|

CoreXY "Arm" Variant January 17, 2017 12:34AM |

Registered: 9 years ago Posts: 127 |

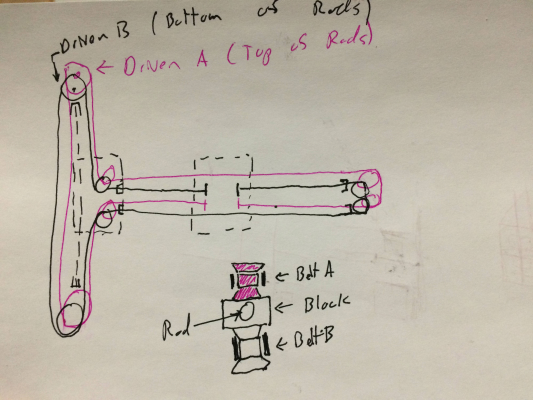

In an attempt to eliminate belt crossings, I've hit upon this variant of the CoreXY concept:

Excuse my poor attempt at a drawing.

Solid pink - top "A" belt.

Solid black - top "B" belt

Dashed lines - moving carriages

The CoreXY belts are driven by co-located steppers (the circles with a "dot" in them) at the top left.

The Y axis (vertical) belts are tensioned on either side of the Y axis smooth rod.

The X axis (horizontal) belts are tensioned centered on the X axis smooth rods.

The left cap of the X axis is mounted on the Y axis smooth rod with a UU style bearing.

The right cap of the X axis rods is 'floating' - the 4 bearings are on a carriage that rests on a smooth rod, with no UU style bearing.

The bottom cap of the Y axis contains separate tension adjustment for each belt.

Since the A and B belts are isolated in Z, there is no 'crossing' of the belts.

Since the right X cap is floating, there is no "competing load" on two UU style bearings on the Y axis rods.

Sacrifices:

* Co-located stepper mounting is a bit of bear.

* The 'floating' right side of the X axis won't exert pressure as much on minor blobs as a UU bearing, so it could lead to 'blob mountains' - I'll need to test that

* If I don't get the tension just right, this assembly will probably torque out of calibration

Has anyone seen a similar CoreXY variant? If so, what can I learn from it before I spent more time on my variant?

Excuse my poor attempt at a drawing.

Solid pink - top "A" belt.

Solid black - top "B" belt

Dashed lines - moving carriages

The CoreXY belts are driven by co-located steppers (the circles with a "dot" in them) at the top left.

The Y axis (vertical) belts are tensioned on either side of the Y axis smooth rod.

The X axis (horizontal) belts are tensioned centered on the X axis smooth rods.

The left cap of the X axis is mounted on the Y axis smooth rod with a UU style bearing.

The right cap of the X axis rods is 'floating' - the 4 bearings are on a carriage that rests on a smooth rod, with no UU style bearing.

The bottom cap of the Y axis contains separate tension adjustment for each belt.

Since the A and B belts are isolated in Z, there is no 'crossing' of the belts.

Since the right X cap is floating, there is no "competing load" on two UU style bearings on the Y axis rods.

Sacrifices:

* Co-located stepper mounting is a bit of bear.

* The 'floating' right side of the X axis won't exert pressure as much on minor blobs as a UU bearing, so it could lead to 'blob mountains' - I'll need to test that

* If I don't get the tension just right, this assembly will probably torque out of calibration

Has anyone seen a similar CoreXY variant? If so, what can I learn from it before I spent more time on my variant?

|

Re: CoreXY "Arm" Variant January 17, 2017 01:21AM |

Registered: 11 years ago Posts: 5,780 |

A regular corexy mechanism can be built with the belts on two vertical levels so they don't have to cross (at least not on the same vertical level). Leaving one end of the X axis floating in space means the extruder carriage is cantilevered out on the X axis rail. I know people do make printers with things cantilevered, but it isn't a good way to start your design if you care about print quality. What happens to that X axis rail as the extruder carriage moves out toward the far, unsupported end? It bends and sags and the extruder moves closer to the print bed.

Ignoring all that, I'm not sure your belt arrangement will result in the expected motion of the extruder carriage or translation of the X axis along the Y axis.

Edited 1 time(s). Last edit at 01/17/2017 11:13AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ignoring all that, I'm not sure your belt arrangement will result in the expected motion of the extruder carriage or translation of the X axis along the Y axis.

