|

Introducing the Slot Bot! February 07, 2015 05:00PM |

Registered: 10 years ago Posts: 105 |

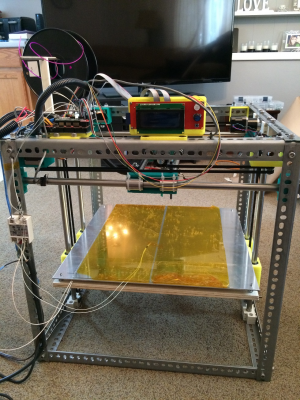

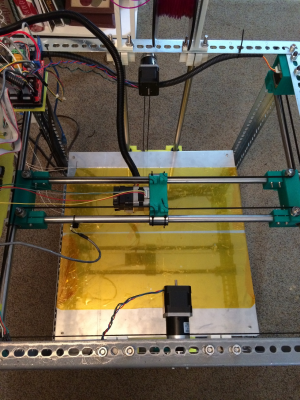

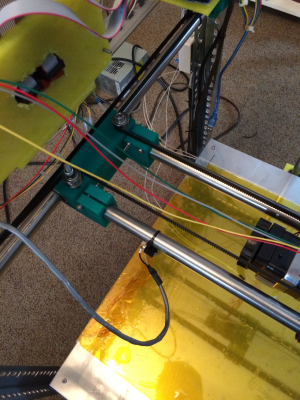

I'm ready to introduce a new project of mine. I call it the Slot Bot since the frame is made from slotted angle (2' lengths) that can be purchased at the local hardware store. I'm using lm16uus on 5/8" rod with no problem. I may try to design a 10-12mm version in the future since 5/8" or 16mm rods are a little overkill. The build volume is large at 550 mm x 550 mm x 320 mm! My main goals were to use a standardized frame and a belt driven z-axis. Two geared motors (27:1 ratio) are used for the z-axis. The build plate doesn't drop with the motors unpowered. I also designed my own build plate that's powered from 120VAC and a solid state relay. This saves needing an extra power supply and it only draws ~2A. I'm still getting the extruder configured, but should have first test print soon and then I'll post the files on thingiverse. Here are some pics:

|

Re: Introducing the Slot Bot! February 08, 2015 03:24PM |

Registered: 10 years ago Posts: 77 |

Nice job. I like the use of angle and the mains voltage heatbed. You can also get corner gussets that will bolt in that would stiffen things up if needed.

It looks like the Z axis geared steppers will limit your carriage travel. I realize the carriage is below the Z steppers but you may need to limit your carriage travel to avoid your extruder or filament in-feed from clashing with them - particularly with the shaft sticking out the non-geared end. Is it possible to turn the Z stepper axis thru 90° so that it runs along under the angle?

My Prusa Mendel i2 inspired Repstrap with welded steel frame: [youtu.be]

And my Smartrap derived Briefcase 3D printer: [youtu.be]

It looks like the Z axis geared steppers will limit your carriage travel. I realize the carriage is below the Z steppers but you may need to limit your carriage travel to avoid your extruder or filament in-feed from clashing with them - particularly with the shaft sticking out the non-geared end. Is it possible to turn the Z stepper axis thru 90° so that it runs along under the angle?

My Prusa Mendel i2 inspired Repstrap with welded steel frame: [youtu.be]

And my Smartrap derived Briefcase 3D printer: [youtu.be]

|

Re: Introducing the Slot Bot! February 08, 2015 03:49PM |

Registered: 10 years ago Posts: 105 |

Hi n.glasson, thanks for the compliment! That's a good point, I had played around with turning it 90. The benefit of the current away is eliminating a couple printed brackets with it bolted to the frame. My carriage right now will clear the z-axis motors but I didn't think about the filament. I had the idea that I could get away with using one Z-axis motor in the 90 degree orientation you mentioned. I'm still working through the pulley configuration for it, which would be similar to Richrap's Slid3r design.

Edited 1 time(s). Last edit at 02/08/2015 03:50PM by runninfarmer.

