My SmartRap Core Build

Posted by phinsil6

|

My SmartRap Core Build April 11, 2015 12:35PM |

Registered: 10 years ago Posts: 24 |

Hello All,

I am gearing up for my first 3D printer build and am really excited about the building the SmartRap Core. I believe I have all of the mechanical equipment and I am in the process of printing the parts necessary to get the Core up and running.

Here is what I have so far:

-3 Nema 17s

-3 GT2 20 tooth pulleys

-5m GT2 belting

-Ramps 1.4 & Mega & A4988 drivers

-Bulldog XL Extruder

-E3D v6 1.75mm

-(6) 406mm chromed linear rail

-(10) 608zz bearings

-(12) LM8UU linear bearings

-MK2B Heated Bed w/ 3mm Boro Glass (also have new Alu MK3 that I am excited to experiment with and use; having a hard time finding SMD 100k thermistor)

-1/2" Plywood box

However in printing some parts and beginning to try to put it together I have some questions:

1. Are there any assembly instructions or videos or is this one of those figure it out as you go type of things?

2. For the motor mounts, I printed two of the openjscad "motor xy.stl" mounts and am realizing, are they supposed to be mirrored or are they universal?

3. For the Head mounts, my current 3d printer (jimmy rigged Shapeoko 2) is having a hard time printing the "teeth" part of the belt portion of the head. So my question is, is belting supposed to be able to move freely between these or is it more of a clamp?

4. Will an E3D v6 fit the extruder mounting?

5. My linear bearings seem to be QUITE loud on the rails, what kind of oiling should I use? Good ole WD-40?

6. If need be, would someone be willing to print/ship certain parts that I'm unable to for a cost?

I'm completely new to this realm and am very excited about getting started with my SmartRap Core. Although I think my wife is getting tired of hearing about it

Thank you for all the help to come!

I am gearing up for my first 3D printer build and am really excited about the building the SmartRap Core. I believe I have all of the mechanical equipment and I am in the process of printing the parts necessary to get the Core up and running.

Here is what I have so far:

-3 Nema 17s

-3 GT2 20 tooth pulleys

-5m GT2 belting

-Ramps 1.4 & Mega & A4988 drivers

-Bulldog XL Extruder

-E3D v6 1.75mm

-(6) 406mm chromed linear rail

-(10) 608zz bearings

-(12) LM8UU linear bearings

-MK2B Heated Bed w/ 3mm Boro Glass (also have new Alu MK3 that I am excited to experiment with and use; having a hard time finding SMD 100k thermistor)

-1/2" Plywood box

However in printing some parts and beginning to try to put it together I have some questions:

1. Are there any assembly instructions or videos or is this one of those figure it out as you go type of things?

2. For the motor mounts, I printed two of the openjscad "motor xy.stl" mounts and am realizing, are they supposed to be mirrored or are they universal?

3. For the Head mounts, my current 3d printer (jimmy rigged Shapeoko 2) is having a hard time printing the "teeth" part of the belt portion of the head. So my question is, is belting supposed to be able to move freely between these or is it more of a clamp?

4. Will an E3D v6 fit the extruder mounting?

5. My linear bearings seem to be QUITE loud on the rails, what kind of oiling should I use? Good ole WD-40?

6. If need be, would someone be willing to print/ship certain parts that I'm unable to for a cost?

I'm completely new to this realm and am very excited about getting started with my SmartRap Core. Although I think my wife is getting tired of hearing about it

Thank you for all the help to come!

|

Re: My SmartRap Core Build April 11, 2015 03:15PM |

Registered: 9 years ago Posts: 178 |

Welcome to the Core club

1. Yes there are some videos see this link Smartfriendz Youtube Channel

2. Yes they need to be mirrored. Your really want to generate a build plate on the youmagine link and break those parts out, if you just view individual parts and try to download the stl you wont get all the parts right. I used cura to just save each axis parts as seperate stl "plates"

3. Yes they are to act as clamps, belts should slide in from top and be held solid.

4. I believe the default head mount will fit an e3d but can't be positive as I never printed it

5. Lube you will want to use a grease, lube the bearings before installing on the rail, personally I use engine assembly lube.

6. Depending on what your after I can help you out with with printing,...I am sure others here as well, but I am having some technical difficulties ATM with my SmartCore so it will be hit or miss for me.

1. Yes there are some videos see this link Smartfriendz Youtube Channel

2. Yes they need to be mirrored. Your really want to generate a build plate on the youmagine link and break those parts out, if you just view individual parts and try to download the stl you wont get all the parts right. I used cura to just save each axis parts as seperate stl "plates"

3. Yes they are to act as clamps, belts should slide in from top and be held solid.

4. I believe the default head mount will fit an e3d but can't be positive as I never printed it

5. Lube you will want to use a grease, lube the bearings before installing on the rail, personally I use engine assembly lube.

