Coffeetable CoreXY:: new build :: small apartment rep-strap solutions

Posted by realthor

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 10:00AM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

I don't get it. You guys will use 3D printed parts for the most inappropriate things, but when it comes to something as simple as the square plugs to fit the tubing, all of a sudden you need machined metal? How about just measuring the tube and 3D printing a solid piece to fit? Tap it in with a rubber mallet then drill your holes and bolt the whole thing together.

For that matter, a piece of wood should work fine, too.

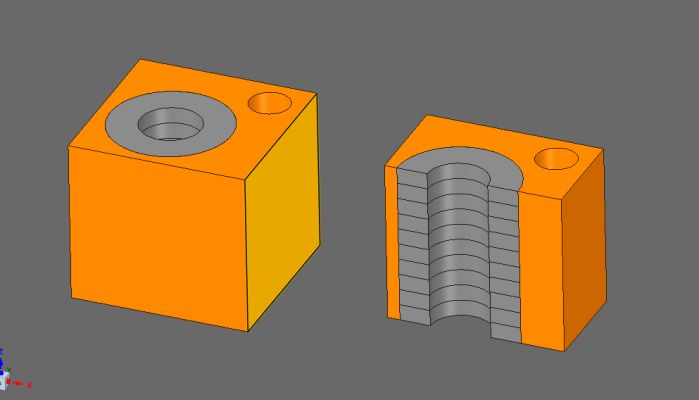

The above are square plugs, with a twist (hex coupler+washers included). Wood would work for me too, I just want to avoid the ALU crushing @lkcl is talking about. Will a completely 3D printed plug take the crushing resulted from fastening the ALU tubes together? I am planning to use of course locknuts and M5 bolt (if only one) or M4 bolts if two per connection (I'd rather use two to be frank).

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 11:56AM |

Registered: 11 years ago Posts: 1,049 |

Print a block leaving hex hole to insert hex nut -- no tapping

Cut square stock with hacksaw drill with hand drill tap with hand tap (aluminum soft -easy to tap)

?? short section of tubing (conduit, metal or PVC) cut and filed down in square tube ??

?? threaded insert in block of wood ??

Not going to get 0.1 tolerance with a hand drill, hacksaw and stuff from the Dollar General

I guess the Dollar general doesn't have a tap and die set

You see the original coffee table welded frame solved all these problems

instead of spending 100s of hours diddling with junk.

this is realthor -- find weird ways to spend 1000s hours designing Rube Goldberg solutions to simple projects

Perhaps a bamboo frame with joints wrapped with ratan ( if wrapped wet, it shrinks very tight) ?

But

John Harrison (1693– 1776) was a self-educated English carpenter and clockmaker (without a machine shop) who invented the marine chronometer, a long-sought after device for solving the problem of calculating longitude while at sea.

financial rewards of up to £20,000 (equivalent to £2.84 million today) under the 1714 Longitude Act.

BTW a scout tower depends on diagonal bracing to stand!!!

Cut square stock with hacksaw drill with hand drill tap with hand tap (aluminum soft -easy to tap)

?? short section of tubing (conduit, metal or PVC) cut and filed down in square tube ??

?? threaded insert in block of wood ??

Not going to get 0.1 tolerance with a hand drill, hacksaw and stuff from the Dollar General

I guess the Dollar general doesn't have a tap and die set

You see the original coffee table welded frame solved all these problems

instead of spending 100s of hours diddling with junk.

this is realthor -- find weird ways to spend 1000s hours designing Rube Goldberg solutions to simple projects

Perhaps a bamboo frame with joints wrapped with ratan ( if wrapped wet, it shrinks very tight) ?

But

John Harrison (1693– 1776) was a self-educated English carpenter and clockmaker (without a machine shop) who invented the marine chronometer, a long-sought after device for solving the problem of calculating longitude while at sea.

financial rewards of up to £20,000 (equivalent to £2.84 million today) under the 1714 Longitude Act.

BTW a scout tower depends on diagonal bracing to stand!!!

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 12:22PM |

Registered: 9 years ago Posts: 1,035 |

haha... pretty much nailed it. I don't see anything wrong with that though. I am not in desperate need for a 3D printer. If I needed that I would have built some already existing open source variation.

Just a note: I choose to spend 100s of hours on these projects, they are not a consequence of me failing to follow in the footsteps of others .

.

