

As you can imagine I'm new to the 3D printing world and bought a kit from Smartfriendz that I hope you can see in the attached photo.

It's the 0.47 model with the fishing wire with Repetier host software.

After several weeks and lots of reading as well as confusing the temperature resistor for the heating block I got it built and all wired up and it seemed to move in the right directions under manual control.

However the extruder motor does not move ;-(

I tried a print in my excitement and now have filamente stuck in the bowden tube and during the pint just a little melted out of the hot end (Huxley hot end comes with the kit).... doh!!!

I also managed to overheat the PLA plastic support for the hot end that is now bent ... I could almost cry...

When it tried to print I was suprised to see the hot end dragging through the dried film of wood glue and water that I had applied to the glass (the night before) but this could be because I bent the PLA support rod when it all overheated. I had followed the instructions with the G29, M555 Z (offset) and M500 at the end of Serge¡s build instructions.

Thinking about this now the offset might have been wrong.

As checks I have tried connecting the extruder motor to the Z axis pins on the Arduino and it moved!! So I think the motor is OK.

I then tried the Z motor on the Extruder motor pins and no movement.

So I think the Arduino is not working right.

So my questions are:

1. Are there any other tests to perform or do I have to buy a new Arduino (expensive)?

2. Do I need to buy a new RAMPS board as well (I hope not)?

3. How do I get the PLA out of the hot end and bowden tube or can I just leave it till the next print and the temperature will free it all up?

4. Should I replace the hot-end PLA support (now bent) before attempting to print again?

5. Does anyone have any settings for extrusion, fan temperature and hot end temperature that I could try?

Many thanks in advance for any help you may be able to offer.

Greg

Edited 3 time(s). Last edit at 06/21/2014 02:35PM by zackary.

Great forum and really sound advice - much of it is a little over my head though.

As you can imagine I'm new to the 3D printing world and bought a kit from Smartfriendz that I hope you can see in the attached photo.

It's the 0.47 model with the fishing wire with Repetier host software.

After several weeks and lots of reading as well as confusing the temperature resistor for the heating block I got it built and all wired up and it seemed to move in the right directions under manual control.

However the extruder motor does not move ;-(

I tried a print in my excitement and now have filamente stuck in the bowden tube and during the pint just a little melted out of the hot end (Huxley hot end comes with the kit).... doh!!!

I also managed to overheat the PLA plastic support for the hot end that is now bent ... I could almost cry...

When it tried to print I was suprised to see the hot end dragging through the dried film of wood glue and water that I had applied to the glass (the night before) but this could be because I bent the PLA support rod when it all overheated. I had followed the instructions with the G29, M555 Z (offset) and M500 at the end of Serge¡s build instructions.

Thinking about this now the offset might have been wrong.

As checks I have tried connecting the extruder motor to the Z axis pins on the Arduino and it moved!! So I think the motor is OK.

I then tried the Z motor on the Extruder motor pins and no movement.

So I think the Arduino is not working right.

So my questions are:

1. Are there any other tests to perform or do I have to buy a new Arduino (expensive)?

2. Do I need to buy a new RAMPS board as well (I hope not)?

3. How do I get the PLA out of the hot end and bowden tube or can I just leave it till the next print and the temperature will free it all up?

4. Should I replace the hot-end PLA support (now bent) before attempting to print again?

5. Does anyone have any settings for extrusion, fan temperature and hot end temperature that I could try?

Many thanks in advance for any help you may be able to offer.

Greg

Edited 3 time(s). Last edit at 06/21/2014 02:35PM by zackary.

|

Re: Greg's SmartRap Build June 21, 2014 02:48PM |

Registered: 10 years ago Posts: 814 |

|

Re: Greg's SmartRap Build June 21, 2014 02:51PM |

Registered: 10 years ago Posts: 814 |

Z Offset

Lower the nozzle till it just touches the glass. Raise it .1 or until a piece of paper just slides under it.

Set Z to 0 using M555 Z0

Lower the Z axis testing the Z Endstop after each step for triggered using M119

After it triggers use M114 to get the location of the Z axis

Set the Z offset with M555 Zx where x was the number listed for Z with the M114 command

i.e. M555 Z15.5

Use M500 to store the value on the EEPROM.

Since there is some movement with the Z axis on the Smartrap, I have to adjust it every now and again. I usually take the starting Z offset and adjust it up or down .1 at a time using the M555 Zx command till it lays down a nice looking layer. Then use M500 to save it. To skip from doing the whole process again.

Edit: Oops, just noticed you were Servoless... I edited it, so hopefully it works. Some one who uses the Servoless version might be able to tell you an easier way.

Edited 1 time(s). Last edit at 06/21/2014 03:45PM by madmike8.

Lower the nozzle till it just touches the glass. Raise it .1 or until a piece of paper just slides under it.

Set Z to 0 using M555 Z0

Lower the Z axis testing the Z Endstop after each step for triggered using M119

After it triggers use M114 to get the location of the Z axis

Set the Z offset with M555 Zx where x was the number listed for Z with the M114 command

i.e. M555 Z15.5

Use M500 to store the value on the EEPROM.

Since there is some movement with the Z axis on the Smartrap, I have to adjust it every now and again. I usually take the starting Z offset and adjust it up or down .1 at a time using the M555 Zx command till it lays down a nice looking layer. Then use M500 to save it. To skip from doing the whole process again.

Edit: Oops, just noticed you were Servoless... I edited it, so hopefully it works. Some one who uses the Servoless version might be able to tell you an easier way.

Edited 1 time(s). Last edit at 06/21/2014 03:45PM by madmike8.

|

Re: Greg's SmartRap Build June 21, 2014 02:58PM |

Registered: 10 years ago Posts: 814 |

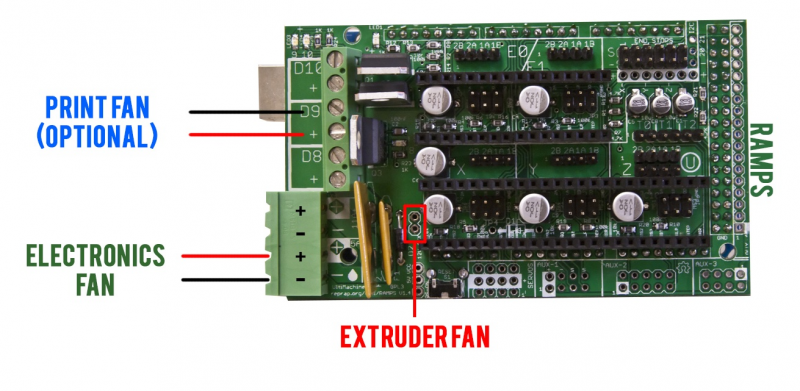

Your fan on the huxley hotend should be running full blast all the time. Connect it to the aux 12v pins on the ramps.