Edited 1 time(s). Last edit at 02/08/2015 03:50PM by runninfarmer.

|

Re: Introducing the Slot Bot! March 04, 2015 12:18AM |

Registered: 10 years ago Posts: 105 |

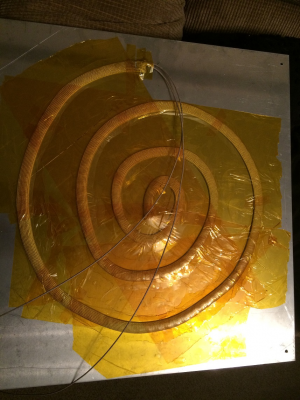

Installed hotend finally and got it printing. Here's a video of the first print: [www.youtube.com]

Here's a pic of the cube:

Here's a pic of the cube:

|

Re: Introducing the Slot Bot! March 04, 2015 07:34AM |

Registered: 9 years ago Posts: 1,011 |

Congratulations for your build, I like the way you engineered the Z axis. I have a couple of questions. What printing speed do you reach ? What are the microstepping settings for the Z axis and what is its step for mm value ? Steel is well known to transmit vibrations. Do you noticed vibrations issues during repetitive quick back and forth motion ?

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Introducing the Slot Bot! March 04, 2015 10:02AM |

Registered: 10 years ago Posts: 105 |

Thanks! I printed the cube a little too fast. I think it was 45-50 mm/s. It did shake the bed a little bit, but it's so heavy that the frame itself didn't move. I need to do some more tests at 30mm/s. I also think my acceleration is too low since I'm getting bowed in sides on the cube. I'm using 1/16th stepping and my steps/mm for Z-axis is 2148, which is close to 8mm threaded rod.

|

Re: Introducing the Slot Bot! March 04, 2015 03:47PM |

Registered: 9 years ago Posts: 1,011 |

Thank you for your awnser. That 2148 value seems strange to me. If you have 20 tooth pulleys souldn't it be 2160 ? Maybe it's not a GT2 pulley and the pitch is different ? For the microstepping, you could even use a 1/2 setting without precision issues on the Z axis.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Introducing the Slot Bot! March 04, 2015 05:12PM |

Registered: 10 years ago Posts: 105 |

I used the actual reduction ratio of 26.85 for the calculation, not 27. Sorry I rounded numbers in the first post,  . Good point with the 1/2 setting. With 1/2 setting will my A4988 driver run cooler? I'm not sure how to set 1/2 stepping for just the z-axis and have 1/16th for X and Y since in repetier configuration it's:

. Good point with the 1/2 setting. With 1/2 setting will my A4988 driver run cooler? I'm not sure how to set 1/2 stepping for just the z-axis and have 1/16th for X and Y since in repetier configuration it's:

/** \brief Micro stepping rate of X, Y and Y tower stepper drivers */

#define MICRO_STEPS 16

Edited 2 time(s). Last edit at 03/04/2015 05:21PM by runninfarmer.

. Good point with the 1/2 setting. With 1/2 setting will my A4988 driver run cooler? I'm not sure how to set 1/2 stepping for just the z-axis and have 1/16th for X and Y since in repetier configuration it's:

. Good point with the 1/2 setting. With 1/2 setting will my A4988 driver run cooler? I'm not sure how to set 1/2 stepping for just the z-axis and have 1/16th for X and Y since in repetier configuration it's:/** \brief Micro stepping rate of X, Y and Y tower stepper drivers */

#define MICRO_STEPS 16

Edited 2 time(s). Last edit at 03/04/2015 05:21PM by runninfarmer.

|

Re: Introducing the Slot Bot! March 05, 2015 09:04AM |

Registered: 9 years ago Posts: 1,011 |

You should give a try while reducing microstepping. You should get less heat from the driver and the motors. Maybe there will be more operating noise, but the Z increments not that often. You'll get more holding torque too, but I don't think you need it with gearboxes.

To change, you'll need to arange jumpers under the pololu you need to set :

Jumpers (-none, x in)

1 2 3

- - - 1/1 (no microstepping)

x - - 1/2

x - x 1/4 pas

x x - 1/8 pas

x x x 1/16 pas

Of course you won't forget to calculate new steps per millimeter for that axis.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

To change, you'll need to arange jumpers under the pololu you need to set :

Jumpers (-none, x in)

1 2 3

- - - 1/1 (no microstepping)

x - - 1/2

x - x 1/4 pas

x x - 1/8 pas

x x x 1/16 pas

Of course you won't forget to calculate new steps per millimeter for that axis.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Sorry, only registered users may post in this forum.