Would a hybrid Horizontal-Vertical XCarriage bring any advantage?

Posted by realthor

|

Would a hybrid Horizontal-Vertical XCarriage bring any advantage? June 08, 2016 06:11AM |

Registered: 9 years ago Posts: 1,035 |

Hello guys,

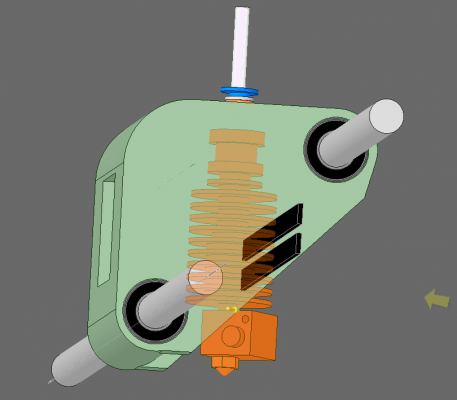

I have been toying with both Vertical XCarriage and Horizontal XCarriage arrangements and each has its own set of advantages but never both sets in one go. I want my nozzle to be in between XRods and also at the center/middle of the YCarriage and again at the center of the YRods too, to minimize nozzle shifting due to play in bearings, flex in rods, etc.

So I am thinking of a horizontal-vertical hybrid XCarriage where one rod is closest to the YRods and the other one remains up just like with the Vertical arrangement.

I like that the hotend is not enclosed so much in plastic as with my horizontal XCarriage and it's easier to cool the coldend. It also uses the same real estate as either the horizontal or vertical ones would.

It seems like this approach can easier receive a direct extruder (for the horizontal I wouldn't mount a stepper ontop of the thing as it would be too high and would introduce too gig moments while accelerating or decelerating).

Edited 2 time(s). Last edit at 06/08/2016 07:16AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I have been toying with both Vertical XCarriage and Horizontal XCarriage arrangements and each has its own set of advantages but never both sets in one go. I want my nozzle to be in between XRods and also at the center/middle of the YCarriage and again at the center of the YRods too, to minimize nozzle shifting due to play in bearings, flex in rods, etc.

So I am thinking of a horizontal-vertical hybrid XCarriage where one rod is closest to the YRods and the other one remains up just like with the Vertical arrangement.

I like that the hotend is not enclosed so much in plastic as with my horizontal XCarriage and it's easier to cool the coldend. It also uses the same real estate as either the horizontal or vertical ones would.

It seems like this approach can easier receive a direct extruder (for the horizontal I wouldn't mount a stepper ontop of the thing as it would be too high and would introduce too gig moments while accelerating or decelerating).

Edited 2 time(s). Last edit at 06/08/2016 07:16AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would a hybrid Horizontal-Vertical XCarriage bring any advantage? June 08, 2016 09:38AM |

Registered: 9 years ago Posts: 346 |

Quick comments:

Basically, for any design with two smooth rods you pay a toll on the print area. The distance from rod to rod plus bearing size is print area lost relative to your outer frame diameter. A bigger outer frame means more bracing and more weight all around.

The decision about mounting the two rods vertically or horizontal is then in-parts about either sacrificing Z height (vertical) or Y length (horizontal).

When you make like you do now, you are sacrificing both Y and Z length - But maybe you can do them closer together in this design? So it will be sort of a compromise between the two.

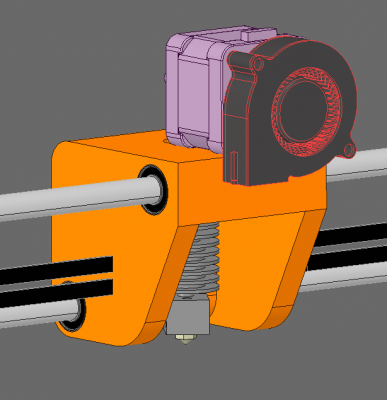

The advantage is that it will be easier to mount the hotend in a solid way. You can latch on to it both top and bottom and you get that nice "natural" position for the fan.

The belts are maybe easier to place in the center of rotation (like you sketched it now).

Actually I kinda like it. Now making a bracket for it on the Y carriages is the hard part, like it is the hard part for all vertical mounted rod designs.

Basically, for any design with two smooth rods you pay a toll on the print area. The distance from rod to rod plus bearing size is print area lost relative to your outer frame diameter. A bigger outer frame means more bracing and more weight all around.

The decision about mounting the two rods vertically or horizontal is then in-parts about either sacrificing Z height (vertical) or Y length (horizontal).

When you make like you do now, you are sacrificing both Y and Z length - But maybe you can do them closer together in this design? So it will be sort of a compromise between the two.

The advantage is that it will be easier to mount the hotend in a solid way. You can latch on to it both top and bottom and you get that nice "natural" position for the fan.

The belts are maybe easier to place in the center of rotation (like you sketched it now).