Can you use washers to shim the hotend back level?

The next time you heat the hotend to 185 to 200. Try retracting the extruder manually and see if it comes out.

When I built my Smartrap I used the Slic3r config from the Smartrap Github. It worked pretty much perfect. Then I tweaked the settings to learn what they do, but other than slowing it down a bit to make the extruder work without skipping that's all I did.

Edited 1 time(s). Last edit at 06/21/2014 03:01PM by madmike8.

Can you use washers to shim the hotend back level?

The next time you heat the hotend to 185 to 200. Try retracting the extruder manually and see if it comes out.

When I built my Smartrap I used the Slic3r config from the Smartrap Github. It worked pretty much perfect. Then I tweaked the settings to learn what they do, but other than slowing it down a bit to make the extruder work without skipping that's all I did.

Edited 1 time(s). Last edit at 06/21/2014 03:01PM by madmike8.

|

Re: Greg's SmartRap Build June 21, 2014 04:29PM |

Registered: 10 years ago Posts: 46 |

The filament in the tube will probably work just fine when you get the heat up again. It normally stays in the tube between prints. I have some reels that work better in the 210 degree range, so I tend to start around 200 and print a few test objects to find out what each reel needs.

A blown RAMPS or Arduino is much less likely than the (inexpensive) driver board. Did the extruder motor move in the beginning, or have you gotten the filament stuck by pushing it with your hand instead? If it never moved, you might try turning the power potentiometer (although you would normally still have some kind of skipping movement if that were the problem).

If you heat up the extruder without a fan running again, the PLA will become soft once more, and you can then turn on the fan and turn the heat off, and hold the heatsink it the upright position while it cools down. Afterwards, with a bit of luck you can just tighten the screws and make a new holder as one of your first succesful prints. Been there, done that. :-)

If you want to be on the safe side, use the connector suggested by madmike8. Mine is currently stationed in the living room, so having the fan turn off in the end is a nice feature.

I use the optional print fan connector for mine, and have modified my start G codes to begin with "M106 ; FAN ON", and the end codes to end with this BEFORE the final M84:

M106 ; FAN ON (keep on while cooling the hotend)

M109 S30 ; Wait for hotend to reach 30 degrees (5-10 degrees above ambient temperature in this part of the world)

M107 ; FAN OFF

M104 S0 ; turn hotend off

This keeps the fan running from before heating until the temperature is down to a level where PLA isn't soft anymore.

A blown RAMPS or Arduino is much less likely than the (inexpensive) driver board. Did the extruder motor move in the beginning, or have you gotten the filament stuck by pushing it with your hand instead? If it never moved, you might try turning the power potentiometer (although you would normally still have some kind of skipping movement if that were the problem).

If you heat up the extruder without a fan running again, the PLA will become soft once more, and you can then turn on the fan and turn the heat off, and hold the heatsink it the upright position while it cools down. Afterwards, with a bit of luck you can just tighten the screws and make a new holder as one of your first succesful prints. Been there, done that. :-)

If you want to be on the safe side, use the connector suggested by madmike8. Mine is currently stationed in the living room, so having the fan turn off in the end is a nice feature.

I use the optional print fan connector for mine, and have modified my start G codes to begin with "M106 ; FAN ON", and the end codes to end with this BEFORE the final M84:

M106 ; FAN ON (keep on while cooling the hotend)

M109 S30 ; Wait for hotend to reach 30 degrees (5-10 degrees above ambient temperature in this part of the world)

M107 ; FAN OFF

M104 S0 ; turn hotend off

This keeps the fan running from before heating until the temperature is down to a level where PLA isn't soft anymore.

|

Re: Greg's SmartRap Build June 21, 2014 08:51PM |

Registered: 11 years ago Posts: 791 |

Quote

ZeAllan

I use the optional print fan connector for mine, and have modified my start G codes to begin with "M106 ; FAN ON", and the end codes to end with this BEFORE the final M84:

M106 ; FAN ON (keep on while cooling the hotend)

M109 S30 ; Wait for hotend to reach 30 degrees (5-10 degrees above ambient temperature in this part of the world)

M107 ; FAN OFF

M104 S0 ; turn hotend off

This keeps the fan running from before heating until the temperature is down to a level where PLA isn't soft anymore.

That is a good idea too for anyone that has a printer going while sleeping (like me often)

I end up getting up in the middle of the night to turn off the printer because the fan is going all the time otherwise.

Using this method would allow me to stay in bed as everything would be turned off to just idle and not drawing much current, and the fan would not be going (and wearing out)

Even us "old hands" can learn something, thanks.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Greg's SmartRap Build June 22, 2014 09:59PM |

Registered: 10 years ago Posts: 349 |

Reg,

When I have my ATX board ready you can send a complete Power OFF to the PSU.

Greg, cute little printer!

Just keep at it one step at a time, the educative part is what really makes it worth it.

I see most questions are already answered, though here are my answers.

1. Are there any other tests to perform or do I have to buy a new Arduino (expensive)?

RAMPSTestCode.pde

RAMPS Wiki for more info

2. Do I need to buy a new RAMPS board as well (I hope not)?

As long as you keep the + and - of the power suply the right way around RAMPS will probably be OK. Maybe a diode might die.. though thats an easy fix (Vertees had that issue i beleive)

3. How do I get the PLA out of the hot end and bowden tube or can I just leave it till the next print and the temperature will free it all up?

It's best to leave it in, if you don't have PLA in and the hotend heats up then the Hotend might get clogged due to PLA glazing in the hotend.

And it would be a lot of hassle if you take it out every day.