Edited 1 time(s). Last edit at 01/17/2017 11:13AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY "Arm" Variant January 17, 2017 02:12AM |

Registered: 7 years ago Posts: 249 |

Looks like an H-bot with the right side cut off, and the orphaned motor moved to the left side. Even more prone to racking, and without the extra support, more wobble.

The AxiDraw is similar in kenimatics. Though you most likely have parallel rods in a vertical plane, rather than horizontal.

Suggestions:

You could put a idler with bearings on the motor shaft, along with a drive pulley, if the shaft is long enough.

Though you may also want to put another bearing on the end of the shaft as support.

If the X runs were close enough, two stacked idlers on the end of the arm could work.

The AxiDraw is similar in kenimatics. Though you most likely have parallel rods in a vertical plane, rather than horizontal.

Suggestions:

You could put a idler with bearings on the motor shaft, along with a drive pulley, if the shaft is long enough.

Though you may also want to put another bearing on the end of the shaft as support.

If the X runs were close enough, two stacked idlers on the end of the arm could work.

|

Re: CoreXY "Arm" Variant January 17, 2017 08:26AM |

Registered: 9 years ago Posts: 127 |

1) the end of the X axis rests on a (not drawn) Y smooth rod. It's "floating" only in that there is no solid mechanical linkage like a UU bearing.

2) yes, in retrospect, I think there may be an issue with my belt design making the movements I want. I'll need to make a mockup.

3) Thanks for the AxiDraw reference - its giving me some ideas about how to resolve some other issues.

2) yes, in retrospect, I think there may be an issue with my belt design making the movements I want. I'll need to make a mockup.

3) Thanks for the AxiDraw reference - its giving me some ideas about how to resolve some other issues.

|

Re: CoreXY "Arm" Variant January 21, 2017 11:37AM |

Registered: 9 years ago Posts: 288 |

|

Re: CoreXY "Arm" Variant January 21, 2017 12:09PM |

Registered: 9 years ago Posts: 127 |

|

Re: CoreXY "Arm" Variant January 22, 2017 01:27AM |

Registered: 9 years ago Posts: 223 |

It's not that hard, all you have to do is to offset the motors.

Check this out.

[www.thingiverse.com]

Check this out.

[www.thingiverse.com]

|

Re: CoreXY "Arm" Variant January 22, 2017 05:48AM |

Admin Registered: 16 years ago Posts: 13,891 |

... this is another "similar" concept - [www.youtube.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: CoreXY "Arm" Variant January 22, 2017 07:42AM |

Registered: 11 years ago Posts: 5,780 |

What's the advantage of cantilevering everything that way?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY "Arm" Variant January 22, 2017 01:24PM |

Admin Registered: 16 years ago Posts: 13,891 |

... smaller footprint and both motors fixed to a single piece, so no moving/bending cables ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: CoreXY "Arm" Variant January 22, 2017 02:14PM |

Registered: 11 years ago Posts: 5,780 |

No moving/bending cables, but everything else moving and bending? In corexy both motors are fixed. The only moving, bending cable goes to the extruder, which you will have with this design, too.

If the machine is going to print over a 12" square area, its footprint is going to be a bit bigger than that with either design. In order to keep everything from flexing so badly that it screws the print quality, everything will have to be much bigger in cross section to increase its rigidity which normally translates to heavier. Moving heavier stuff usually means going slower to keep it under control so it doesn't screw the print quality. Is the slight reduction in footprint worth the probable reduction in print speed and quality?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If the machine is going to print over a 12" square area, its footprint is going to be a bit bigger than that with either design. In order to keep everything from flexing so badly that it screws the print quality, everything will have to be much bigger in cross section to increase its rigidity which normally translates to heavier. Moving heavier stuff usually means going slower to keep it under control so it doesn't screw the print quality. Is the slight reduction in footprint worth the probable reduction in print speed and quality?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY "Arm" Variant January 22, 2017 02:43PM |

Registered: 7 years ago Posts: 249 |

I like the design referenced in the youtube GRAYWOLF posted.

Access to the print bed is really good, part count is low. Belt lengths are shorter than a standard CoreXY

Z-Column adds to the foot print some, and needs a filament guide.

Looks to be good enough for 3d printing.

Edited 1 time(s). Last edit at 01/22/2017 02:44PM by prot0typ1cal.

Access to the print bed is really good, part count is low. Belt lengths are shorter than a standard CoreXY

Z-Column adds to the foot print some, and needs a filament guide.

Looks to be good enough for 3d printing.