6. Depending on what your after I can help you out with with printing,...I am sure others here as well, but I am having some technical difficulties ATM with my SmartCore so it will be hit or miss for me.

|

Re: My SmartRap Core Build April 12, 2015 10:02PM |

Registered: 9 years ago Posts: 180 |

|

Re: My SmartRap Core Build April 13, 2015 09:51AM |

Registered: 10 years ago Posts: 24 |

Quote

djinn5150

1. Yes there are some videos see this link Smartfriendz Youtube Channel

2. Yes they need to be mirrored. Your really want to generate a build plate on the youmagine link and break those parts out, if you just view individual parts and try to download the stl you wont get all the parts right. I used cura to just save each axis parts as seperate stl "plates"

3. Yes they are to act as clamps, belts should slide in from top and be held solid.

4. I believe the default head mount will fit an e3d but can't be positive as I never printed it

5. Lube you will want to use a grease, lube the bearings before installing on the rail, personally I use engine assembly lube.

6. Depending on what your after I can help you out with with printing,...I am sure others here as well, but I am having some technical difficulties ATM with my SmartCore so it will be hit or miss for me.

1. Thank you for the videos, when i searched youtube for smartrap core nothing came up for assembly. but it looks like there are quite a few so i will be reviewing and asking any questions here for anything i don't understand.

2. wish i would have known about the parts plate+blender a LONG time ago, would have saved me many hour of printing duplicates of parts i didn't need.

3. so as i understand it you would basically slide in the belt in one end of the "clamp" put the belting around all the pulley/bearings and then stretch it to get it tight and clamp on the other end

4. i guess i will have to print the mount/head and see if it'll fit.

5. so the lube would be like this Amazon

6. alright, well my main concern was the precision of the "head" piece with the belting part. i thought the belt was supposed to move freely, but if all i need to do is squeeze a belt in there, i should be able to do that. Nice to know though that the community is willing to help out

|

Re: My SmartRap Core Build April 13, 2015 10:08AM |

Registered: 9 years ago Posts: 178 |

As for the lube, should work but what I am using is Lubriplate No 105 from Napa Auto Parts, also known as white grease. You might even have a bad lm8auu, it happens. I just happened to have a 10oz tube laying around so thats what I have been using. As for the belts, yes the lower belt should start at "front left" and end at "Rear Right" Upper belt should start at "Front Right" and end at "Left Rear". As Serge shows in one of the assembly video's tension will have an effect on square so keep that in mind. I'm pretty familiar with the machine at this point so if you run into snags feel free to post them up, if you need a quicker response PM me if I don't get back to you real fast, for some reason. Notifications on threads can be a bit slow at times. Without this community I would not have never got my SmartRap printing let alone built a new machine so I am quite happy to help others out.

|

Re: My SmartRap Core Build April 13, 2015 02:12PM |

Registered: 10 years ago Posts: 24 |

I will stop by my local automotive store tonight and see what lubricants they have (O'Reilys).

Two questions on the assembly videos:

1. Is it just me or is there no sound?

2. Watching the XY Assemblies, I don't see any M3 nuts in use anywhere. are the plastic holes supposed to be M3 tapped??? I've been drilling them out and figuring that my bolts weren't fitting because of my printer's tolerance.

Two questions on the assembly videos:

1. Is it just me or is there no sound?

2. Watching the XY Assemblies, I don't see any M3 nuts in use anywhere. are the plastic holes supposed to be M3 tapped??? I've been drilling them out and figuring that my bolts weren't fitting because of my printer's tolerance.

|

Re: My SmartRap Core Build April 13, 2015 05:50PM |

Registered: 9 years ago Posts: 178 |

|

Re: My SmartRap Core Build April 13, 2015 11:41PM |

Registered: 10 years ago Posts: 24 |

Ok I am having some slight depression with trying to print these parts and assemble everything. I would like to formally ask for some help printing the x carriage mounts. my setup just can't cut the teeth as it is right now.

Such depression right now i am designing in my mind a different printer using MakerSlide with Delrin V-wheels...

Such depression right now i am designing in my mind a different printer using MakerSlide with Delrin V-wheels...

|

Re: My SmartRap Core Build April 14, 2015 12:23AM |

Registered: 9 years ago Posts: 178 |

|

Re: My SmartRap Core Build April 14, 2015 01:00AM |

Registered: 10 years ago Posts: 24 |

i'm not sure what you mean by PLA bushing?