4. Should I replace the hot-end PLA support (now bent) before attempting to print again?

I also had that happening to me

I replaced it with a 10x10 U profile, wood will also be fine, i just happened to have that alu laying around

And please share how you fixed it, we might learn something from you. :-)

5. Does anyone have any settings for extrusion, fan temperature and hot end temperature that I could try?

Start at a low speed, 15mm/sec

You need to find the 'sticky zone'

Right now i print at 203Celcius, i'd say stay between 200 and 210...

Connect the fan to 12v directly so that it is always on (like madmike pointed out)

Layer height 0.2 worked best for me. (i had lots of issues though at .2mm i still managed to print a few reasonable prints)

Keep in mind that i'm also a beginner, ...bugs may live in my advise.

When I have my ATX board ready you can send a complete Power OFF to the PSU.

Greg, cute little printer!

Just keep at it one step at a time, the educative part is what really makes it worth it.

I see most questions are already answered, though here are my answers.

1. Are there any other tests to perform or do I have to buy a new Arduino (expensive)?

RAMPSTestCode.pde

RAMPS Wiki for more info

2. Do I need to buy a new RAMPS board as well (I hope not)?

As long as you keep the + and - of the power suply the right way around RAMPS will probably be OK. Maybe a diode might die.. though thats an easy fix (Vertees had that issue i beleive)

3. How do I get the PLA out of the hot end and bowden tube or can I just leave it till the next print and the temperature will free it all up?

It's best to leave it in, if you don't have PLA in and the hotend heats up then the Hotend might get clogged due to PLA glazing in the hotend.

And it would be a lot of hassle if you take it out every day.

4. Should I replace the hot-end PLA support (now bent) before attempting to print again?

I also had that happening to me

I replaced it with a 10x10 U profile, wood will also be fine, i just happened to have that alu laying around

And please share how you fixed it, we might learn something from you. :-)

5. Does anyone have any settings for extrusion, fan temperature and hot end temperature that I could try?

Start at a low speed, 15mm/sec

You need to find the 'sticky zone'

Right now i print at 203Celcius, i'd say stay between 200 and 210...

Connect the fan to 12v directly so that it is always on (like madmike pointed out)

Layer height 0.2 worked best for me. (i had lots of issues though at .2mm i still managed to print a few reasonable prints)

Keep in mind that i'm also a beginner, ...bugs may live in my advise.

|

Re: Greg's SmartRap Build June 23, 2014 08:03AM |

Registered: 11 years ago Posts: 791 |

The pin for power off is next to the 5v pin which is close to the reset button on RAMPS. There are three pins there, vcc the inner pin, 5v the middle pin and the outer pin is for power control.

It puts the ATX power supply into standby mode which is off but still connected to the mains.

Edited 1 time(s). Last edit at 06/23/2014 08:05AM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

It puts the ATX power supply into standby mode which is off but still connected to the mains.

Edited 1 time(s). Last edit at 06/23/2014 08:05AM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Greg's SmartRap Build June 24, 2014 06:30PM |

Registered: 9 years ago Posts: 20 |

Hey Guys,

awsome responses thank you very very much!! Particulary Madmike8, ZeAllen, BackEMF and RegPye for not making me feel like an idiot!!

thank you...

i thought I was going to look at this on Sunday but then some things from work rose up that we have not got on top of till today.

So I had an hour or two to play and found out where the stepper motor drivers are and what they do!!

In the kit the RAMPS, Arduino and drivers are all connected for you...effectively one unit.

Here's the embarrasing part... When I went to switch the extruder driver With a working axis driver, as described by Madmike, I could see that it had

Not been mounted on the board right and one side of the legs were hanging out the socket.

Whipped it off and after a little closing of the legs, I now have a working extruder.... Yipeee!!!!!!

Less expensive than I thought but I guess the kit pampered me too much...

I really like the alluminium bar fix by BackEMF nice and profesional however that takes time and I need to see my toy print something... Anything !!!!

So heated the bar a few times and tried to bend the plastic a little straighter... I can hear you cringing...

Tried the cube again starting the fan manually and noticed that the G code overrides the manual settings so I aborted.

However when I kill the job the hotend carries on getting hotter.. So in a moment of panic I pulled the plug..

I either need to re-wire the fan or try the G-code fix be ZeAllen... I think the code might be a quicker fix and. i think I can see where to put it in Repetier host....

Off to bed now and more as soon as I get another break....

Many thanks again guys

greg

Edited 1 time(s). Last edit at 06/24/2014 06:39PM by zackary.

awsome responses thank you very very much!! Particulary Madmike8, ZeAllen, BackEMF and RegPye for not making me feel like an idiot!!

thank you...

i thought I was going to look at this on Sunday but then some things from work rose up that we have not got on top of till today.

So I had an hour or two to play and found out where the stepper motor drivers are and what they do!!

In the kit the RAMPS, Arduino and drivers are all connected for you...effectively one unit.

Here's the embarrasing part... When I went to switch the extruder driver With a working axis driver, as described by Madmike, I could see that it had

Not been mounted on the board right and one side of the legs were hanging out the socket.

Whipped it off and after a little closing of the legs, I now have a working extruder.... Yipeee!!!!!!

Less expensive than I thought but I guess the kit pampered me too much...

I really like the alluminium bar fix by BackEMF nice and profesional however that takes time and I need to see my toy print something... Anything !!!!

So heated the bar a few times and tried to bend the plastic a little straighter... I can hear you cringing...

Tried the cube again starting the fan manually and noticed that the G code overrides the manual settings so I aborted.

However when I kill the job the hotend carries on getting hotter.. So in a moment of panic I pulled the plug..

I either need to re-wire the fan or try the G-code fix be ZeAllen... I think the code might be a quicker fix and. i think I can see where to put it in Repetier host....

Off to bed now and more as soon as I get another break....

Many thanks again guys

greg

Edited 1 time(s). Last edit at 06/24/2014 06:39PM by zackary.

|

Re: Greg's SmartRap Build June 24, 2014 06:36PM |

Registered: 10 years ago Posts: 814 |

|

Re: Greg's SmartRap Build July 13, 2014 03:26PM |

Registered: 9 years ago Posts: 20 |

Hey Guys,

Finally got a break from painting the house and work his weekend to play with my SmartRap - it's the fishing line servo-less version.