Edited 1 time(s). Last edit at 04/23/2016 12:24PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Just a note: I choose to spend 100s of hours on these projects, they are not a consequence of me failing to follow in the footsteps of others

.

.Edited 1 time(s). Last edit at 04/23/2016 12:24PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 01:15PM |

Registered: 8 years ago Posts: 776 |

Quote

cozmicray

Print a block leaving hex hole to insert hex nut -- no tapping

not strong enough. it'll crush and crack as and when pressure is exerted on it from the outside as the bolts are tightened.

Quote

Not going to get 0.1 tolerance with a hand drill, hacksaw and stuff from the Dollar General

yehh but the cuts are not going to be in the critical dimension. if you get an aluminium bar of OD 16x16 off-the-shelf and matching OD 20x20 with ID 16x16 square-section, chances are they'll be accurately made and fit one inside the other, which is exactly what's needed here. the hacksaw need only cut off at least 40mm length +/- 2 or 3mm.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 04:15PM |

Registered: 9 years ago Posts: 1,035 |

If I understand correctly you are suggesting an aluminum bar (I suppose flat if you are specifying 16x16, square actually by those dimensions). Is such a thing you have at your HW store? I don't remember seeing such thing but will double check.

On the other hand I have just noticed that an M10 Nut is 16mm between flats ... so a printed part with an M10 Nut space ....interesting.

Edited 1 time(s). Last edit at 04/23/2016 04:16PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

On the other hand I have just noticed that an M10 Nut is 16mm between flats ... so a printed part with an M10 Nut space ....interesting.

Edited 1 time(s). Last edit at 04/23/2016 04:16PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 07:50PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

If I understand correctly you are suggesting an aluminum bar (I suppose flat if you are specifying 16x16, square actually by those dimensions). Is such a thing you have at your HW store? I don't remember seeing such thing but will double check.

whatever ID square-section aluminium tube you pick, it needs to match whatever square OD bar you can also easily get [at the same store]. otherwise as cozmicray says you're looking at machining a block to tolerances that are beyond what can be achieved with a hacksaw.

it's your design, and you set the parameters (to use aluminium hollow square-section from hardware stores).

don't use [pure] steel for the inside spacer: when in direct contact, steel and aluminium react, and the aluminium oxidises within about 18 months - it basically crumbles and turns to dust. people who make and maintain aluminium body cars find this out when things start to drop off the car...

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 07:55PM |

Registered: 11 years ago Posts: 1,049 |

If your going to tighten the bolts that much

may have to use titanium, inconel

Will you be using NASCAR 3000psi air gun to tighten?

I challenge you to crush a well printed block with a bolt and a standard allen wrench

may have to use titanium, inconel

Will you be using NASCAR 3000psi air gun to tighten?

I challenge you to crush a well printed block with a bolt and a standard allen wrench

Quote

lkcl

not strong enough. it'll crush and crack as and when pressure is exerted on it from the outside as the bolts are tightened.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 08:29PM |

Registered: 8 years ago Posts: 776 |

Quote

cozmicray

If your going to tighten the bolts that much

may have to use titanium, inconel

Will you be using NASCAR 3000psi air gun to tighten?

pair of pliers, man, come on! didn't you work out by now that i'm a cowboy engineer??

Quote

I challenge you to crush a well printed block with a bolt and a standard allen wrench

i do it all the time by accidentally overtightening both M3 and M5 bolts, and i've definitely managed to "dent" heavily-filled large blocks - enough to know that relying on the "well printed" bit of that sentence is probably nooot a good idea. even the mendel90 that nophead sold me, after 2 years of use the carriage on that was beginning to crack where the hotend went in, i'd had to take it off and on so many times to fix jamming.

also, i know from experience that PLA, when left in sunlight, tends to approach its glass point and gets soft. relying on such a material as PLA for any kind of structural load-bearing integrity... yeah i just don't feel it's a good idea.

Edited 1 time(s). Last edit at 04/23/2016 08:30PM by lkcl.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 23, 2016 11:52PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

don't use [pure] steel for the inside spacer: when in direct contact, steel and aluminium react, and the aluminium oxidises within about 18 months - it basically crumbles and turns to dust. people who make and maintain aluminium body cars find this out when things start to drop off the car...