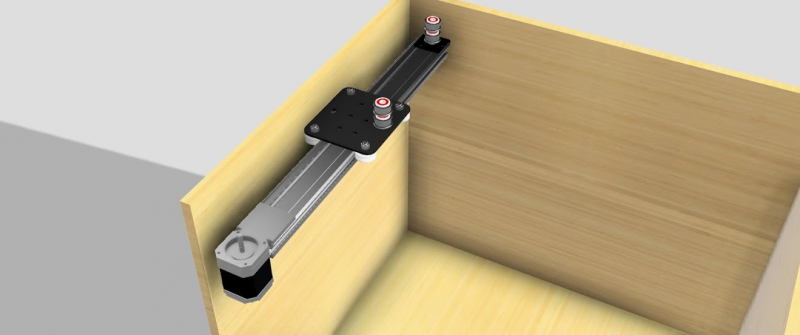

Also, this MS idea isn't as hairbrained as I thought, this is what I've dreamed up so far

Also, this MS idea isn't as hairbrained as I thought, this is what I've dreamed up so far

|

Re: My SmartRap Core Build April 14, 2015 01:19AM |

Registered: 9 years ago Posts: 178 |

|

Re: My SmartRap Core Build April 14, 2015 01:27AM |

Registered: 10 years ago Posts: 814 |

|

Re: My SmartRap Core Build April 14, 2015 02:08PM |

Registered: 10 years ago Posts: 24 |

I guess I'm still confused. Because I have the LM8UU bearings I just am having a hard time printing the "head" pieces with the belt clampsQuote

djinn5150

Bushings would go in place of the lm8uu bearings, what cad are you using?

Yeah I'm beginning to realize this actually might be a good idea...Quote

madmike8

Lol, I have so much makerslide and spindle carriages hehe... I could do that...

What do you think the drawbacks would be?

|

Re: My SmartRap Core Build April 14, 2015 03:10PM |

Registered: 9 years ago Posts: 178 |

|

Re: My SmartRap Core Build April 14, 2015 04:05PM |

Registered: 10 years ago Posts: 814 |

Quote

phinsil6

Yeah I'm beginning to realize this actually might be a good idea...Quote

madmike8

Lol, I have so much makerslide and spindle carriages hehe... I could do that...

What do you think the drawbacks would be?

hmm, I'll have to look more closely when I get home. I have a an assembled spindle plate sitting around... but I think you may have problem with belt alignments with the spindle plate being in the way. You might could flip the rail over so that it rides on bottom use longer M5 bolts through the wheels and create a plate that attaches to the longer bolts. It would allow that plate to ride closer to the MS and be able to attach your pulleys where you want them to. You would mount your motor plate and pulley to the ends. (Hopefully i explained that clearly).

maybe I can mock it up and take a pic when I get home from work.

|

Re: My SmartRap Core Build April 14, 2015 10:27PM |

Registered: 9 years ago Posts: 180 |

I found this modified extruder for the SmartRapCore in Thingiverse listed under SmartRap. I don't know if it works but looks like it will, especially with the added nut holes.

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: My SmartRap Core Build April 16, 2015 02:57PM |

Registered: 10 years ago Posts: 24 |

Just a little update:

I've got everything together now, and I'm not entirely impressed. Not the designs fault but the tolerances of some things. The X rails are loose and the whole thing does not slide square. I do not have the belts completely hooked up since I can't get the last belt into the little clamp. Maybe it would all slide more square if the belts were attached. As for the Z, I think the bearings aren't aligned or something because they do not slide well AT ALL. In fact a couple balls broke out of the linear bearing trying to slide up and down.

the more I tinker in Fusion 360 CAD with the MakerSlide option the more I am swayed to the concept. I built up a extra carriage with wheels/parts I had laying around and I put on the makerslide and was relieved of how smooth and QUIET everything was, unlike with the linear rail/linear bearings.

It seems like so far I could sum up the differences with:

Linear Rail/Linear Bearings (per SmartRap Core design)

-Much simpler and cleaner design

-more challenging mounting methods

-Tolerances are super critical

MakerSlide with Delrin V-Wheels

-slightly bulkier design and more complicated design

-easier mounting (simple bolting with standard components with attachments)

-basically no maintenance necessary with Delrin V-Wheels/bearings

-Tolerances not an issue since wheel positions are set with Eccentric Nut

Some pictures of the MakerSlide Design I have so far in CAD

I've got everything together now, and I'm not entirely impressed. Not the designs fault but the tolerances of some things. The X rails are loose and the whole thing does not slide square. I do not have the belts completely hooked up since I can't get the last belt into the little clamp. Maybe it would all slide more square if the belts were attached. As for the Z, I think the bearings aren't aligned or something because they do not slide well AT ALL. In fact a couple balls broke out of the linear bearing trying to slide up and down.

the more I tinker in Fusion 360 CAD with the MakerSlide option the more I am swayed to the concept. I built up a extra carriage with wheels/parts I had laying around and I put on the makerslide and was relieved of how smooth and QUIET everything was, unlike with the linear rail/linear bearings.