I discovered my overheating issue was due to a virus ridden windows PC (main problem was the anti-virus) and have moved over to my son's MAC and Repetier does not hang when heating up preparing for print jobs now(!) - I want to try an old linux PC as that would make good use of old hw if it can handle Repetier!!.

I still have the bent Huxley support bar but it's triggering the z stop so I've been trying to print a new one as a priority.

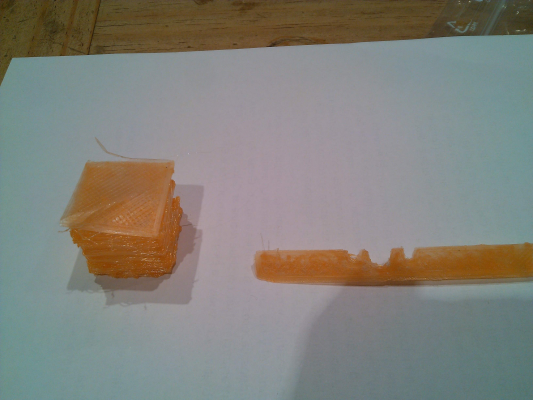

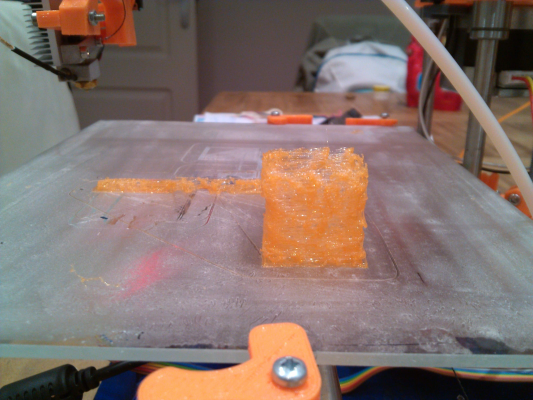

FOTO of bent bar here

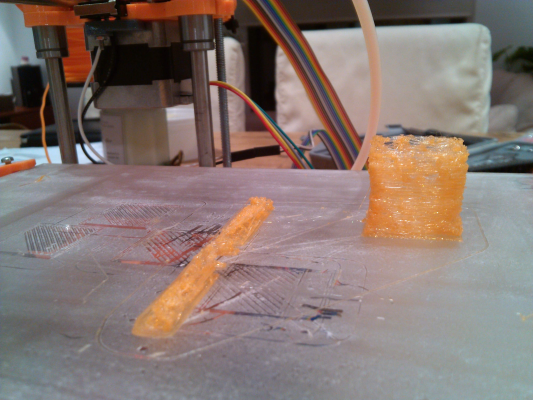

The first layer seems to go down well

FOTO 1st layer

but the infill and all other layers are a mess.

FOTO of mess

I've been trying to follow the following setup guide by Serge (my comments in brackets):

Do a home X and Y by clicking on the respective home button for each axis. ( I also do a Z home here - to get z to 0).

Enter a command in the command line . For now, we will test if it does what it should :

G29 (enter)

Now it should up a little, go to first point (20,20) go down until the head touches the bed and activate the Z-stop. It will do three points this way and stop at the third point, head on the glass ! At this point, you can manually move the head up with +Z button. To win time, you can go 1mm , then going by 0.1mm steps until the head is right on top of the glass , counting how much you travelled - normally, repeater host will show the right value for Z , as we started right after a z-stop that reset the Z value. (I've found that Z stop does NOT reset Z home to 0 or I'm doing this but wrong)

This value will be used to tell the Smartrap how height you want the head from the last probe point. To do this you will enter another command :

M555 Z(your value) . The log should tell that you just set a new value for the offset.

Now we need to keep this value after we turned off the power . We will save it to the card with a general command to save all values :

M500.

That’s it. Setup is finished.

I'm using the settings that Serge put up on GitHub with the Repetier ini file that others have had success with.

I was watching the 3rd print of the Huxley support bar and the hot end is scraping the print bed and several layers are printed with the Z stop triggered - not good I think - this I am sure is my poor set up of the Z off-set. and nothing to do with the printer

I put in the value that Repeier shows as Serge stated but I'm sure it's not right.

Madmike8 kindly offered the following alternative set up process re-hacked from the servo version (my comments in brackets):

Z Offset

Lower the nozzle till it just touches the glass. Raise it .1 or until a piece of paper just slides under it. (Assume this is at x,y origin).

Set Z to 0 using M555 Z0

Lower the Z axis testing the Z Endstop after each step for triggered using M119 (not sure I understand "after each step for triggered" - checked M119 is Get Endstop Status)

After it triggers use M114 to get the location of the Z axis (M114 is Get Current Position)

Set the Z offset with M555 Zx where x was the number listed for Z with the M114 command (assume I need to probe the bed at 3 points and take the largest z offset value of the 3 values? - can I also use G29 here?)

i.e. M555 Z15.5 (understood)

Use M500 to store the value on the EEPROM. (understood)

Any pointers as to what I am doing wrong would be greatly appreciated? Thanks in advance!

Edited 1 time(s). Last edit at 07/13/2014 03:28PM by zackary.

Finally got a break from painting the house and work his weekend to play with my SmartRap - it's the fishing line servo-less version.

I discovered my overheating issue was due to a virus ridden windows PC (main problem was the anti-virus) and have moved over to my son's MAC and Repetier does not hang when heating up preparing for print jobs now(!) - I want to try an old linux PC as that would make good use of old hw if it can handle Repetier!!.

I still have the bent Huxley support bar but it's triggering the z stop so I've been trying to print a new one as a priority.

FOTO of bent bar here

The first layer seems to go down well

FOTO 1st layer

but the infill and all other layers are a mess.

FOTO of mess

I've been trying to follow the following setup guide by Serge (my comments in brackets):

Do a home X and Y by clicking on the respective home button for each axis. ( I also do a Z home here - to get z to 0).

Enter a command in the command line . For now, we will test if it does what it should :

G29 (enter)

Now it should up a little, go to first point (20,20) go down until the head touches the bed and activate the Z-stop. It will do three points this way and stop at the third point, head on the glass ! At this point, you can manually move the head up with +Z button. To win time, you can go 1mm , then going by 0.1mm steps until the head is right on top of the glass , counting how much you travelled - normally, repeater host will show the right value for Z , as we started right after a z-stop that reset the Z value. (I've found that Z stop does NOT reset Z home to 0 or I'm doing this but wrong)

This value will be used to tell the Smartrap how height you want the head from the last probe point. To do this you will enter another command :

M555 Z(your value) . The log should tell that you just set a new value for the offset.