Aren't bolts and washers Steel too? I don't suppose you're connecting extrusions together using anything else than steel. T-nuts,etc ...?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 02:33AM |

Registered: 8 years ago Posts: 776 |

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 02:39AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Quote

lkcl

don't use [pure] steel for the inside spacer: when in direct contact, steel and aluminium react, and the aluminium oxidises within about 18 months - it basically crumbles and turns to dust. people who make and maintain aluminium body cars find this out when things start to drop off the car...

Aren't bolts and washers Steel too? I don't suppose you're connecting extrusions together using anything else than steel. T-nuts,etc ...?

*sigh* i know.... i think it's why the aluminium is anodised, but honestly i've not really looked into this, whether it's plain steel, stainless steel. it was something i heard..... about... 12 years ago, i met someone who was restoring an aston martin DB5 (from scratch), he mentioned it to me that the DB5 uses leather to keep steel parts away from the aluminium chassis. i think, in my mind, i sort-of went, "hmm, how long am i going to be running this printer, this is anodised aluminium, is it going to matter.... mmm...." and i came up with a decision of "no".

that doesn't mean it won't be a problem... but like all these things, i thought you might appreciate knowing so that you can also make an informed decision... as opposed to blindly "copying whatever else everyone is doing" and then wondering later why the printer literally falls apart or doesn't work.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 06:33AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

that doesn't mean it won't be a problem... but like all these things, i thought you might appreciate knowing so that you can also make an informed decision... as opposed to blindly "copying whatever else everyone is doing" and then wondering later why the printer literally falls apart or doesn't work.

My "problem" is that I don't like to follow up in anyone else's steps. Besides choosing the stacked bearings for the corexy idlers that I've had inspiration in Smartrapcore (and some others as well), there is not much in this printer that is copied. But It's my believe that we can barely invent anything new that wasn't invented already. My "scout-tower-like" frame has actually been done before in 3D printers (Quadrap) and I've found about it a few weeks ago.

Thanks for pointing that out, I have actually read a bit on it on different papers on web. Interesting. Some say stainless doesn't affect aluminum. But it would be expensive. Others have put threadlockers (loctite) so it creates a buffer between the two metals. Will study it further but as you say, how long will I be running this printer....

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 07:19AM |

Registered: 11 years ago Posts: 5,780 |

I don't know about steel/aluminum interactions, but when I built my CF bicycle I used aluminum drop-outs for the wheels and isolated the aluminum from the CF using a single layer of glass cloth between them. Plastic washers will isolate steel from aluminum easily enough, if you're worried about it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 08:04AM |

Registered: 9 years ago Posts: 1,035 |

How hard should a bolt be fastened to connect two square alu tubes together? Why does @lkcl say that over-tightening is quite easily achievable to the point that alu will be irreversibly crushed? We should fasten to a point before that. That way we can easily use plastic plugs, as @the_digital_dentist suggests and I can even embed steel in that plug and this way the steel is not in contact with aluminum.

Moreover, if I use plastic washers, wouldn't the force needed to securely connect the two tubes together crush the plastic washer too? I must admit, this is an issue I couldn't have imagined

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Moreover, if I use plastic washers, wouldn't the force needed to securely connect the two tubes together crush the plastic washer too? I must admit, this is an issue I couldn't have imagined

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 12:06PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

How hard should a bolt be fastened to connect two square alu tubes together?

really, you should be testing it, by buying two bars in the next day or so and trying it out. get two bars, drill holes 10mm front the ends, bolt them together in parallel then prise them apart with your hands. if they bend or they separate even by a couple of millimetres with a mild amount of force, you know you've got a problem that needs to be fixed before proceeding further.

the suggestions i've made are so that you can be absolutely absolutely sure that you can lock the bolts down hard, and guarantee that nothing will move *and* at the same time not be irreversibly damaged by doing so.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 12:14PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

Quote

realthor

How hard should a bolt be fastened to connect two square alu tubes together?

really, you should be testing it, by buying two bars in the next day or so and trying it out. get two bars, drill holes 10mm front the ends, bolt them together in parallel then prise them apart with your hands. if they bend or they separate even by a couple of millimetres with a mild amount of force, you know you've got a problem that needs to be fixed before proceeding further.

the suggestions i've made are so that you can be absolutely absolutely sure that you can lock the bolts down hard, and guarantee that nothing will move *and* at the same time not be irreversibly damaged by doing so.

Considering that 3 tubes will be connected with at least 3 (maybe 6) bolts ... does it really matter that two such tubes can be forced into rotating against each other? I know I can test but I am looking at establishing a minimum amount of fastening force for the actual situation not a theoretical limit that can be achieved if one forces the tubes beyond their working parameters. I mean no offence of course, if anyone it's at fault here it's probably me

.