Edited 1 time(s). Last edit at 01/22/2017 02:44PM by prot0typ1cal.

|

Re: CoreXY "Arm" Variant January 23, 2017 03:22AM |

Registered: 9 years ago Posts: 288 |

|

Re: CoreXY "Arm" Variant February 16, 2017 10:57PM |

Registered: 9 years ago Posts: 127 |

Followup:

I ended up building a single-belt version of this design, which the Google+ community named 'Core-T':

[plus.google.com]

[plus.google.com]

Works pretty well for a 'scraps' 3D printer. Quite happy with the Core-T motion (it's a 0.8mm nozzle printer, so I can get away with a lot of slop)

I ended up building a single-belt version of this design, which the Google+ community named 'Core-T':

[plus.google.com]

[plus.google.com]

Works pretty well for a 'scraps' 3D printer. Quite happy with the Core-T motion (it's a 0.8mm nozzle printer, so I can get away with a lot of slop)

|

Re: CoreXY "Arm" Variant February 17, 2017 10:08AM |

Registered: 11 years ago Posts: 5,780 |

In the first video he has the belt twisted in the very short distance between the motor and the first pulley- that is going to wear the belt out fast! The only reason he needs to twist the belts is because the pulleys are so tiny. Larger pulleys would cost only a few cents more and wouldn't require any belt twisting. Twisted belts tend to ride against the pulley flanges all the time- another belt wear factor and possible print quality defect creator.

In the second video you can see the belt to the left of the extruder carriage is twisted again in the variable length portion of the belt. That's going to be wear problem for the belt, and it will probably cause print problems like distortion because the belt tension is going to change as the extruder moves back and forth. When the extruder is moving to the left end of the rails, the motor will have to supply more torque because you're fighting the force required to twist the belt in an ever tighter twist.

I'm generally not in favor of 3D printed parts in printers, and especially dislike poorly designed 3D printed parts. Look at the motor mount in the first video- it is typical of 3D printed parts people design for their printers. Knowing that there's going to be tension on the belt, why would you design the motor mount with the thin part that clamps it to the MDF like that instead of making it a larger solid piece with a slot to fit the MDF? I don't know if they're trying to save plastic, or make it look pretty, or want it to look as it would if it were made of cast metal, but it's just plastic- you have to bulk it up to get the strength/rigidity to resist the belt tension.

Yeah, it works, sort of, but for how long and what sort of prints will it produce? Meh.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In the second video you can see the belt to the left of the extruder carriage is twisted again in the variable length portion of the belt. That's going to be wear problem for the belt, and it will probably cause print problems like distortion because the belt tension is going to change as the extruder moves back and forth. When the extruder is moving to the left end of the rails, the motor will have to supply more torque because you're fighting the force required to twist the belt in an ever tighter twist.

I'm generally not in favor of 3D printed parts in printers, and especially dislike poorly designed 3D printed parts. Look at the motor mount in the first video- it is typical of 3D printed parts people design for their printers. Knowing that there's going to be tension on the belt, why would you design the motor mount with the thin part that clamps it to the MDF like that instead of making it a larger solid piece with a slot to fit the MDF? I don't know if they're trying to save plastic, or make it look pretty, or want it to look as it would if it were made of cast metal, but it's just plastic- you have to bulk it up to get the strength/rigidity to resist the belt tension.

Yeah, it works, sort of, but for how long and what sort of prints will it produce? Meh.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY "Arm" Variant February 17, 2017 10:28AM |

Registered: 9 years ago Posts: 127 |

Thanks for the comments about the belt twisting issues - I've recently acquired flanged bearings and will be untwisting the belts.

The reason all the parts are 3D printed is that I don't have a ready machine shop, but I do have a delta printer - and since I had no reference design to work off of, I expect to do quite a bit of iteration.

This is a "experimentation with scraps laying around my workshop" printer. I'm not going for sub micron accuracy, merely something I could cheaply whip together for my 6 year old to use to print with.

(Hence the 0.8mm nozzle - fast prints for impatient an impatient child).

It succeeds at its purpose.

The reason all the parts are 3D printed is that I don't have a ready machine shop, but I do have a delta printer - and since I had no reference design to work off of, I expect to do quite a bit of iteration.

This is a "experimentation with scraps laying around my workshop" printer. I'm not going for sub micron accuracy, merely something I could cheaply whip together for my 6 year old to use to print with.

(Hence the 0.8mm nozzle - fast prints for impatient an impatient child).

It succeeds at its purpose.

|

Re: CoreXY "Arm" Variant February 17, 2017 11:21AM |

Registered: 9 years ago Posts: 127 |

Sorry, only registered users may post in this forum.