Now we need to keep this value after we turned off the power . We will save it to the card with a general command to save all values :

M500.

That’s it. Setup is finished.

I'm using the settings that Serge put up on GitHub with the Repetier ini file that others have had success with.

I was watching the 3rd print of the Huxley support bar and the hot end is scraping the print bed and several layers are printed with the Z stop triggered - not good I think - this I am sure is my poor set up of the Z off-set. and nothing to do with the printer

I put in the value that Repeier shows as Serge stated but I'm sure it's not right.

Madmike8 kindly offered the following alternative set up process re-hacked from the servo version (my comments in brackets):

Z Offset

Lower the nozzle till it just touches the glass. Raise it .1 or until a piece of paper just slides under it. (Assume this is at x,y origin).

Set Z to 0 using M555 Z0

Lower the Z axis testing the Z Endstop after each step for triggered using M119 (not sure I understand "after each step for triggered" - checked M119 is Get Endstop Status)

After it triggers use M114 to get the location of the Z axis (M114 is Get Current Position)

Set the Z offset with M555 Zx where x was the number listed for Z with the M114 command (assume I need to probe the bed at 3 points and take the largest z offset value of the 3 values? - can I also use G29 here?)

i.e. M555 Z15.5 (understood)

Use M500 to store the value on the EEPROM. (understood)

Any pointers as to what I am doing wrong would be greatly appreciated? Thanks in advance!

Edited 1 time(s). Last edit at 07/13/2014 03:28PM by zackary.

|

Re: Greg's SmartRap Build July 13, 2014 06:18PM |

Registered: 10 years ago Posts: 46 |

If I read your pictures correctly, the first layer is too low. I usually set my Slic3r to use a thick first layer (.4mm) and very low speed for the first layer too, to give it a better chance at gripping the bed. Then I can also verify the thickness while the skirt around the first layer is laid down, and stop the print or adjust the height manually depending on whether the whole skirt is too low or high, or if it is not evenly distributed across the bed, indicating that the auto levelling has failed.

Apart from that, my impressions are that you are probably extruding too little filament, and perhaps you have Z-wobble.

Try measuring your filament diameter and compare it to your slicer setting. Also, verify that your extruder is working correctly (is the movement smooth, or does the motor miss a step or the filament slip on the drive wheel?) and that the steps per unit for the extruder is correct -- use a ruler to see how much filament gets pulled in when you tell it to extrude, say, 10cm (after heating up, of course). If it is off, you can either correct it in firmware or use M92 Exxx in your Gcode to compensate. Let us know if you need assistance in calculating (you need to know the existing steps/unit - multiply by the amount you told it to extrude, and divide by what was actualy extruded).

As for the Z wobble, tell the printer to go up, say 50mm, and note if the hotend is moving straight up or moving in zig-zags. If it is not moving straight up, and you have the the flat two-part coupling and a motor with a flat side on the shaft, you might be able to turn the shaft so that the coupling is sitting on the "round edges" instead of one side on the flat motor side.

Then again, some of the problem might well be the hanging head, since it lokks to be extruding a bit sideways. You could try heating the Huxley bar up and straightening it by hand...

Apart from that, my impressions are that you are probably extruding too little filament, and perhaps you have Z-wobble.

Try measuring your filament diameter and compare it to your slicer setting. Also, verify that your extruder is working correctly (is the movement smooth, or does the motor miss a step or the filament slip on the drive wheel?) and that the steps per unit for the extruder is correct -- use a ruler to see how much filament gets pulled in when you tell it to extrude, say, 10cm (after heating up, of course). If it is off, you can either correct it in firmware or use M92 Exxx in your Gcode to compensate. Let us know if you need assistance in calculating (you need to know the existing steps/unit - multiply by the amount you told it to extrude, and divide by what was actualy extruded).

As for the Z wobble, tell the printer to go up, say 50mm, and note if the hotend is moving straight up or moving in zig-zags. If it is not moving straight up, and you have the the flat two-part coupling and a motor with a flat side on the shaft, you might be able to turn the shaft so that the coupling is sitting on the "round edges" instead of one side on the flat motor side.

Then again, some of the problem might well be the hanging head, since it lokks to be extruding a bit sideways. You could try heating the Huxley bar up and straightening it by hand...

|

Re: Greg's SmartRap Build July 14, 2014 02:54AM |

Registered: 10 years ago Posts: 992 |

Hi Zackary,

From what i see and read, there are two separate problems : the auto leveling process ( that would be great to see a video of starting print? ) . and the extruder / head not extruding enough filament. I can see on your object that it does the print . The bad look is really mostly the extruder problem ( when it will work you will be amazed by the difference) .

I suggest you to try this for the extruder :

- heat the head manually ( with the fan on, as we have this weak point with the huxley attach actually) . Ckick motor off and try to push the filament by hand. It should be a little hard but very possible to see the filament getting out. if not , you will need to get all out ( bowden cable from extruder, separate head and place it on the glass so you can heat it ). the best is to be able to try the filament directly in the heated head , without bowden cable : there it should be very easy to get filament out of the head. If not : try to get out the little ptfe tube inside the nozzle to clean it.

If that part is ok. Try to pass filament in the bowden alone, it should not force . If it does, it can be the brass ends blocking the filament. Then you can try to drill a little with 2mm drill. Another way is to replace the brass ends with M4 nuts . You will find the assembly on reprap.org smartrap_mini doc ( just updated with last version). We are now using all with m4 nuts because we had problems with those brass ends blocking the filament.

When all that is done, you can re assemble all and try again the filament by hand. It should now be more easy to push.

Try to extrude manually from repeater. ( 200 degrees, 200 mm/s extrude). try 5 mm then 20 or 30 . The extruder shouldn't force. You can also verify that the filament gets out continuously. If not , you must check the bearing on the extruder to see if it turns always. If not, you can use some tape on it to force the filament . You will need maybe to re-print the extruder part . IT can happen that the bearing is too far from the gear .