.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 12:19PM |

Registered: 9 years ago Posts: 1,035 |

Interesting find? :-/

80/20 Inc: Ready Tube Overview : [youtu.be]

Also here: [8020.net]

Edited 1 time(s). Last edit at 04/24/2016 12:20PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

80/20 Inc: Ready Tube Overview : [youtu.be]

Also here: [8020.net]

Edited 1 time(s). Last edit at 04/24/2016 12:20PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 03:39PM |

Registered: 9 years ago Posts: 1,035 |

I was wondering ... two metals react by corroding if there is enough humidity to act as an electrolyte. If the tubes are plugged at the ends and one uses some sort of hard plastic washers for the bolts, which then acts as a gasket to prevent moisture to leak inside the tube should there be any the problem should be diminished greatly right? We might be overthinking this.

I am settling on 10 M6 washers (by standard it's 1.6mm thick) makes exactly 16mm .... with some kapton tape or some other thin tape on the contacting surfaces between washers and aluminum should work as a low-cost solution. I have this in mind for the two-bolts connection:

These are the washers: [www.fastenal.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am settling on 10 M6 washers (by standard it's 1.6mm thick) makes exactly 16mm .... with some kapton tape or some other thin tape on the contacting surfaces between washers and aluminum should work as a low-cost solution. I have this in mind for the two-bolts connection:

These are the washers: [www.fastenal.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 04:26PM |

Registered: 11 years ago Posts: 1,049 |

Most washers are zinc or cadmium plated

Perhaps if your printer will be used on your ocean going yatch

or

on the back of a salt spreading truck

Don't think you have to worry for the life of your printer

The only thing I see here is who is the

better manure spreader

(mechanical design excellence) ikcl

or

(I don't like to follow up in anyone else's steps) un-realthor

Perhaps if your printer will be used on your ocean going yatch

or

on the back of a salt spreading truck

Don't think you have to worry for the life of your printer

The only thing I see here is who is the

better manure spreader

(mechanical design excellence) ikcl

or

(I don't like to follow up in anyone else's steps) un-realthor

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 04:33PM |

Registered: 9 years ago Posts: 1,035 |

Playing smart by pointing over and over again things that no one asked is not that cool either  ...

...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

...

...RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 24, 2016 06:12PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 25, 2016 05:52PM |

Registered: 9 years ago Posts: 1,035 |

Moved the columns according to the above sketch.

Also sketched the frame with connectors like in the previous post (10 washers stack).

Modified the motor mounts quite a bit in the process.

I believe I am pretty close to something I can start building... I need to find some time though.

Latest version @ [sketchfab.com]

Edited 4 time(s). Last edit at 04/25/2016 06:00PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 25, 2016 11:15PM |

Registered: 11 years ago Posts: 1,049 |

IMHO

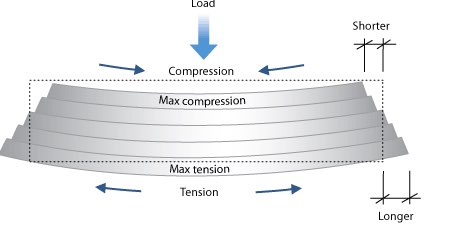

Your washer block puts the non-washer hole (drilled thru both sides of tube)

very close to edge of aluminum stock

the worst place to remove metal, weakening the tension/compression web.

FWIW

Fastenal says

Base metal

Aluminum & Aluminum Alloys

Fastener

Zinc & Galvanized Steel

Result

The corrosion of the base metal is not increased by the fastener.

[www.fastenal.com]

Your washer block puts the non-washer hole (drilled thru both sides of tube)

very close to edge of aluminum stock

the worst place to remove metal, weakening the tension/compression web.

FWIW

Fastenal says

Base metal

Aluminum & Aluminum Alloys

Fastener

Zinc & Galvanized Steel

Result

The corrosion of the base metal is not increased by the fastener.

[www.fastenal.com]

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 26, 2016 03:58AM |

Registered: 9 years ago Posts: 1,035 |

Quote

cozmicray

IMHO

Your washer block puts the non-washer hole (drilled thru both sides of tube)

very close to edge of aluminum stock

the worst place to remove metal, weakening the tension/compression web.