It seems like so far I could sum up the differences with:

Linear Rail/Linear Bearings (per SmartRap Core design)

-Much simpler and cleaner design

-more challenging mounting methods

-Tolerances are super critical

MakerSlide with Delrin V-Wheels

-slightly bulkier design and more complicated design

-easier mounting (simple bolting with standard components with attachments)

-basically no maintenance necessary with Delrin V-Wheels/bearings

-Tolerances not an issue since wheel positions are set with Eccentric Nut

Some pictures of the MakerSlide Design I have so far in CAD

|

Re: My SmartRap Core Build April 16, 2015 05:20PM |

Registered: 9 years ago Posts: 178 |

Sorry to hear you are having such a rough time with this build, as for square, YES the belt has everything to do with square between x/y belts must be equally tensioned. For the Z it seems I may not have been having issues with my print on my belt version after all. When I originally started to print parts the belt Z was my first print and I too had some tension issues, like maybe the carriage was a tad bit wider then the positioning of the rods, towards the middle things were "ok" at the ends it just wanted to bind. When I was about to print it again the Z leadscrew was released and I opted to go that route instead. From the pic it doesn't appear you have the x rod lock screws installed( at least that I can see) That will have an effect on the tension of the rods as well. I found they have to be installed on at least one side of the "y slide" to keep the rods in position.

Very glad to see someone else playing around in Fusion 360, the more I use it the more I am loving it. I was kicking around the idea of using extrusion for at least the x carriage myself. It will definately be a more robust design that is for sure.

Very glad to see someone else playing around in Fusion 360, the more I use it the more I am loving it. I was kicking around the idea of using extrusion for at least the x carriage myself. It will definately be a more robust design that is for sure.

|

Re: My SmartRap Core Build April 16, 2015 06:32PM |

Registered: 10 years ago Posts: 814 |

|

Re: My SmartRap Core Build April 19, 2015 08:22PM |

Registered: 9 years ago Posts: 180 |

I printed out the top Z plate that holds the 608zz bearing in place and noticed that the slot for the bearing is not centered on the piece. Anyone else notice this? Any reason why it would be off centered?

Duh, I found the answer by looking at the CAD drawing. It's off centered so that the left side of the belt lines up with the little belt holders on the printed bed support slide.

Edited 1 time(s). Last edit at 04/19/2015 08:28PM by rcjoseb.

Duh, I found the answer by looking at the CAD drawing. It's off centered so that the left side of the belt lines up with the little belt holders on the printed bed support slide.

Edited 1 time(s). Last edit at 04/19/2015 08:28PM by rcjoseb.

|

Re: My SmartRap Core Build April 20, 2015 11:41AM |

Registered: 10 years ago Posts: 24 |

I didn't even realize I needed to do that. Upon further inspection this morning I noticed the holes. I will tap them tonight and see if that helps at all. My bigger problem is attaching the belts to the x carriage. I have 3/4 pushed in but the last one got gummed up on the print, so I'm gonna have to try to remove some material somehow to fit the belt in there.Quote

djinn5150

From the pic it doesn't appear you have the x rod lock screws installed( at least that I can see) That will have an effect on the tension of the rods as well. I found they have to be installed on at least one side of the "y slide" to keep the rods in position.

I love Fusion 360. Of course the free part is fantastic and the modeling is great! But for me, the CAM functionality and simulation is the biggest factor. With my CNC mill, having one piece of software for everything is AWESOME! Simplifies the entire process.Quote

djinn5150

Very glad to see someone else playing around in Fusion 360, the more I use it the more I am loving it. I was kicking around the idea of using extrusion for at least the x carriage myself. It will definately be a more robust design that is for sure.

Why do you think the belts wouldn't work? I was thinking they'd be easy because you could just add spacers/washers to the Idler/Bolt combo to get the heights right.Quote

madmike8

So, do you think the belts will work with the way you have your makerslide configured?

I didn't notice mine off center, but the bearing was too tight in mine though, and the belt wouldn't fit through between the plastic and the bearing. I ended up drilling out the slot quite a bit to get it all to fit.Quote

rcjoseb

I printed out the top Z plate that holds the 608zz bearing in place and noticed that the slot for the bearing is not centered on the piece. Anyone else notice this? Any reason why it would be off centered?

Sorry, only registered users may post in this forum.