That's all i do when i have a bad extrude here. Usually, we find the problem .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

From what i see and read, there are two separate problems : the auto leveling process ( that would be great to see a video of starting print? ) . and the extruder / head not extruding enough filament. I can see on your object that it does the print . The bad look is really mostly the extruder problem ( when it will work you will be amazed by the difference) .

I suggest you to try this for the extruder :

- heat the head manually ( with the fan on, as we have this weak point with the huxley attach actually) . Ckick motor off and try to push the filament by hand. It should be a little hard but very possible to see the filament getting out. if not , you will need to get all out ( bowden cable from extruder, separate head and place it on the glass so you can heat it ). the best is to be able to try the filament directly in the heated head , without bowden cable : there it should be very easy to get filament out of the head. If not : try to get out the little ptfe tube inside the nozzle to clean it.

If that part is ok. Try to pass filament in the bowden alone, it should not force . If it does, it can be the brass ends blocking the filament. Then you can try to drill a little with 2mm drill. Another way is to replace the brass ends with M4 nuts . You will find the assembly on reprap.org smartrap_mini doc ( just updated with last version). We are now using all with m4 nuts because we had problems with those brass ends blocking the filament.

When all that is done, you can re assemble all and try again the filament by hand. It should now be more easy to push.

Try to extrude manually from repeater. ( 200 degrees, 200 mm/s extrude). try 5 mm then 20 or 30 . The extruder shouldn't force. You can also verify that the filament gets out continuously. If not , you must check the bearing on the extruder to see if it turns always. If not, you can use some tape on it to force the filament . You will need maybe to re-print the extruder part . IT can happen that the bearing is too far from the gear .

That's all i do when i have a bad extrude here. Usually, we find the problem .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Greg's SmartRap Build July 15, 2014 02:50AM |

Registered: 9 years ago Posts: 20 |

|

Re: Greg's SmartRap Build July 17, 2014 05:57PM |

Registered: 10 years ago Posts: 992 |

I hope it will work for you ?

About the bended huxley head support, it's THE black point of the smartrap actually.. working hard on it to make it better. For waiting, you can maybe try the hair dryer method . All structure is in PLA and a hair dryer applied to it around one minute long..or less, make it soft ! ( it's a little scary by the way !). I repaired a lot of not so good parts like that . You certainly can make your support straight again this way . Again, it's not a good solution, but it works ..for me

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

About the bended huxley head support, it's THE black point of the smartrap actually.. working hard on it to make it better. For waiting, you can maybe try the hair dryer method . All structure is in PLA and a hair dryer applied to it around one minute long..or less, make it soft ! ( it's a little scary by the way !). I repaired a lot of not so good parts like that . You certainly can make your support straight again this way . Again, it's not a good solution, but it works ..for me

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Greg's SmartRap Build July 17, 2014 06:28PM |

Registered: 9 years ago Posts: 20 |

|

Re: Greg's SmartRap Build July 20, 2014 01:39PM |

Registered: 9 years ago Posts: 20 |

Hi Guys - quick update on progress here:

The hairdryer trick worked a treat with the PLA - it was like playing with hot plasticine !! Laid it flat and gently pushed it down - looks perfect now.

Tried out the bowden tube - whilst not perfectly smooth it didn't seem too bad .... so I drilled out the brass fittings a bit just in case.

It only appears hard getting the filament past the brass fittings the first time, once it's past the brass fittings it feels fine... to the non-experienced builder!

Had to disconnect the Huxley head that appears to be blocked still - as I push filament through just a thin hair width of melted plastic comes out.

Looking out smartrap's printing in videos the plastic laid down appears to be a lot thicker.

Pulled out lots of PLA ,the PTFE tube (that was clean) but it still appears to be very thin the PLA coming out.

Measured pins, paperclips etc to push through the Huxley head from the other side, but they were all too thick at 0.75 mm - I understand the hole is 0.5mm

Will try and get to a hardware shop this week for something thinner to poke through.

As always many thanks for the pointers so far ....

The hairdryer trick worked a treat with the PLA - it was like playing with hot plasticine !! Laid it flat and gently pushed it down - looks perfect now.

Tried out the bowden tube - whilst not perfectly smooth it didn't seem too bad .... so I drilled out the brass fittings a bit just in case.

It only appears hard getting the filament past the brass fittings the first time, once it's past the brass fittings it feels fine... to the non-experienced builder!

Had to disconnect the Huxley head that appears to be blocked still - as I push filament through just a thin hair width of melted plastic comes out.

Looking out smartrap's printing in videos the plastic laid down appears to be a lot thicker.

Pulled out lots of PLA ,the PTFE tube (that was clean) but it still appears to be very thin the PLA coming out.

Measured pins, paperclips etc to push through the Huxley head from the other side, but they were all too thick at 0.75 mm - I understand the hole is 0.5mm

Will try and get to a hardware shop this week for something thinner to poke through.

As always many thanks for the pointers so far ....

|

Re: Greg's SmartRap Build July 20, 2014 06:38PM |

Registered: 9 years ago Posts: 5 |

Hi Greg,

I find that the best solution for fixing a blocked nozzle is to use a blowtorch. This seems to be the most common fix for this problem and I've seen Reg posting this before.

Poking the nozzle with a thin sharp object might damage it.

Unscrew the nozzle from the hotend (when cold), remove the PTFE liner, hold the nozzle with a pair of plyers and use the blowtorch for a few seconds.

Be careful not to overheat the nozzle, it should not start glowing. Dip it in water and you should have a very clean nozzle.

Do this outside and don't breathe the fumes! Fire and health hazard.

It's very important that you remember to remove the PTFE. When subjected to high temperatures it will release toxic fumes like HF and a lot of other nasty stuff (although in small quantaties...) See: [www.ewg.org]

Good luck!

I find that the best solution for fixing a blocked nozzle is to use a blowtorch. This seems to be the most common fix for this problem and I've seen Reg posting this before.

Poking the nozzle with a thin sharp object might damage it.

Unscrew the nozzle from the hotend (when cold), remove the PTFE liner, hold the nozzle with a pair of plyers and use the blowtorch for a few seconds.

Be careful not to overheat the nozzle, it should not start glowing. Dip it in water and you should have a very clean nozzle.