Hmmm, I thought that having the hole close to the tube wall would actually benefit from the increased compression that can be absorbed by the vertical wall. But that is a logic of an untrained/inexperienced guy. In any case, I believe that for this particular application the hole near the tube wall won't affect the structural integrity because the forces will not stress much the frame.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 26, 2016 01:22PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Considering that 3 tubes will be connected with at least 3 (maybe 6) bolts ... does it really matter that two such tubes can be forced into rotating against each other? I know I can test but I am looking at establishing a minimum amount of fastening force for the actual situation not a theoretical limit that can be achieved if one forces the tubes beyond their working parameters. I mean no offence of course, if anyone it's at fault here it's probably me

nono, i'm working it through in my head just as much as you are. i just grabbed 3 bits of extrusion i have here and bashed them together. having done that, i think that my concerns about rotation are only valid if the square-section is distorted in some way (due to overtightening and crushing for example).

one thing that does occur to me though: if the drill-holes are not perfectly aligned, the bolts will be sheared as you tighten them, as they'll try to be pushed against the edges of the holes. it would be better to slightly oversize the holes, to ensure that doesn't happen.

but... really - test it.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 26, 2016 01:23PM |

Registered: 8 years ago Posts: 776 |

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 26, 2016 02:41PM |

Registered: 11 years ago Posts: 1,049 |

The vertical walls are taking the load

holes near top / bottom get easily squooshed / stretched

under highest compression / tension

removing material (hole) just weakens beam

with your desire for less than 0.01 tolerance

find a maker space or a tech school with a drill press or mill

and a full set of drills and make a clearance hole ( fastener just fits)

But tightening fastener with 36" bar or ikcl's pliers this may be moot

holes near top / bottom get easily squooshed / stretched

under highest compression / tension

removing material (hole) just weakens beam

with your desire for less than 0.01 tolerance

find a maker space or a tech school with a drill press or mill

and a full set of drills and make a clearance hole ( fastener just fits)

But tightening fastener with 36" bar or ikcl's pliers this may be moot

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 27, 2016 08:53AM |

Registered: 9 years ago Posts: 1,035 |

If the inside piece (e.g the stack of washers) is the same height as the inside of the tube, 16mm if 20x20x2mm tubes are considered, then there will be no stretching/compressing but in the very crystalline structure of the ALU top and bottom walls, those in between washers. And squishing the solid wall in between washers will take some force.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 27, 2016 11:58AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

If the inside piece (e.g the stack of washers) is the same height as the inside of the tube, 16mm if 20x20x2mm tubes are considered, then there will be no stretching/compressing but in the very crystalline structure of the ALU top and bottom walls, those in between washers. And squishing the solid wall in between washers will take some force.

i've used washers for a friction hinge on a laptop. washers are not flat, they're banged out of low-quality (random tolerance) material to be circular on one side and flat on the other. even in the same bag you get massive variations in thickness.... but not only that, if you stack a bunch together they act as springs (which is why i'm using them in a friction-hinge).

so even if you think, "hmmm, i'll get a stack 16mm high" which will take forever to do because of the massive variation, you then think, "ok i've got exactly 16.0000mm here", you put them in.... and under load when you tighten the bolt SQUASH the whole stack compresses by an entire 0.5 to 0.75mm, making it completely pointless to even have them in there.

soo you go, "okaaay that didn't work, throw that extrusion away, it's wrecked: let's jam some more in next time" and now you're banging washers in with a hammer and a screwdriver, hoping like hell that when you try to put the bolt in that you get them all lined up.... and ARGH, one mishit with the screwdriver and SPANGGGG they all fly down the tube and you have to start again.

... you're planning to do TWENTY FOUR of these experiences??

get some 16x16 alu bar!! at least if you hit that with a hammer down the end it's a solid block, you'll be fine.

get some 16x16 alu bar!! at least if you hit that with a hammer down the end it's a solid block, you'll be fine.p.s. i like hitting things with a hammer, especially when it doesn't matter and you can still get good results.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions April 27, 2016 12:45PM |

Registered: 9 years ago Posts: 1,035 |

Lol, that's a very plausible scenario. It's just that the availability of

the square solid stock is quite limited around here. I haven't seen it

anywhere in a hardware store.

I'll see what I can get my hands on.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

the square solid stock is quite limited around here. I haven't seen it

anywhere in a hardware store.

I'll see what I can get my hands on.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.