Actually I kinda like it. Now making a bracket for it on the Y carriages is the hard part, like it is the hard part for all vertical mounted rod designs.

|

Re: Would a hybrid Horizontal-Vertical XCarriage bring any advantage? June 08, 2016 09:47AM |

Registered: 9 years ago Posts: 1,035 |

I don't think you gain anything from a Vertical vs Horizontal XRods you are just shifting the printarea (to the front for vertical, and a little to he back for horizontal). The Y bearings have to be set as wide apart in both configurations so yeah... no gain. Z just the same, if you want the least effect of either configuration on the nozzle movement relative to its designated position you want it right there at the center of everything (XCarriage, YCarriage and at the very center axis of the YRods).

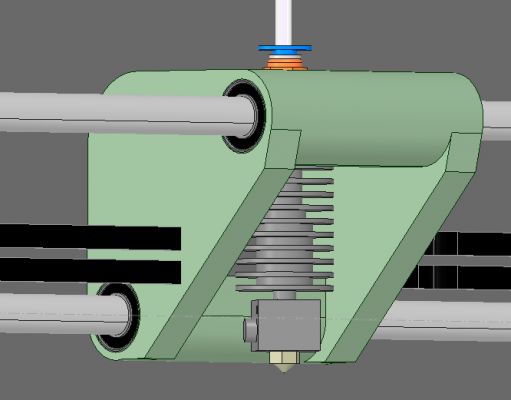

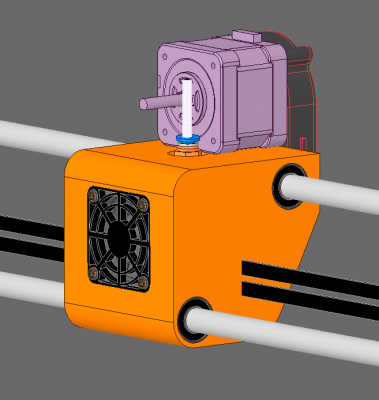

I start to like more and more this arrangement as it's quite perfect for both bowden and direct extruder. If you have the direct extruder which has the heatsink embedded in the motor mount and short heatbreak and heaterblock you can just insert the whole package in the place where I have the fan in the picture below and have a very very compact printhead. I'll come back with a design for that later. For now here's what I have:

I am yet to find a good way to funnel the air from the squirrel-cage blower for the Part cooling (tbd).

Edited 1 time(s). Last edit at 06/08/2016 09:49AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I start to like more and more this arrangement as it's quite perfect for both bowden and direct extruder. If you have the direct extruder which has the heatsink embedded in the motor mount and short heatbreak and heaterblock you can just insert the whole package in the place where I have the fan in the picture below and have a very very compact printhead. I'll come back with a design for that later. For now here's what I have:

I am yet to find a good way to funnel the air from the squirrel-cage blower for the Part cooling (tbd).

Edited 1 time(s). Last edit at 06/08/2016 09:49AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would a hybrid Horizontal-Vertical XCarriage bring any advantage? June 08, 2016 04:12PM |

Registered: 9 years ago Posts: 1,035 |

@LarsK: How would you "latch on to it" at the bottom? When I was designing the Horizontal XCarriage the only way I have found was to have 4 screws pointing and touching the hotend central column to keep it constrained. But any plastic there will most certainly creep because of heat and any metal there will obstruct air flow from the fan.

The more I think about it the more the 4 screws seem to be the logical choice....

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The more I think about it the more the 4 screws seem to be the logical choice....

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would a hybrid Horizontal-Vertical XCarriage bring any advantage? June 08, 2016 05:23PM |

Registered: 9 years ago Posts: 346 |

Just like we hold most other things.

Imagine this with a hole equal to the outer diameter of the hotend> [www.llamatech.be]

It can be anything. You just want to support it firmly so it dosent go side to side.

Also - On the same subject, in my opinion, you should enclose the hotend so you do not have any cooling air escaping down on the part being printed, but there is no consensus about the strict necessity of this. I only print ABS.

Imagine this with a hole equal to the outer diameter of the hotend> [www.llamatech.be]

It can be anything. You just want to support it firmly so it dosent go side to side.

Also - On the same subject, in my opinion, you should enclose the hotend so you do not have any cooling air escaping down on the part being printed, but there is no consensus about the strict necessity of this. I only print ABS.

|

Re: Would a hybrid Horizontal-Vertical XCarriage bring any advantage? June 09, 2016 09:04AM |

Registered: 9 years ago Posts: 1,035 |

I compared it to the Horizontal XCarriage I have previously designed and I must admit I don't like this as much... the Horizontal is way better (albeit more complicated to print and put together). I'd rather invest more time in refining that one so I'll drop this design.

Edited 1 time(s). Last edit at 06/09/2016 09:08AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 1 time(s). Last edit at 06/09/2016 09:08AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.