Do this outside and don't breathe the fumes! Fire and health hazard.

It's very important that you remember to remove the PTFE. When subjected to high temperatures it will release toxic fumes like HF and a lot of other nasty stuff (although in small quantaties...) See: [www.ewg.org]

Good luck!

|

Re: Greg's SmartRap Build July 20, 2014 06:49PM |

Registered: 9 years ago Posts: 20 |

|

Re: Greg's SmartRap Build July 22, 2014 09:00AM |

Registered: 11 years ago Posts: 791 |

Quote

Sogeking

Hi Greg,

I find that the best solution for fixing a blocked nozzle is to use a blowtorch. This seems to be the most common fix for this problem and I've seen Reg posting this before.

Poking the nozzle with a thin sharp object might damage it.

Unscrew the nozzle from the hotend (when cold), remove the PTFE liner, hold the nozzle with a pair of plyers and use the blowtorch for a few seconds.

Be careful not to overheat the nozzle, it should not start glowing. Dip it in water and you should have a very clean nozzle.

Do this outside and don't breathe the fumes! Fire and health hazard.

It's very important that you remember to remove the PTFE. When subjected to high temperatures it will release toxic fumes like HF and a lot of other nasty stuff (although in small quantaties...) See: [www.ewg.org]

Good luck!

The easiest way to clean the nozzle out is to heat it in a gas flame and let the PLA burn out. Take the nozzle off the hotend. Don't get it so hot that it turns the nozzle red.

After getting it hot for a few seconds, put it in water and the nozzle can then be checked to see if daylight can be seen through the nozzle hole.

Forget about trying to drill the hole out or using solvents to disolve the filament, burning out is the only good way to do it.

Edited 1 time(s). Last edit at 07/22/2014 09:01AM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Greg's SmartRap Build July 22, 2014 03:41PM |

Registered: 10 years ago Posts: 992 |

Happy it worked zakary,

I'm playing myself with hair dryer and PLA for not long time, but it's definitely a tool to have for anyone working with pla structures.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I'm playing myself with hair dryer and PLA for not long time, but it's definitely a tool to have for anyone working with pla structures.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Greg's SmartRap Build July 23, 2014 07:55AM |

Registered: 11 years ago Posts: 791 |

Quote

zackary

Many thanks Sogeking.... I have a camping gas stove that I may be able to use instead of a blow torch ... Not as good I,m sure but loads cheaper for me!!

Hopefully will get some time this week to try it out. Thanks again!!

Camper stove will work well - safer too for the nozzle.

Take a piece of wire about 150mm long and bend the end a little so you can hold the nozzle in the flame. You will be able to see the PLA burn out.Don't get the nozzle red hot, it may collapse quickly if you do.

Just do it is so it is nearly starting to go red, and then drop it into some cold water.

Some PLA, especially the Chinese cheap black is full of rubbish because it is mostly recycled PLA. Prints badly and leaves rubbish to collect in the nozzle.

If you find a cheap black that prints well, keep getting from that supplier, I have tried several and some are very good and some are very bad.

Edited 1 time(s). Last edit at 07/24/2014 03:38PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Greg's SmartRap Build July 24, 2014 09:44AM |

Registered: 10 years ago Posts: 349 |

|

Anonymous User

Re: Greg's SmartRap Build July 25, 2014 08:41PM |

Making a hundred hot ends is easy. Selling a hundred hot ends is a gut wrenching nightmare. I shipped a package to the Crimea area a couple months ago and now he's mad because he didn't get his package. What the am I supposed to do about a freaking war? The passion for the product fades pretty quickly when you actually have to deal with customers.

|

Re: Greg's SmartRap Build July 26, 2014 03:52AM |

Registered: 10 years ago Posts: 992 |

It's true when you enter in the real world of preparing /shipping / maintaining your product, it changes a bit the feeling.

Overall, i'm eventually quiet happy with that, even i do lots of mistales ans re-ship lot of things :-)

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

Overall, i'm eventually quiet happy with that, even i do lots of mistales ans re-ship lot of things :-)

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Greg's SmartRap Build July 26, 2014 05:30AM |

Registered: 11 years ago Posts: 791 |

Quote

smartfriendz

It's true when you enter in the real world of preparing /shipping / maintaining your product, it changes a bit the feeling.

Overall, i'm eventually quiet happy with that, even i do lots of mistales ans re-ship lot of things :-)

I guess I have been lucky so far. Had some problems getting stuff though, seems to go missing in the post.

Nearly always takes a long time from China, around 5-6 weeks is normal unless you pay through the nose and get it sent by DHL

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Greg's SmartRap Build July 26, 2014 04:51PM |

Registered: 10 years ago Posts: 349 |

Then you can imagine how hard the Chinese have worked to get their shipping and handling worked out. I think many post companies could learn something there...

China is the factory of the world, thoughas long as there are no local 'China shops' then China could become the shop of the world. I always try to source locally but what a pain that is...

Hardware stores only sell 'low tech' parts and if you go to a more specialised shop. then you need to have a company or else they won't even sell things to you. And their prices are insane.

Right now i'm looking for a local store who sells linear rods (now i have the feeling that i can hear everyone laugh). I found one who has them but only at full lenght, and they refuse to name a price or even sell them to me because i'm not a company. And i know that they are about to go out of business due to the crappy economy.

A few reasons why i like to have local sourced parts.

- direct available (no need to wait 1-6 weeks)

- the ability to see (and feel) what i buy.

- eventually it will save the planet a bit (less packaging in the bin, and less air traffic, now 80% of the Chinese airfreight is shipping the packaging materials)

On the other hand i'm wondering if the Chinese way eventually could be more eco-friendly then local sourced. I also see some advantages, it's hard to figure out actually. But the local economy also need to stay alive. In a way this is also a reason why i chose the (European) Smartrap. Sure, the parts all come from China, but i also supported the work Serge has put in it and kept a part of the French economy alive. (I hope) :-D

And to add some contradiction in the mix

- sourcing from China is better for my personal economy (although it takes ages for the goods to arrive)

- due to the recession the politicians RAISED the tax. So it became even more senseless to buy stuff locally (this makes you wonder where they've learned their economy...)

So yes, lots of respect to the ones like Serge and RegPye who actually make the effort to produce things, create, ship, support, deal with customers, etc.

Edited 1 time(s). Last edit at 07/26/2014 04:51PM by BackEMF.

China is the factory of the world, thoughas long as there are no local 'China shops' then China could become the shop of the world. I always try to source locally but what a pain that is...

Hardware stores only sell 'low tech' parts and if you go to a more specialised shop. then you need to have a company or else they won't even sell things to you. And their prices are insane.

Right now i'm looking for a local store who sells linear rods (now i have the feeling that i can hear everyone laugh). I found one who has them but only at full lenght, and they refuse to name a price or even sell them to me because i'm not a company. And i know that they are about to go out of business due to the crappy economy.

A few reasons why i like to have local sourced parts.

- direct available (no need to wait 1-6 weeks)

- the ability to see (and feel) what i buy.

- eventually it will save the planet a bit (less packaging in the bin, and less air traffic, now 80% of the Chinese airfreight is shipping the packaging materials)

On the other hand i'm wondering if the Chinese way eventually could be more eco-friendly then local sourced. I also see some advantages, it's hard to figure out actually. But the local economy also need to stay alive. In a way this is also a reason why i chose the (European) Smartrap. Sure, the parts all come from China, but i also supported the work Serge has put in it and kept a part of the French economy alive. (I hope) :-D

And to add some contradiction in the mix

- sourcing from China is better for my personal economy (although it takes ages for the goods to arrive)

- due to the recession the politicians RAISED the tax. So it became even more senseless to buy stuff locally (this makes you wonder where they've learned their economy...)

So yes, lots of respect to the ones like Serge and RegPye who actually make the effort to produce things, create, ship, support, deal with customers, etc.

Edited 1 time(s). Last edit at 07/26/2014 04:51PM by BackEMF.

|

Re: Greg's SmartRap Build July 26, 2014 09:09PM |

Registered: 11 years ago Posts: 791 |

I would have to agree with you BackEMF.

I needed a digital vernier as the one I had at the time was not good any more (dropped it)

I went to a local store to get one and the price really floored me, they wanted $85 for plus tax. I had a close look at it and it had "Made in China" label on the back,

I didn't buy it, not because it was made in China, but because of the price.

I went home and got online and found the same vernier for less than $10 with free shipping.

OK, it took about 3 weeks to get here, but I saved a bundle.

After it arrived I found it to be so good I ordered a few more just to have available.

I have given a few away to friends and I am still in front.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

I needed a digital vernier as the one I had at the time was not good any more (dropped it)

I went to a local store to get one and the price really floored me, they wanted $85 for plus tax. I had a close look at it and it had "Made in China" label on the back,

I didn't buy it, not because it was made in China, but because of the price.

I went home and got online and found the same vernier for less than $10 with free shipping.

OK, it took about 3 weeks to get here, but I saved a bundle.

After it arrived I found it to be so good I ordered a few more just to have available.

I have given a few away to friends and I am still in front.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Greg's SmartRap Build July 26, 2014 11:18PM |

Registered: 10 years ago Posts: 349 |

Also buy a tray of spare batteries.  Those calipers tend to be a bit thirsty they automatically turn on when you even think about them.

Those calipers tend to be a bit thirsty they automatically turn on when you even think about them.

I think we need a little Shenzen on every streetcorner. When i go to the local electronics store then they already double the price of a resistor when they walk to the storage box only to come back to tell me that they only have 10 on stock, please come back tomorrow, and the gas i put in the car to go back the next day doubled the price once again. They are stuck in the stoneage and the stupid politicians ain helping to get them op to date, even worse they claim more tax and make things even more expensive.

Opensource is helping the economy that's a sure thing, i see people doing better business with open source then by working for a greedy company. (and i also see opensource ripp offs)

But open source hardware could be doing a lot more for our economy if the local stores where a bit more 'Chinese', then we could source the parts more easy, and faster and the shop owner still would make money, where he now looses customers to China and the National economy will loose to China aswell.

When politicians are about to earn less money then they just raise the tax, they never fire a politician. and they never take a step back, they just squeese more out of the working class. I wonder where they where sleeping during economy class...

Those calipers tend to be a bit thirsty they automatically turn on when you even think about them.

Those calipers tend to be a bit thirsty they automatically turn on when you even think about them. I think we need a little Shenzen on every streetcorner. When i go to the local electronics store then they already double the price of a resistor when they walk to the storage box only to come back to tell me that they only have 10 on stock, please come back tomorrow, and the gas i put in the car to go back the next day doubled the price once again. They are stuck in the stoneage and the stupid politicians ain helping to get them op to date, even worse they claim more tax and make things even more expensive.

Opensource is helping the economy that's a sure thing, i see people doing better business with open source then by working for a greedy company. (and i also see opensource ripp offs)

But open source hardware could be doing a lot more for our economy if the local stores where a bit more 'Chinese', then we could source the parts more easy, and faster and the shop owner still would make money, where he now looses customers to China and the National economy will loose to China aswell.

When politicians are about to earn less money then they just raise the tax, they never fire a politician. and they never take a step back, they just squeese more out of the working class. I wonder where they where sleeping during economy class...

|

Re: Greg's SmartRap Build July 26, 2014 11:57PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Also buy a tray of spare batteries.Those calipers tend to be a bit thirsty they automatically turn on when you even think about them.

I think we need a little Shenzen on every streetcorner. When i go to the local electronics store then they already double the price of a resistor when they walk to the storage box only to come back to tell me that they only have 10 on stock, please come back tomorrow, and the gas i put in the car to go back the next day doubled the price once again. They are stuck in the stoneage and the stupid politicians ain helping to get them op to date, even worse they claim more tax and make things even more expensive.

Opensource is helping the economy that's a sure thing, i see people doing better business with open source then by working for a greedy company. (and i also see opensource ripp offs)

But open source hardware could be doing a lot more for our economy if the local stores where a bit more 'Chinese', then we could source the parts more easy, and faster and the shop owner still would make money, where he now looses customers to China and the National economy will loose to China aswell.

When politicians are about to earn less money then they just raise the tax, they never fire a politician. and they never take a step back, they just squeese more out of the working class. I wonder where they where sleeping during economy class...

You're not wrong there. Get rid of ALL politicians, we would be far better off without any of them.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Sorry, only registered users may post in this forum.